Machining process of thick 5083 aluminum alloy plate for ships

A processing technology and aluminum alloy technology, which is applied in the processing technology field of marine 5083 aluminum alloy plates, can solve the problems of not being able to improve the corrosion resistance of aluminum alloy plates, and fail to meet the production approval requirements of ABS marine aluminum alloy plates. The effect of mechanical properties and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

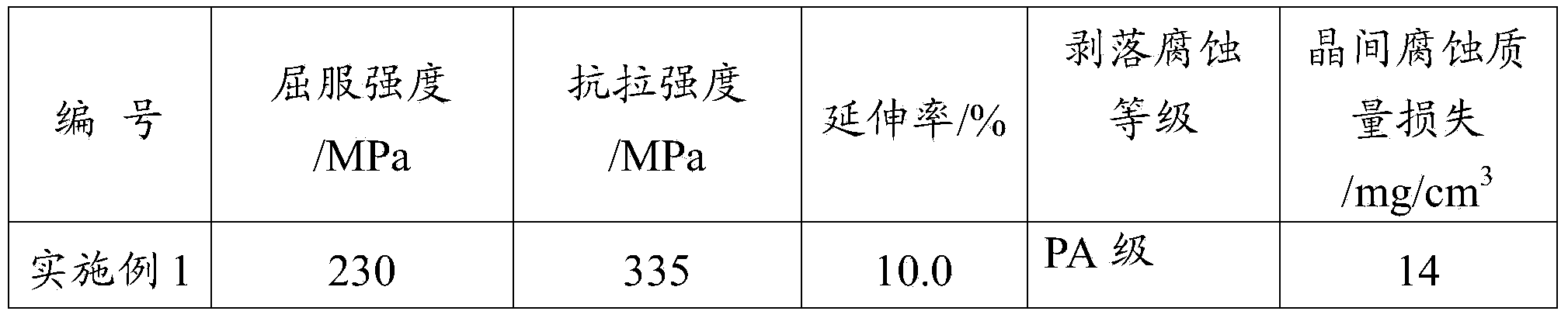

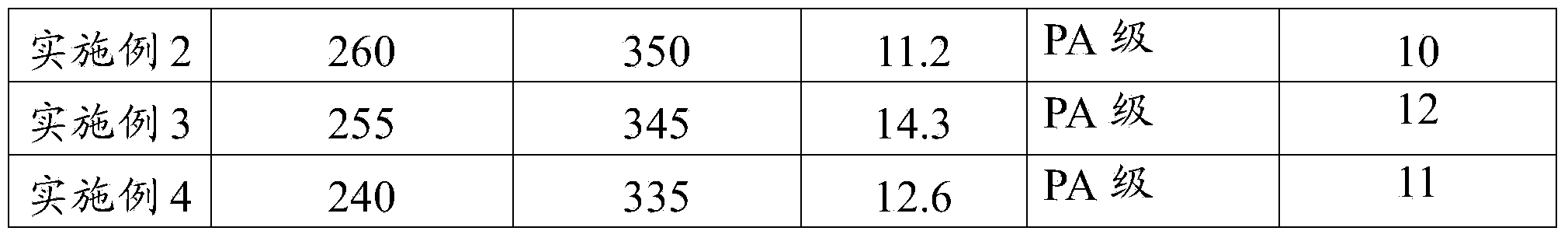

[0034] Milling a 500mm 5083 aluminum alloy plate, heating the milled aluminum alloy plate at 450 degrees Celsius, and performing the first rolling on the heated plate, wherein the rolling temperature is 460 degrees Celsius, After rolling, the plate reaches 150mm, and the plate is cooled, wherein, after the cooling temperature reaches 300°C, the plate is subjected to the second rolling, and after the second rolling, the thickness of the plate is 50mm , the temperature of the plate is 250°C. Cut the plate after the above rolling process with 120mm scissors. After cutting, the plate is stretched, straightened and sawed to length. After acceptance and packaging, the 5083 aluminum alloy thick plate can be obtained.

[0035] The performance of the aluminum alloy thick plate in the H321 state is measured, wherein the corrosion resistance is tested for exfoliation corrosion sensitivity according to ASTM G66 or equivalent standards. Take a sample in the middle of the width of the two ...

Embodiment 2

[0037] Milling a 500mm 5083 aluminum alloy plate, heating the milled aluminum alloy plate at 450 degrees Celsius, and performing the first rolling on the heated plate, wherein the rolling temperature is 470 degrees Celsius, After rolling, the plate reaches 100mm, and the plate is cooled, wherein, after the cooling temperature reaches 300°C, the plate is subjected to the second rolling, and after the second rolling, the thickness of the plate is 35mm , the temperature of the plate is 200°C. Cut the plate after the above rolling process with 120mm scissors. After cutting, the plate is stretched, straightened and sawed to length. After acceptance and packaging, the 5083 aluminum alloy thick plate can be obtained.

[0038] The performance of the aluminum alloy thick plate in the H321 state is measured, wherein the corrosion resistance is tested for exfoliation corrosion sensitivity according to ASTM G66 or equivalent standards. Take a sample in the middle of the width of the two ...

Embodiment 3

[0040] Milling a 500mm 5083 aluminum alloy plate, heating the milled aluminum alloy plate at 450 degrees Celsius, and performing the first rolling on the heated plate, wherein the rolling temperature is 480 degrees Celsius, After rolling, the plate reaches 120mm, and the plate is cooled, wherein, after the cooling temperature reaches 300°C, the plate is subjected to the second rolling, and after the second rolling, the thickness of the plate is 40mm , the temperature of the plate is 220°C. Cut the plate after the above rolling process with 100mm scissors. After cutting, the plate is stretched, straightened and sawed to length. After acceptance and packaging, the 5083 aluminum alloy thick plate can be obtained.

[0041] The performance of the aluminum alloy thick plate in the H321 state is measured, wherein the corrosion resistance is tested for exfoliation corrosion sensitivity according to ASTM G66 or equivalent standards. Take a sample in the middle of the width of the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com