Zn-contained high-strength aluminum-based lightweight medium-entropy alloy and preparation method thereof

An aluminum alloy and high-strength technology, which is applied in the field of high-strength aluminum-based light-weight medium-entropy alloys and their preparation, can solve problems such as difficulty in increasing strength, low alloy strength, and strength-limited development of aluminum alloy materials, and achieve machinability Improvement, improvement of mechanical properties, and the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a Zn-containing high-strength aluminum-based lightweight medium-entropy alloy, comprising the steps of:

[0030] Pre-treatment steps: use sandpaper to grind the 5083 aluminum alloy and Zn raw materials, and then use an electronic balance to weigh according to the formula amount, and make a ratio. The error of the ratio of each component is within the range of ±0.2%;

[0031] The step of placing the graphite crucible: placing the prepared aluminum alloy and Zn in the graphite crucible;

[0032] The steps of vacuum ventilation treatment: put the graphite crucible into the induction coil, and the induction coil is electrically connected with the high-frequency induction device; vacuumize with a mechanical pump, and then introduce argon;

[0033] Steps of high-frequency melting: turn on the power of the high-frequency induction device, and after the alloy ingot is completely melted, keep it warm for 12-18 minutes to make the alloy elements diffuse ev...

Embodiment 1

[0048] The molecular formula of the high-strength aluminum-based light-weight medium-entropy alloy in this example is 5083 aluminum alloy-xZn, where x=2%, and its preparation steps are as follows: 100 g of raw material Zn with a purity greater than 99.9% and 5083 aluminum alloy are prepared in proportion. Put the prepared raw materials into the graphite crucible in order of melting point from high to low, put the graphite crucible filled with the alloy material into the induction coil, evacuate to below 20Pa, and then fill with argon to 0.3MPa. Start the high-frequency induction device, and when the alloy ingot melts, keep it warm for 15 minutes to make the alloy composition uniform. Cast the uniformly smelted alloy liquid into a steel mold with a diameter of 30 mm. Homogenizing annealing, hot rolling, and solution and aging treatment are carried out on the ingot, wherein the annealing temperature is 460°C for 15 hours; the cumulative rolling reduction in the hot rolling is 80...

Embodiment 2

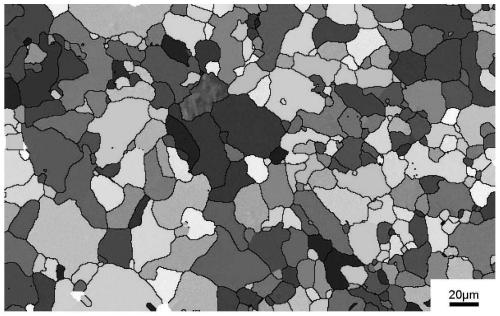

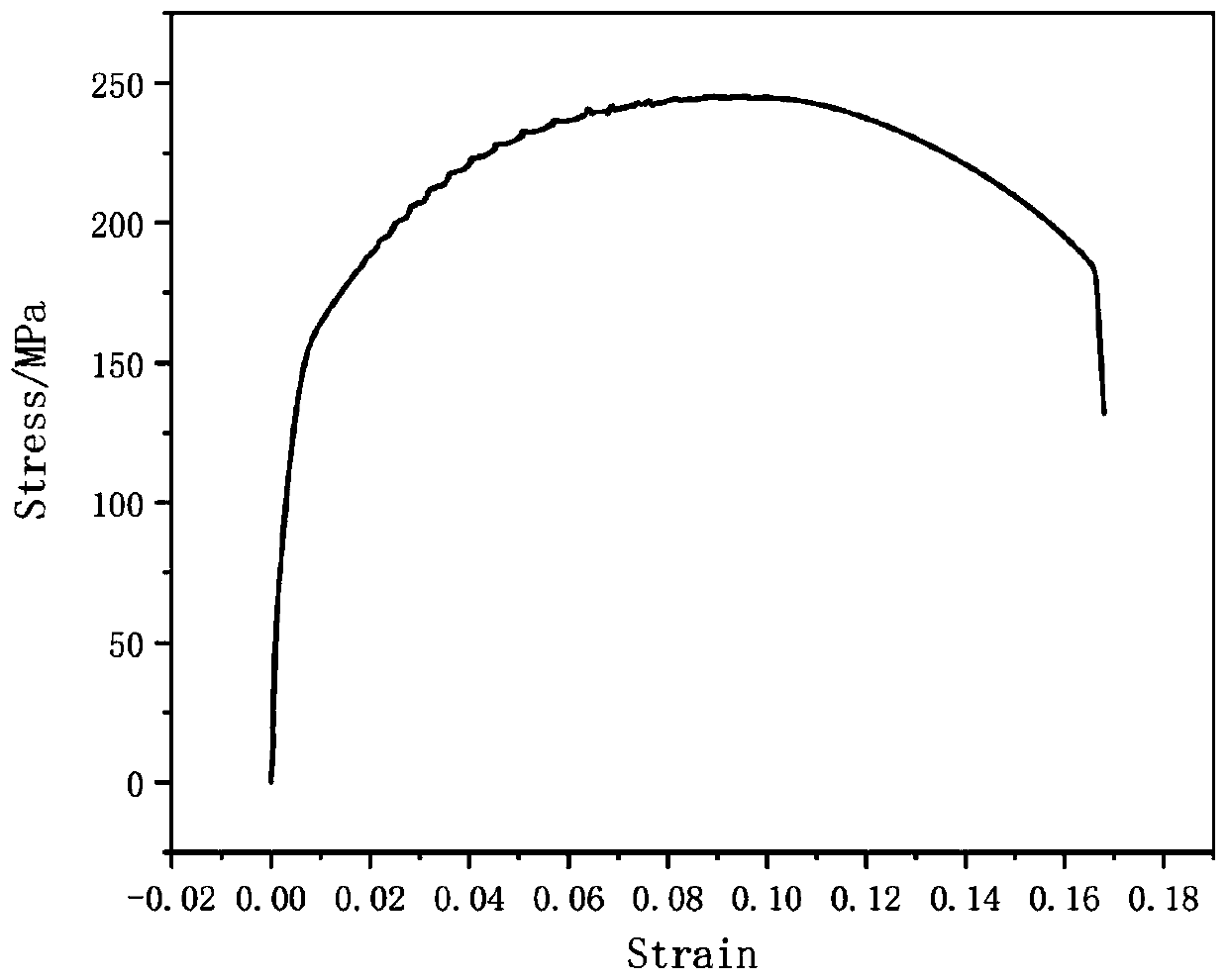

[0050] Such as Figure 1-2 As shown, the molecular formula of the high-strength aluminum-based light-weight medium-entropy alloy in this example is 5083 aluminum alloy-xZn, where x=4%, and the preparation steps are as follows: the raw material Zn with a purity greater than 99.9% and 5083 aluminum alloy are prepared in proportion 100g. Put the prepared raw materials into the graphite crucible in order of melting point from high to low, put the graphite crucible filled with the alloy material into the induction coil, evacuate to below 20Pa, and then fill with argon to 0.3MPa. Start the high-frequency induction device, and when the alloy ingot melts, keep it warm for 15 minutes to make the alloy composition uniform. Cast the uniformly smelted alloy liquid into a steel mold with a diameter of 30mm. Homogenizing annealing, hot rolling, and solution and aging treatment are carried out on the ingot, wherein the annealing temperature is 460°C for 15 hours; the cumulative rolling red...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com