Spraying dust-settling system for concrete factory

A technology for concrete and factory areas, applied in the use of liquid separation agents, construction, construction materials, etc., can solve the problems of limited spraying range of spray heads, unstable road surface structure, increased water resource consumption, etc., achieve good dust reduction effect, improve Dust reduction effect and coverage improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

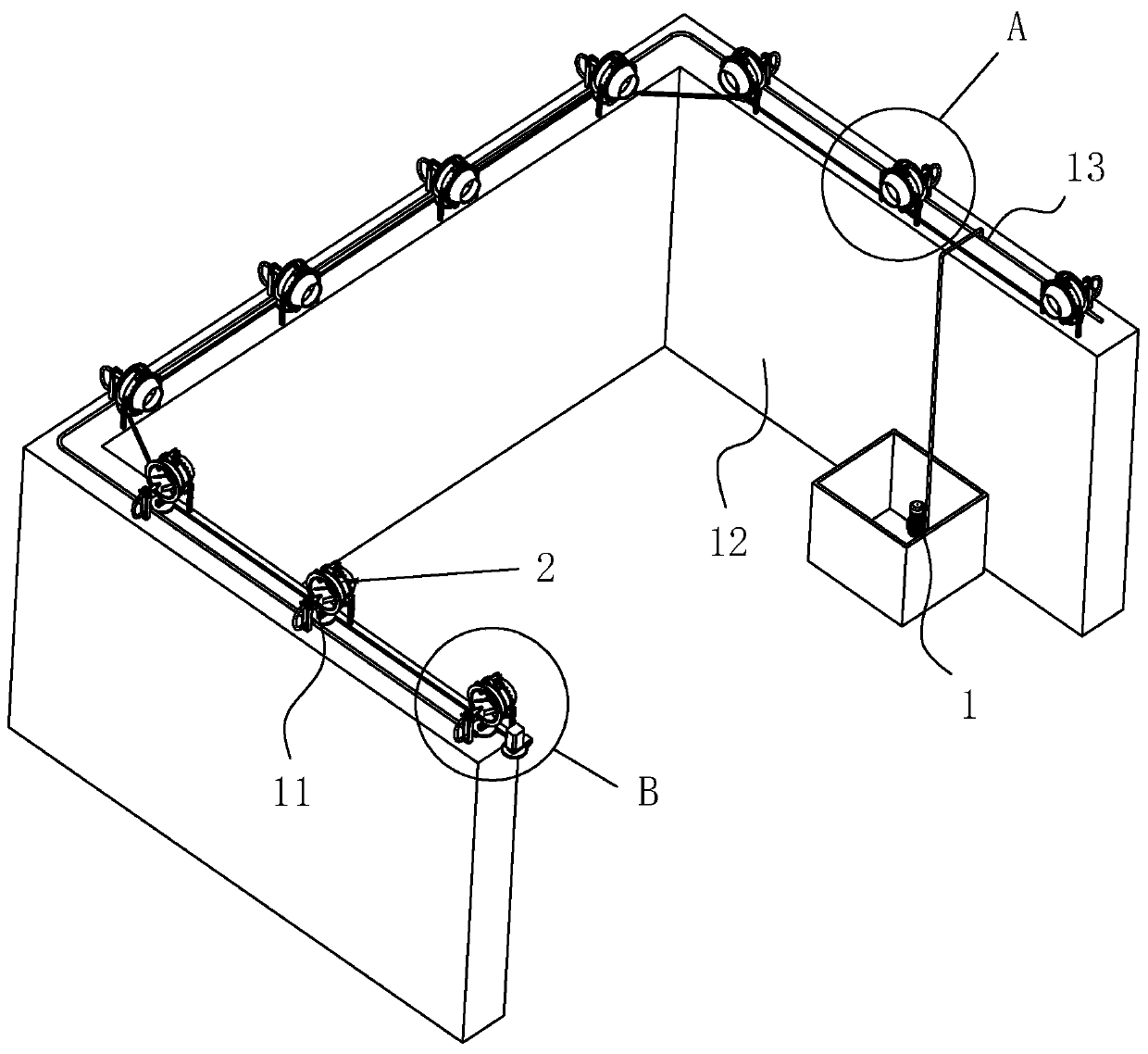

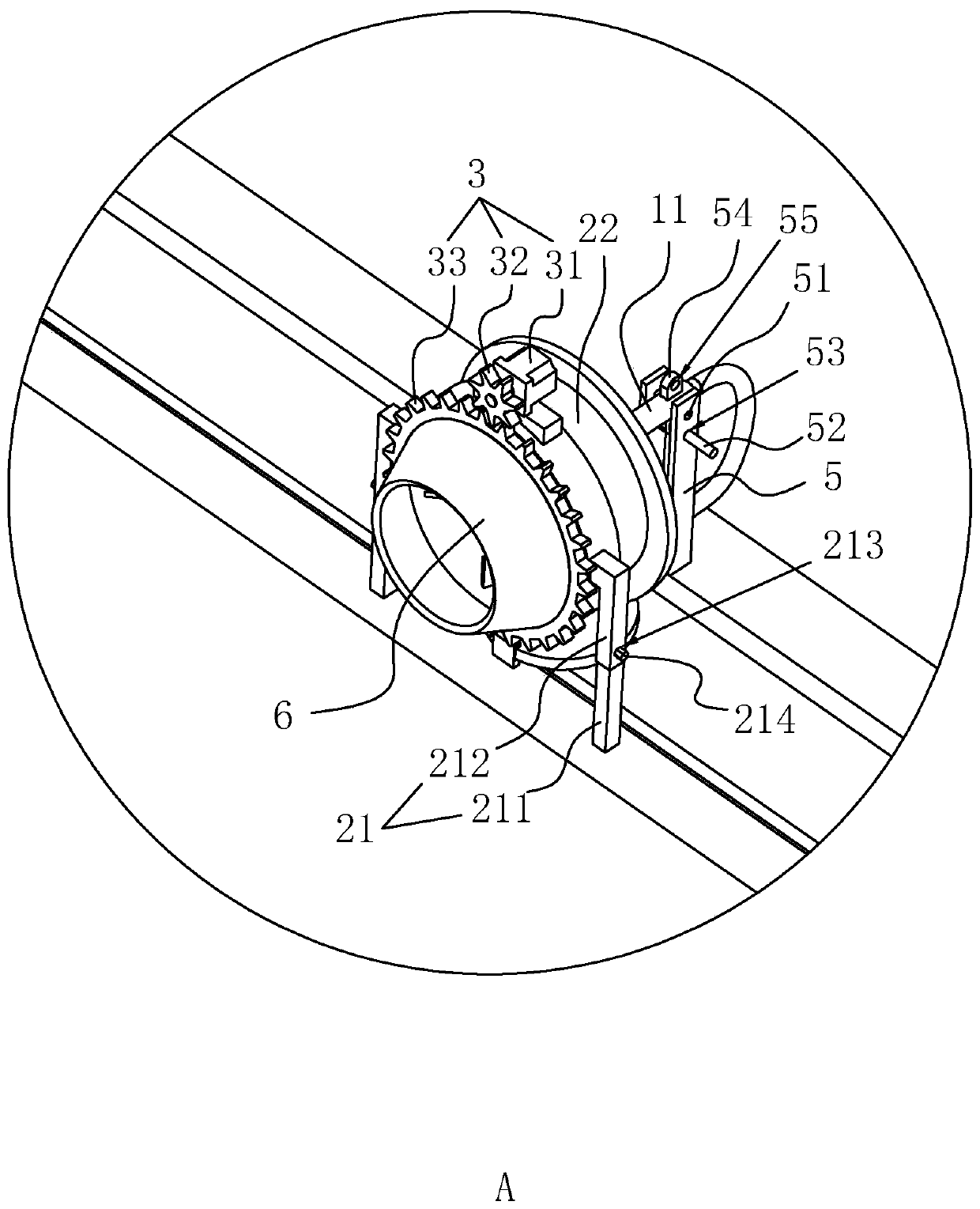

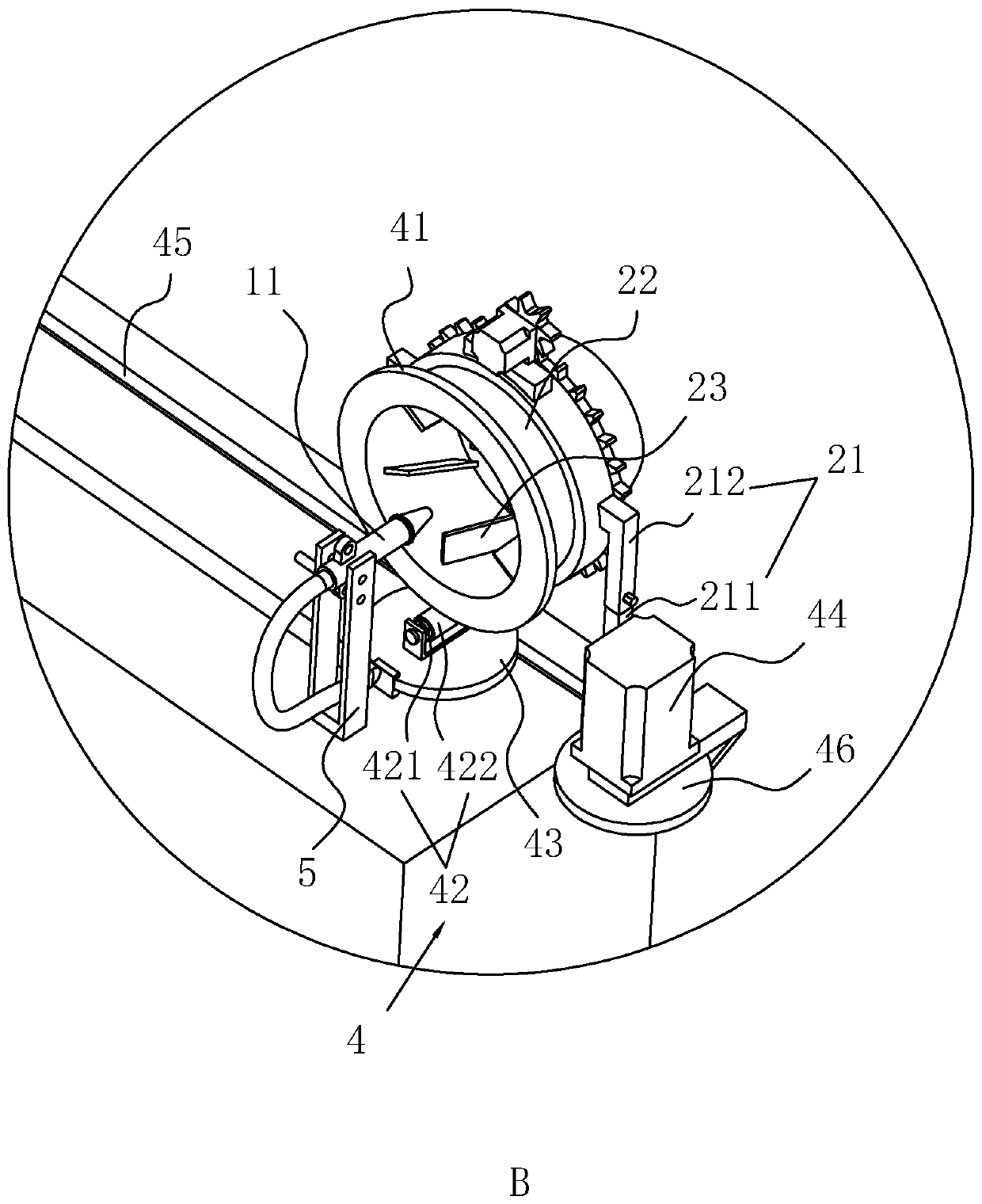

[0036] refer to figure 1 , which is a sprinkler and dust suppression system for a concrete plant area disclosed by the present invention, including a water pump 1 , an atomizing nozzle 11 and a fan 2 . The water pump 1 is fixedly installed on the inner side of the wronged area of the factory area, and the atomizing nozzle 11 is arranged on the top of the enclosure wall 12, and the enclosure wall 12 is fixedly installed with a water pipe 13, and one end of the water pipe 13 is externally connected to the tap water pipe 13. A water pump 1 is installed on the water pipe 13 , and the water inlet end of the water pump 1 is connected to the tap water pipe 13 . The water pipe 13 is provided with a plurality of branch pipes communicating with the water pipe 13, and the branch pipes are hoses, and the end of the hose away from the water pipe 13 communicates with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com