Patents

Literature

83 results about "Concrete plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A concrete plant, also known as a batch plant or batching plant or a concrete batching plant, is equipment that combines various ingredients to form concrete. Some of these inputs include water, air, admixtures, sand, aggregate (rocks, gravel, etc.), fly ash, silica fume, slag, and cement. A concrete plant can have a variety of parts and accessories, including: mixers (either tilt drum or horizontal or in some cases both), cement batchers, aggregate batchers, conveyors, radial stackers, aggregate bins, cement bins, heaters, chillers, cement silos, batch plant controls, and dust collectors.

Portable concrete plant dispensing system

ActiveUS6876904B2Dispensed more accuratelyGood repeatabilitySampled-variable control systemsDischarging apparatusDistribution controlControl system

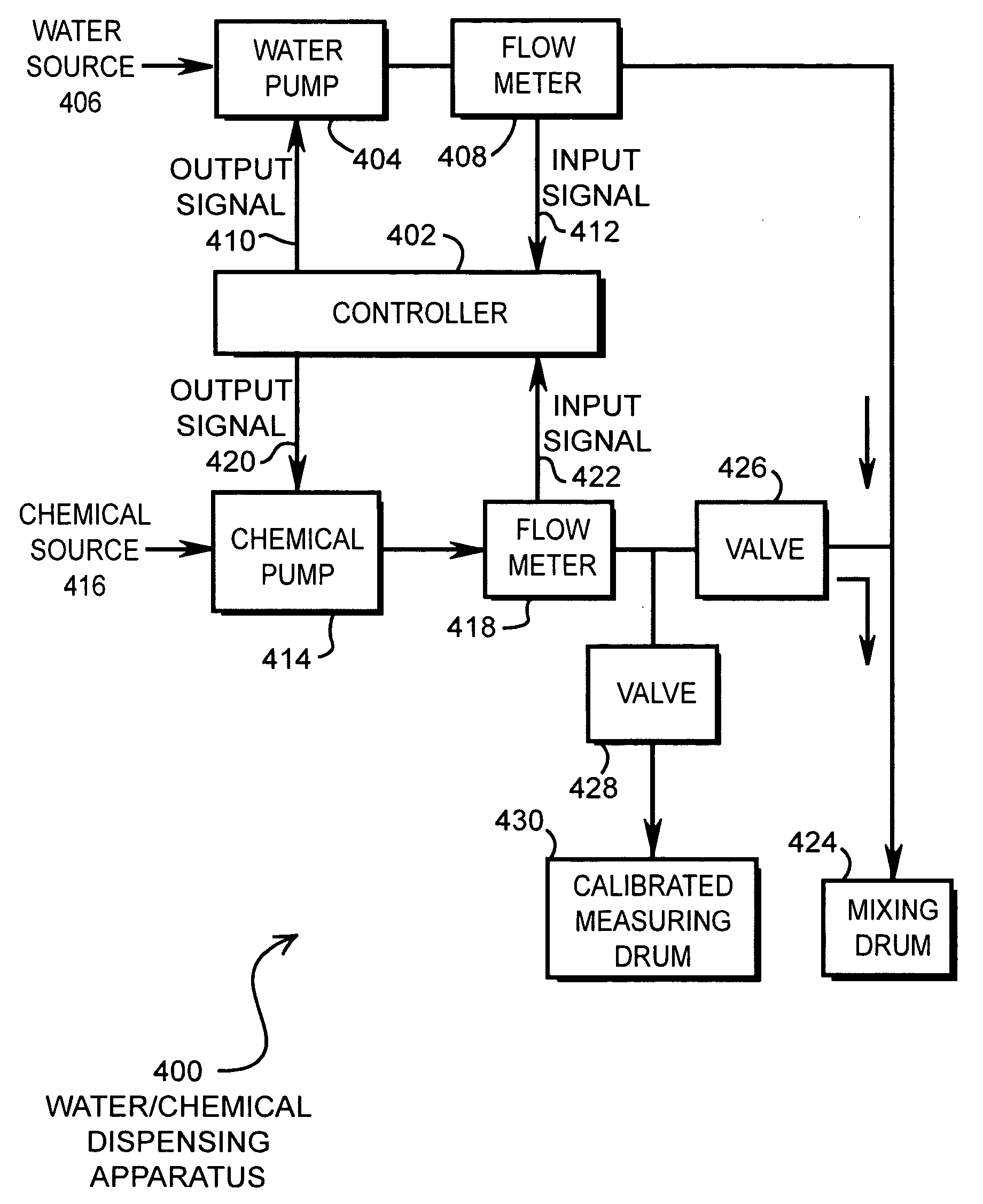

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

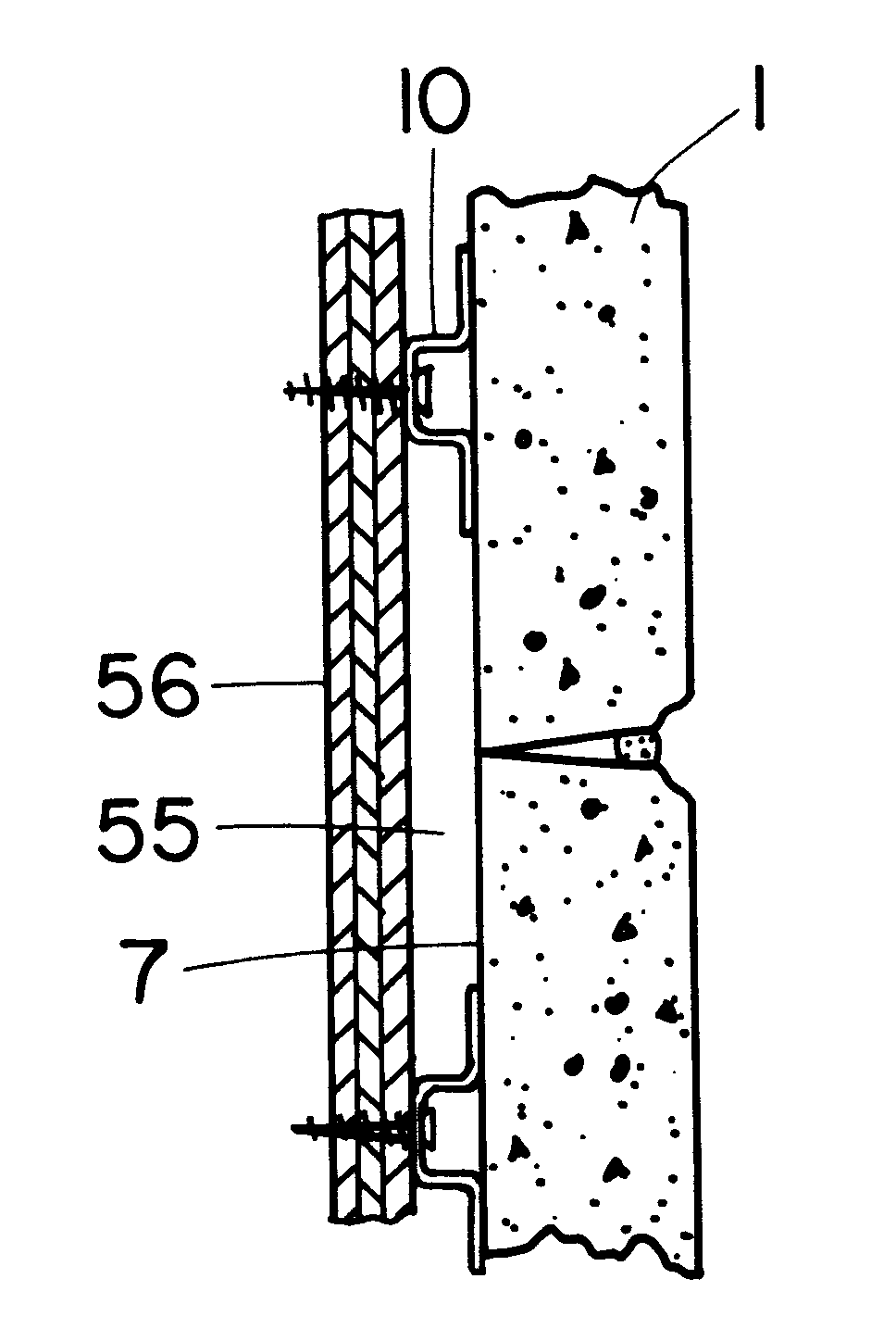

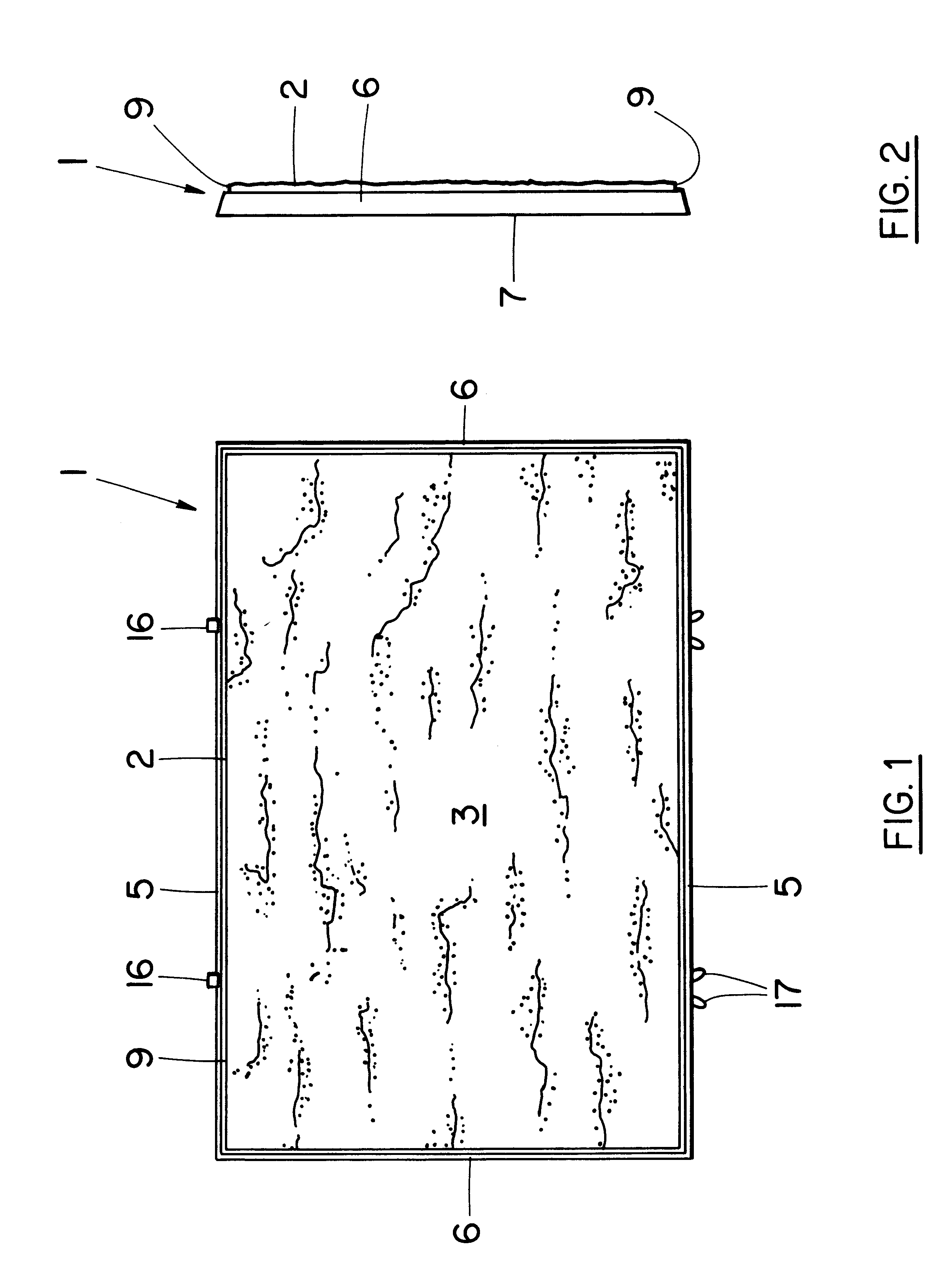

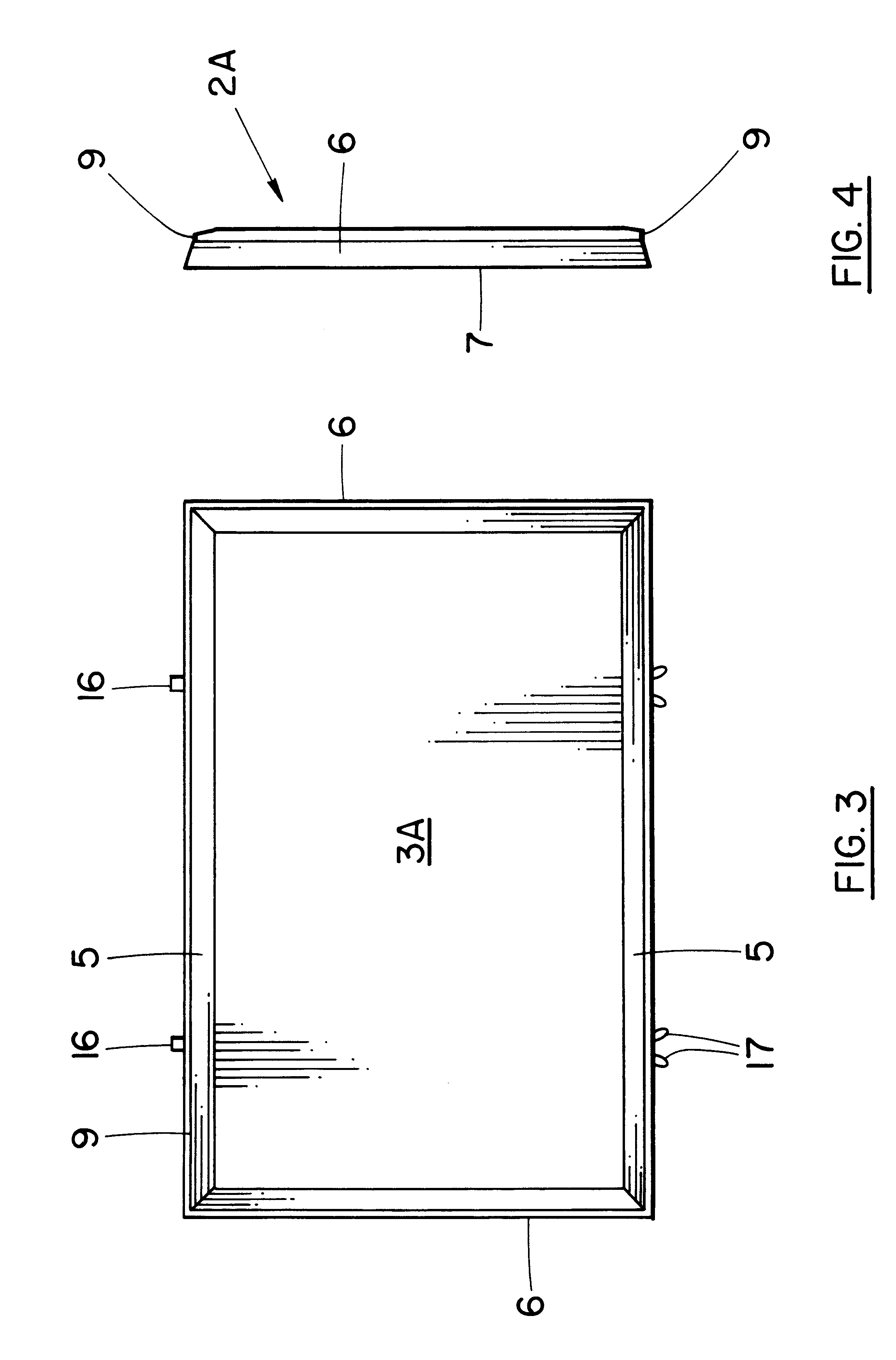

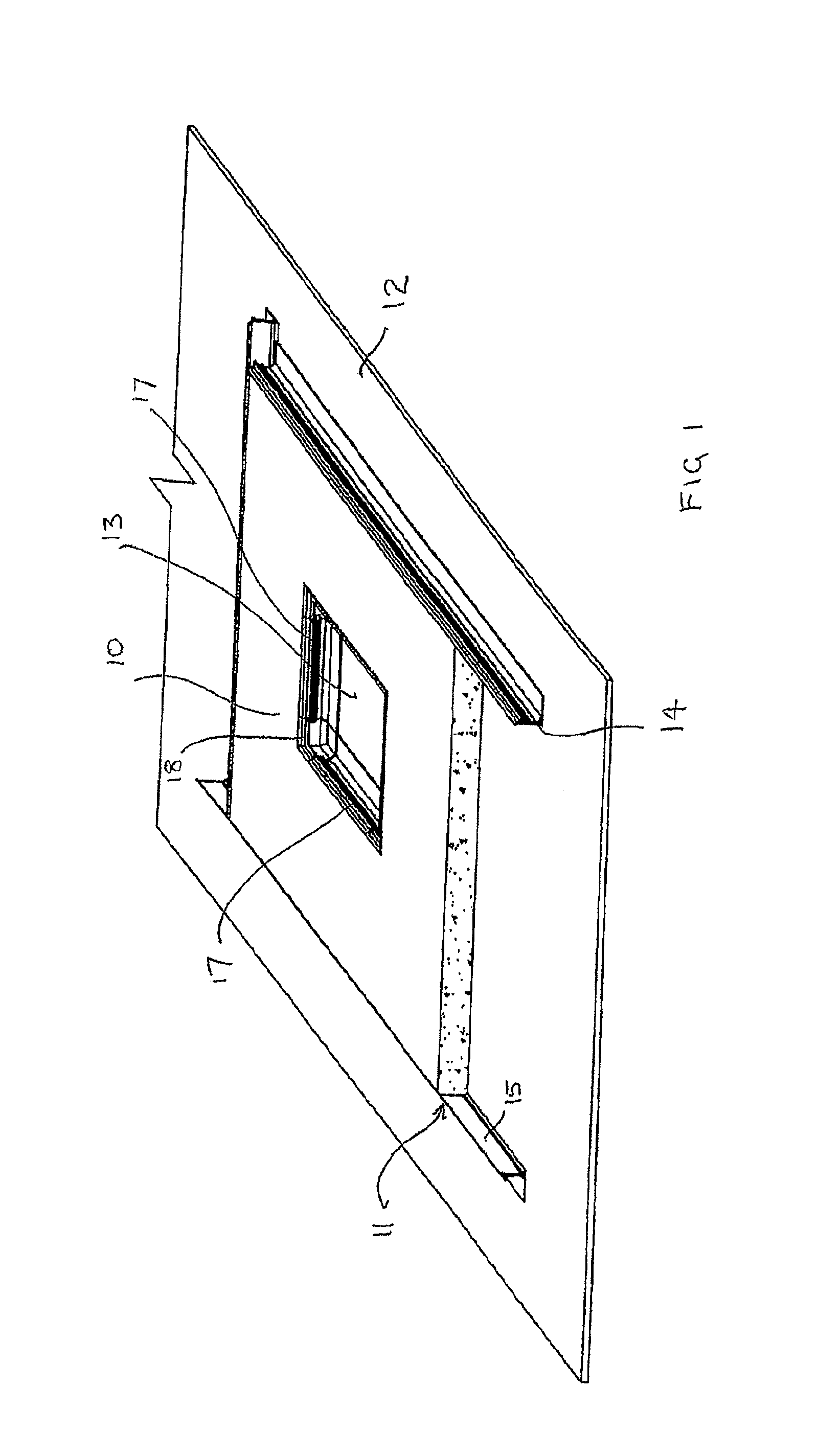

Concrete panel construction

A concrete panel system comprising a plurality of concrete panels arranged in side-by-side fashion on a substantially vertical supporting wall, each of the panels comprising a rectangular body having a front surface and a rear surface and beveled side edges, the side edges each forming an angle of between eighty-five and ninety degrees with the rear surface, and a concave caulking groove lying between and connecting each of the beveled side edges with the front face, the side edges of adjacent panels forming a V-joint between the adjacent panels, a flexible sealant material in a portion of the caulking grooves of adjacent panels and a portion of the V-joint for providing a seal between adjacent panels, and a hanger element embedded in the rear of the panels for securing the panels to the supporting wall.

Owner:STONETILE CANADA

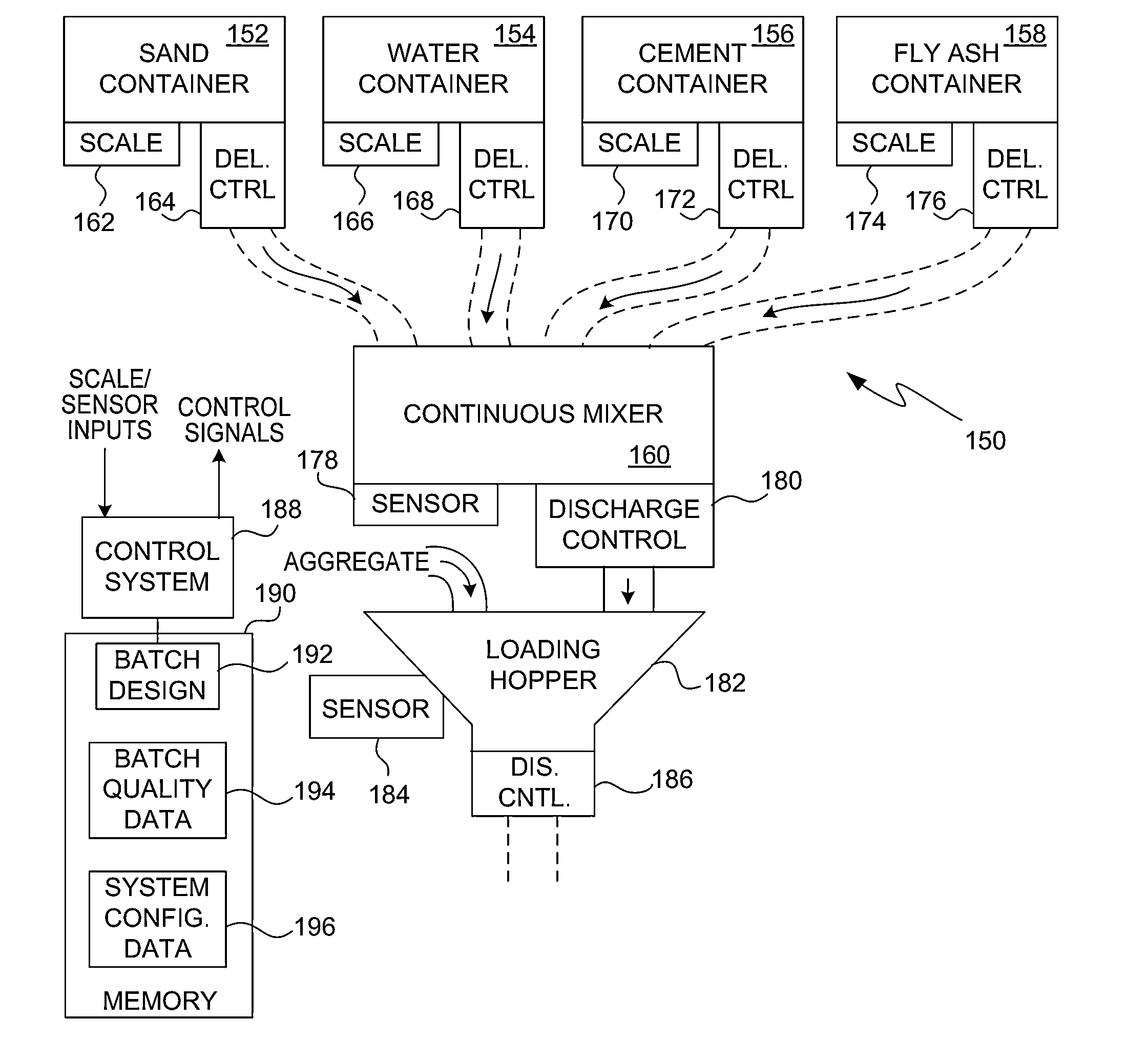

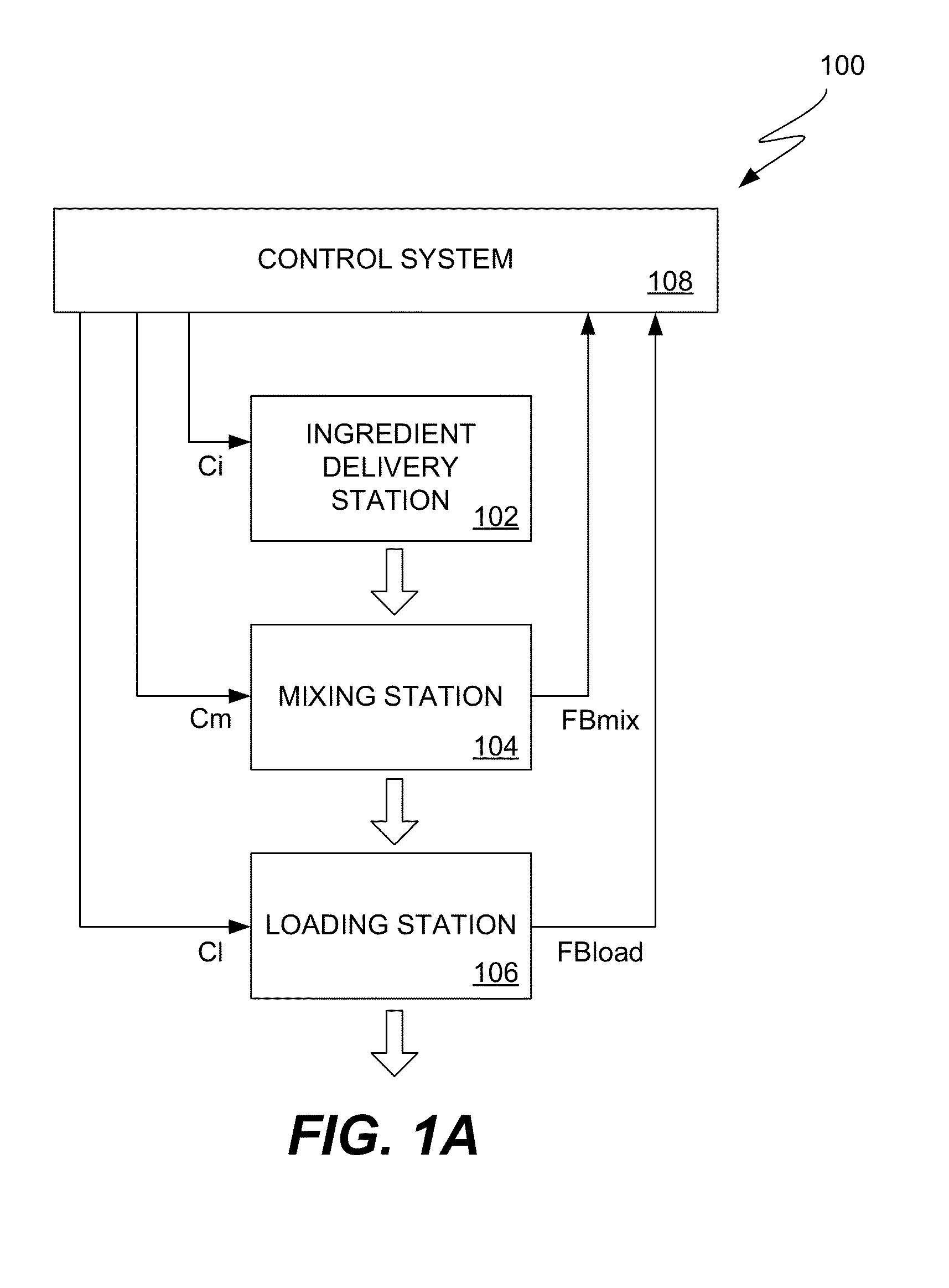

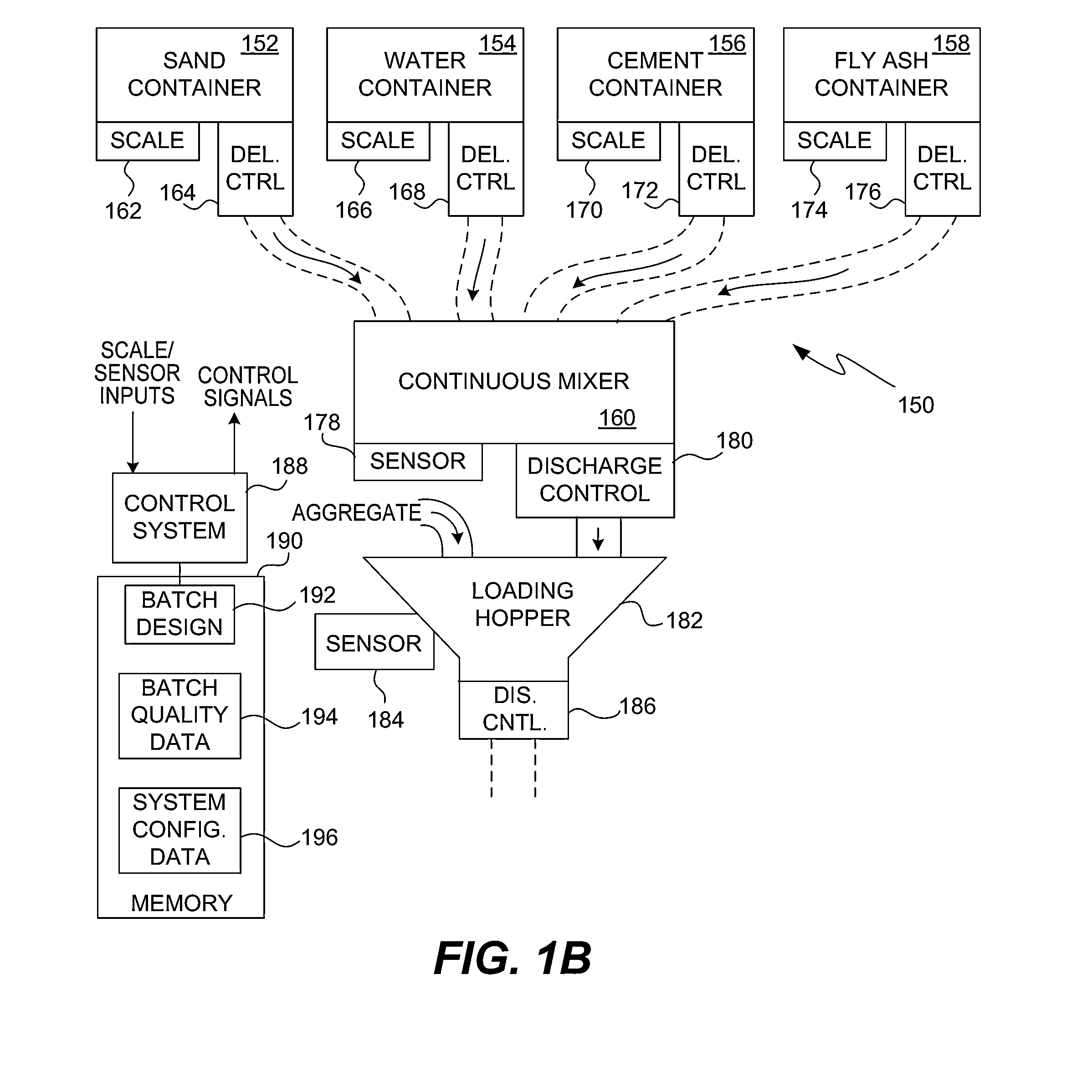

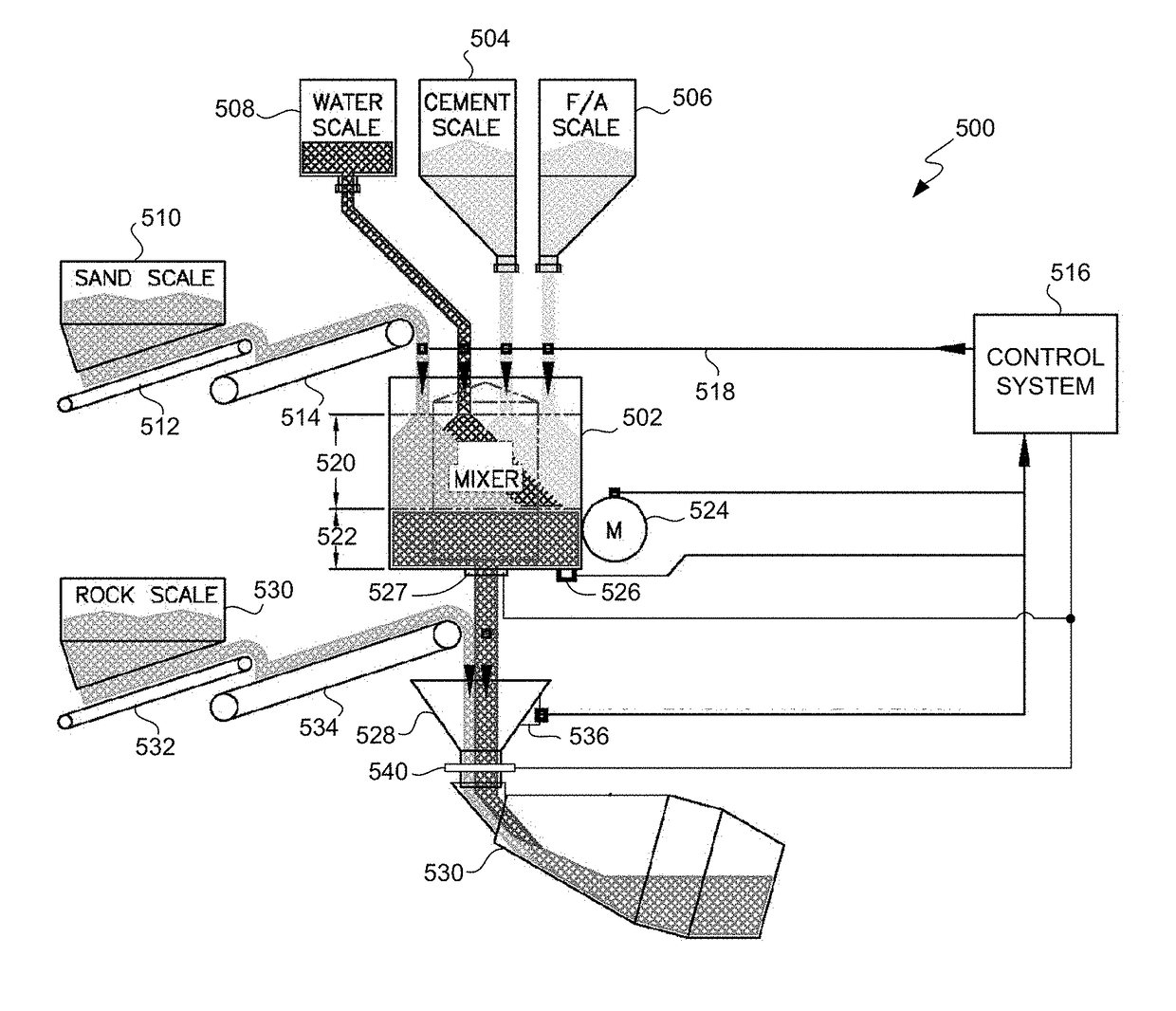

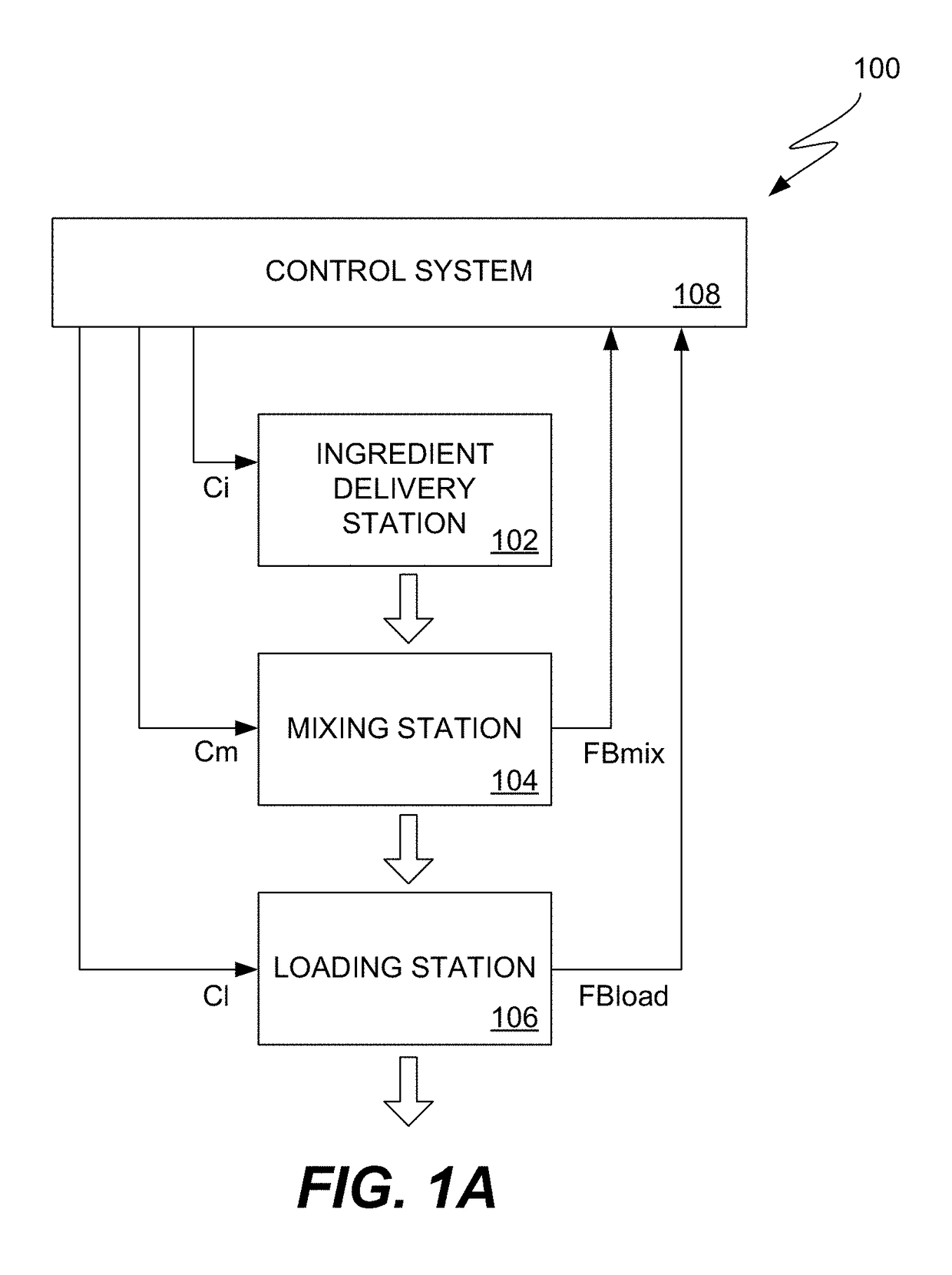

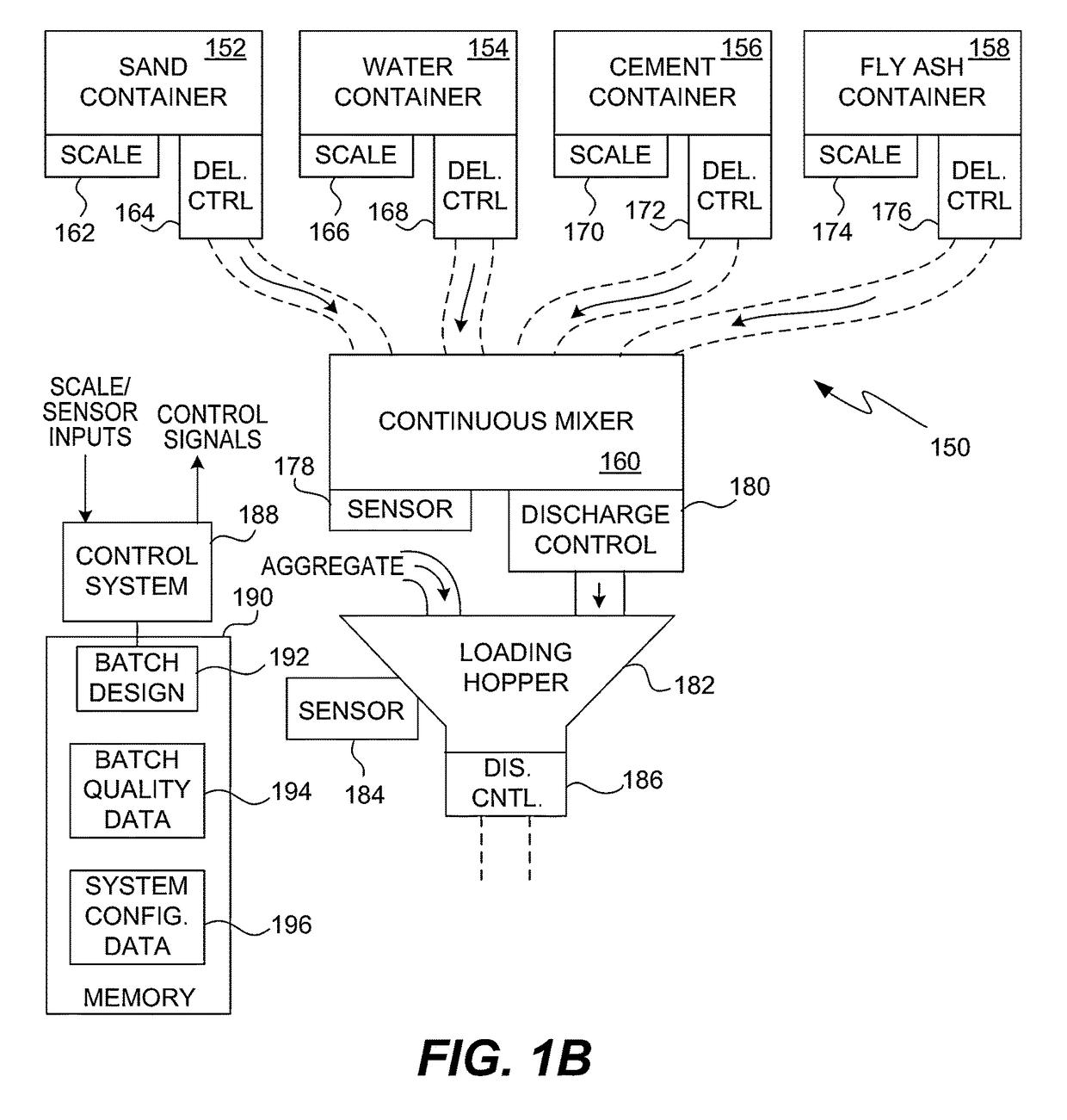

Feedback Controlled Concrete Production

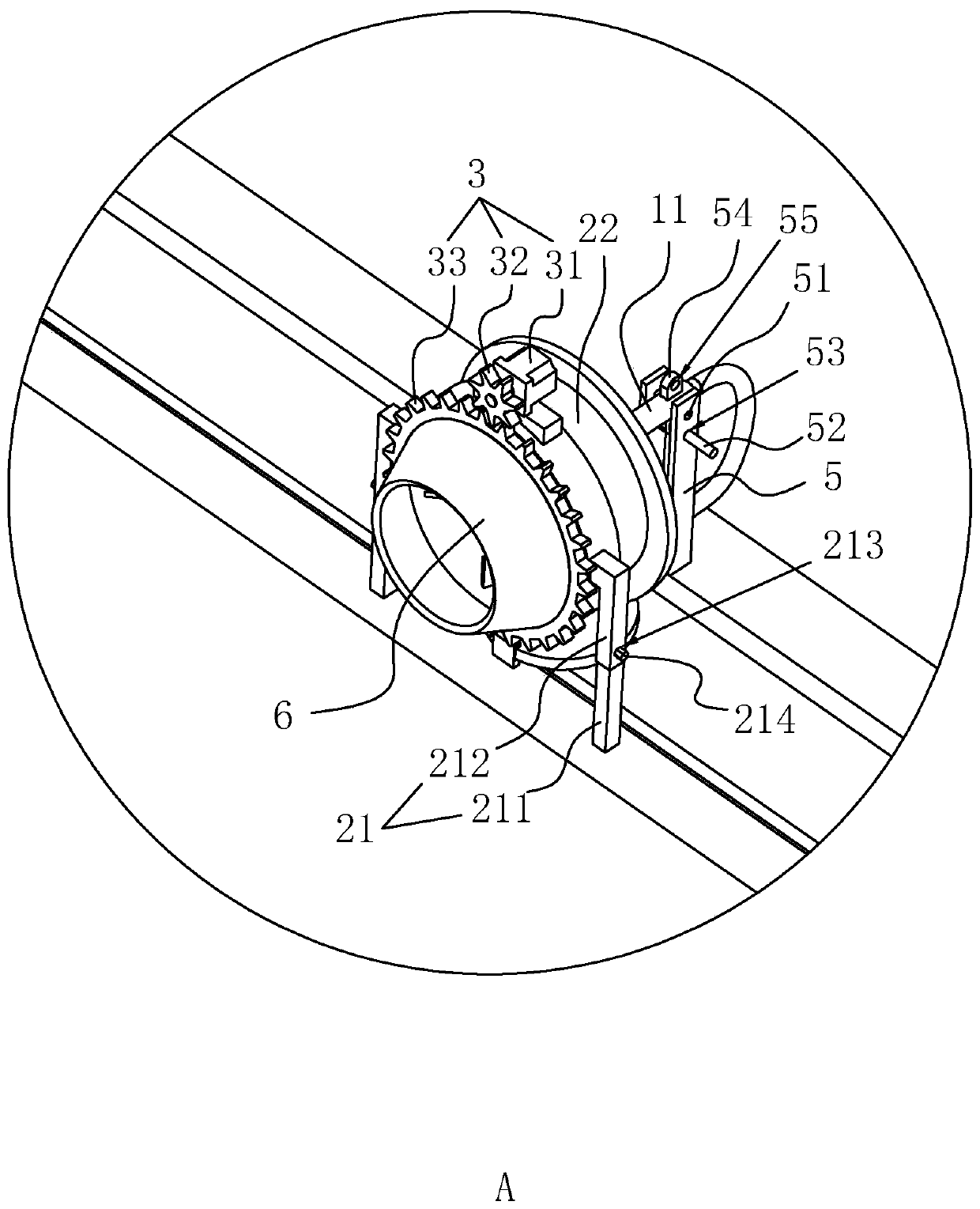

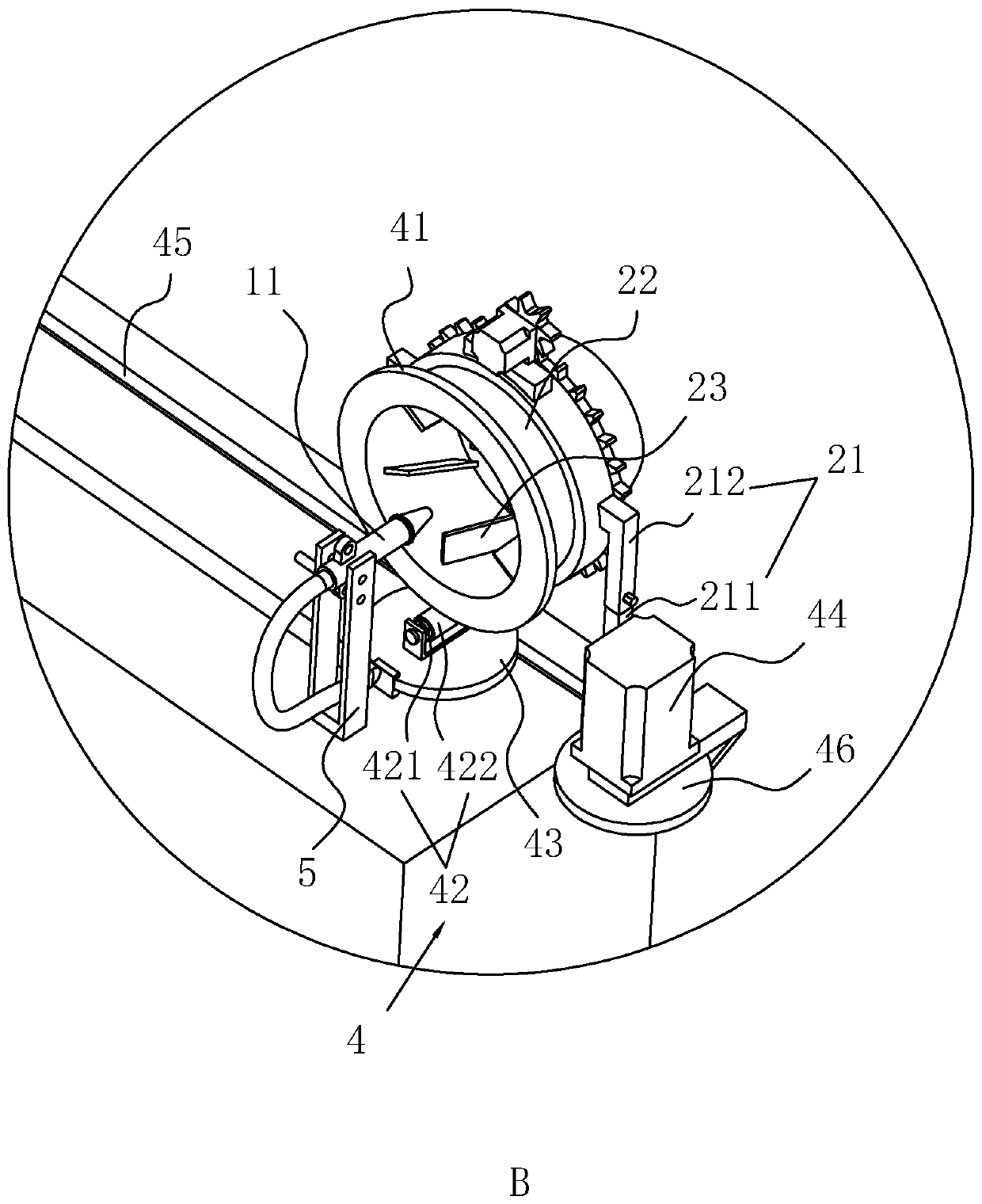

ActiveUS20140355372A1Easy loadingEfficient productionRotary stirring mixersMixing operation control apparatusControl systemStructural engineering

Techniques or processes for efficiently producing concrete using dynamic feedback are disclosed. A concrete plant can use a control system to manage concrete production based on the dynamic feedback. The dynamic feedback can control mixing of concrete ingredients so as to yield uniform particle distribution for the concrete ingredients. The dynamic feedback can also avoid overflow situations as well as yield improved loading of the resulting concrete into a concrete transport vehicle (e.g., concrete truck).

Owner:BLACK MELVIN L +1

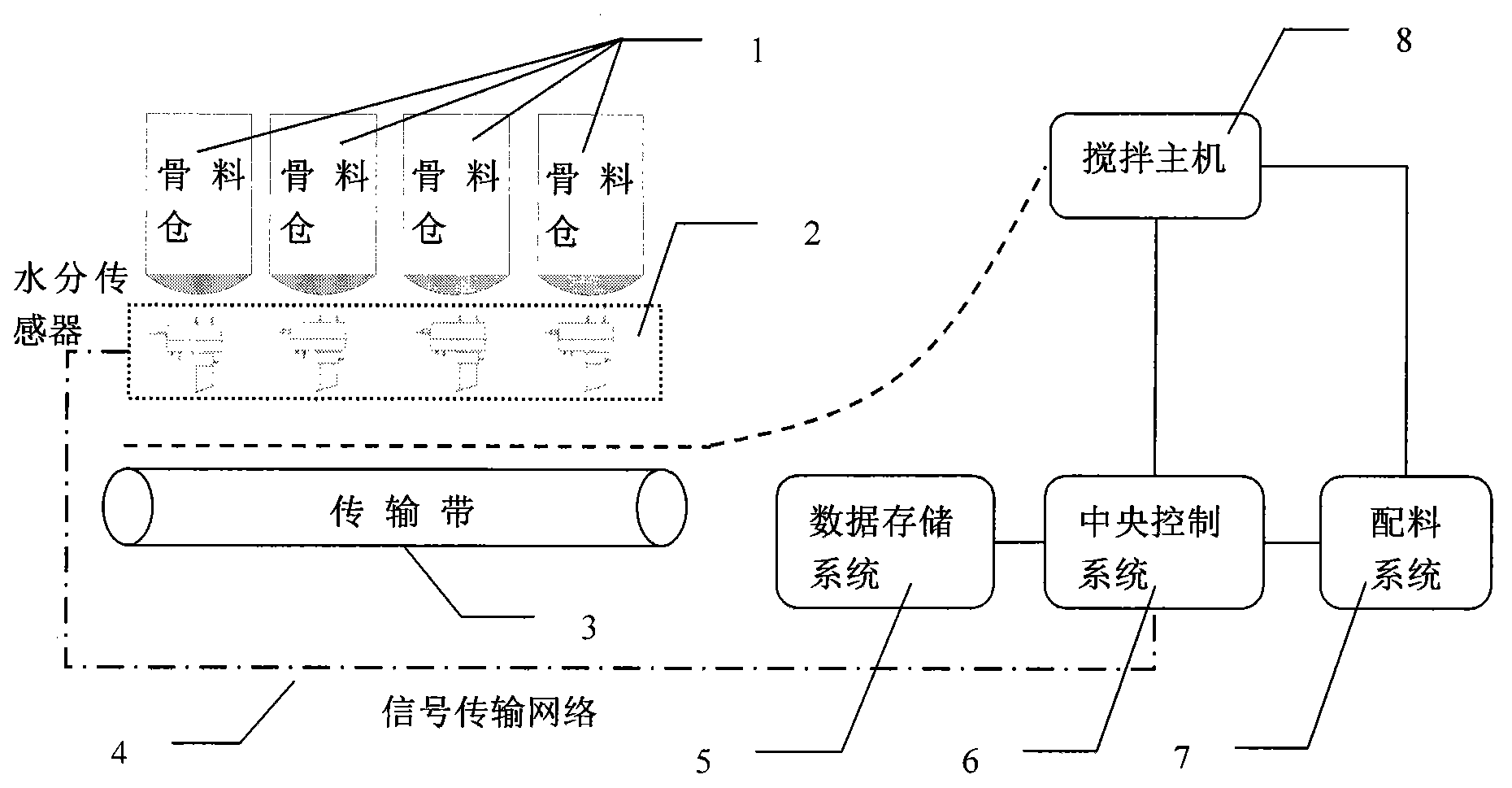

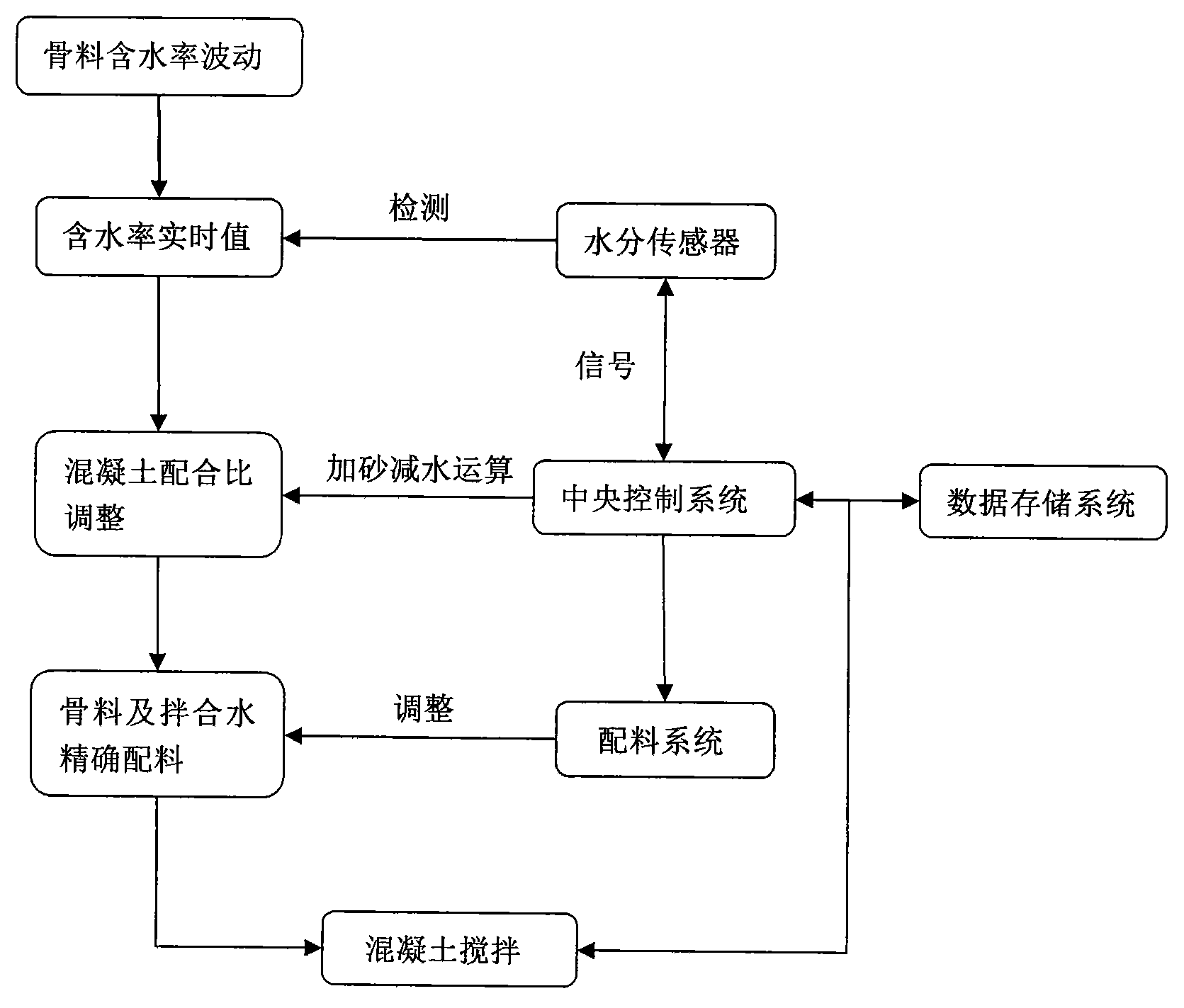

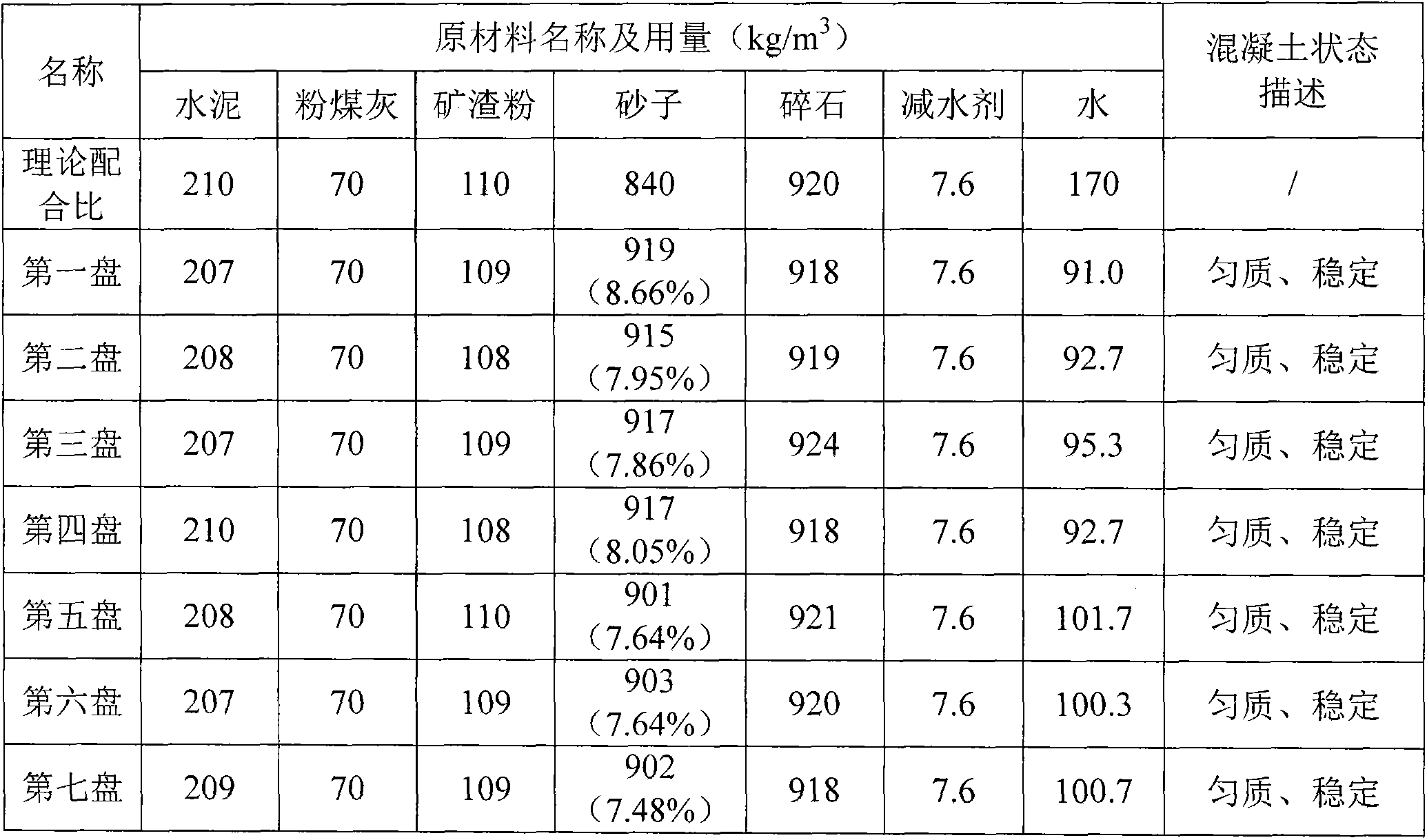

Dynamic regulating system of mix proportion of concrete mixing plant

ActiveCN104175401AReduce Human Intervention FactorsImprove product qualityMixing operation control apparatusIngredients proportioning apparatusControl systemConcrete plant

The invention provides a dynamic regulating system of the mix proportion of a concrete mixing plant. The dynamic regulating system comprises a sensor measurement system, a signal transmitting system, a central control system and a data storage system. The system is used for detecting the aggregate water content on line via a water content sensor installed on the inner wall of a stock bin or below a material outlet, and transmitting the water content information collected automatically to the central control system of the concrete mixing plant in real time; concrete mix proportion parameters can be amended automatically by the system according to the operational rule of increasing the aggregate and reducing mixing water, and the amount of concrete aggregate blended materials and the amount of mixing water blended materials can be regulated simultaneously so as to guarantee the uniformity and stability of concrete quality; the whole dynamic regulation process can be completed within seconds without affecting the production efficiency, so that the system can be widely applied to the concrete mixing plant in the field of civil engineering, not only can improve the automation degree of the mixing plant and improve the production quality of concrete, but also can reduce the working intensity of operators and reduce the personnel configuration, thereby lowering the cost greatly.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

Plant-growing concrete plant growing-suitable materials and use thereof

InactiveCN101381267AEfficiently provideGuaranteed normal growthFertilizer mixturesGrowth plantNormal growth

Owner:SOUTH CHINA UNIV OF TECH

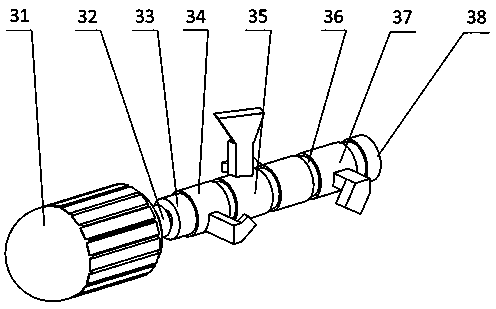

Chemical dispensing system for a portable concrete plant

InactiveUS20050159843A1Dispensed more accuratelyGood repeatabilityLevel controlMouldsDistribution controlControl system

A computer controlled pumping and measuring system is used to dispense chemicals into a concrete mix. The redundant use of positive displacement pumps and flow meters ensure that any problems with the chemical dispensing are immediately caught. The computerized control system may be operable to control exact batch configurations of concrete and aggregate in conjunction with the chemical dispensing, as well as provide precise mixture control and recording of the various components.

Owner:PORT A POUR

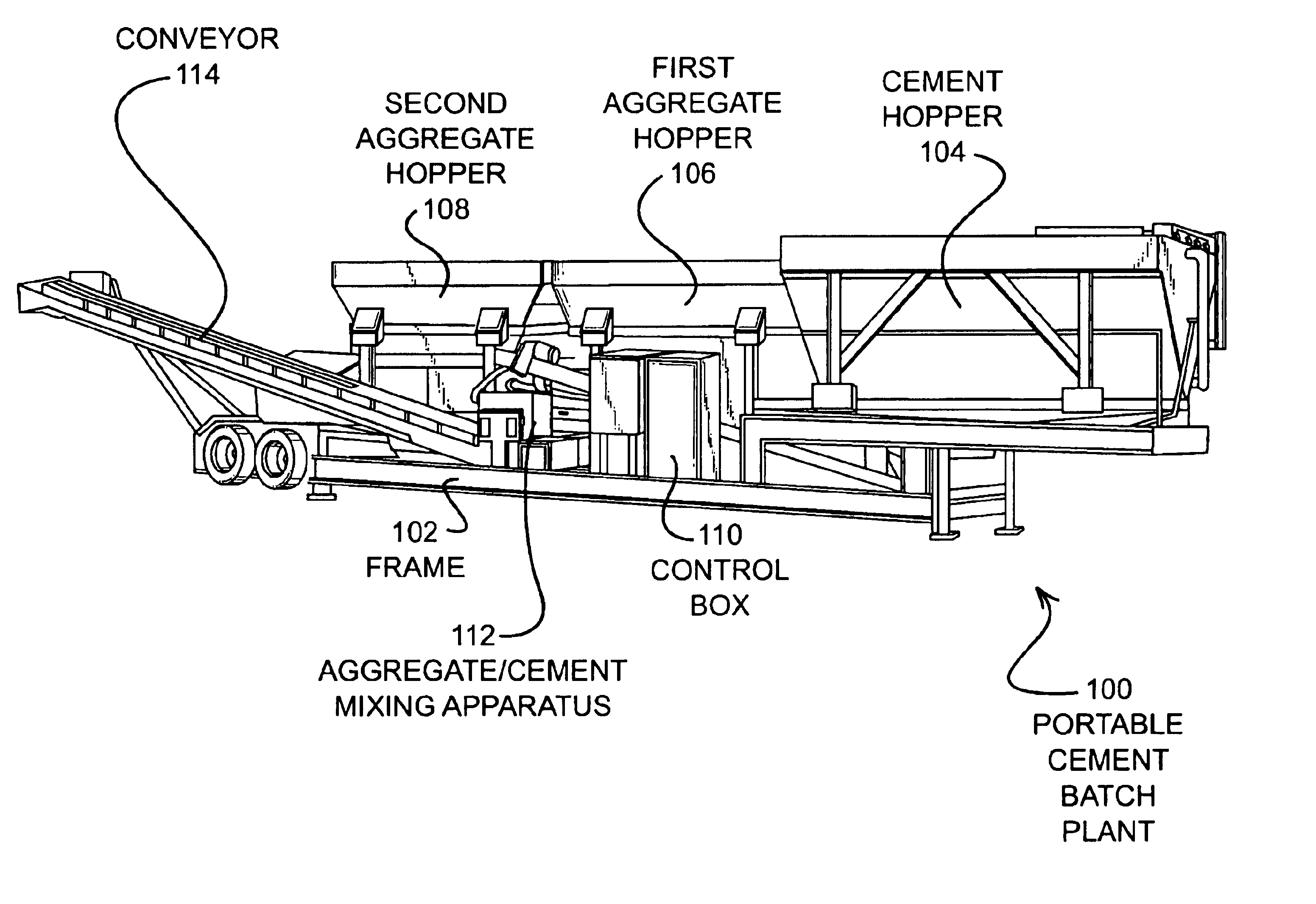

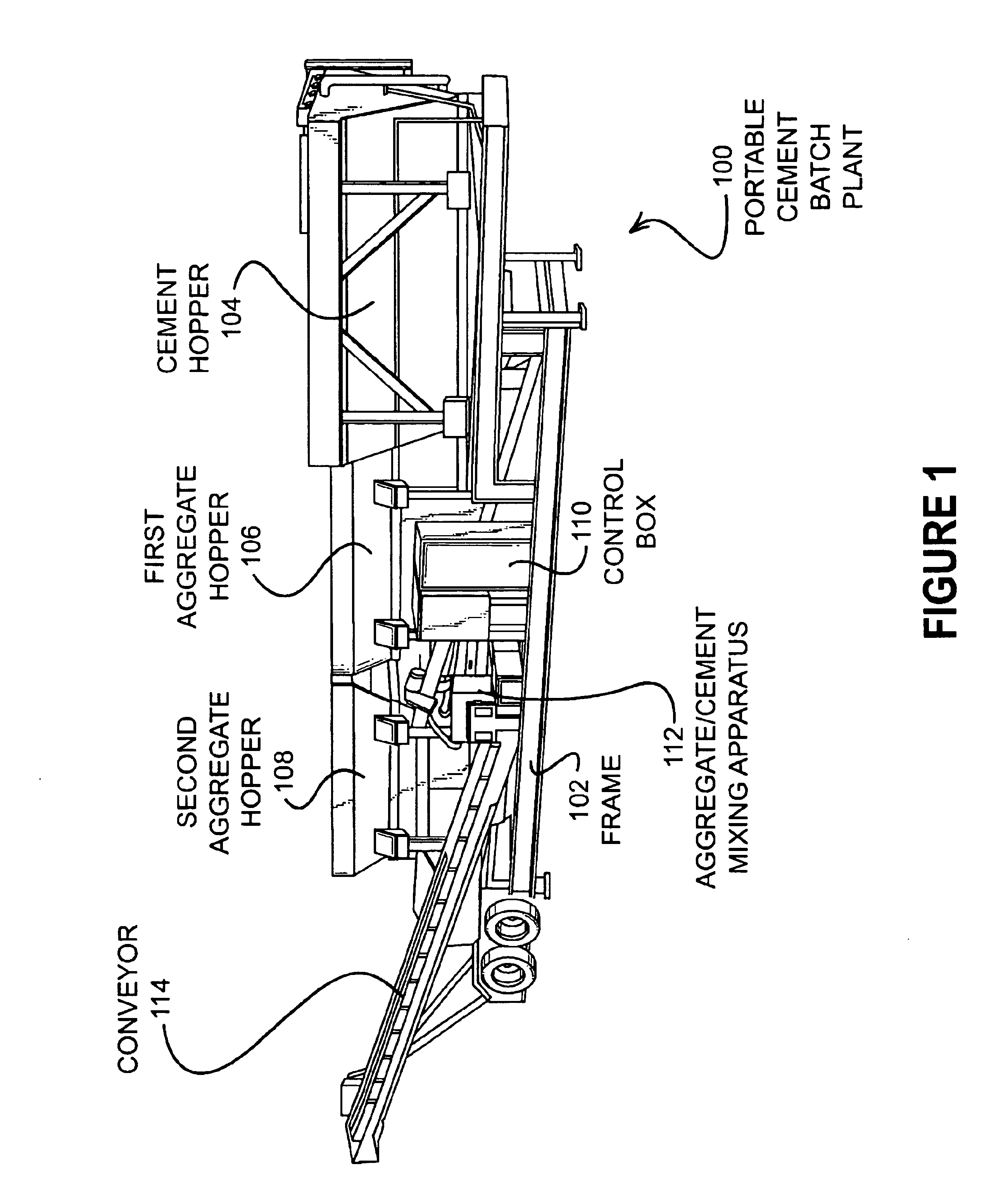

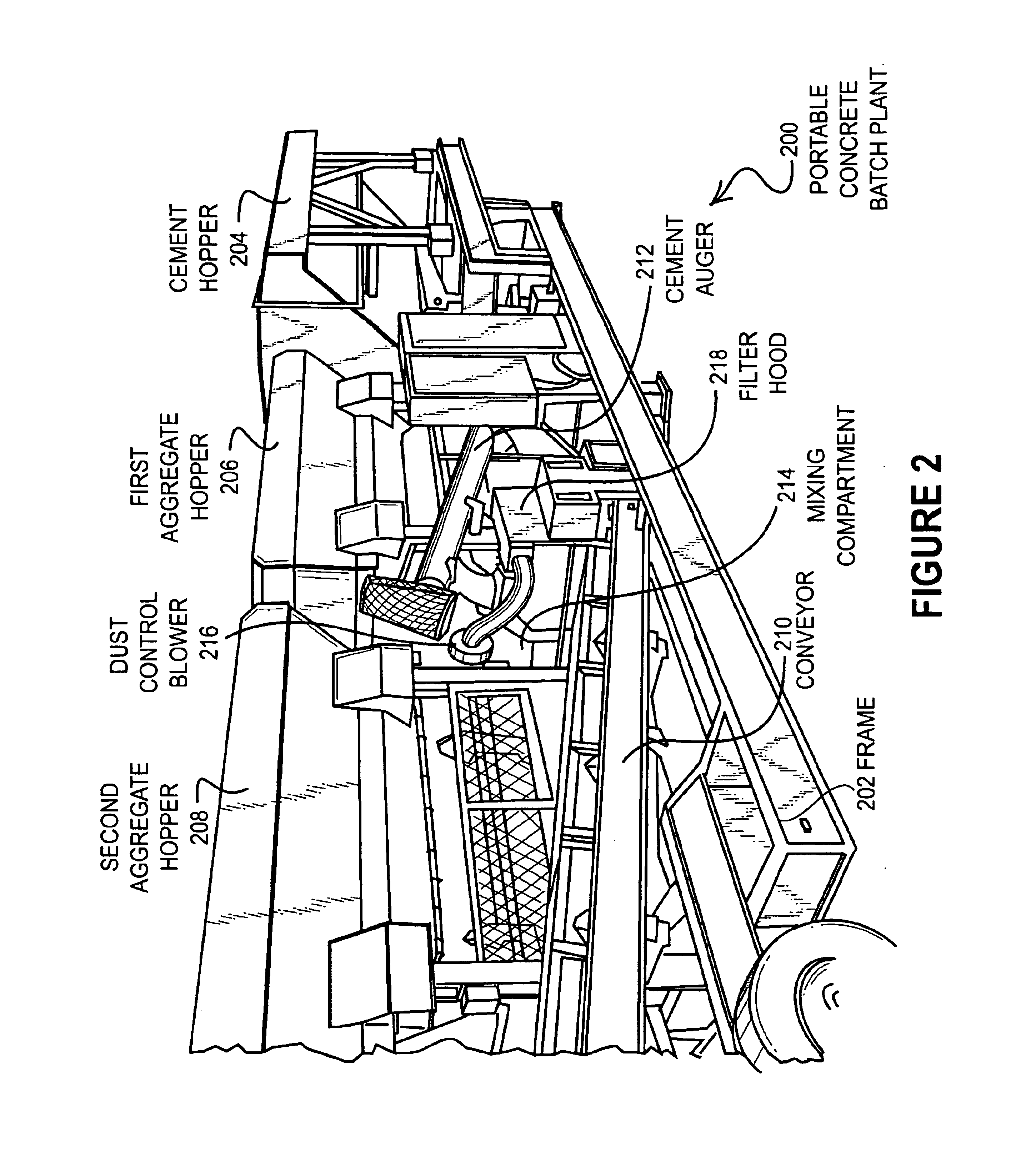

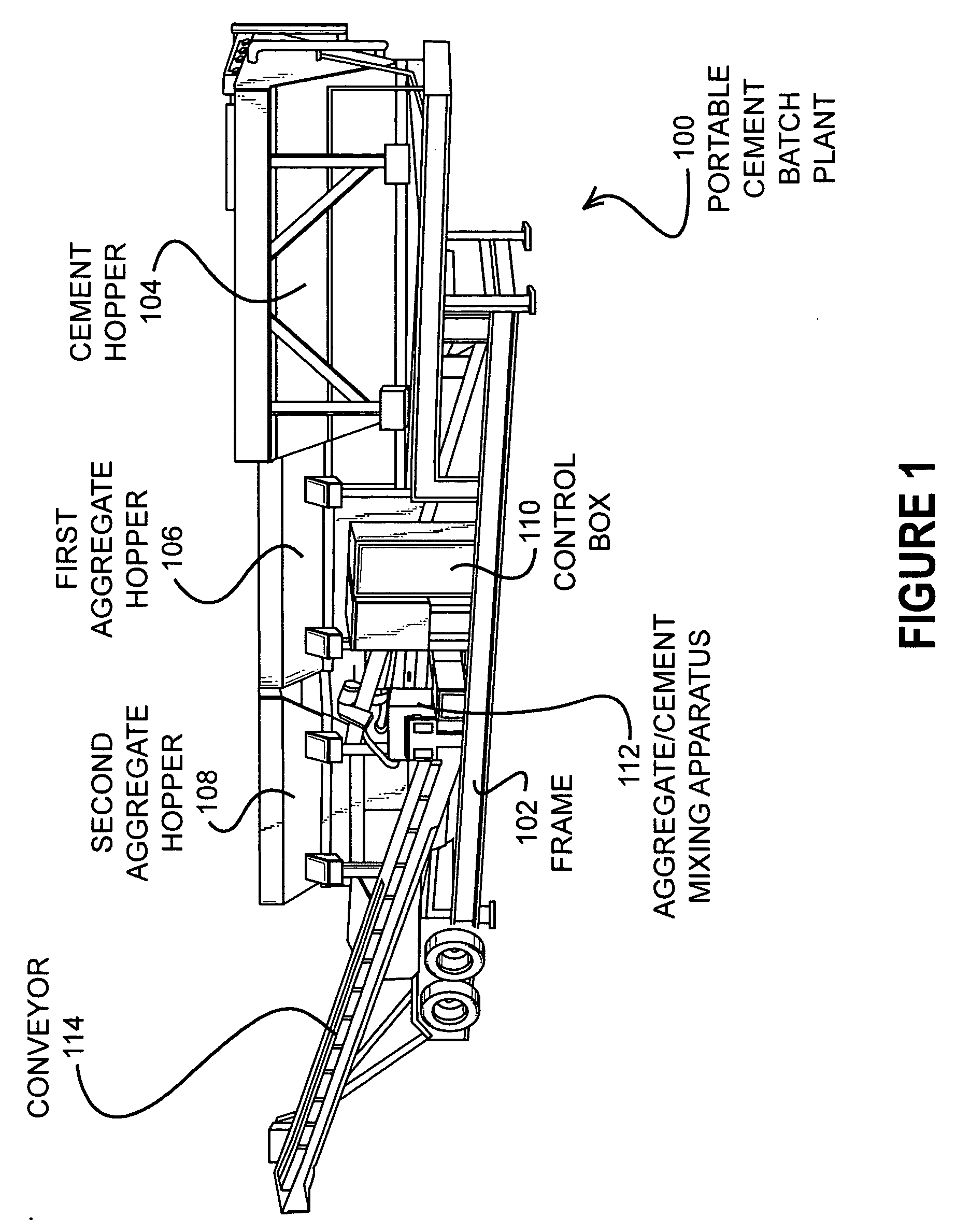

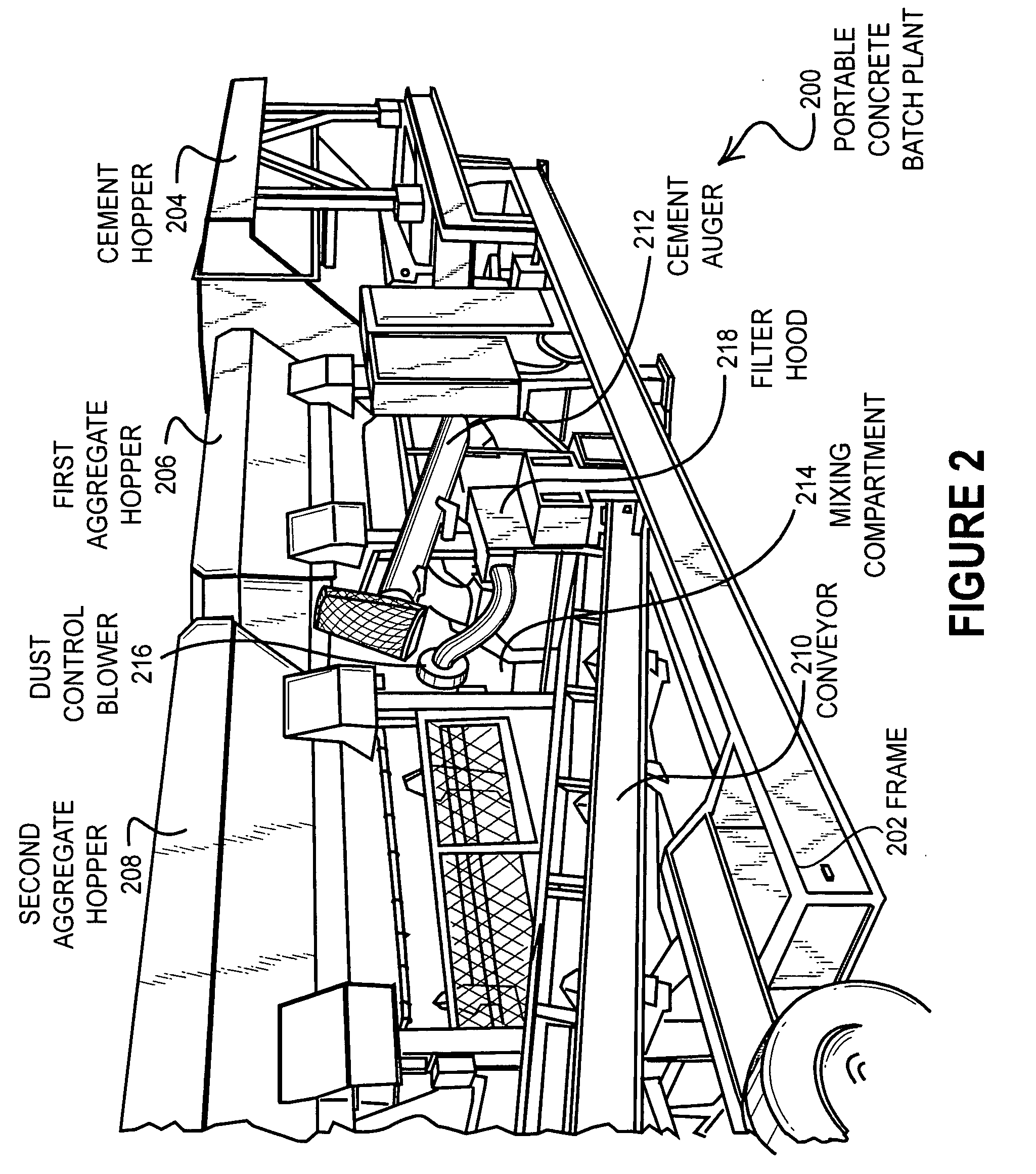

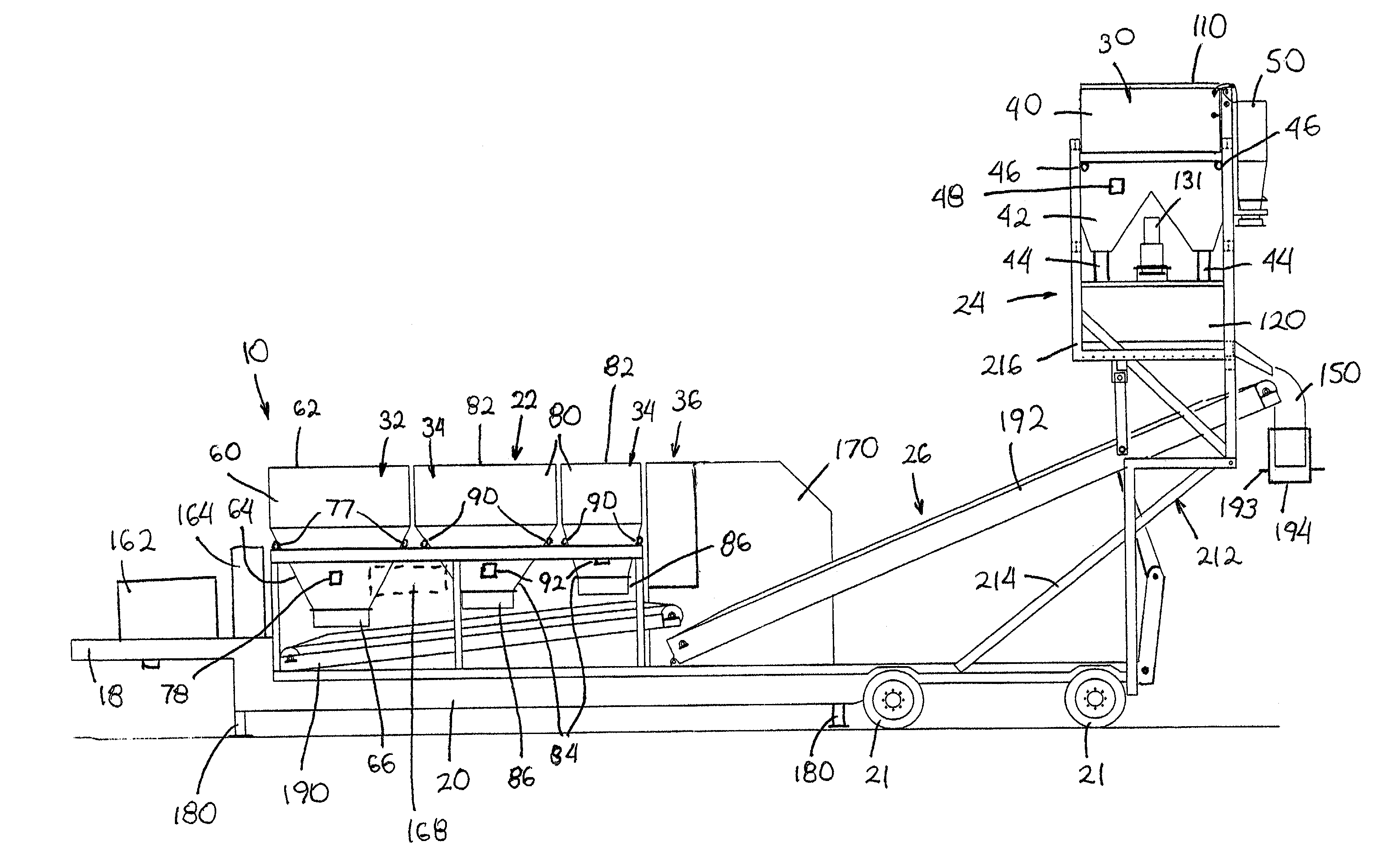

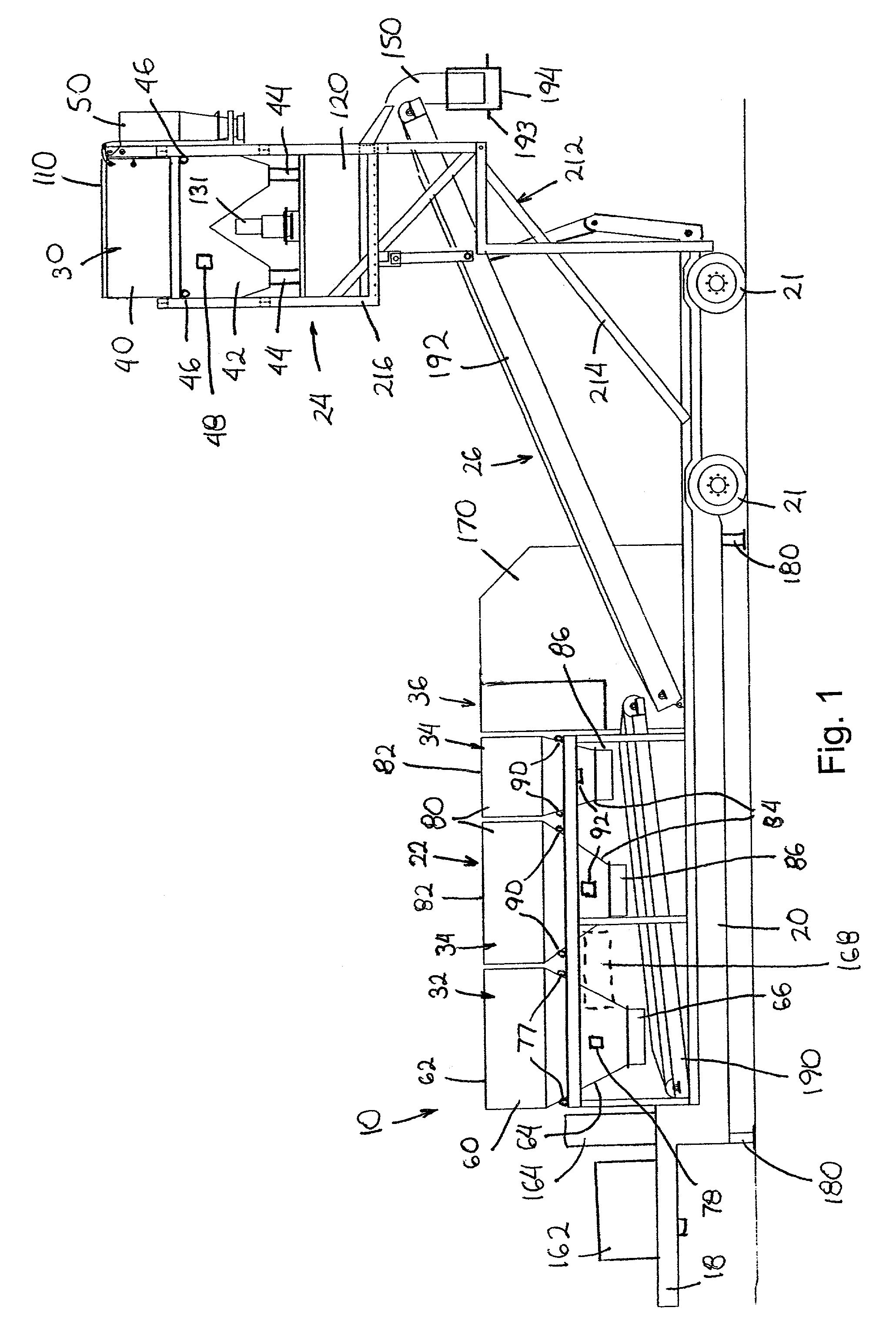

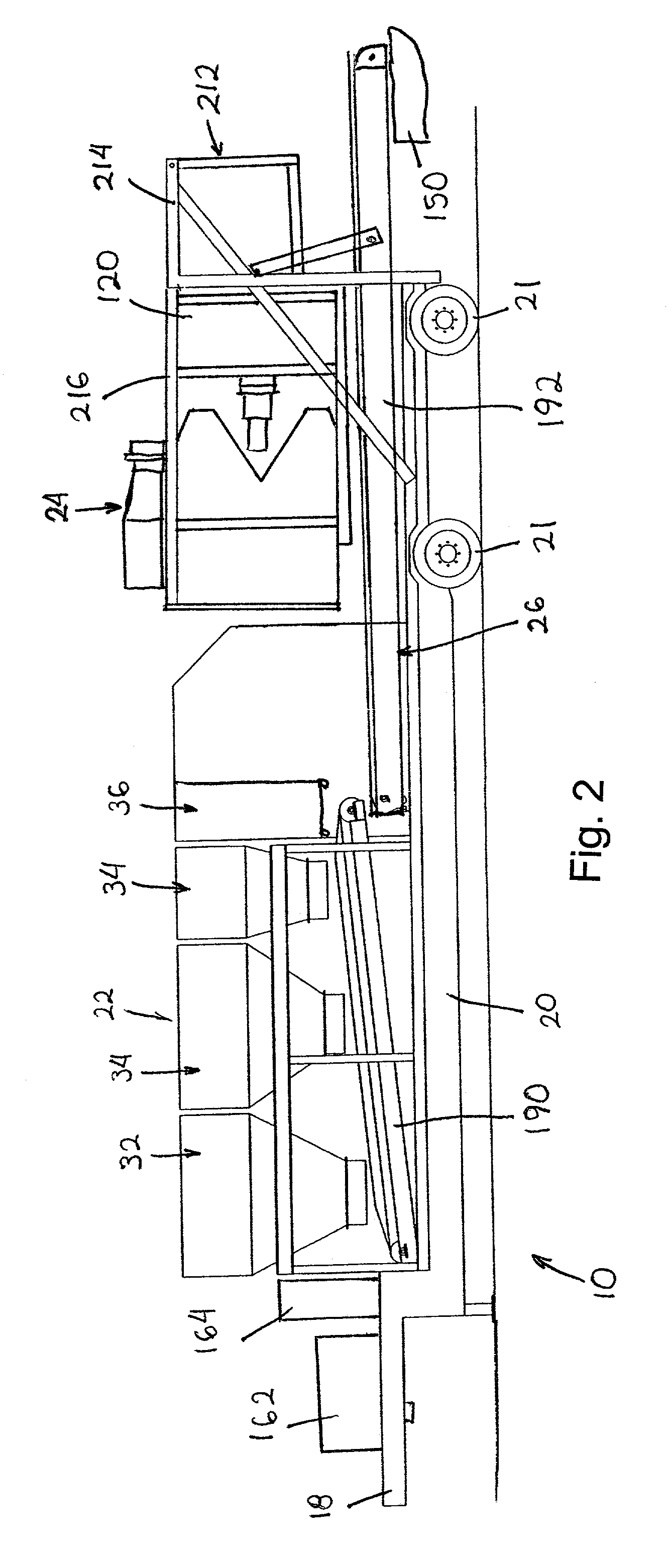

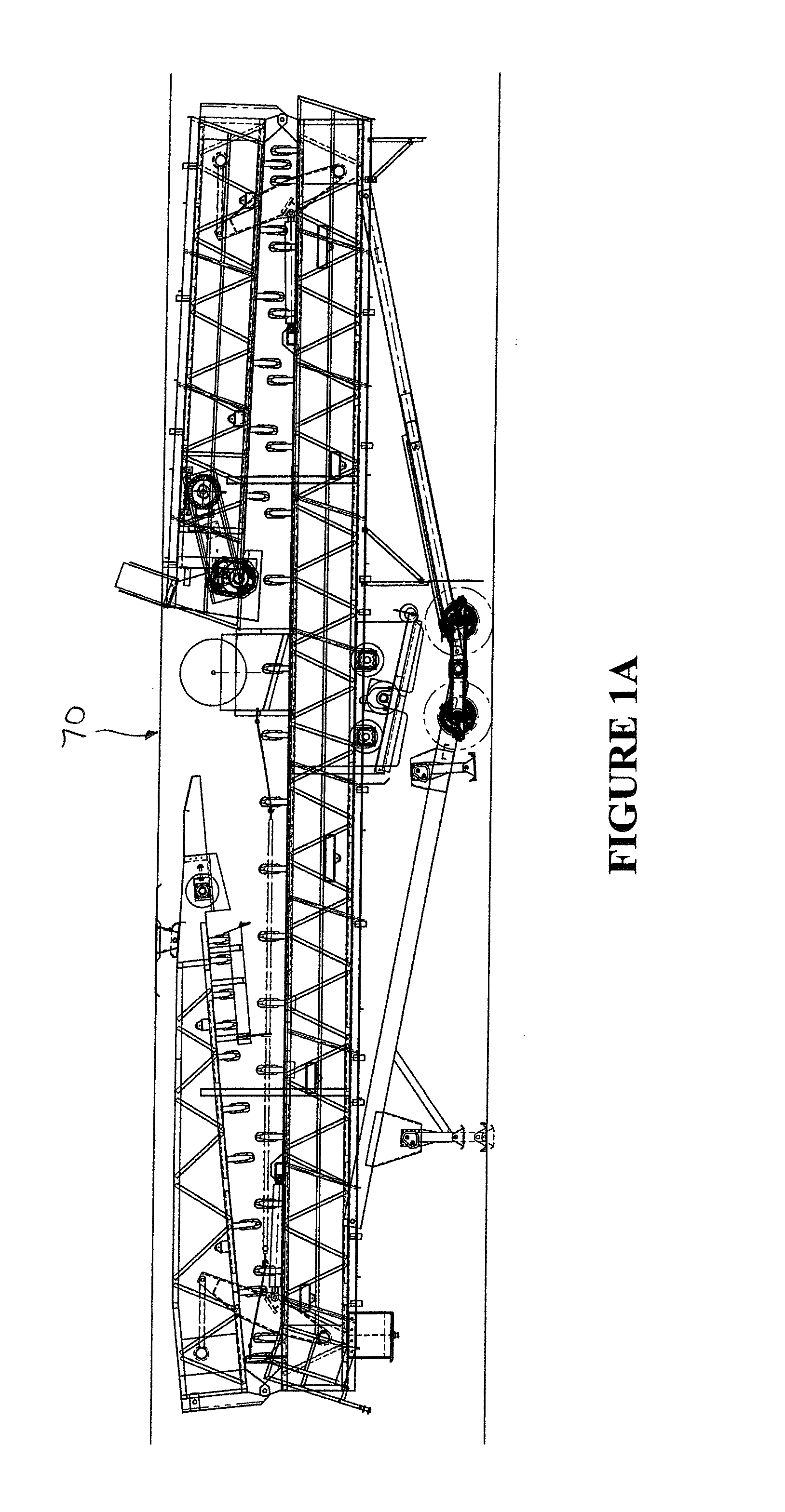

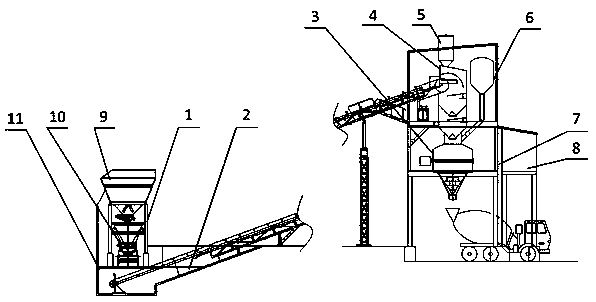

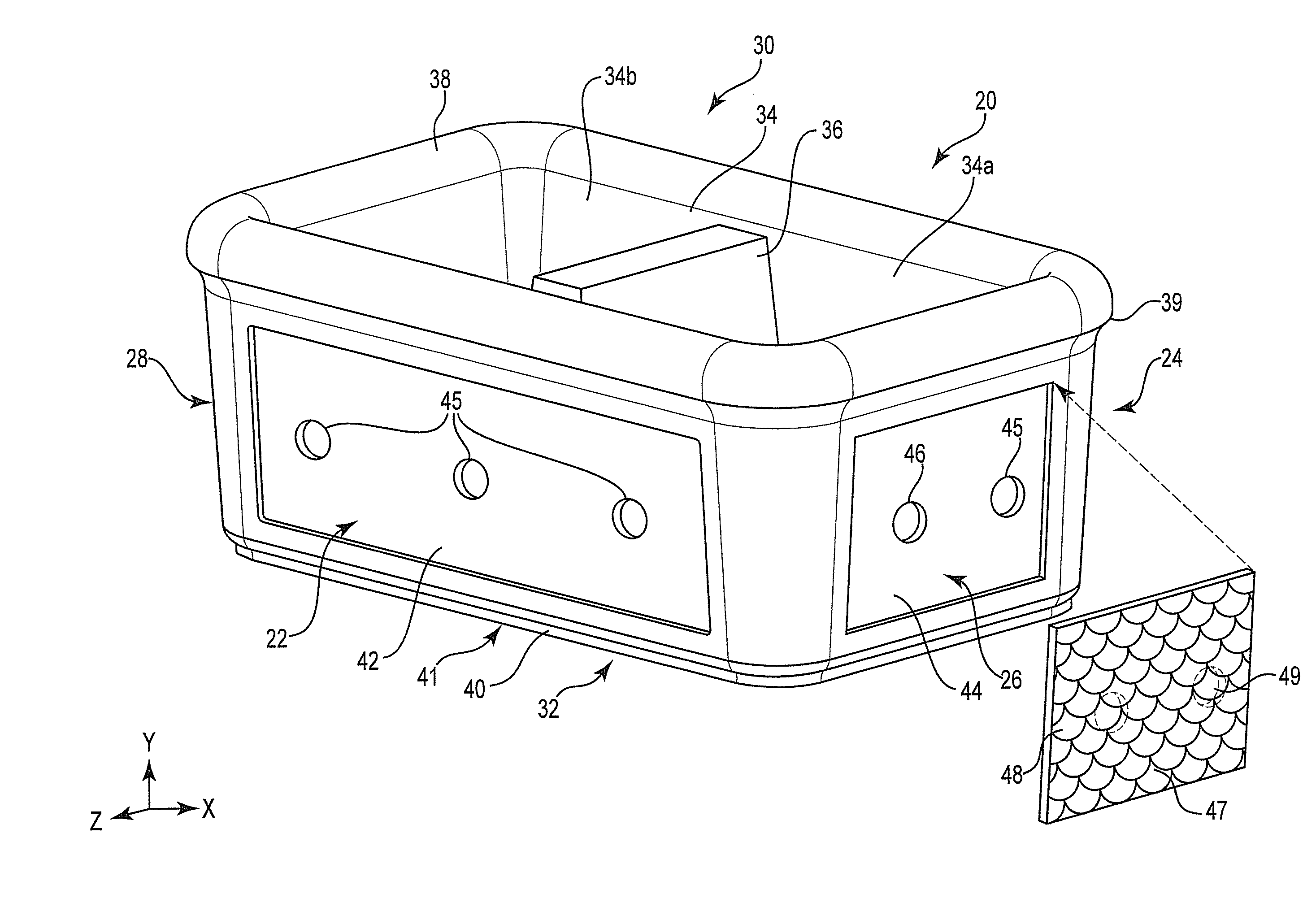

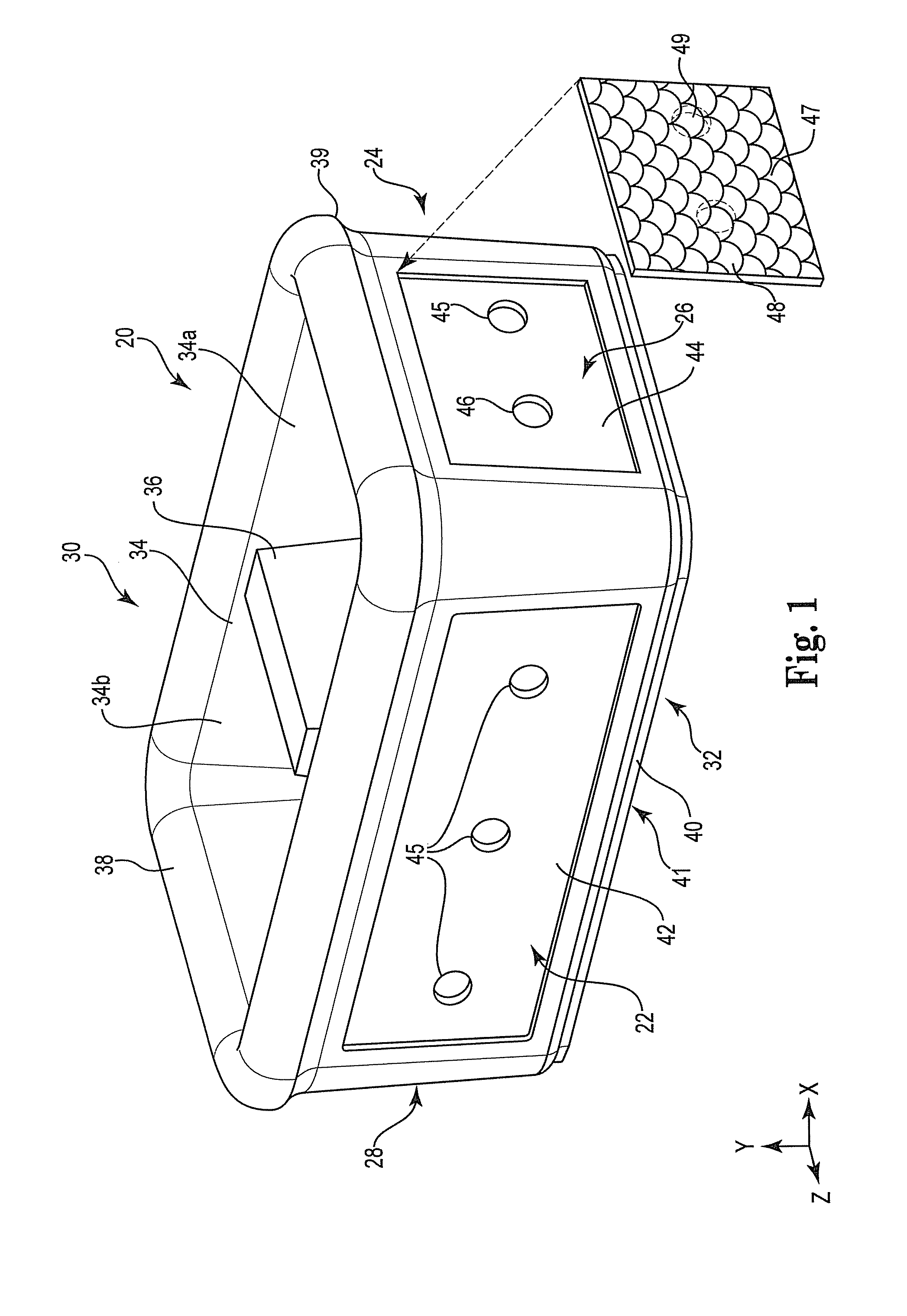

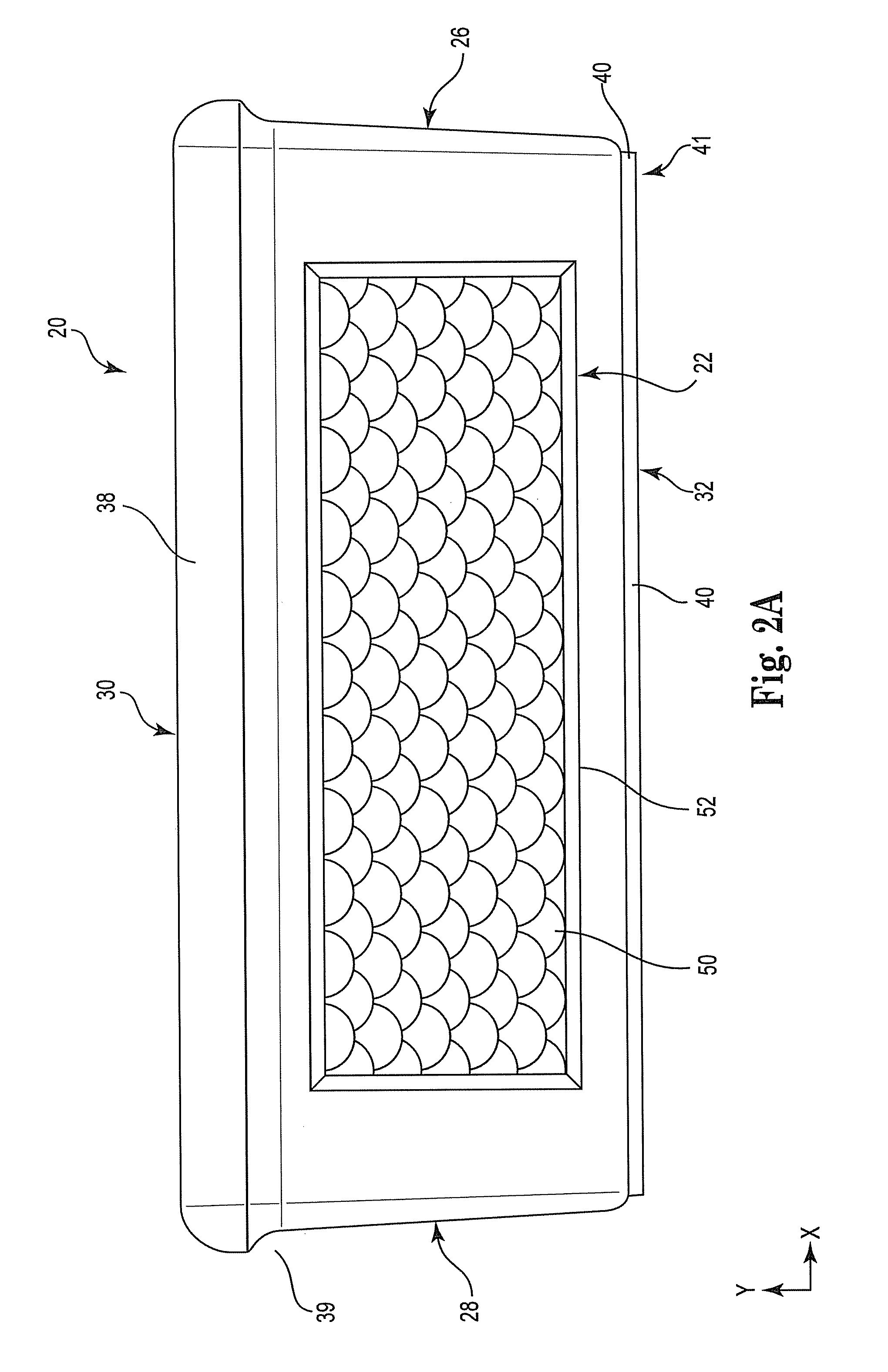

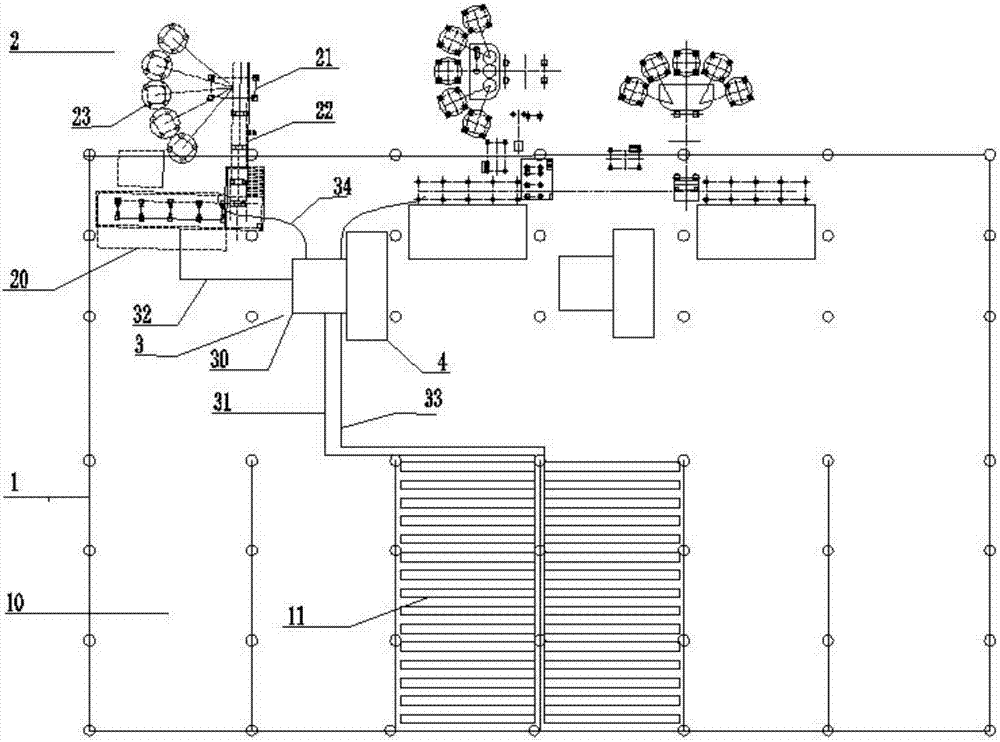

Portable concrete plant

A portable concrete plant for producing ready mix concrete proximate to a location where the ready mix concrete is used. The portable concrete plant includes storage regions for storing components used in the ready mix concrete. The portable concrete plant also includes a slurry mixer for preparing slurry that is used in the ready mix concrete. The portable concrete plant further includes conveying systems for conveying the components from the storage regions and from the slurry mixer to a system discharge port.

Owner:BROCKPAHLER DAVID

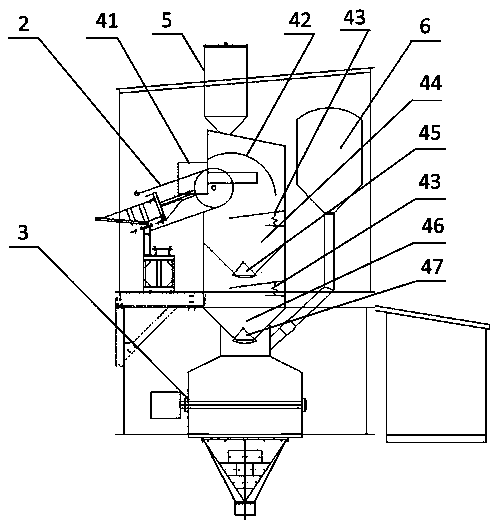

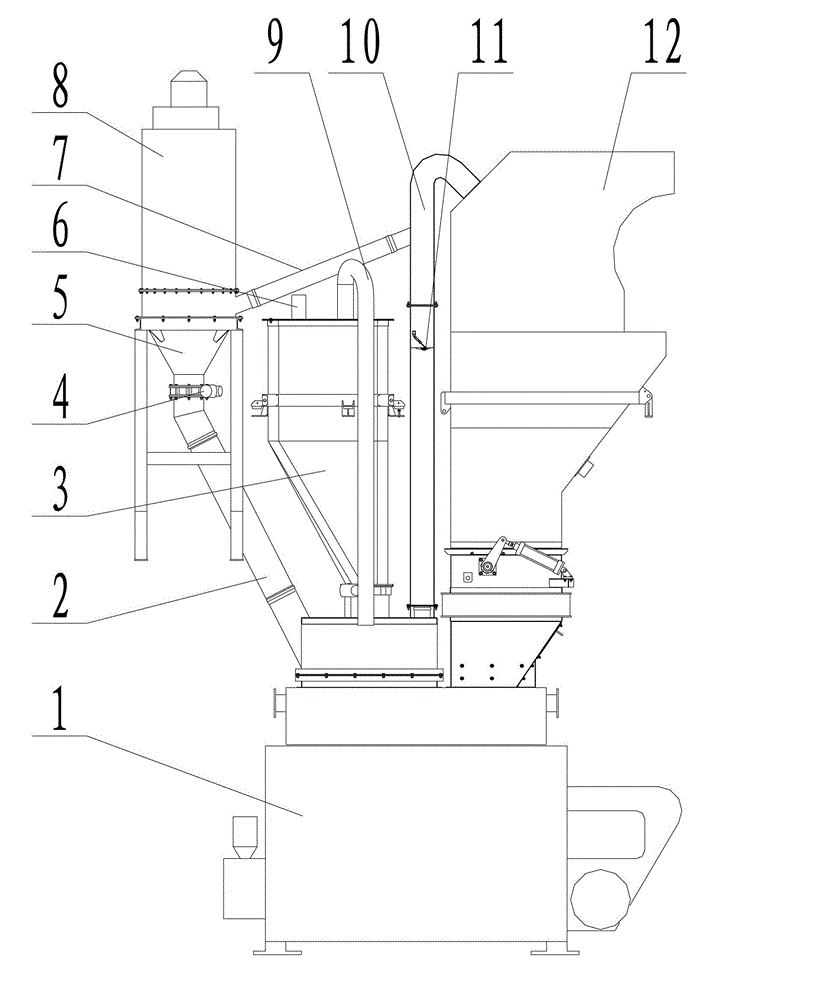

Apparatus and method for a concrete plant

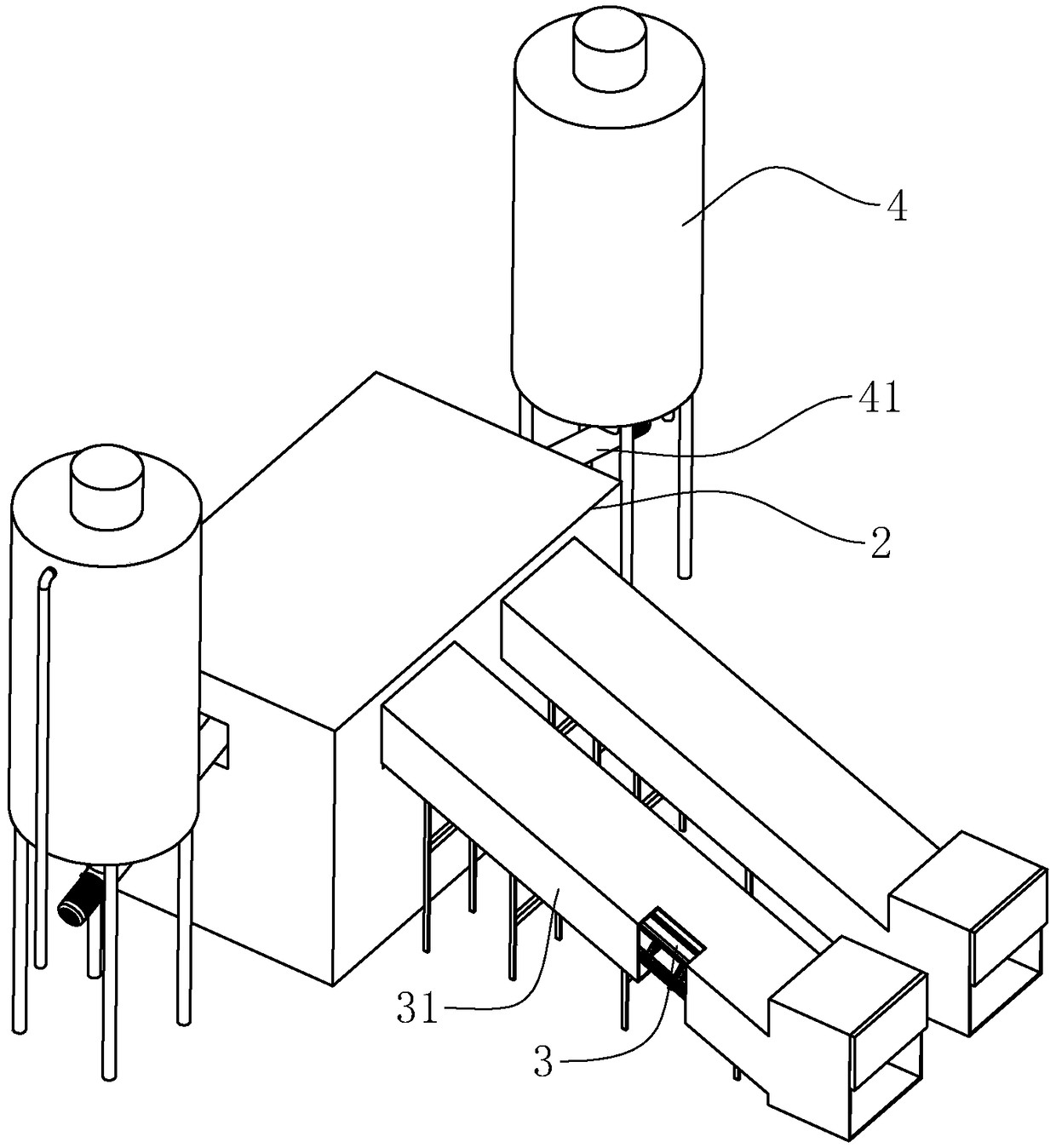

InactiveUS20150103614A1Mixing operation control apparatusTransportation and packagingConcrete plantScrew conveyor

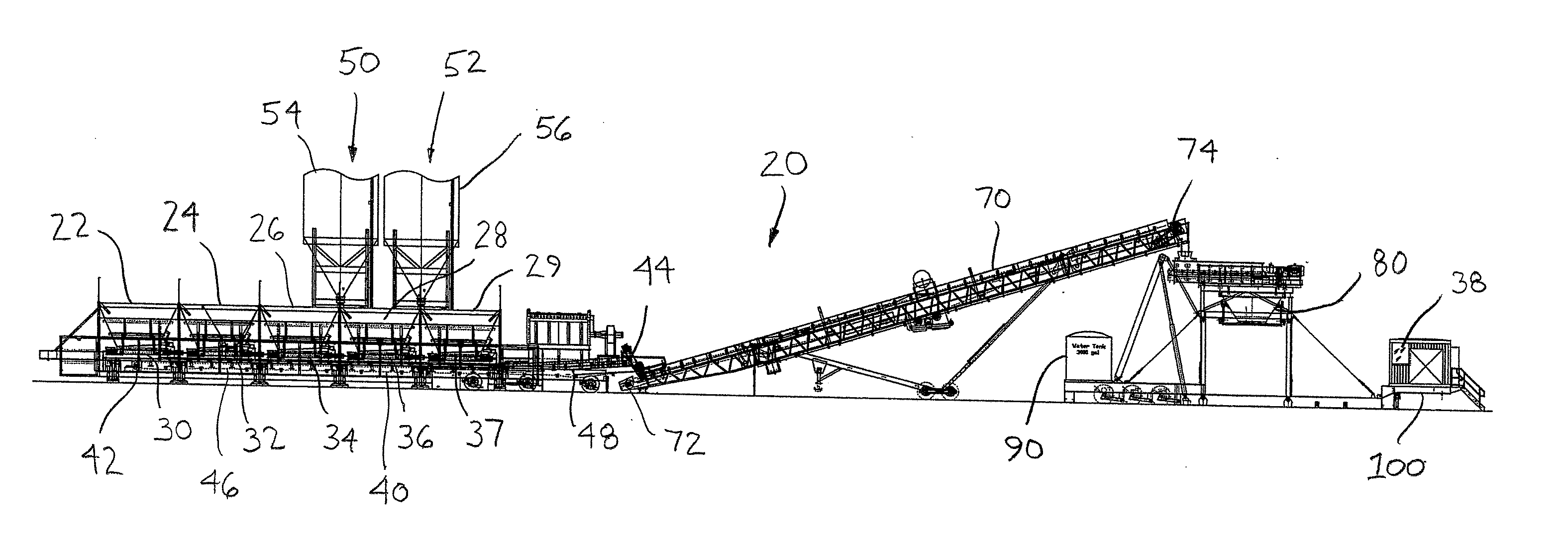

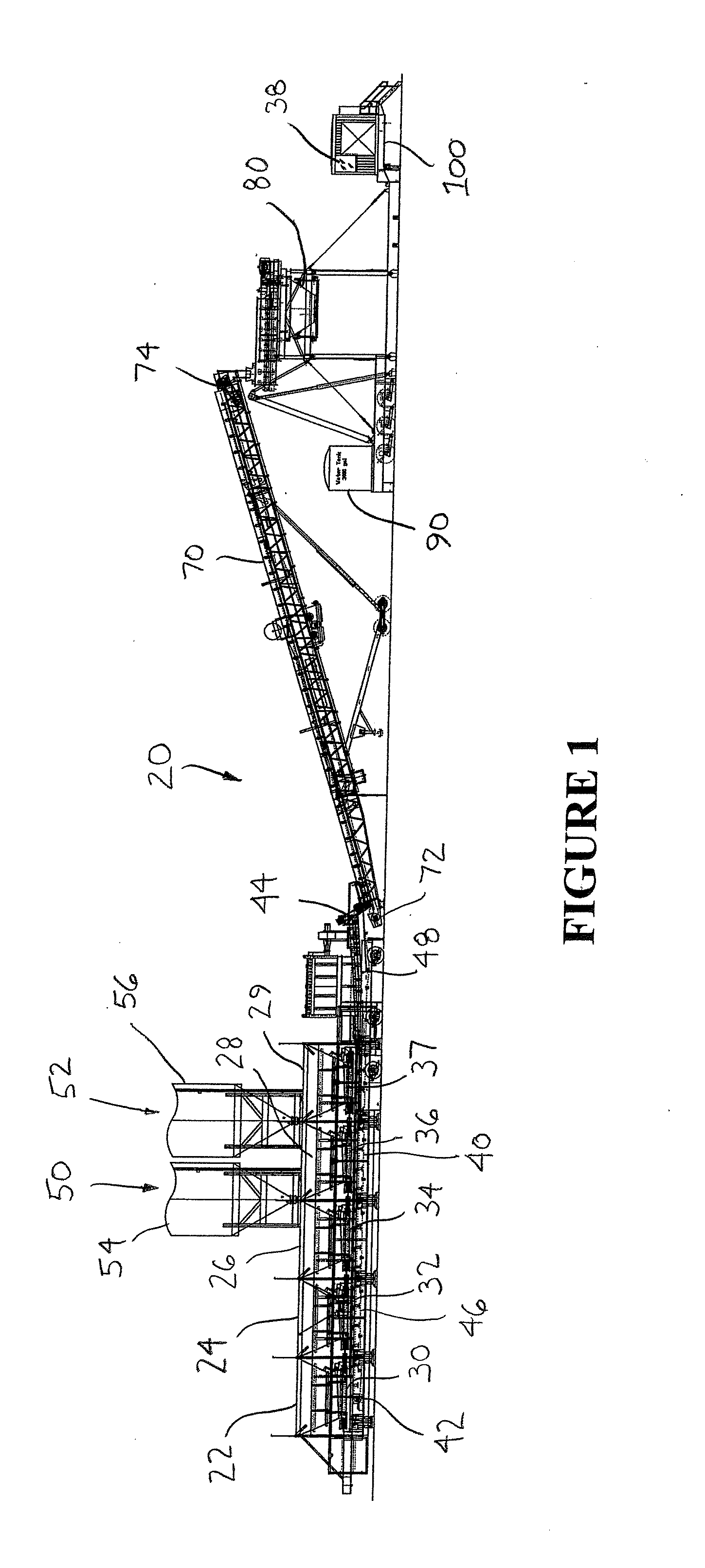

A concrete plant comprising an aggregate feed bin adapted to hold and release aggregate materials, a feed conveyor adapted to receive the aggregate materials from the aggregate feed bin, a collecting belt conveyor adapted to receive the aggregate materials from the feed conveyor, a silo assembly adapted to hold and release components of concrete, a screw conveyor adapted to receive the components of concrete from the silo assembly and convey the components of concrete to the collecting belt conveyor, and a mixer adapted to receive the aggregate materials and components of concrete from the collecting belt conveyor and mix the aggregate materials and components of concrete with water. The amount of aggregate materials received by the collecting belt conveyor from the conveyor and the amount of concrete components received by the collecting belt conveyor from the conveyor are precisely and accurately controlled.

Owner:ASTEC

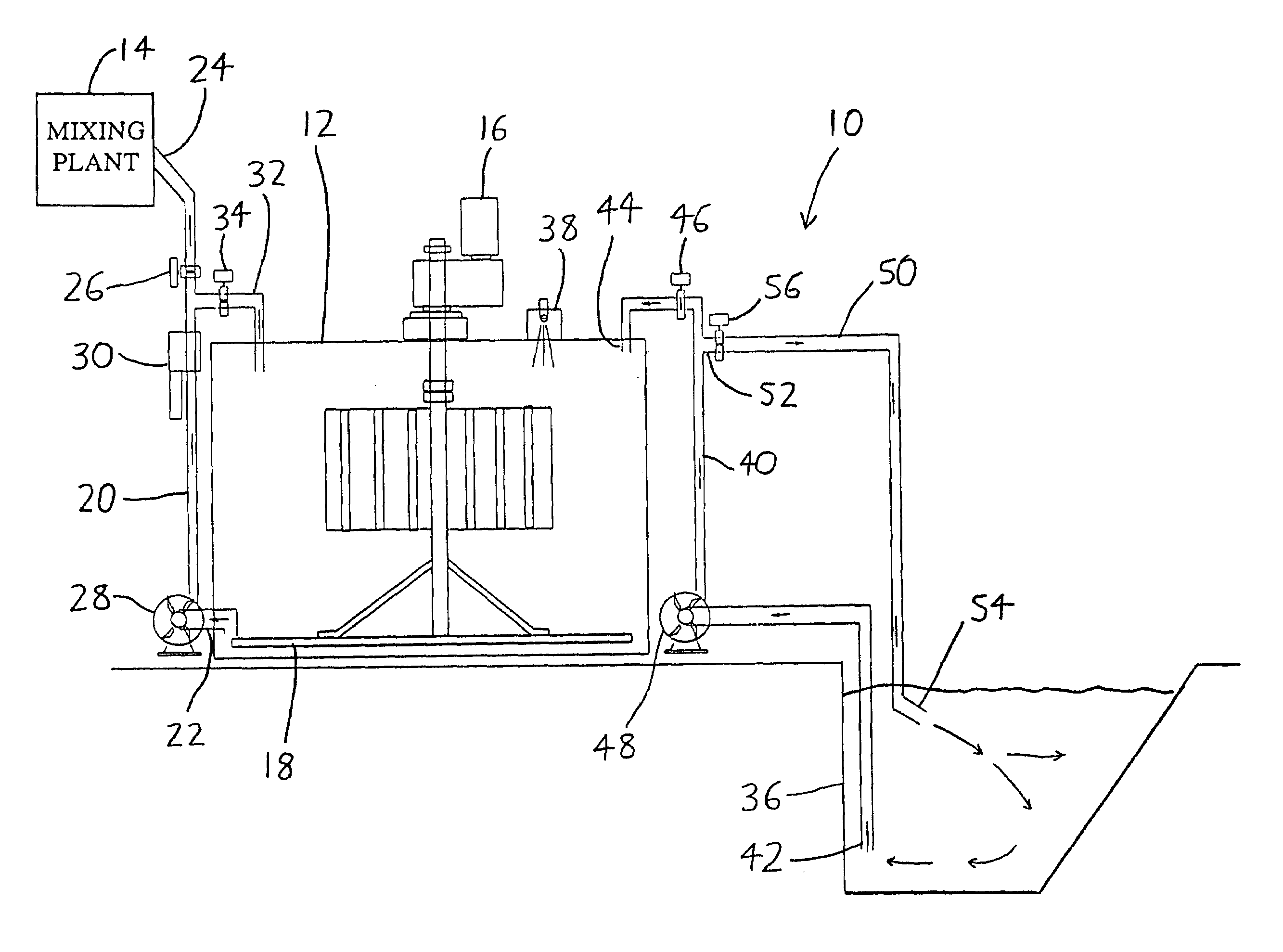

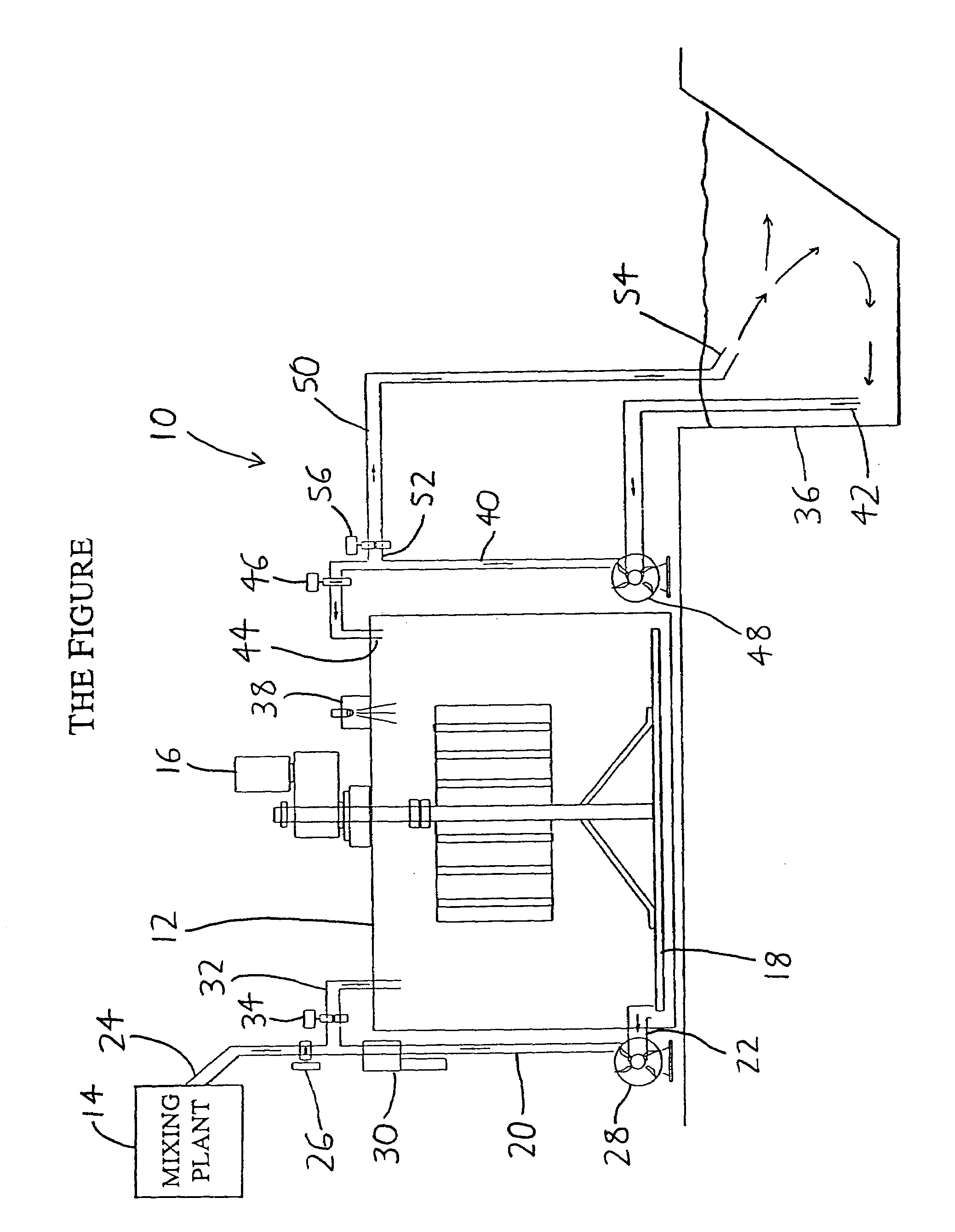

Methods and apparatus for reclaiming components of concrete and other slurries

InactiveUS6929395B1Keep the flowPrevent scalingRotary stirring mixersTransportation and packagingSlurryTruck

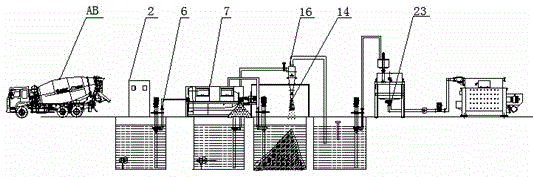

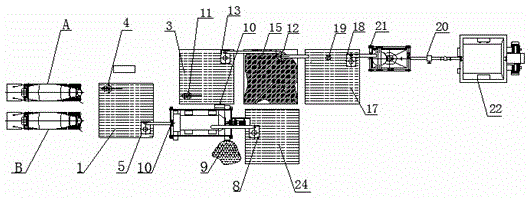

A reclamation system for the recycling of components of fluid concrete (such as concrete fines) and for concrete plant wastewater includes a slurry batch supply vessel which meters process water to a concrete batch mixing plant for use in concrete production processes, and a slurry retention vessel which collects stormwater, concrete truck washout, and other plant waste and wastewater for supply to the batch supply vessel when needed. The retention vessel, which may be no more than a waste pit, includes a fluid supply circuit which supplies water and suspended solids to the batch supply vessel, and a recirculation circuit which collects water and suspended solids from the retention vessel (or from the supply circuit) and reinjects the collected water and solids back into the retention vessel to agitate settled solids back into suspensions (so that they may be taken up by the supply circuit). As a result, the retention vessel will empty itself of accumulated water and waste solids and supply them (via the batch supply vessel) to the concrete batch mixing plant for recycling, rather than requiring the cost and inconvenient of periodic manual emptying.

Owner:METZ JEFFREY LEE

Concrete plant planting and slope protecting method for soft soil river slope

The invention discloses a concrete plant planting and slope protecting method for a soft soil river slope. The concrete plant planting and slope protecting method includes the steps of slope body trimming, soil stabilizer injecting, concrete slope protecting pouring, rib bunching, hole opening, nutrient soil injecting, plant planting, maintaining and the like. The concrete plant planting and slope protecting method is convenient to construct and good in effect, and the survival rate of plants is higher than 95%.

Owner:SUZHOU XINENG ENVIRONMENTAL SCI & TECH CO LTD

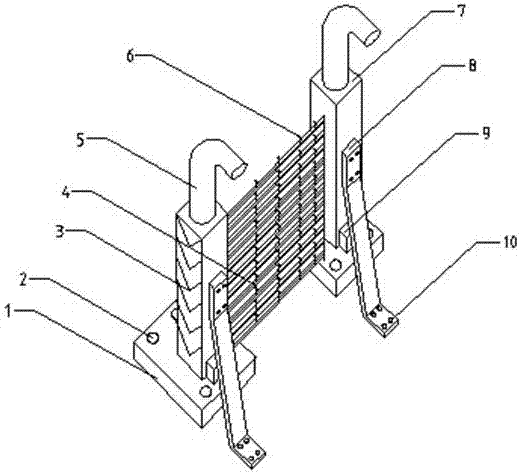

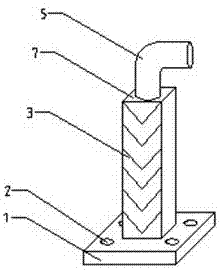

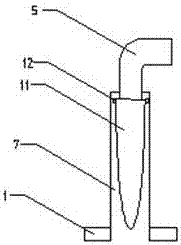

Fiber concrete construction enclosing wall structure

ActiveCN106869584AReduce the impactTo achieve the effect of sound absorption and noise reductionFencingSound proofingFiberCement mortar

The invention discloses a fiber concrete construction enclosing wall structure, and belongs to the field of building construction. The fiber concrete construction enclosing wall structure comprises a fiber concrete base (1), fiber concrete posts (7), a dust removal device and a fiber concrete plant-growing enclosing wall, wherein the fiber concrete base (1) is provided with the fiber concrete posts (7); the fiber concrete posts (7) are of hollow structures; the dust removal device comprises dust removal pipes (5), filtering cloth bags (11) and air exhaust devices (9); the lower ends of the dust removal pipes (5) stretch into the fiber concrete posts (7) and are used for fixing the filtering cloth bags (11); the air exhaust devices (9) are hermetically arranged on the fiber concrete posts (7); the fiber concrete plant-growing enclosing wall is arranged between the adjacent fiber concrete posts (7); the fiber concrete plant-growing enclosing wall comprises a plurality of fiber concrete V-shaped grooves (4) which are arranged from top to bottom; each fiber concrete V-shaped groove (4) is internally filled with soil (13), and a plant (6) is planted in each fiber concrete V-shaped groove (4). Certain sides of the fiber concrete V-shaped grooves (4) are smeared with expanded perlite cement mortar with a thickness of 2cm. By using the fiber concrete construction enclosing wall structure, the improvement of the severe environment of a construction field is facilitated; influences, which are produced by construction, on a worker and a surrounding resident are decreased.

Owner:SUZHOU CONCRETE CEMENT PROD RES INST +1

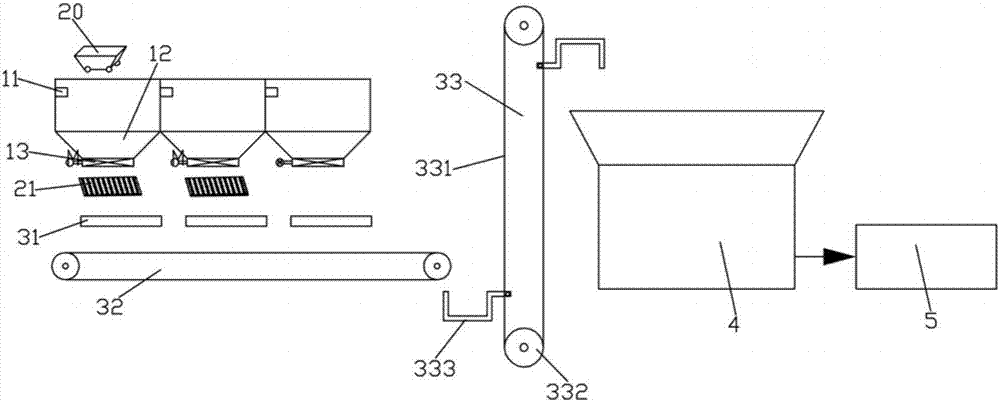

Concrete mixing plant

PendingCN109176890AHigh degree of automationImprove work efficiencyMixing operation control apparatusPretreatment controlElectricityControl system

The invention discloses a concrete mixing plant. The concrete mixing plant comprises a sand stone input station, a conveying belt, a material waiting bin, a mixing device, a steel structure frame anda control system box. The sand stone input station is arranged on the top of the conveying belt. The conveying belt is connected to the side edge of the material waiting bin. The mixing device is arranged below the material waiting bin. The control system box is arranged on the side edge of the mixing device. An arc plate, a second-level material waiting hopper and a first-level material waiting hopper are sequentially arranged in the material waiting bin from top to bottom. A first unloading device and a second unloading device are arranged at the bottom of the first-level material waiting hopper and the bottom of the second-level material waiting hopper correspondingly. A dust removal device is arranged on the outer side of the material waiting bin. A PLC control system is arranged in the control system box. The PLC is electrically connected with the sand stone input station, the conveying belt, the mixing device, the first unloading device and the second unloading device. The concrete mixing plant which is uniform in mixing, capable of reducing raise dust, high in work efficiency and capable of meeting the environment protection requirement is provided.

Owner:GUANGXI DADU CONCRETE GROUP

Dry-cast concrete planter box

Owner:NESS INVENTIONS

Waste residue utilization system of concrete mixing plant and operation technology

A waste residue utilization system of a concrete mixing plant comprises a waste slag pool, and a submersible agitator and a slag slurry pump a are arranged in the waste slag pool; the slag slurry pump a is connected with a classifying screen; one end of a stone outlet of the classifying screen is connected with a clean water pump, and a sand setting pool is arranged on one side of the classifying screen; a slag slurry pump b is arranged in the sand setting pool and is connected with a cyclone separator, and a sand leaking opening is formed in the lower end of the cyclone separator; a sand storage pool is arranged below the sand leaking opening, and a sewage outlet is formed in the top of a cyclone; a sewage pump is arranged in a sewage pool, and is connected with a sewage dosing scale through a connecting pipeline, and the sewage dosing scale is connected with a sewage draining pump; and the sewage draining pump is connected with the agitator. The waste residue utilization system has the beneficial effects that by means of the waste residue utilization system of the concrete mixing plant, waste zero discharge of the mixing plant can be completely achieved, energy saving and environmental protection are achieved, the cost is low, and the system is simple, easy to implement, short in construction period, and high in automation degree and is an energy-saving environment-friendly preferred product of related enterprises.

Owner:SHANDONG LIUGONG CONCRETE EQUIP

Concrete mixing plant

InactiveCN108656361AReduce driftProtect environmentDischarging apparatusMixing operation control apparatusEngineeringConcrete plant

The invention relates to a concrete mixing plant. According to the main design key points, the concrete mixing plant comprises a storage bin, a mixing chamber and a conveying line, the conveying lineextends into the mixing chamber, a conveying pipe is arranged at the lower portion of the storage bin and extends into the mixing chamber, and a discharging port is formed in the lower portion of themixing chamber. The concrete mixing plant further comprises a mixing shed, and the mixing chamber and the conveying line are located in the mixing shed. A dust fall device is arranged in the mixing shed, the mixing shed is arranged on the ground, and a roller shutter door is arranged on one side of the mixing shed. The concrete mixing plant has the beneficial effect that the surrounding environment of the concrete mixing plant is protected.

Owner:北京安捷鑫德混凝土有限公司

Feedback controlled concrete production

ActiveUS9731255B2Easy loadingEfficient productionRotary stirring mixersMixing methodsControl systemStructural engineering

Owner:BLACK MELVIN L +1

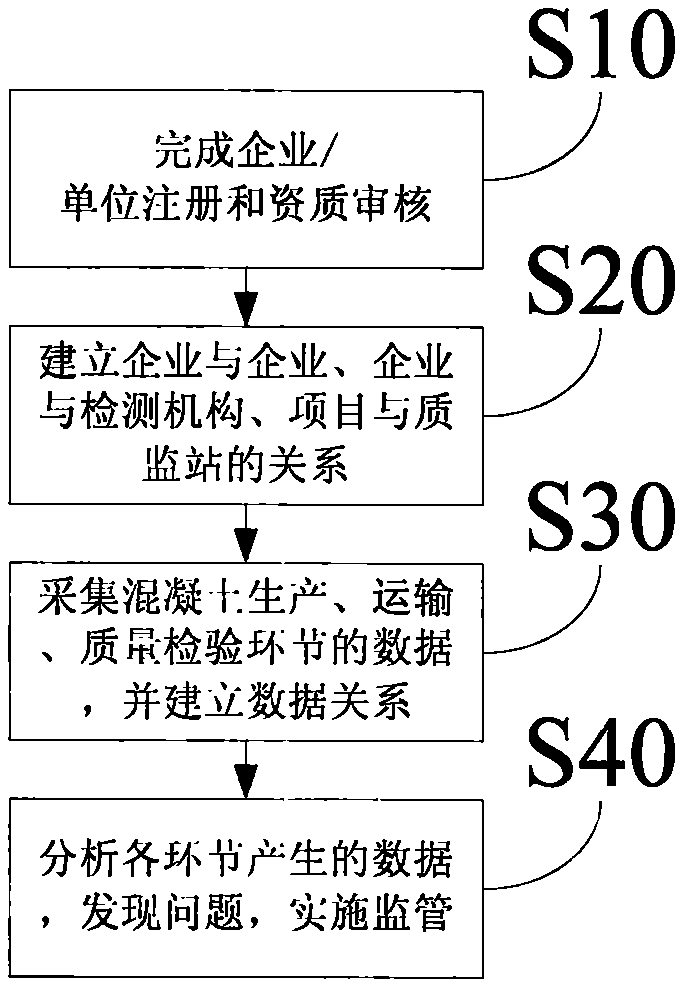

Big data quality supervision method for premixed concrete

InactiveCN107203829AEffective supervisionPromote management upgradesResourcesThe InternetData quality

The invention provides a big data quality supervision method for premixed concrete, and relates to the technical field of Internet big data analysis. The method comprises the steps: completing the enterprise / unit registration and qualification examination and verification; building the relation between enterprises, the relation between enterprises and a detection mechanism, and the relation between a projection and a quality supervision department; collecting the data of concrete production, transportation and quality verification links, and building a data relation; analyzing the data produced by all links, searching a problem, and carrying out the supervision. The method provides data services for a supervision unit, a construction enterprise and a commercial concrete plant, and solves problems in the concrete quality supervision.

Owner:必然云(沈阳)科技有限公司

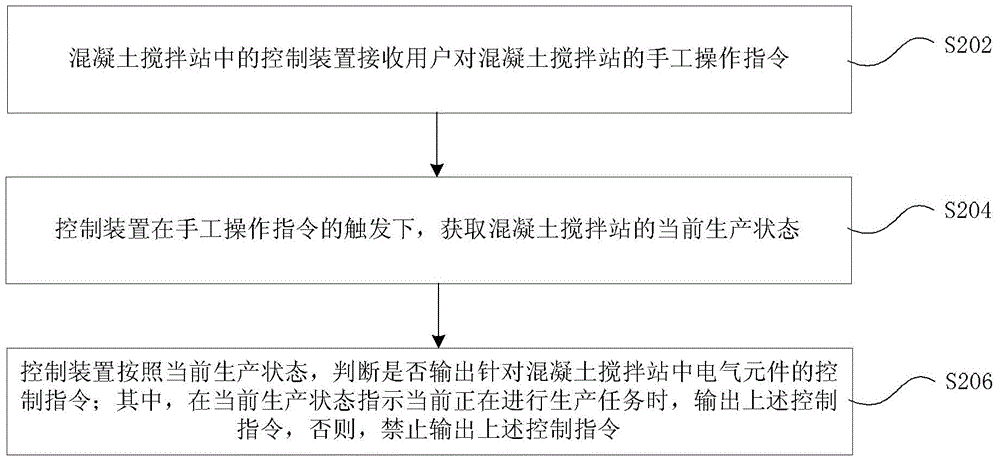

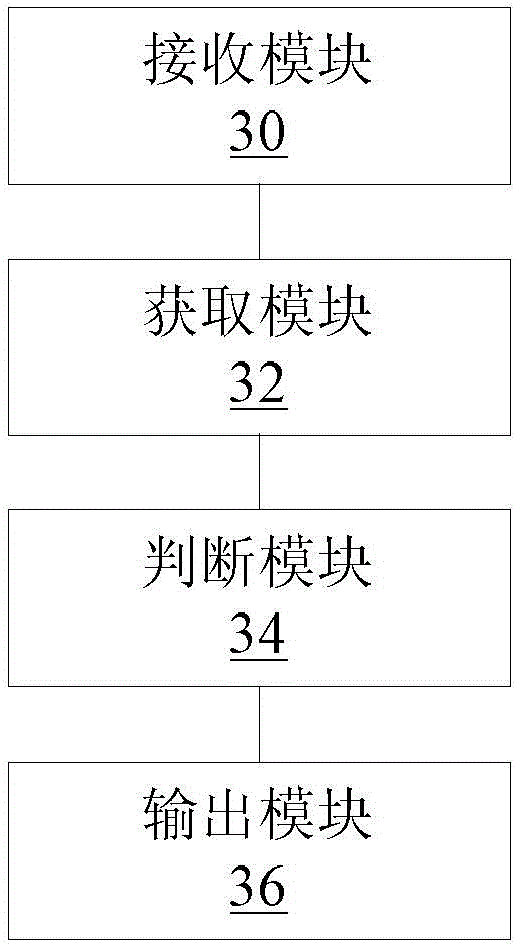

Control method and control device of concrete mixing plant and the concrete mixing plant

The invention provides a control method and a control device of a concrete mixing plant and the concrete mixing plant. The control method comprises the following steps: 1) the control device in the concrete mixing plant receives a manual operation command by users to the concrete mixing plant; 2) the control device acquires present work situation of the concrete mixing plant under trigger of the manual operation command; and 3) the control device determines whether a control command aiming to electrical elements in the concrete mixing plant is outputted or not according to the present work situation, wherein the control command is outputted if a production task is indicated to be carried out by the present work situation, and the control command is forbidden to output if the production task is not carried out. By means of the technical scheme, the technical problem that fine management is difficult to achieve since manual operation record cannot be subdivided to particular production tasks is solved, thereby achieving the fine management even manual operation exists in a concrete production process.

Owner:ZOOMLION HEAVY IND CO LTD

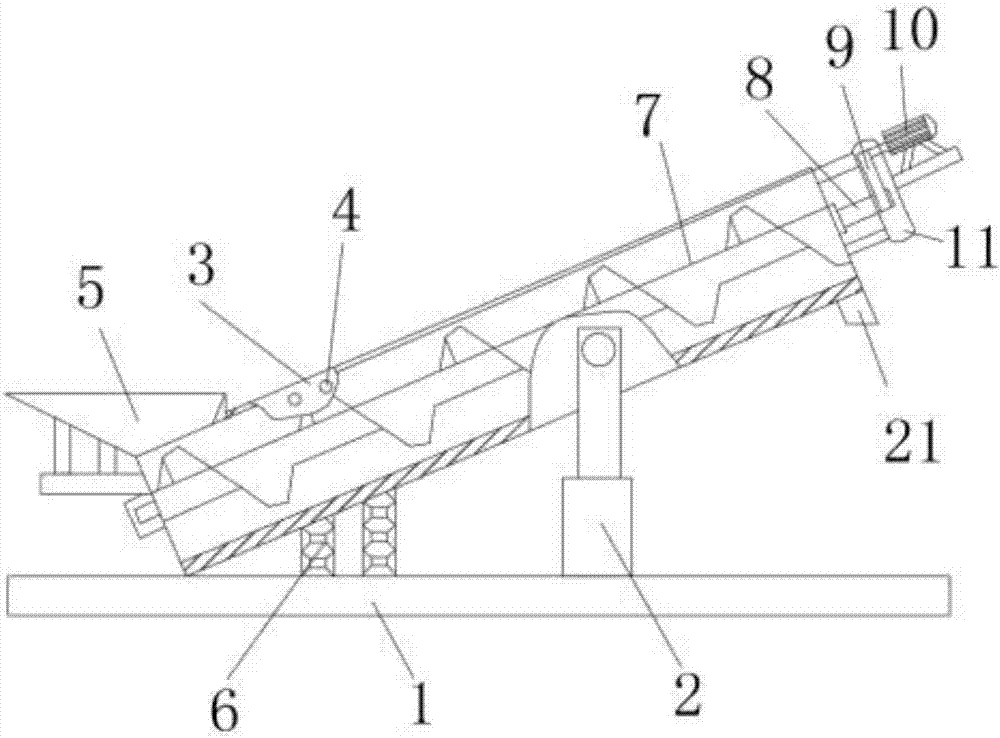

Material conveying device for concrete mixing plant

InactiveCN107234731AEasy to clean and maintainEasy to rinseMixing operation plantEngineeringConcrete plant

The invention discloses a material conveying device for a concrete mixing plant. The material conveying device comprises a bottom plate and a material conveying pipe. A hydraulic telescopic rod is connected with the position between the bottom plate and the material conveying pipe, the hydraulic telescopic rod is perpendicular to the bottom plate, and an elastic rod is connected with the position, on one side of the hydraulic telescopic rod, between the bottom plate and the material conveying pipe; and a charging port is welded in a shell body of the top of one end of the material conveying pipe, a discharging port is formed in a shell body of the bottom of the other end of the material conveying pipe, an overflowing hole is formed in a shell body of the surface of the material conveying pipe, and a spiral material conveying shaft is arranged at the center of the inner portion of the material conveying pipe. According to the material conveying device for the concrete mixing plant, firstly the middle position of the material conveying pipe is fixedly connected with the bottom plate through the hydraulic telescopic rod, one end of the material conveying pipe is fixedly connected with the bottom plate through the elastic rod, the hoisting height of material conveying can be controlled through adjustment of the height of the hydraulic telescopic rod in the using process, material conveying to storing devices with different heights is facilitated, and the application range and the practicability of the material conveying device are promoted.

Owner:黔西南州启腾矿山设备有限公司

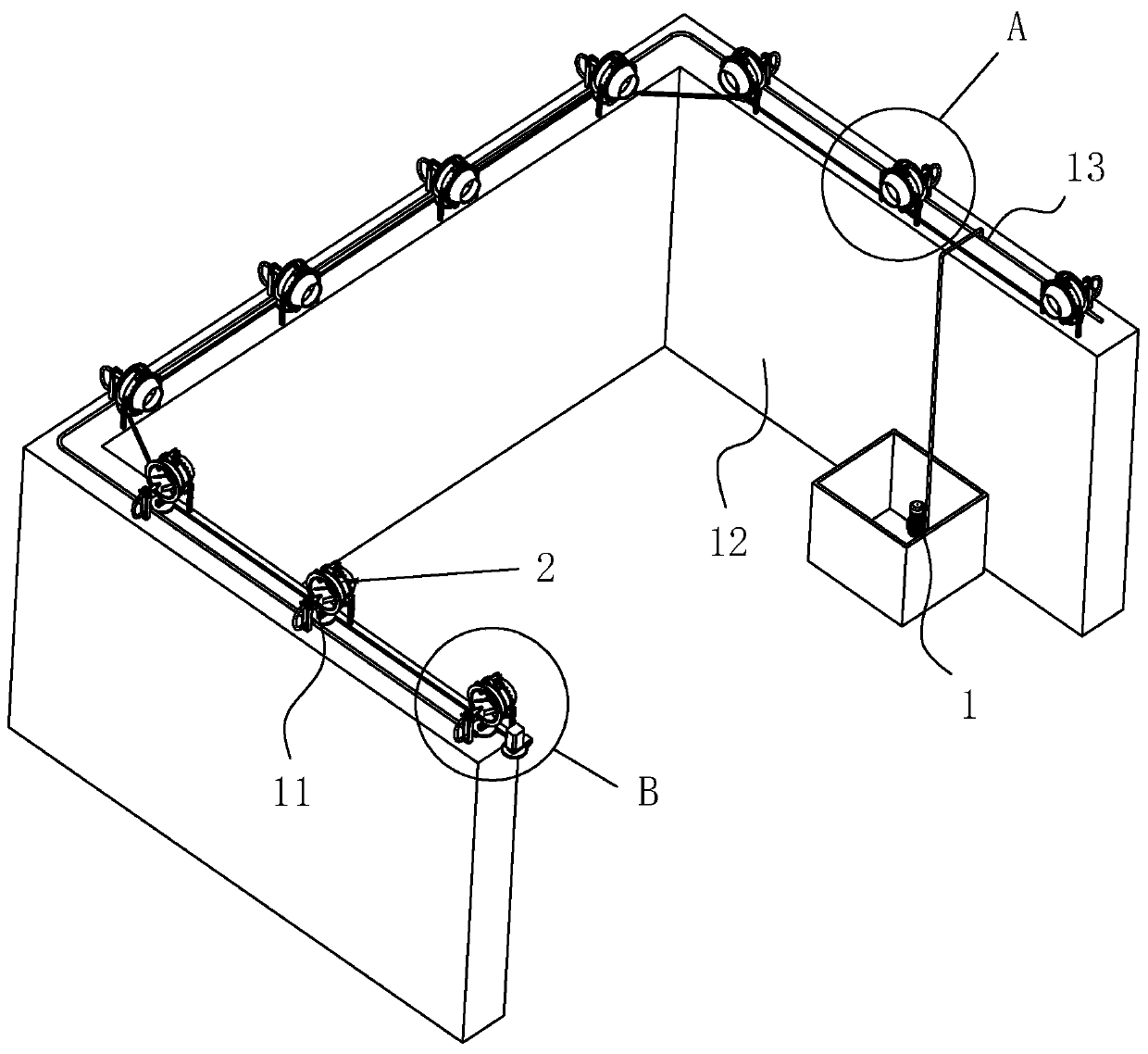

Spraying dust-settling system for concrete factory

ActiveCN111420496AExpand coverageIncrease coverageUsing liquid separation agentBuilding material handlingAir velocityWater source

The invention relates to a spraying dust-settling system for a concrete factory. The system comprises a water pump and an atomizing nozzle, a water inlet of the water pump is externally connected witha water source, a water outlet is connected with a water pipe, the atomizing nozzle is arranged on the top wall of an enclosing wall, the atomizing nozzle is communicated with the water pipe, a wateroutlet of the atomizing nozzle faces the inner side of the wall, a fan is arranged on the side, close to the inner side of the wall, of the atomizing nozzle, a mist outlet end of the atomizing nozzlefaces an air inlet end of the fan, and a driving device for driving the fan to rotate and an adjusting device for adjusting the air speed of the fan back and forth are arranged on the wall. When spraying humidification is carried out in a concrete factory area, water mist is generated by the atomizing nozzle, the fan is driven to rotate to blow water mist to the middle of a plant area, then the air speed of the fan is driven to change in a reciprocating mode, the distance of the sprayed water mist pushed out by wind power is changed in a reciprocating mode, and therefore the coverage range ofthe water mist is enlarged under the condition that the mist outlet amount of the atomization nozzle is not changed, and the device has the advantages of being high in water mist coverage rate and good in dust falling effect.

Owner:仁寿县旭昱商品混凝土有限公司

Fully closed floor heating heat-insulation type concrete plant

ActiveCN107310045AAvoid safety hazardsEnsure safetyMixing operation control apparatusPretreatment controlCombustionFire - disasters

The invention discloses a fully closed floor heating heat-insulation type concrete plant. The fully closed floor heating heat-insulation type concrete plant comprises a fully closed storage bin shed, a mixing station and a heating system mounted in the storage bin shed, wherein the mixing station comprises a dosing machine which is mounted in the storage bin shed and the dosing machine is provided with a heater; the storage bin shed is internally provided with a plurality of gravel storage bins; a floor heating groove is formed in the bin bottom of at least one gravel storage bin; a heat supply pipeline is laid in the floor heating groove; a steel cover plate covers the floor heating groove; the heating system comprises a boiler; the boiler is communicated with a water inlet of a heating pipeline through a first water outlet pipe; and the boiler is communicated with a water inlet of the heater through a second water outlet pipe. According to the fully closed floor heating heat-insulation type concrete plant disclosed by the invention, heating and heat insulation are carried out on gravels through a hot water pipe, so that construction requirements under cold weather are met and the whole storage bin shed does not need to be subjected to the heating and heat insulation, so that the cost is saved and potential safety hazards of a traditional storage bin shed that a combustion oven is used and fire disasters are prone to cause are avoided; and the storage bin shed with a fully closed structure is adopted so that phenomena that dust flies in the air and slurry flows on a whole ground are avoided and civilized construction is facilitated.

Owner:THE 2ND ENG CO LTD MBEC +1

Premixed slurry fluid foam concrete onsite stirring construction method

The invention discloses a premixed slurry fluid foam concrete onsite stirring construction method. Slurry is transported to a construction site for premixing. A mixer truck carries the premixed slurry to the construction site and then is in butt joint with an agitator so as to carry out secondary agitation on the slurry. A feed inlet of the agitator is provided with a steel screen filter unit with the mesh size being 6*6mm. After the premixed slurry from a commercial concrete plant is transported to the construction site, the premixed slurry undergoes secondary agitation by the agitator on the site, and the feed inlet where the premixed slurry mixer truck is in butt joint with the agitator is provided with the specially-produced steel screen filter unit which is used to filter out residual broken stones. Thus, mechanical failure is avoided, and broken stones and foreign materials are also prevented from being mixed in the slurry.

Owner:ZHEJIANG HAITIAN CONSTR GROUP

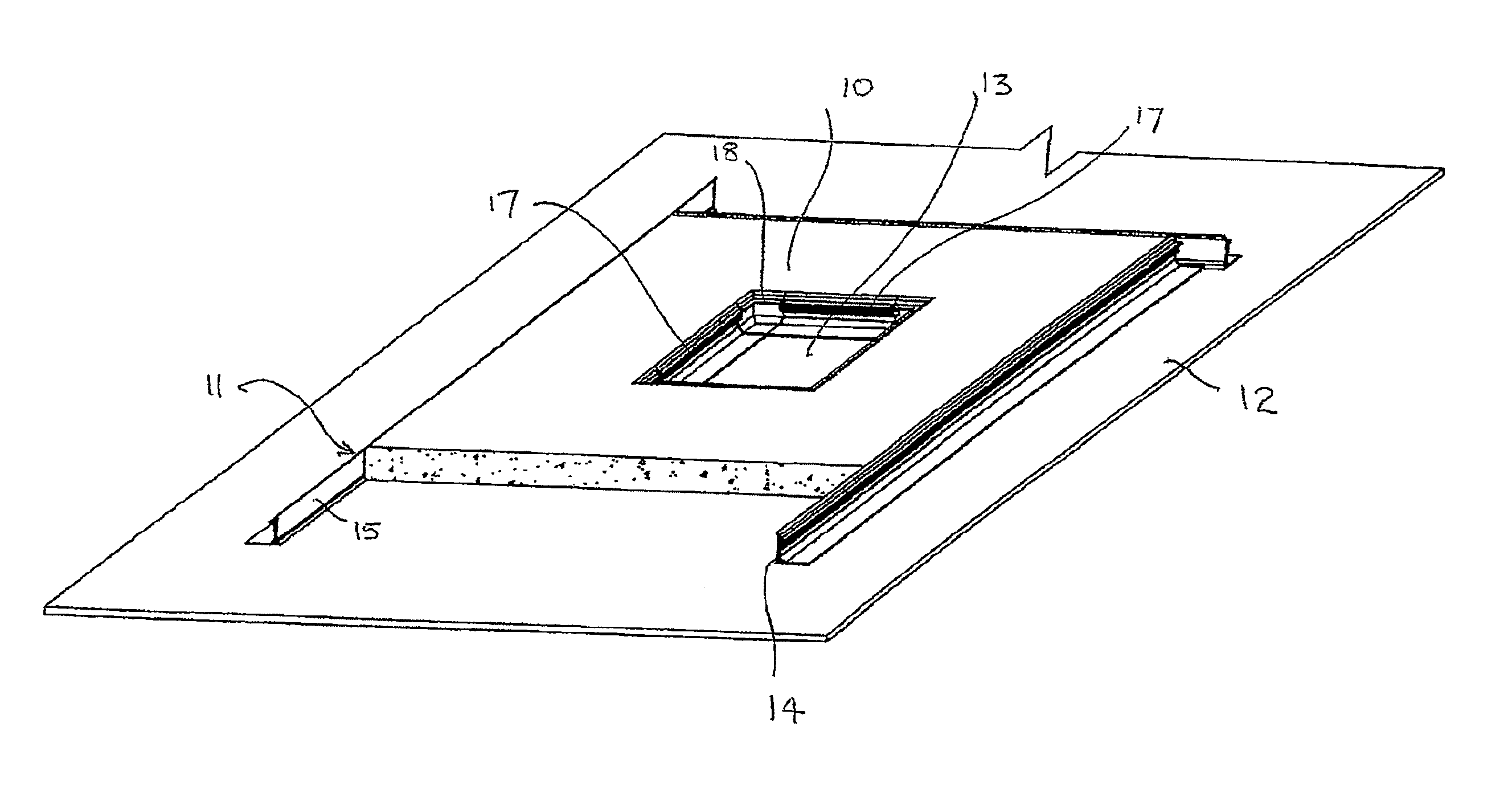

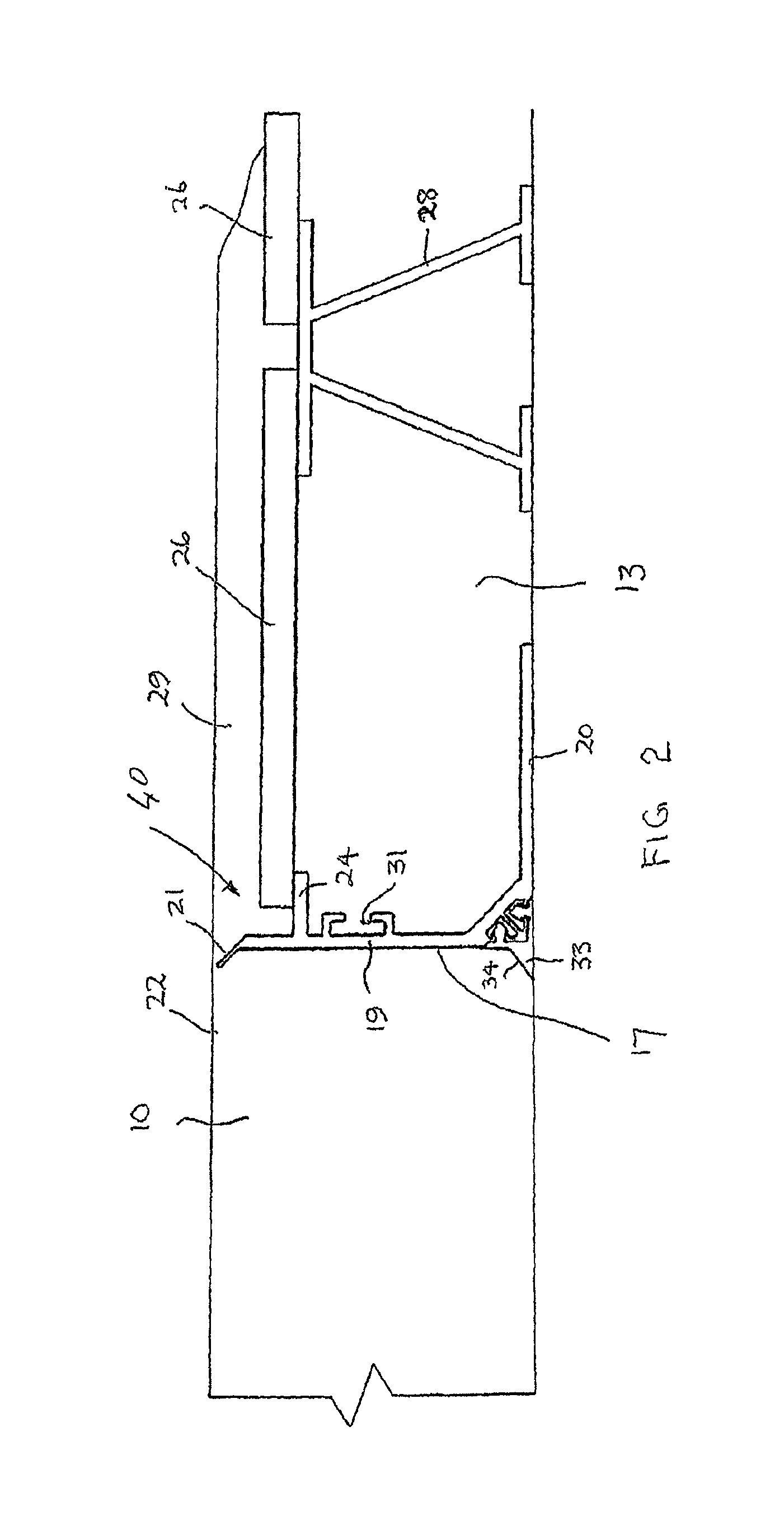

False formwork for moulding concrete panels

A false formwork system (40) includes a plurality of sideforms (17) which are able to be interconnected to define a perimeter of an opening in a panel to be cast. A support structure (24) is carried by the sideforms (17) for supporting components (26) used to mold a false skim coat overlying the opening when the panel is cast. An opening demarcation portion (21) is carried by each of at least some of the sideforms (17). Each opening demarcation portion (21) defines a zone of weakness to demarcate the skim coat of the cast panel from a remainder of the panel and to facilitate removal of the skim coat from the remainder of the panel by breakage along the zone of weakness.

Owner:SRB CONSTR TECH

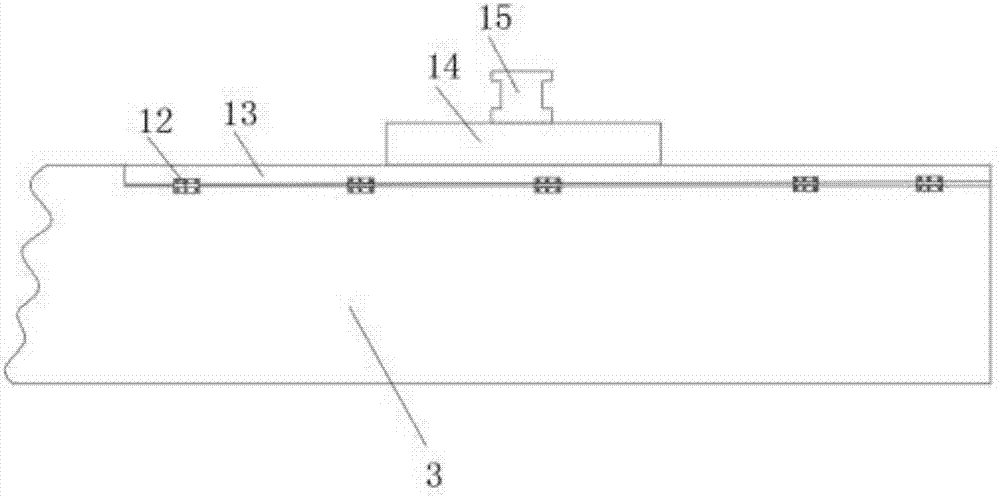

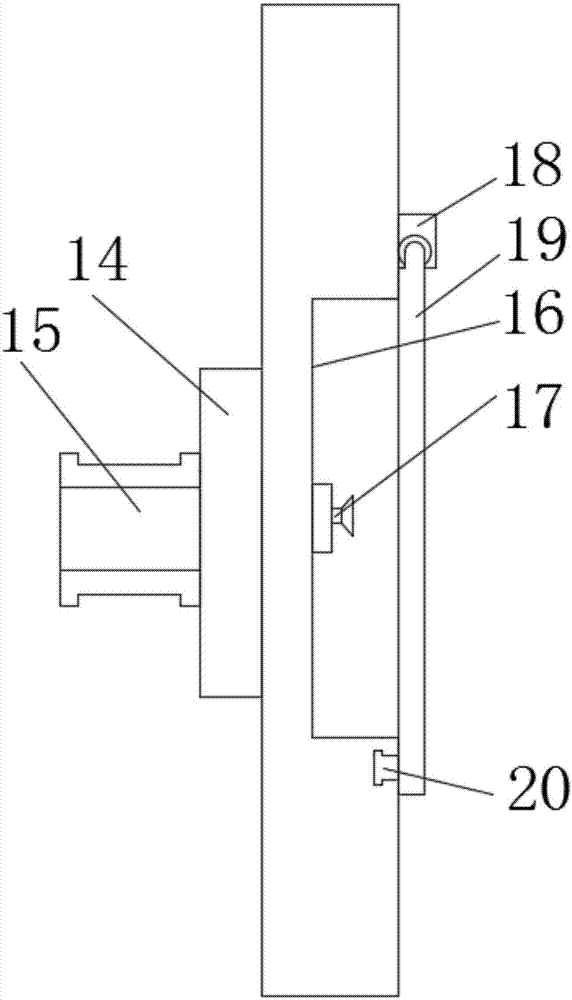

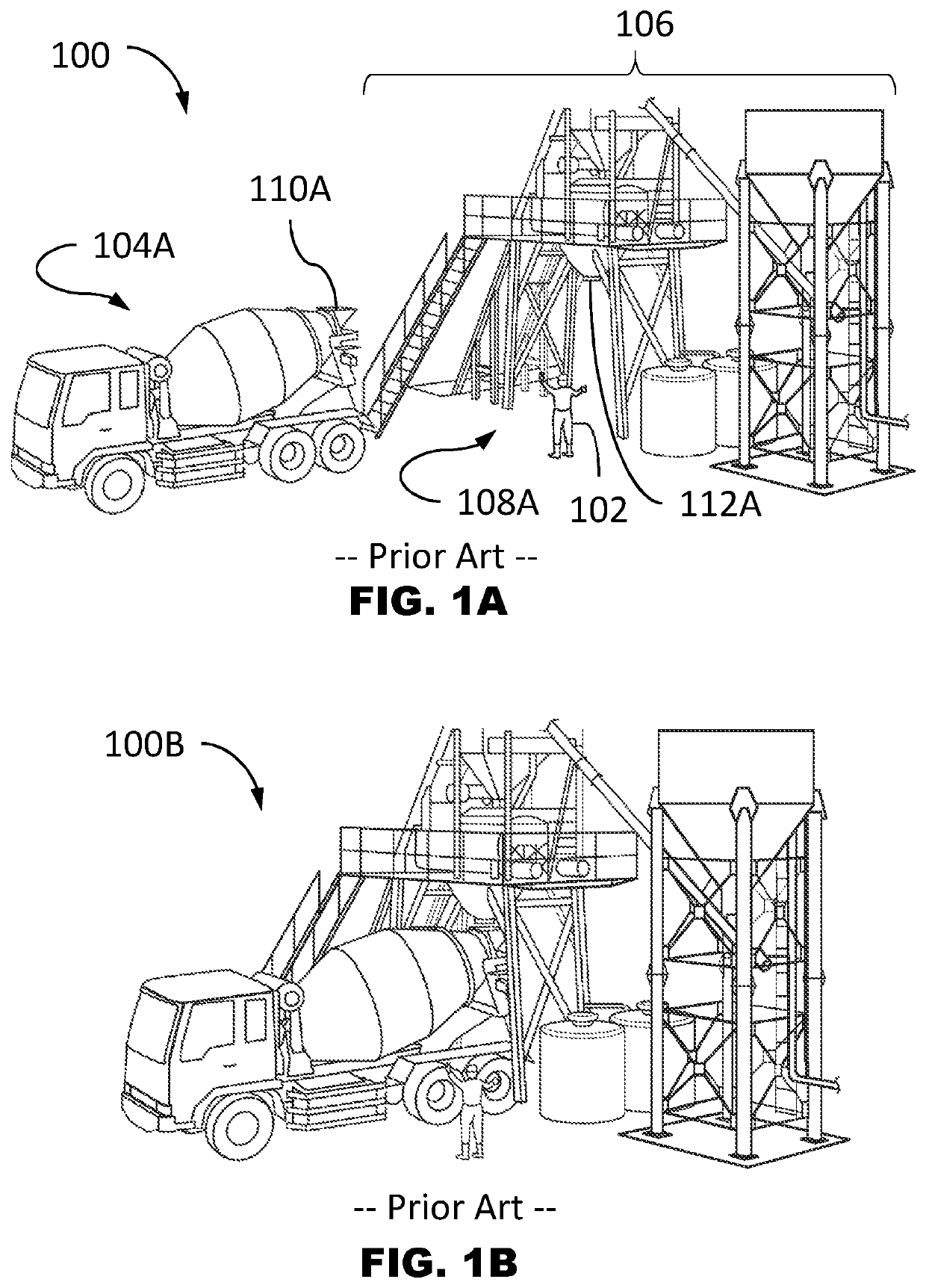

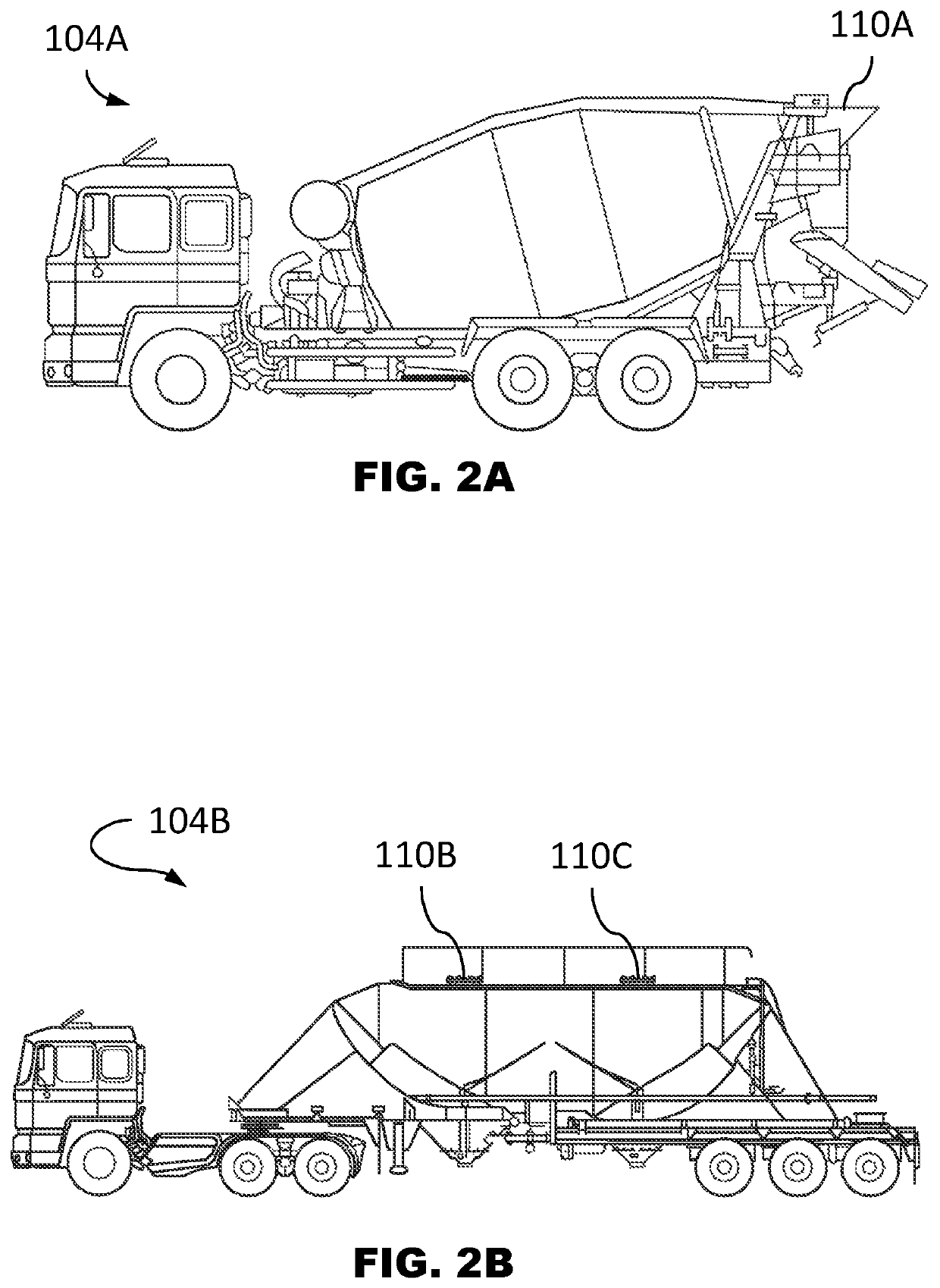

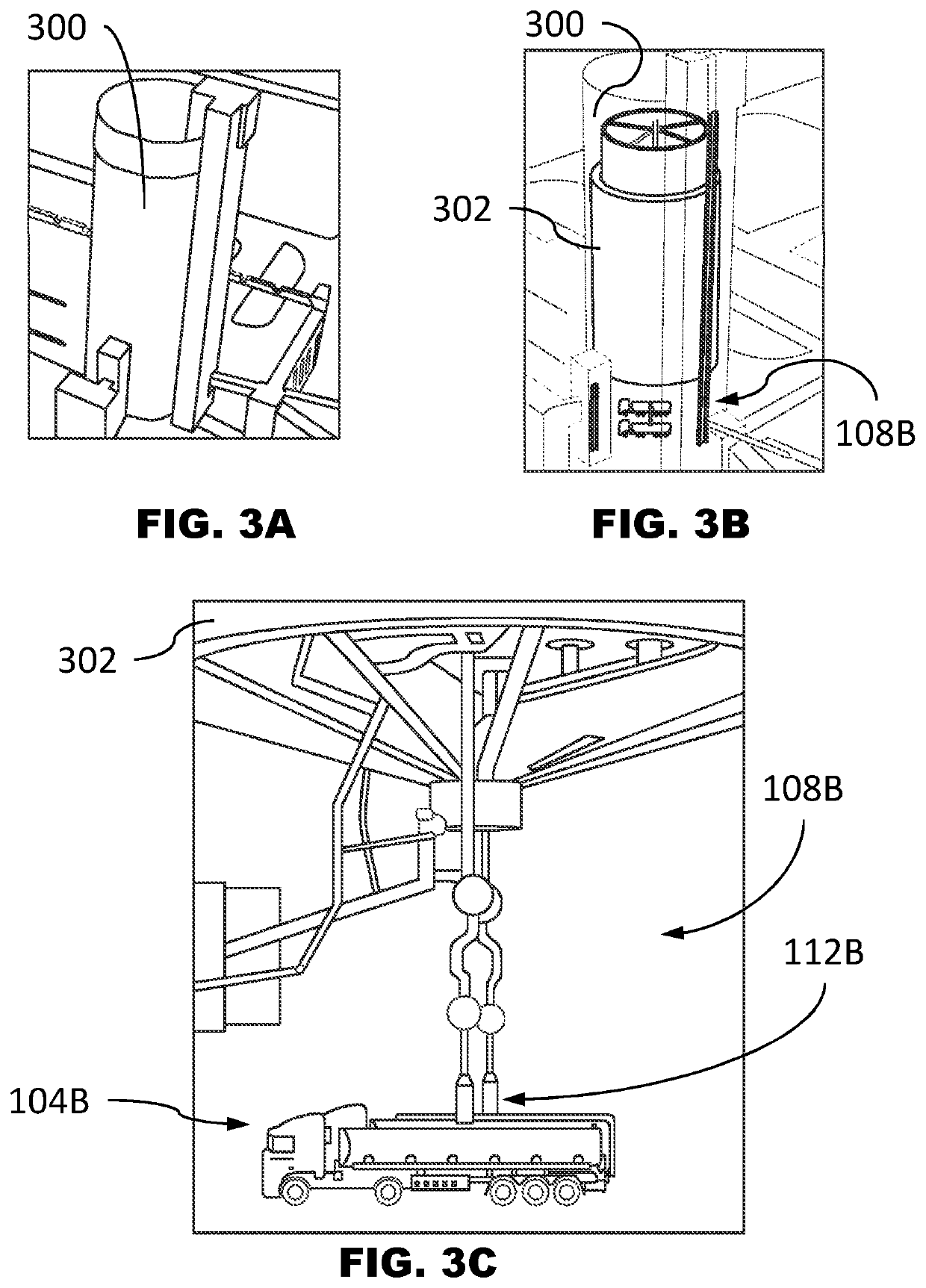

Alignment system and method for a concrete truck at a concrete plant or a cement tanker at a cement loading station

A concrete truck or cement tanker truck alignment system with a loading station having a discharge chute, an electronic sensor that sees through dust or an environmental dust shield, and provides location information used to determine a hopper offset. The hopper offset is a measurement of the physical offset between a feed hopper on the truck and the discharge chute. The system may further include an alignment feedback unit that provides feedback based on the hopper offset. The alignment feedback unit may indicate the hopper offset is within an alignment tolerance. The sensor may use radar. The alignment feedback unit may provide auditory or graphical feedback. The graphical feedback may show a discharge icon representing the position of the discharge chute and a hopper icon representing the feed hopper where the location of the hopper icon is relative to the discharge chute based on the hopper offset.

Owner:FAULKNER GEORGE WAYNE

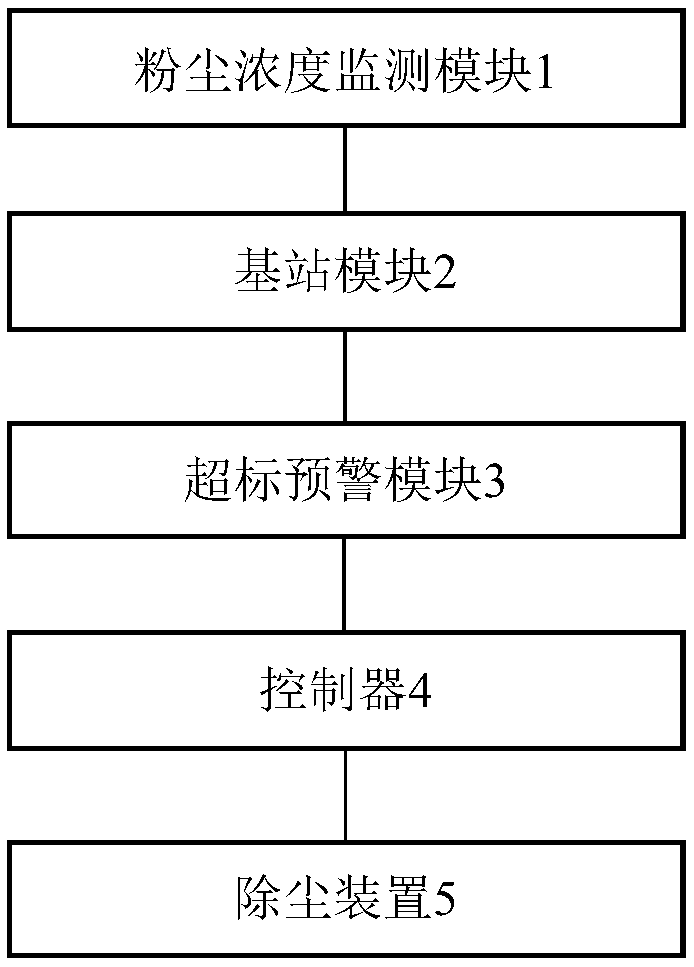

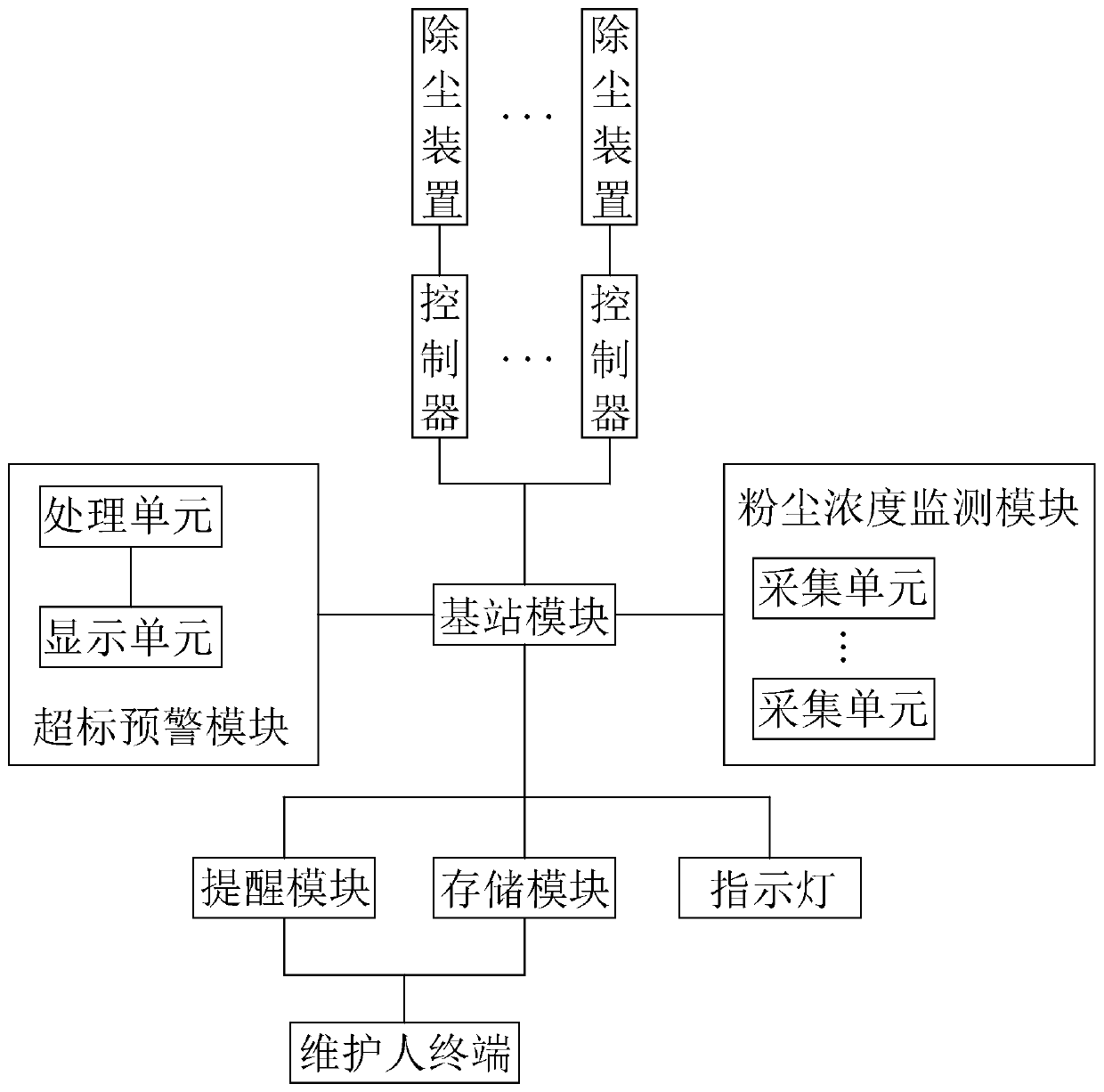

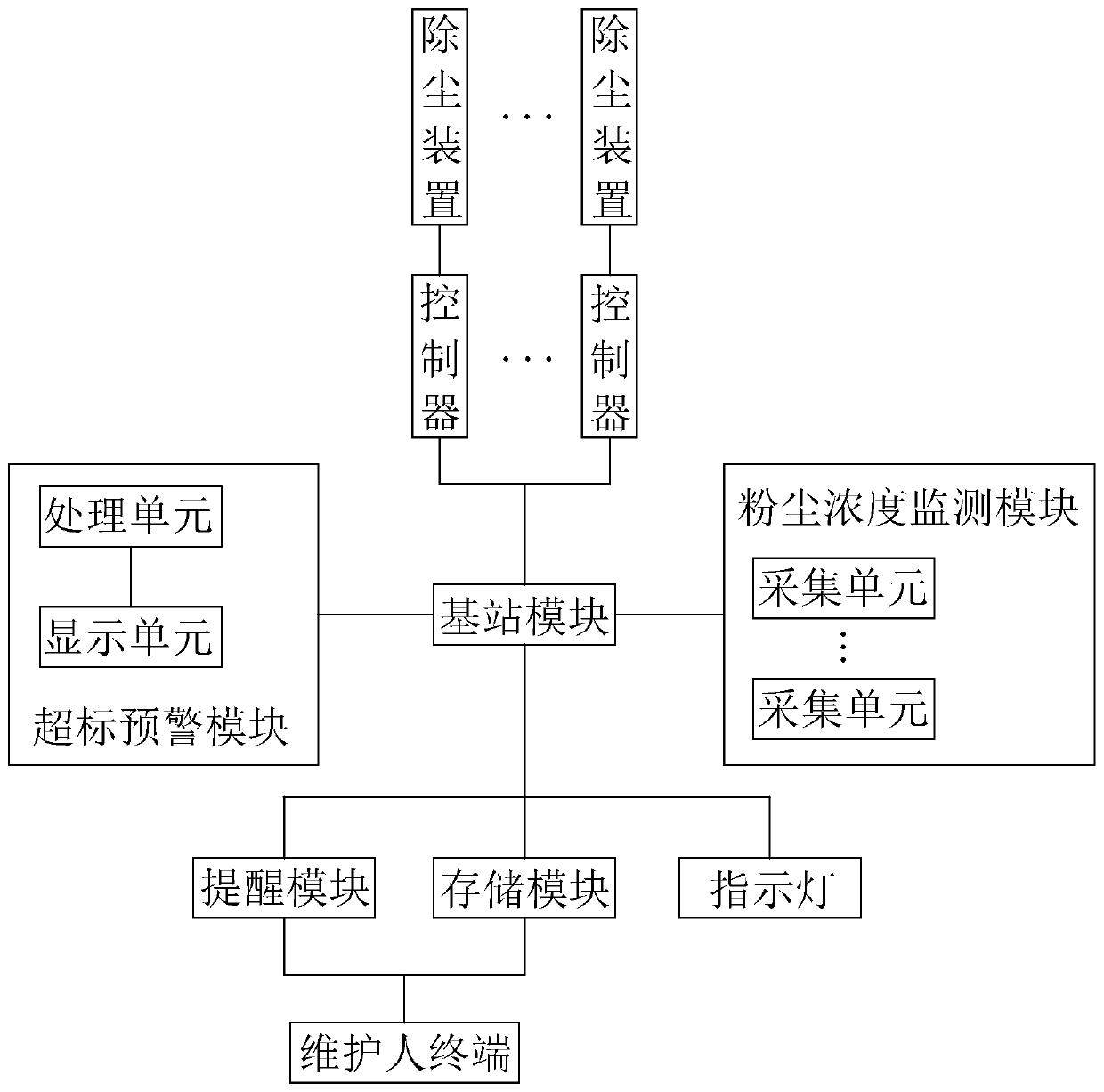

Automatic early warning system for excessive dust in concrete plant

InactiveCN109035711AReal-time monitoring of concentrationA clear understanding of the status quo of the dust environmentAlarmsEarly warning systemMultiple sensor

The invention provides an automatic early warning system for excessive dust in a concrete plant, comprising a dust concentration monitoring module, a base station module and an excess early warning module; the dust concentration monitoring module comprises multiple sensor nodes, the multiple sensor nodes are randomly deployed in set dust monitoring areas of the concrete plant, and the sensor nodesare used for acquiring dust concentration data at monitored positions respectively; the base station module aggregates the dust concentration data of each sensor node, processes and then forwards tothe excess early warning module; and the excess early warning module is used for analyzing and processing the dust concentration data sent by the base station module and executing an alarm when the dust concentration data exceeds a set concentration threshold value.

Owner:SHENZHEN HUICHUANG UNITED AUTOMATION CONTROL CO LTD

A concrete mixing station

InactiveCN105922451BAvoid disadvantagesHigh precisionDischarging apparatusMixing operation control apparatusConcrete plantAutomatic testing

The invention discloses a concrete mixing station. The concrete mixing station comprises a raw material storage system, a raw material weighing system, a mixing and conveying device, a raw material conveying system, a concrete conveyor and a control box. The raw material storage system, the raw material weighing system, the raw material conveying system, the mixing and conveying device and the concrete conveyor are sequentially arranged. By the adoption of the concrete mixing station, the defects of an existing concrete mixing station can be overcome, the structure is simple, operation is easy, automatic batching is achieved, batching precision and batching efficiency are improved, labor force is reduced, and production cost and operating cost are saved.

Owner:岳阳华铭混凝土有限公司

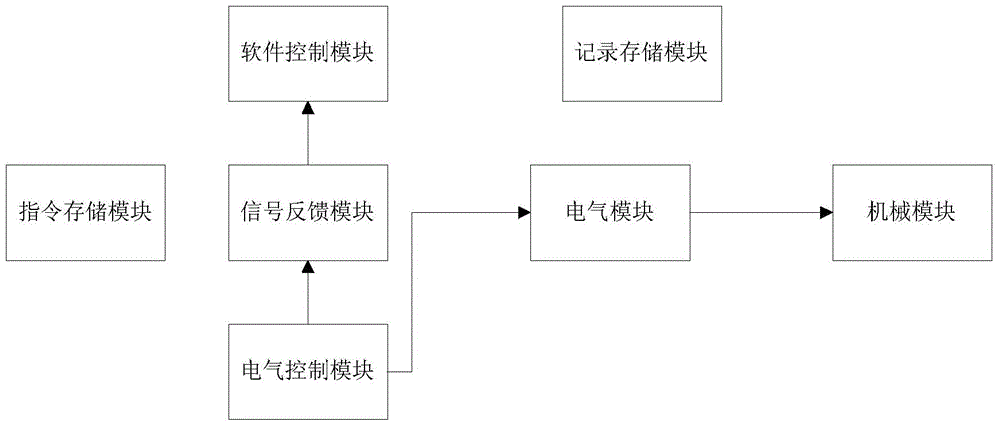

Control system of concrete mixing plant

InactiveCN103034172AReasonable structureImprove work performanceTotal factory controlProgramme total factory controlControl systemProgrammable logic controller

The invention discloses a control system of a concrete mixing plant. The control system comprises a sensing device for receiving and transmitting signals of each working area of the mixing plant, the sensing device is connected with a programmable logic controller (PLC) control device which is connected with a central control device through a wired or wireless network, and the central control device sends out working signals to each working straight-line mechanism. The control system is reasonable in structure, high in task performance and excellent in performance.

Owner:王均炎

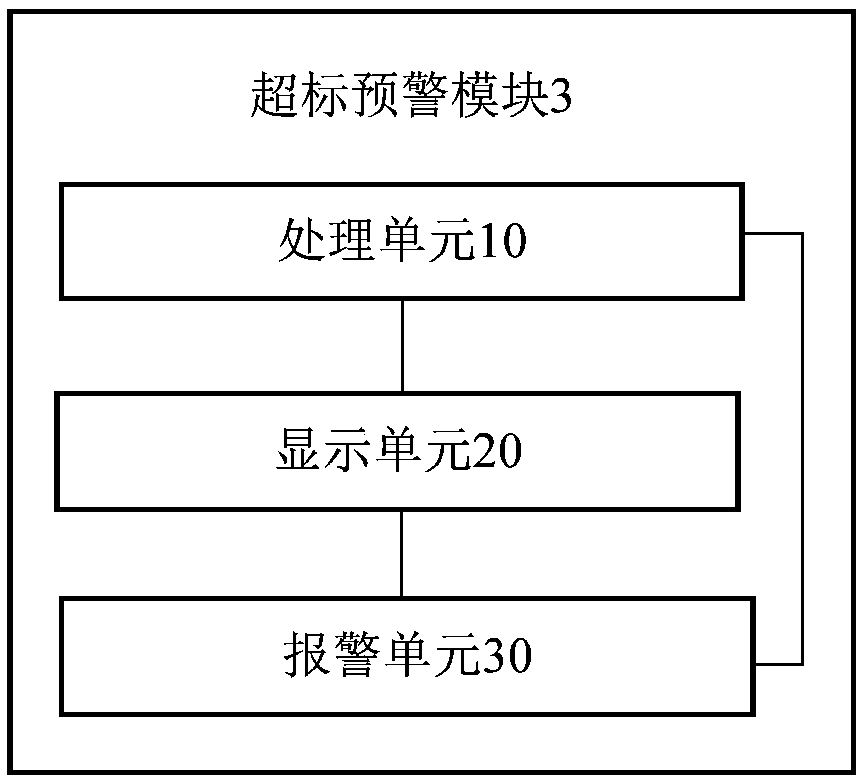

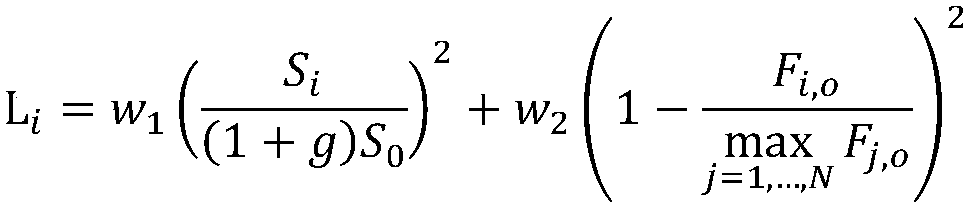

Automatic concrete plant dust exceeding early-warning system

InactiveCN110044786AReal-time monitoring statusA clear understanding of the status quo of the dust environmentParticular environment based servicesParticle suspension analysisEarly warning systemComputer module

The invention relates to an automatic concrete plant dust exceeding early-warning system. The automatic concrete plant dust exceeding early-warning system comprises a dust concentration monitoring module, a base station module and an exceeding early-warning module; the dust concentration monitoring module comprises multiple sets of acquisition units; the multiple sets of acquisition units are randomly deployed in a concrete plant dust monitoring area; each set of acquisition units comprise at least two close sensor nodes; furthermore, the sensor nodes are used for acquiring dust concentrationdata of a detected position; the base station module is respectively in communication connection with the various sensor nodes and the exceeding early-warning module, and used for collecting the dustconcentration data of the various sensor nodes, executing elimination when the dust concentration data difference acquired by each set of acquisition units is beyond the set error threshold value, andforwarding other dust concentration data to the exceeding early-warning module; and the exceeding early-warning module is used for analyzing and processing the dust concentration data sent by the base station module, and giving an alarm when the dust concentration data is beyond the set concentration threshold value.

Owner:四川衡鼎建材有限公司

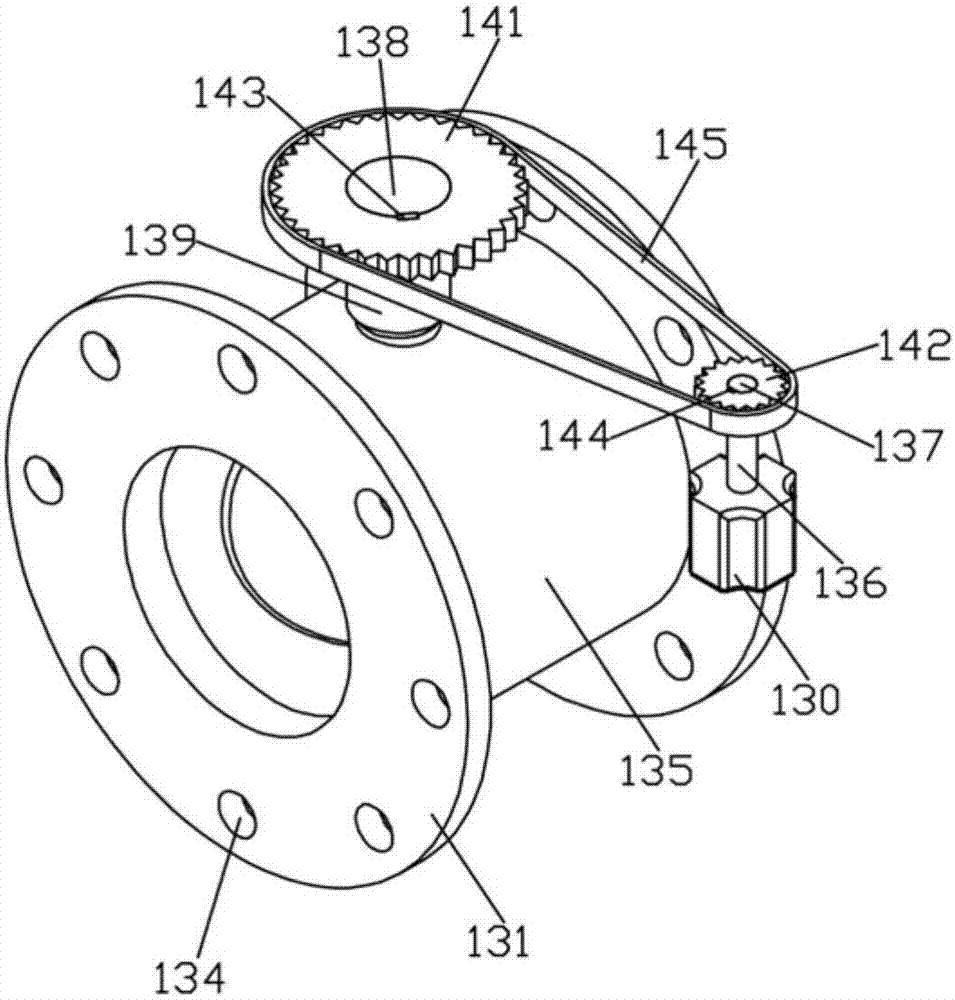

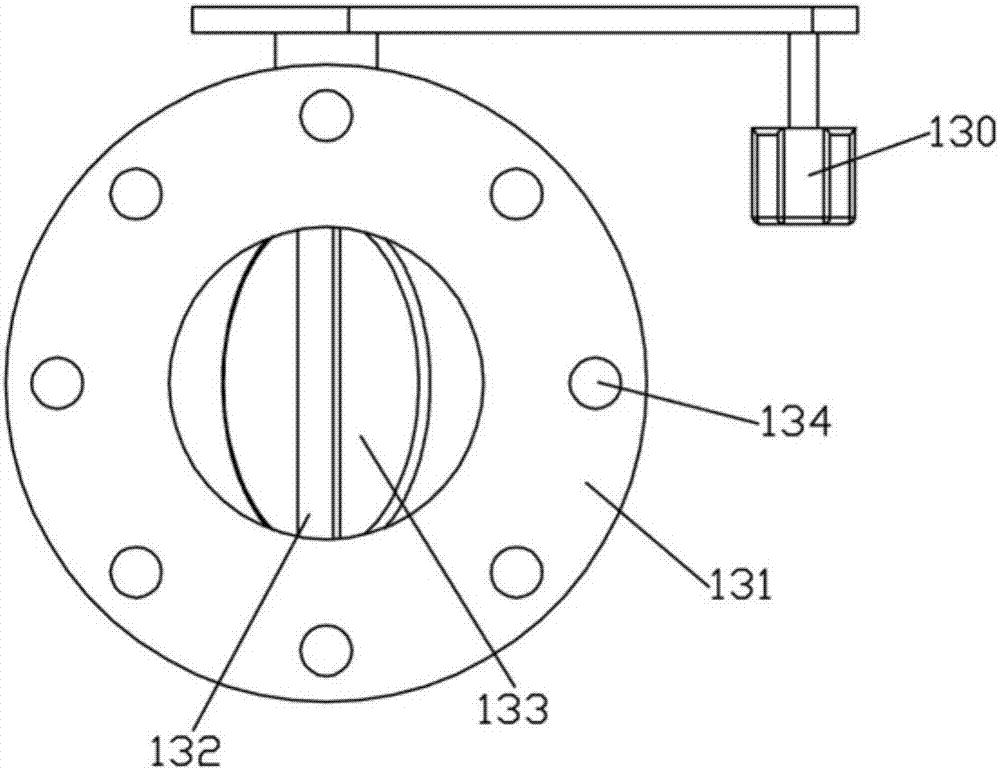

concrete mixing plant

ActiveCN103100542BAvoid pollutionAvoid mutual influenceDirt cleaningMixing operation plantEngineeringControl valves

The invention discloses a dust removal device and a concrete mixing station, and relates to the technical field of engineering machinery. The dust removal device solves the technical problem that a dust removing effect is poor in the prior art. The dust removal device comprises a dust removal machine, a dust removal pipeline and a dust return pipeline, wherein an airflow inlet and an airflow outlet are arranged on the dust removal pipeline, and a dust inlet and a dust outlet are arranged on the dust return pipeline. An exhaust opening on the side portion of the dust removal machine is communicated with the airflow outlet of the dust removal pipeline. A dust output opening at the bottom of the dust removal machine is communicated with the dust inlet of the dust return pipeline. A control valve which is used for controlling breakover between the dust output opening at the bottom of the dust removal machine and the dust inlet of the dust return pipeline is arranged between the dust output opening at the bottom of the dust removal machine and the dust inlet of the dust return pipeline. The concrete mixing station comprises the dust removal device. The dust removal device and the concrete mixing station are used for improving a dust removing effect of the dust removal device.

Owner:XUZHOU XCMG CONSTR MACHINERY CO LTD BUILDING MACHINERY

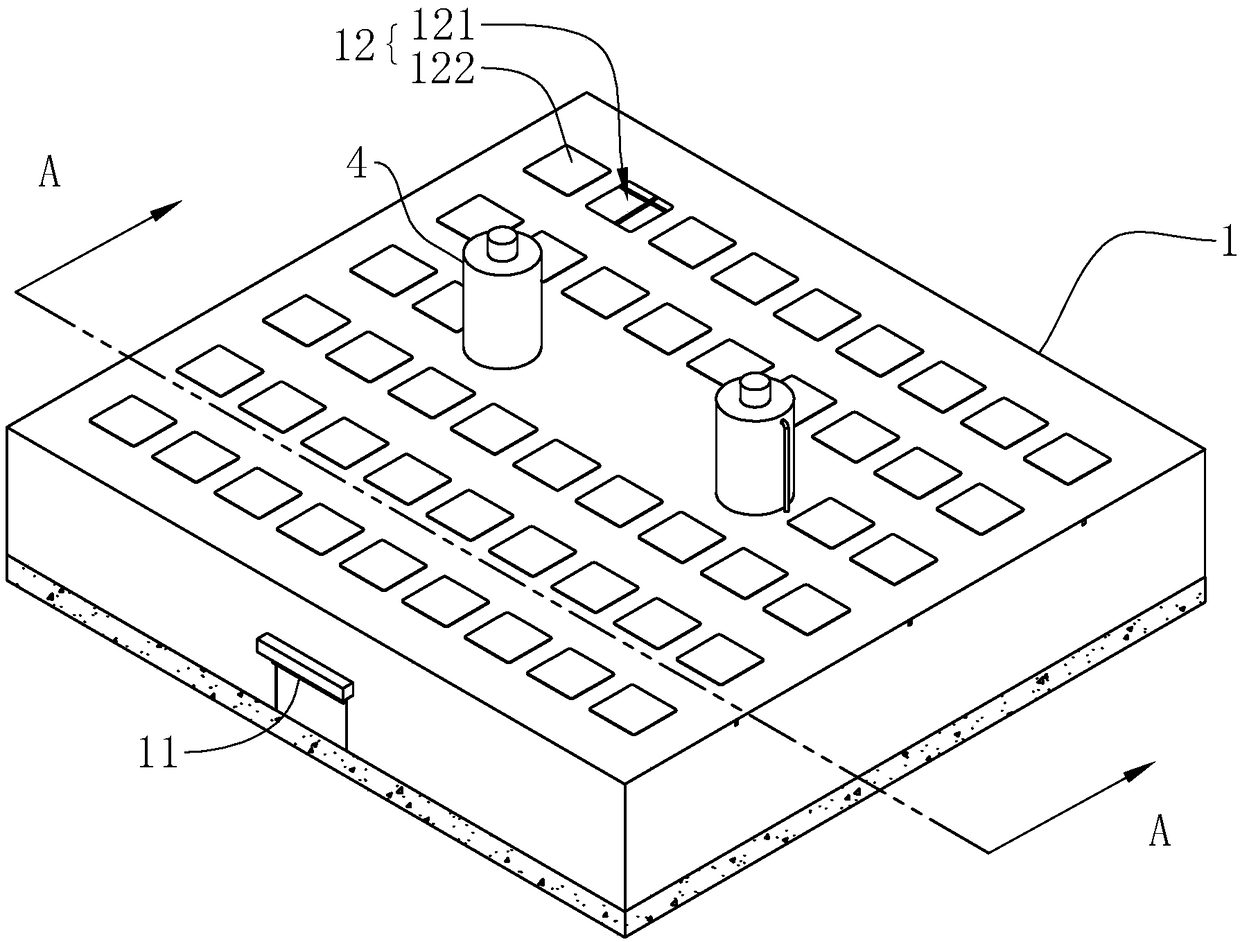

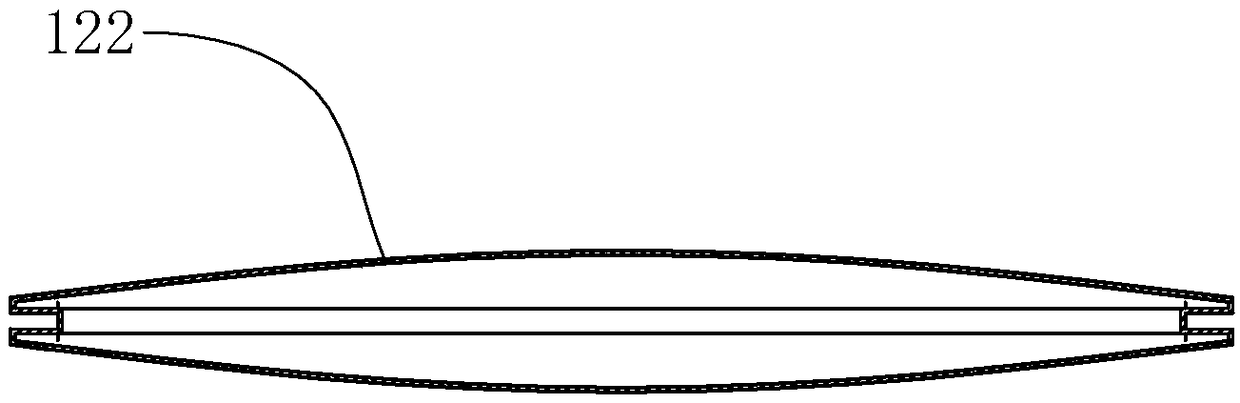

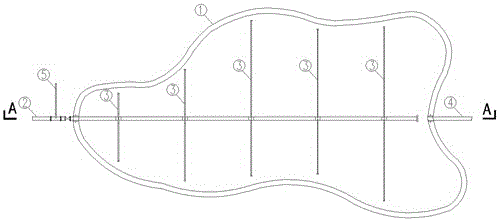

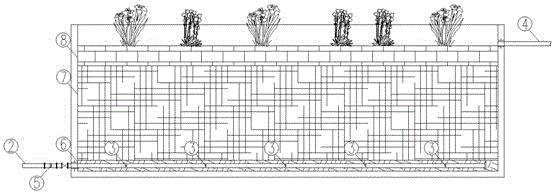

High-load constructed wetland rector based on light stuffing

InactiveCN105776553ALarge specific surface areaHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandPorosity

The invention discloses a high-load constructed wetland reactor based on light stuffing. The high-load constructed wetland reactor is used for deeply processing tail water of an urban sewage plant and is provided with a gravel stuffing layer, a light stuffing layer and a modularized wetland plant planting system from bottom to up; the light stuffing is of a net-fiber porous structure, large in specific surface area, high in porosity and good in biological affinity, can obviously improve the amount of microorganisms on a wetland stuffing carrier and can improve the removal efficiency of pollutant in sewage; the modularized wetland plant planting system uses the light stuffing as a supporting carrier for planting wetland plants, the light stuffing is compressed and then arranged in a hollow concrete plant planting module, and the light stuffing is high in porosity and better in ventilation and water permeability and can facilitate growth of plant roots; the system can be assembled and disassembled at will and brings convenience to maintenance, renovation and landscape design of a constructed wetland. The reactor has the advantages of being low in cost, low in requirement for a civil structure, short in starting time, high in processing load, small in occupancy, convenient to operate and maintain and good in landscape effect.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com