Concrete mixing plant

A mixing station and concrete technology, which is applied in mixing plants, clay preparation devices, mixing operation control, etc., can solve the problems that the surrounding environment of the concrete mixing station has a greater impact, improve the uniformity of water spraying, protect the surrounding environment, and prevent leakage rain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the figure 1 In the directions, the words "bottom" and "top", "inner" and "outer" refer to directions towards or away from the geometric center of a particular part, respectively.

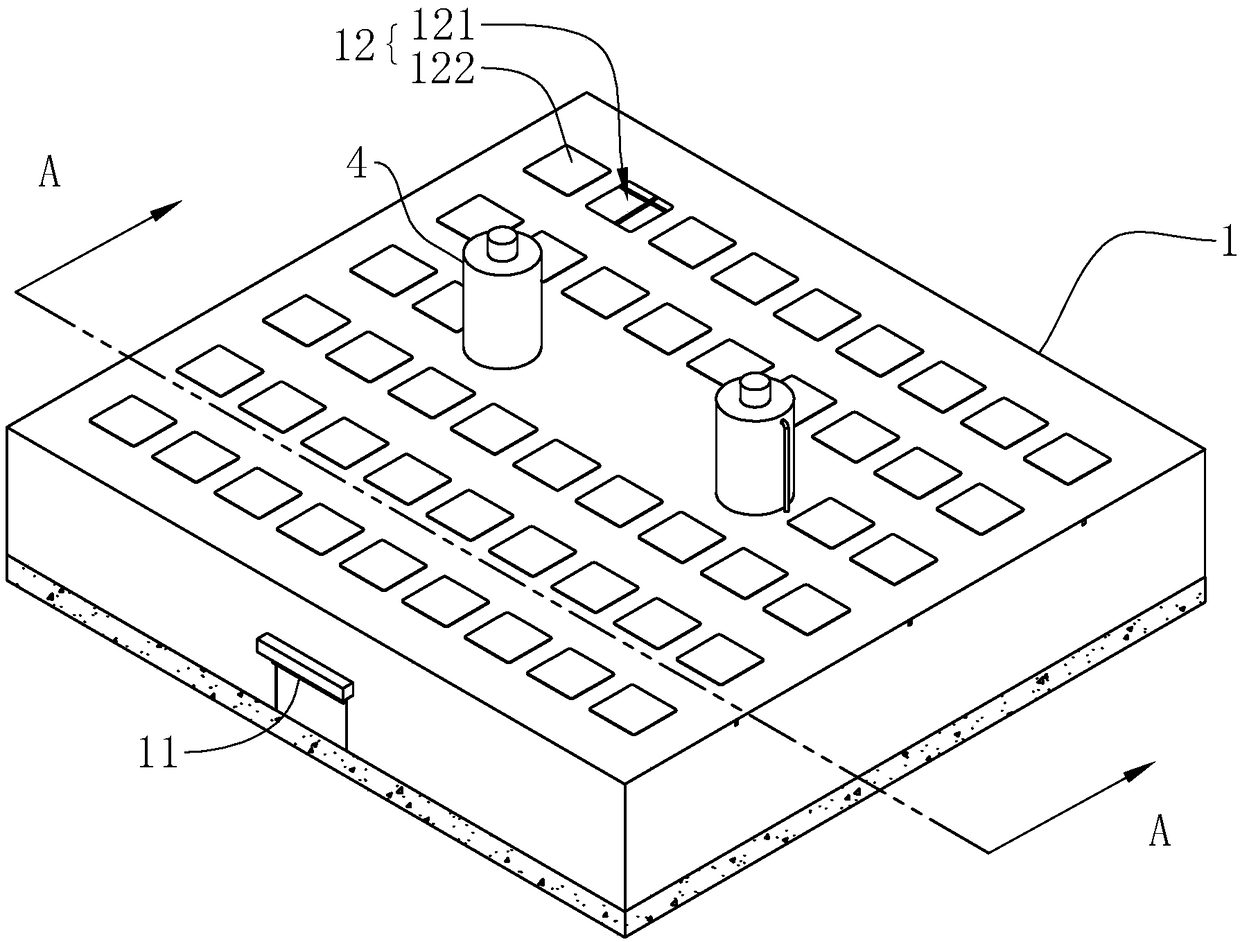

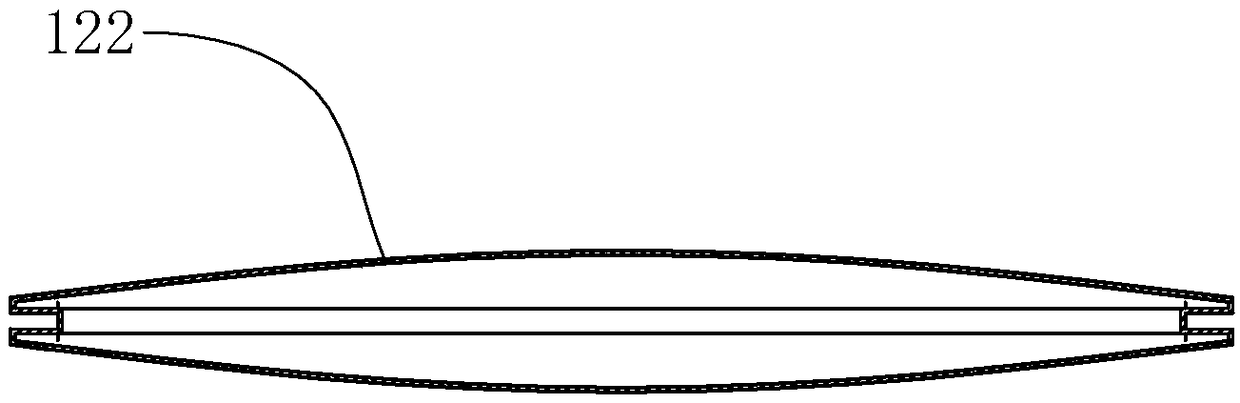

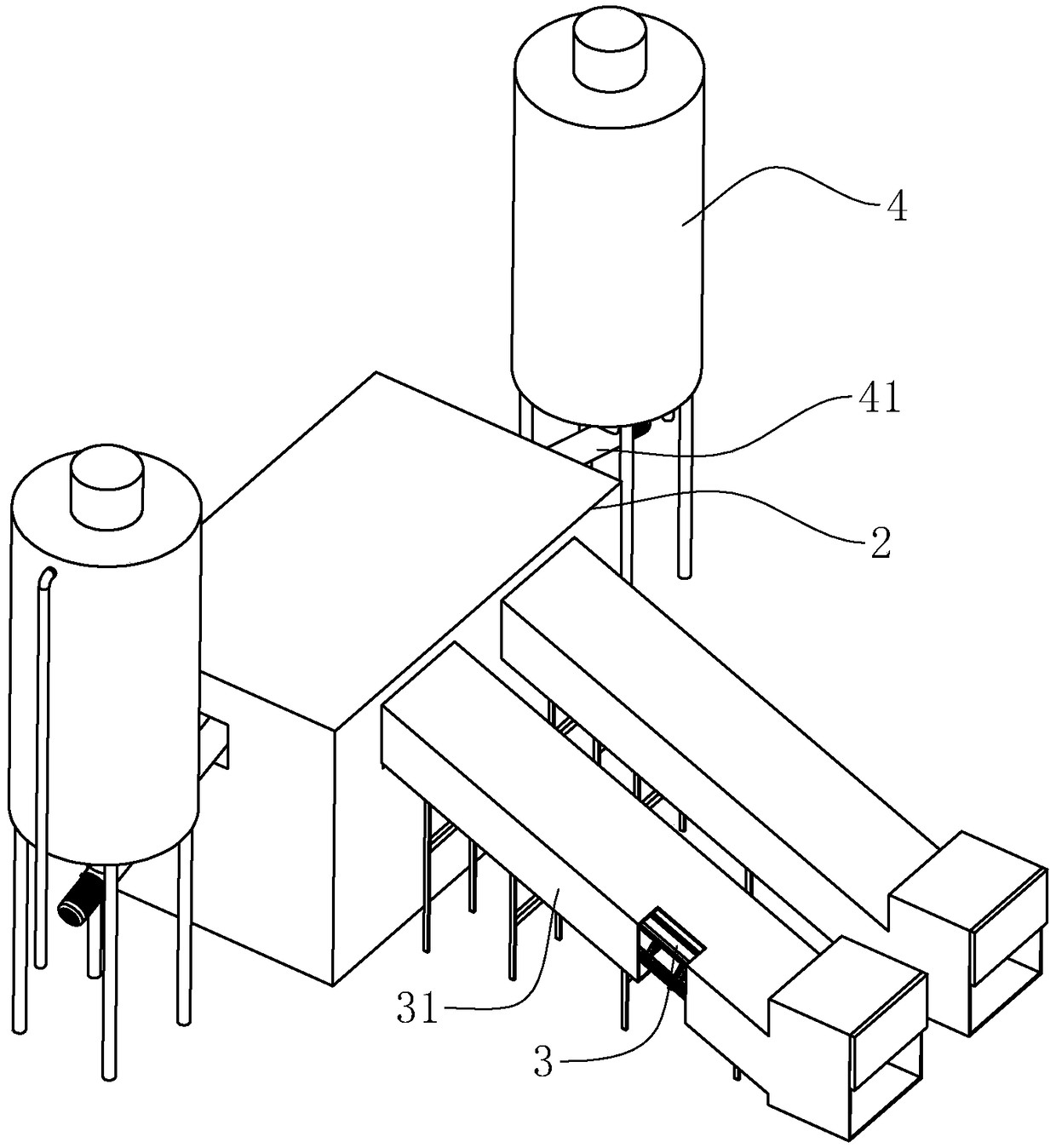

[0039] A concrete mixing station, reference figure 1 , including a mixing shed 1, the mixing shed 1 is built on the ground, and a rolling door 11 is arranged on one side of the mixing shed 1 for the entry and exit of staff and the entry of concrete mixer trucks. A light-transmitting window 12 is arranged on the top of the mixing shed 1, and the light-transmitting window 12 is used to irradiate external light into the mixing shed 1. The light-transmitting window 12 includes a light-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com