Preparation method capable of improving coordinated rheological capacity of fine grain layer and coarse grain layer of gradient structure copper alloy

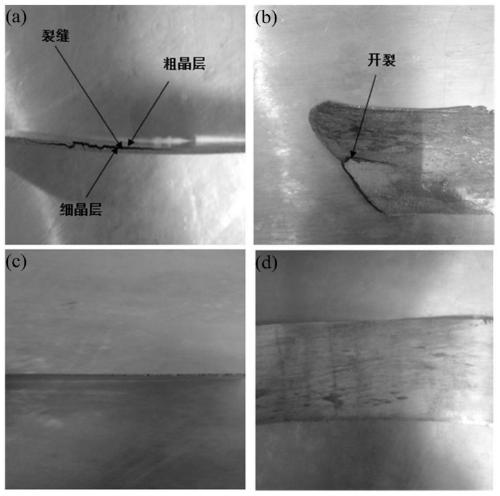

A gradient structure and copper alloy technology, which is applied in the field of metal material processing, can solve the problems of fracture of the middle fine-grained layer and coarse-grained layer, and achieve the effect of improving the coordinated deformation ability, good processing and forming performance, and promoting application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

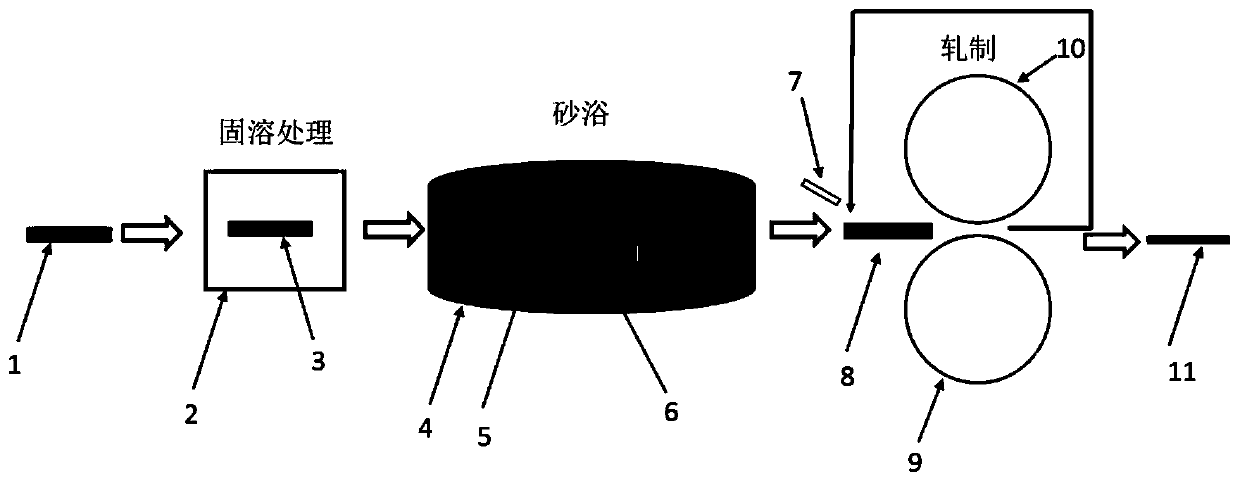

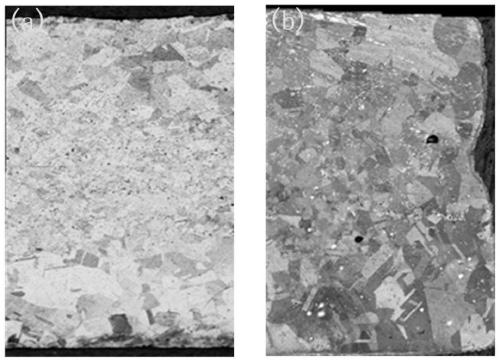

[0021] The invention utilizes the characteristics of a gradient structure copper alloy to perform more rapid and uniform cooling in an environment surrounded by fine sand at -80°C to -105°C, so that the relative shear stress between the coarse and fine grain layers and the inside of the fine grain layer are different Reduced, the fracture stress is distributed more harmoniously between the coarse and fine-grained layers and the fine-grained layers, thereby improving the coordinated deformation ability of the material. figure 1 Shown is the flow chart of the coordination of the large deformation of the coarse and fine grain layers of a high-performance gradient structure copper alloy. figure 1 , The process is as follows:

[0022] The first step: the cast-rolled gradient structure copper alloy sheet 1 is subjected to solution treatment in the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com