Locally reinforced hot-rolled zinc-aluminum plated steel plate and manufacturing method thereof

A local strengthening, galvanized aluminum technology, applied in chemical instruments and methods, pressure inorganic powder coating, layered products, etc., can solve the problem of increasing the complexity of the coating process and unable to realize the preparation of hot-rolled sheet zinc-aluminum alloy coatings and other problems, to avoid the formation of excessive brittle phases at the interface, improve the coordination deformation ability, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

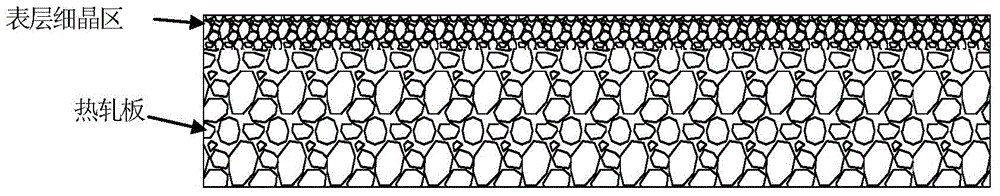

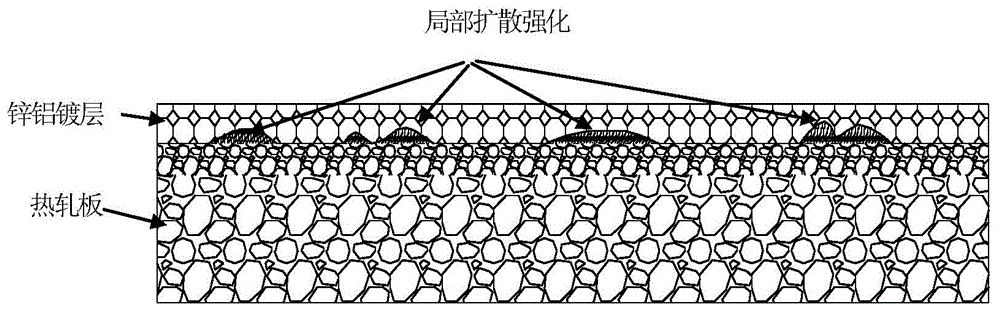

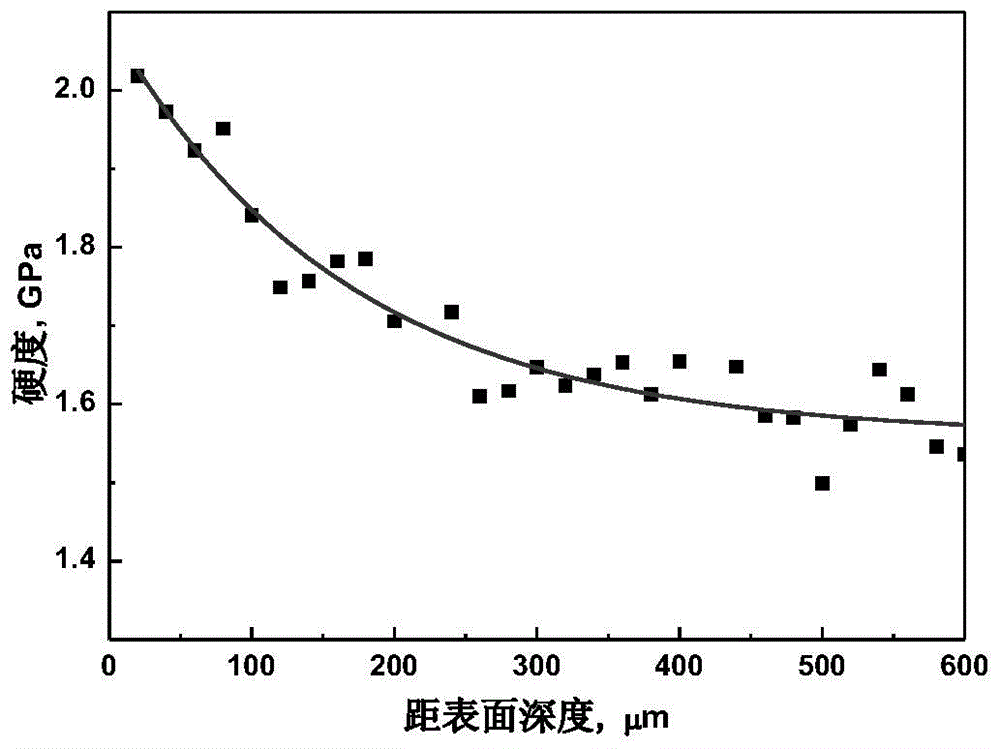

[0040] The substrate is hot-rolled IF steel with a thickness of 4mm. The substrate surface pretreatment adopts a gas-solid two-phase flow composed of compressed air and alumina balls to remove surface oxide scale by high-speed bombardment, and obtain a surface layer with a grain size of 30nm, a roughness of Ra1.2μm, a fine-grain layer thickness of 15μm, and a surface hardness of 2.1 GPa, the hardness of the core is 1.6GPa, the change trend of the hardness of the steel plate from the surface to the core is as follows image 3 As shown, the introduction of hardness difference on the surface improves the coordination between the deformation of the steel substrate and the coating. A 100μm zinc-aluminum alloy coating is deposited by cold spraying on the surface of the above-mentioned pretreated steel sheet. The cross-sectional appearance of the cold sprayed coating is as follows: Figure 4 As shown, the driving gas and carrier gas are industrial nitrogen, the pressure is 2.2MPa, the ...

Embodiment 2

[0042] The base plate is hot rolled Q235 steel with a thickness of 2mm. The substrate surface pretreatment adopts a gas-solid two-phase flow composed of compressed air and cast steel shots to remove surface oxide scale by high-speed bombardment, and obtain a surface layer with a grain size of 27nm, a roughness of Ra2.0μm, a fine grain layer thickness of 25μm, and a surface hardness of 2.5 GPa, heart hardness 1.8GPa. A 200μm zinc-aluminum alloy coating is deposited by cold spraying on the surface of the pretreated steel sheet. The driving gas and carrier gas are industrial nitrogen, the pressure is 2.5MPa, and the particle size range of the powder raw materials used is 15-50μm, the ratio is 52%, and the ratio is 50-80μm. 28%, the remaining particles are 80-100μm, and the powder feeding rate is 290g / min. Heat treatment of the above-mentioned galvanized aluminum Q235 steel plate, the environment is hydrogen reduction atmosphere, the heat treatment temperature is 450℃, the holding...

Embodiment 3

[0044] The base plate is hot rolled Q345 steel with a thickness of 10mm. The substrate surface pretreatment adopts a gas-solid two-phase flow composed of compressed air and stainless steel wire cut pellets, and high-speed bombardment to remove the surface oxide scale. The surface grain size is 0.95μm, the roughness is Ra1.8μm, and the fine grain layer thickness is 50μm. The hardness is 2.8GPa, and the core hardness is 2.0GPa. A 50μm zinc-aluminum alloy coating is deposited by cold spraying on the surface of the above pretreated steel sheet, the driving gas and carrier gas are industrial nitrogen, the pressure is 0.8MPa, and the particle size range of the powder raw materials used is 15-50μm, the ratio is 63%, and the ratio is 50-80μm. 24%, the remaining particles are 80-100μm, and the powder feeding rate is 55g / min. The above-mentioned galvanized aluminum Q345 steel plate is heat treated, the environment is hydrogen reduction atmosphere, the heat treatment temperature is 390℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com