Fiber concrete construction enclosing wall structure

A technology of fiber-reinforced concrete and fiber-reinforced concrete columns, applied in the field of fiber-reinforced concrete construction wall structures, can solve problems such as pollution, affecting the work and life of on-site workers and surrounding residents, and loud noise of construction machinery, so as to beautify the environment of the industrial site and reduce the impact , the effect of reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

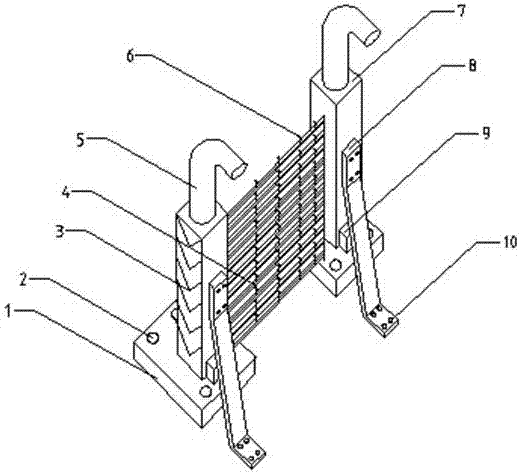

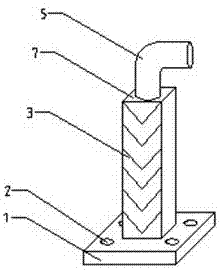

[0029] Such as Figures 1 to 3b As shown, a fiber concrete construction fence structure includes a fiber concrete base 1, a fiber concrete column 7, dust removal equipment, and a fiber concrete planting fence.

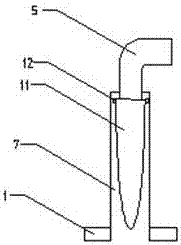

[0030] The fiber concrete column 7 is arranged on the fiber concrete base 1, and the fiber concrete column 7 is a hollow structure;

[0031] Described dedusting equipment comprises dedusting pipe 5, filter cloth bag 11, air extraction equipment 9; Dust removal pipe 5 lower ends extend in the described fiber concrete column 7 and fix described filter cloth bag 11; Air extraction equipment 9 seals are arranged on described fiber concrete on column 7;

[0032] The fiber concrete planting fence is set between adjacent fiber concrete columns 7, and the fiber concrete planting wall includes several fiber concrete V-shaped grooves 4 arranged from top to bottom, and each fiber concrete V-shaped groove 4 is filled with soil 13 and planted plant6.

[0033] A number of V-shape...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com