Bearable and monitorable shearing-resistant non-pulling-resistant piston type expansion joint device

An expansion joint and piston-type technology, which is applied in construction, bridge construction, bridges, etc., can solve the problems of difficult and impossible detection of super-long structures, and achieve the effects of delaying the aging process of rubber, improving stability, and avoiding direct sunlight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Next, the technical solutions in the embodiments of the present invention will be described in connection with the drawings of the embodiments of the present invention, and it is understood that the described embodiments are merely the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art are in the range of the present invention without making creative labor premise.

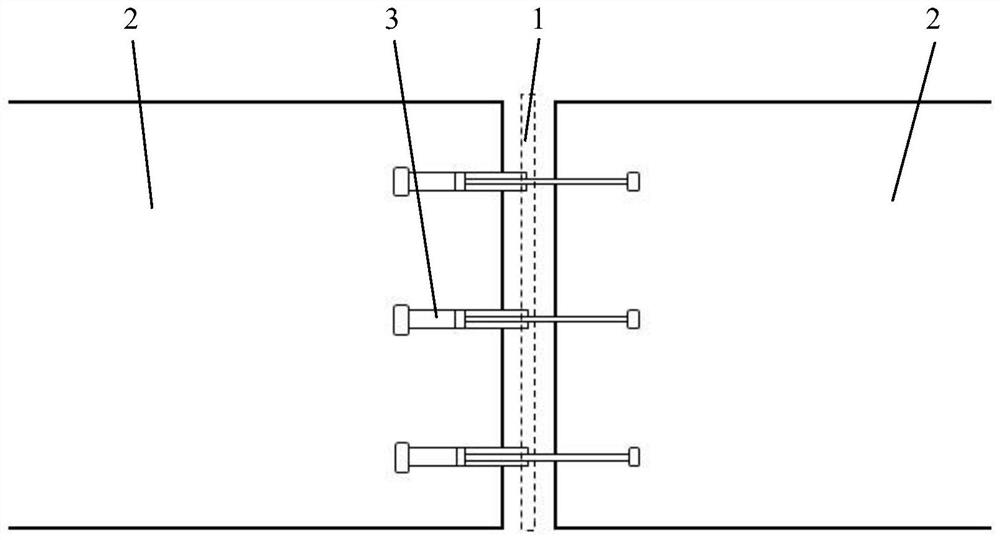

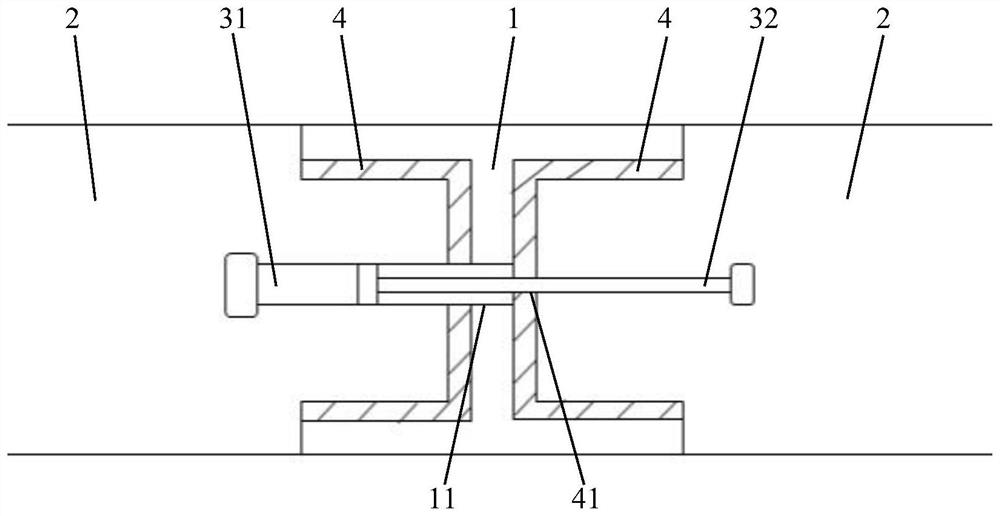

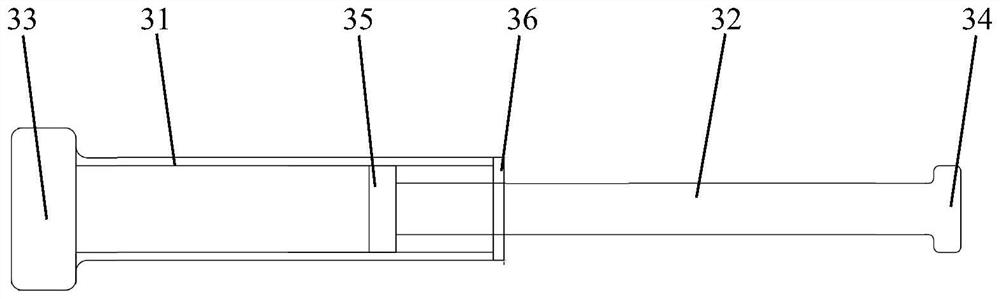

[0043] See figure 1 Attachment Figure 5 In the embodiment of the present invention, the present invention discloses a can carry monitorable shear disconnecting piston type telescopic seam device, including:

[0044] Written steel 1; two sides of the web 1 of the orthopedical steel 1 fixed rubber layer 4 inside the flange plate;

[0045] Connecting member 2; The connecting member 2 of the present embodiment is fixed to both sides of the web of the wire text steel 1 by a concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com