A cement concrete pavement health monitoring sensor fixing device

A technology for cement concrete and health monitoring, applied in roads, road repairs, roads, etc., can solve the problems of cumbersome operation, time-consuming, general versatility, reliability and stability, etc., to simplify the size and form of the device, and improve coordination and deformation Ability, the effect of solving the problem of cable redundancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

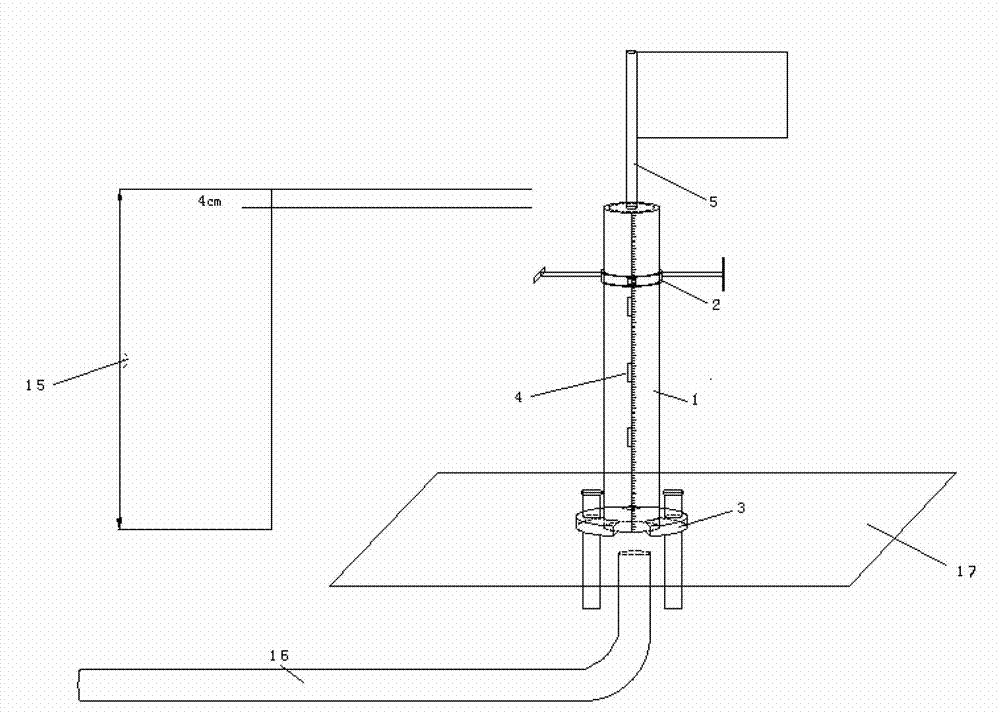

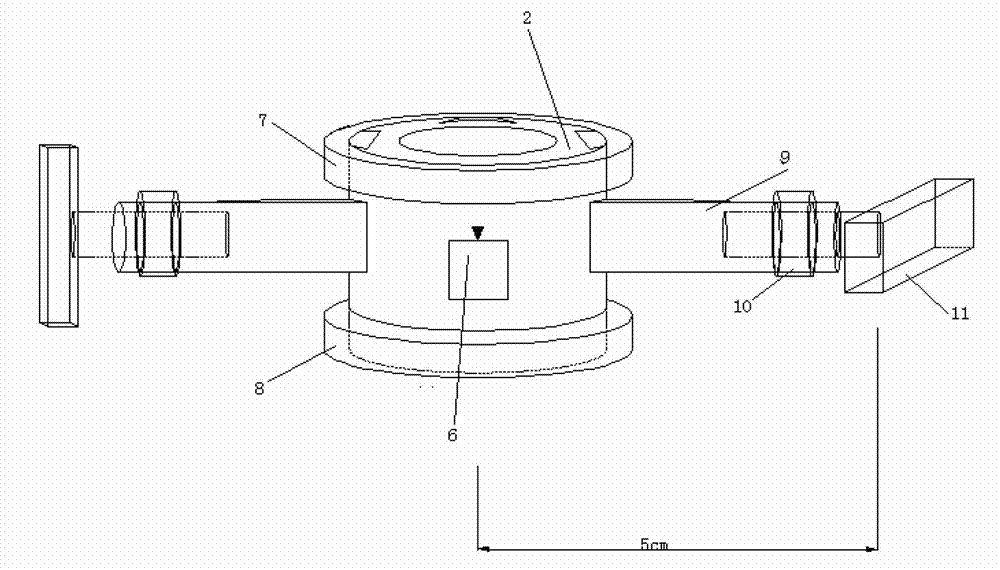

[0093] Example 1 (precise and deep laying of thick road surface at the airport):

[0094] Such as Image 6 As shown, a new main runway health monitoring project in an airport, the monitoring items include: the horizontal strain of the top and bottom of the board at the designated point, the temperature gradient in the middle and corner of the board, the sensors are all electrical signal equipment, and the cables are 4-core armored. The diameter is 5mm, and the gauge length of the sensor is 4-6cm. The sensor layout plan takes concrete slabs as units, and is evenly distributed in the direction parallel and perpendicular to the main runway. The slab is the comprehensive information capture position. The project requires installation and construction: 1. As an airport pavement project, the pavement structure must be guaranteed to the greatest extent Safety; 2. The sensor cable must be connected through the internal pipeline of the base layer, and the cable cannot be left in the w...

Embodiment 2

[0096] Example 2 (large-span, distributed, rapid laying of expressways):

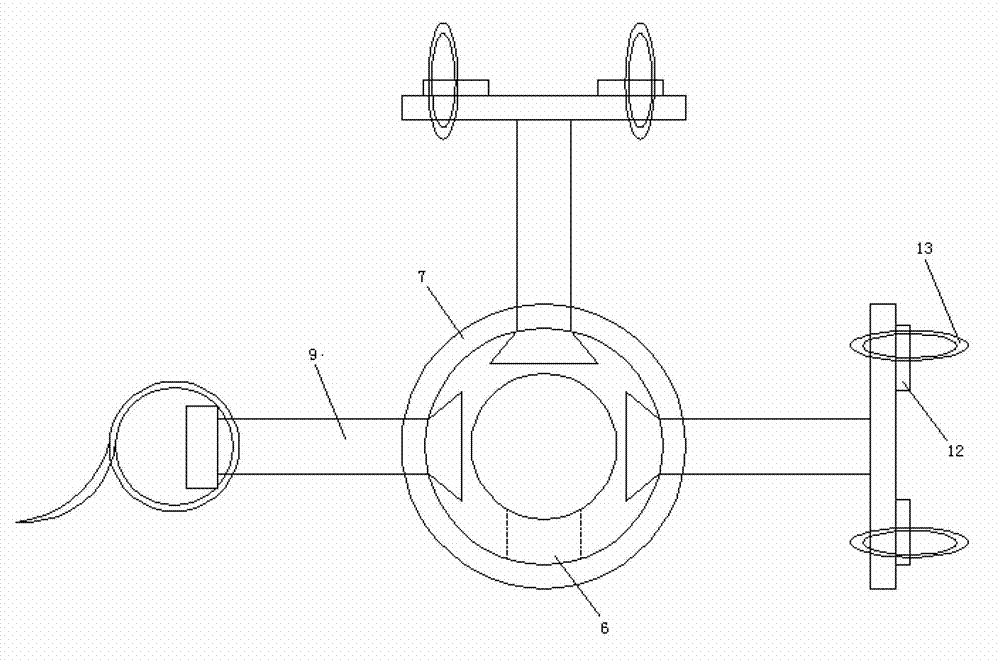

[0097] A high-grade highway health monitoring project, the project goal is to evaluate the service life of the pavement under heavy traffic, the monitoring objects include: the horizontal strain of the top and bottom of the slab, and the vertical strain of the concrete slab. The sensor adopts fiber grating technology, and the gauge length is 3-5cm. Project requirements: 1. In order to capture the driving speed information, the strain gauges must be arranged in a distributed manner, such as Figure 7 as shown; 2, such as Figure 8 As shown, in order to capture the wheel track information, the spacing of the vertical strain gauges is 10cm perpendicular to the driving direction. 3. In order to ensure the construction period, it is required that the sensor installation project cannot affect the pavement pouring process, that is, the concrete construction and the sensor embedding are carried out simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com