Concrete panel construction

a technology of concrete panels and construction, applied in the direction of building components, discharging arrangements, feeding arrangments, etc., can solve the problems of difficult monitoring of accurate formulas on the building site, system encountering a large number of potential problems, and difficulty in ensuring the quality of mortar materials, etc., to achieve the effect of simple and efficien

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

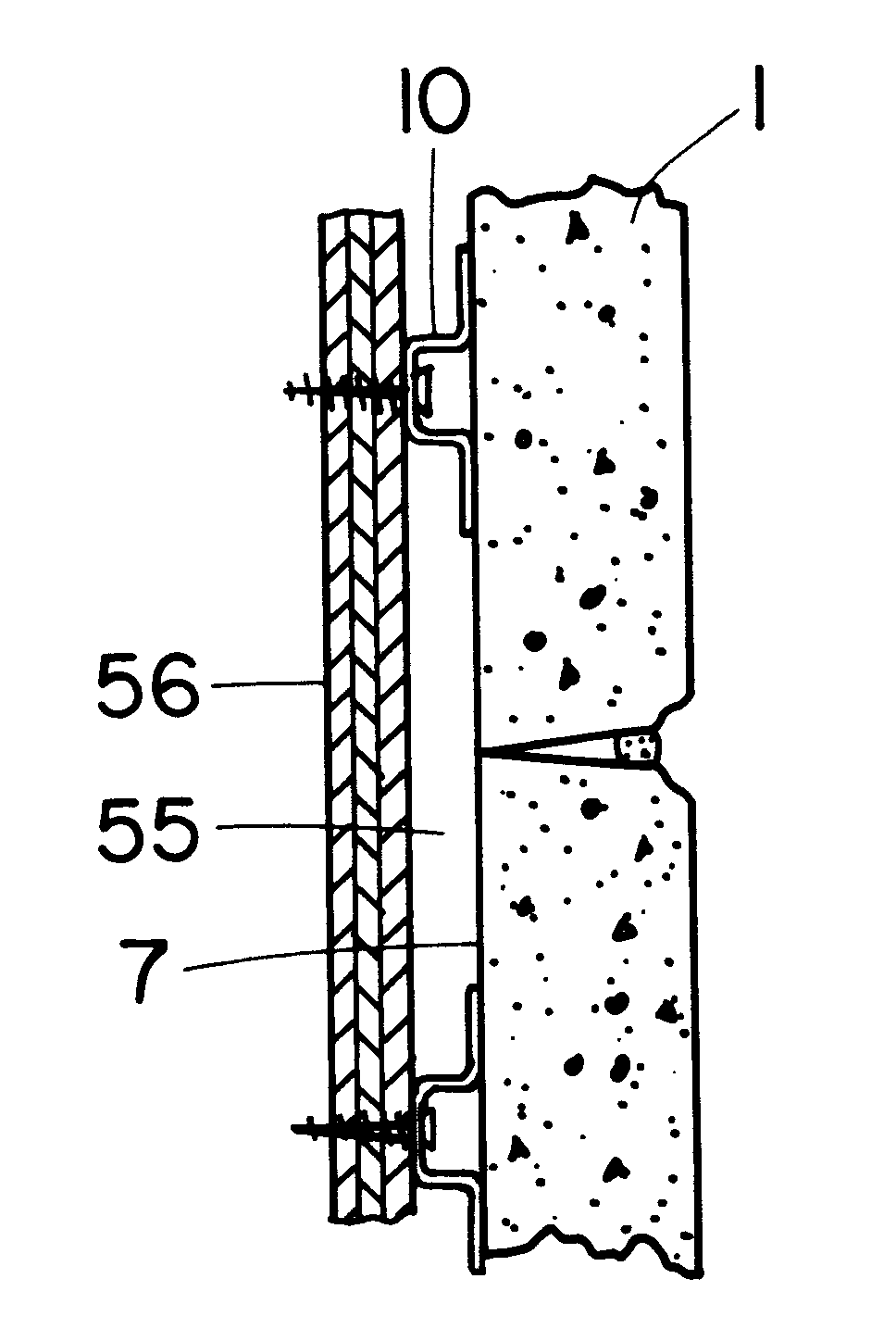

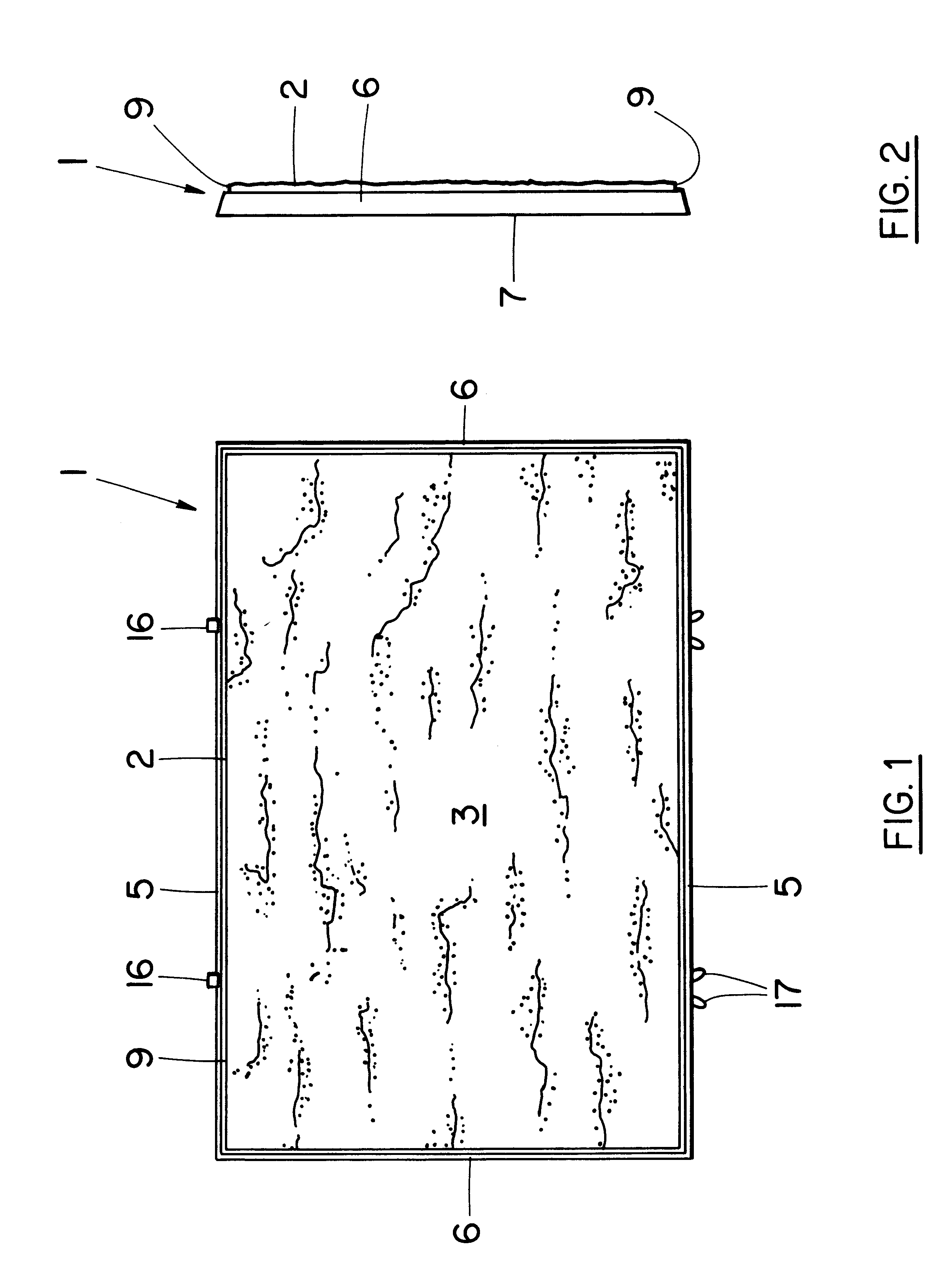

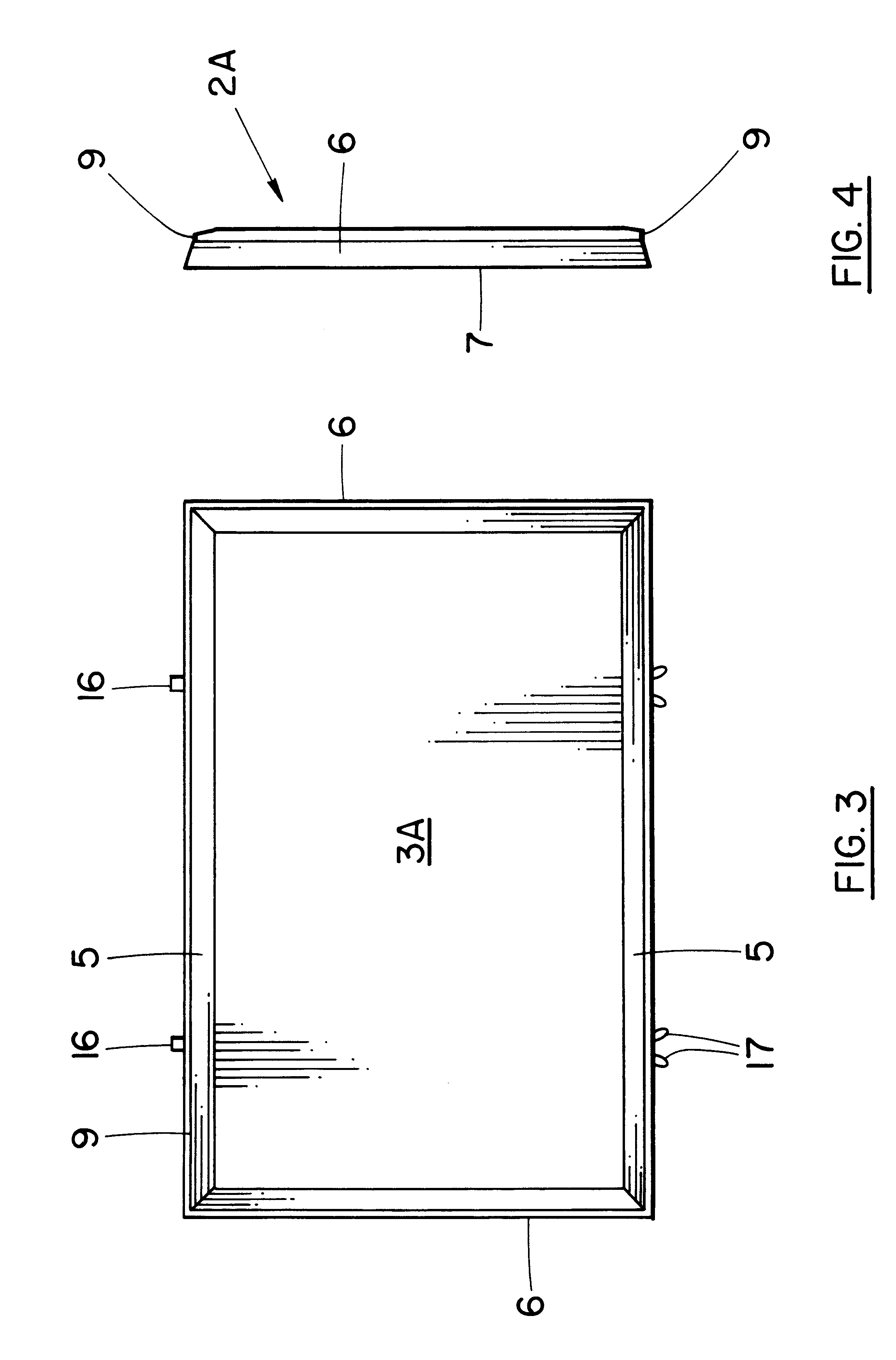

[0092]Referring to FIGS. 1 to 6, the method and apparatus of the present invention are designed to produce a concrete panel generally indicated at 1. The panel includes a thin rectangular body 2, typical dimensions of which are 12″×18″×⅝″, however, irregular shapes as shown in FIG. 5 may also be formed. The body 2 has a textured, beveled or irregular outer or front surface 3, sloping, tapered sides 5 and 6 and a rough, planar inner or rear surface 7. A groove 9 or caulking ledge extends around the side periphery of the panel 1. FIGS. 3 and 4 show a similar panel 1A to that of FIGS. 1 and 2 but with smooth face 3A &2A. A pair of hangers 10 are embedded in the rear surface 7 of the panel 1A. The hangers 10 (FIG. 6) are used to mount the panel 1 on plywood backing or other suitable backing shown in FIGS. 20 and 21 when finishing a wall. A flexible grout is provided between the panels to complete the exterior wall.

[0093]As shown in FIGS. 7 to 10, each hanger 10 includes an elongated, ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com