High-reaming high-plasticity 980MPa-grade dual-phase galvanized steel plate and preparation method thereof

A galvanized steel, 980mpa technology, applied in the field of metal materials, can solve problems affecting resistance spot welding performance, poor hole expansion performance, insufficient hole expansion rate, etc., achieve a breakthrough in incompatibility between hole expansion and drawing performance, and improve coordinated deformation Ability to optimize the effect of alloy design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

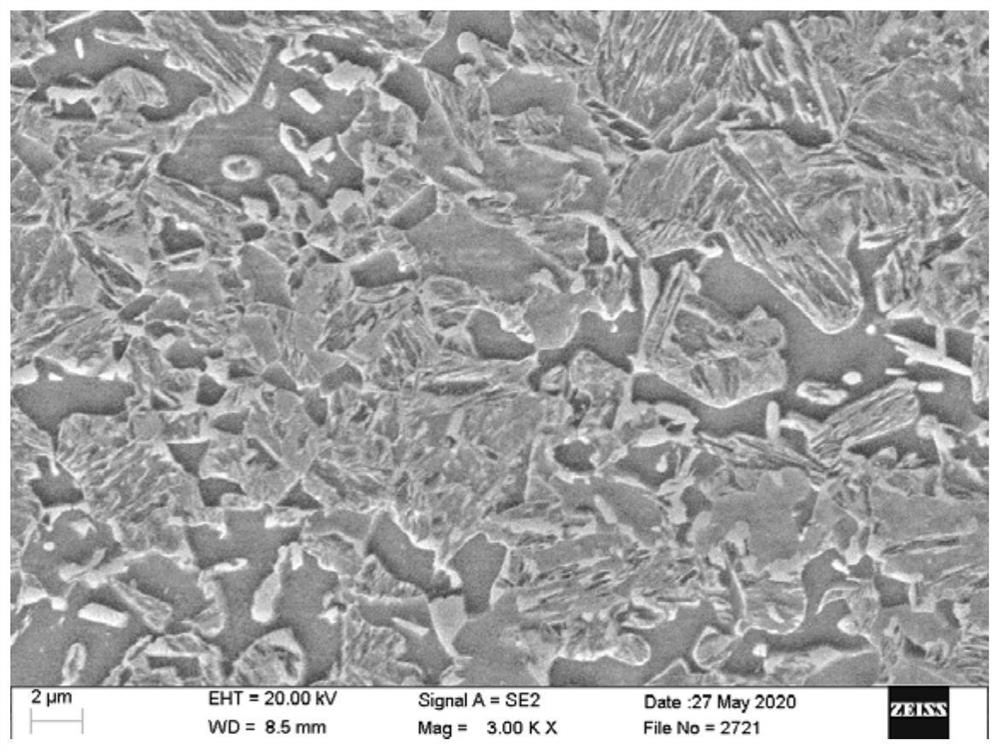

Embodiment Construction

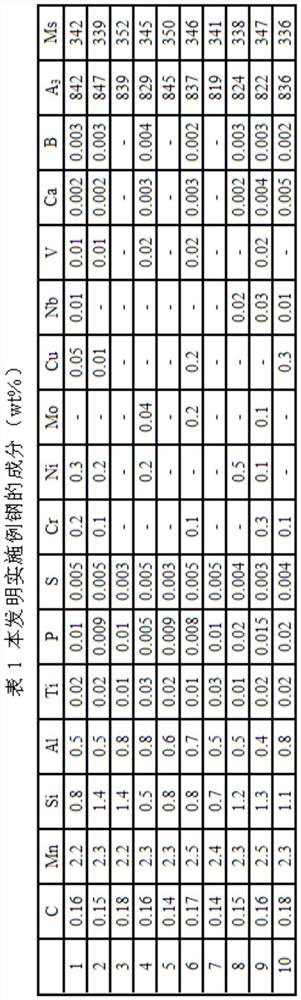

[0050] Below by embodiment the present invention will be further described.

[0051] In the embodiment of the present invention, according to the composition ratio of the technical solution, smelting, casting, hot rolling, pickling, cold rolling, continuous annealing galvanizing, and skin pass are carried out.

[0052] (1) Hot rolling: the heating temperature is 1230-1280°C, the starting rolling temperature is 1100-1150°C, the final rolling temperature is above 900°C, and the coiling temperature is 550-620°C;

[0053] (2) Cold rolling: the cold rolling reduction rate is 50% to 58%;

[0054] (3) continuous annealing galvanizing:

[0055] ①The atmosphere in the furnace is 5%~15%H 2 , and the rest are N 2 , the dew point temperature is controlled between -20~-10℃; the heating isothermal temperature A 3 ±20℃, the isothermal time is 50~100s, among them, A 3 It is the austenitizing temperature; after that, it is slowly cooled to 650-700°C, and the cooling rate is controlled at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com