A kind of al-ni-y-ce aluminum base amorphous alloy and preparation method thereof

An al-ni-y-ce, amorphous alloy technology, applied in the field of Al-Ni-Y-Ce aluminum-based amorphous alloy and its preparation, can solve the problem of high preparation cost, difficult industrial production, pure rare earth element Easy to oxidize and other problems, to achieve the effect of simple method, improved amorphous formation ability and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

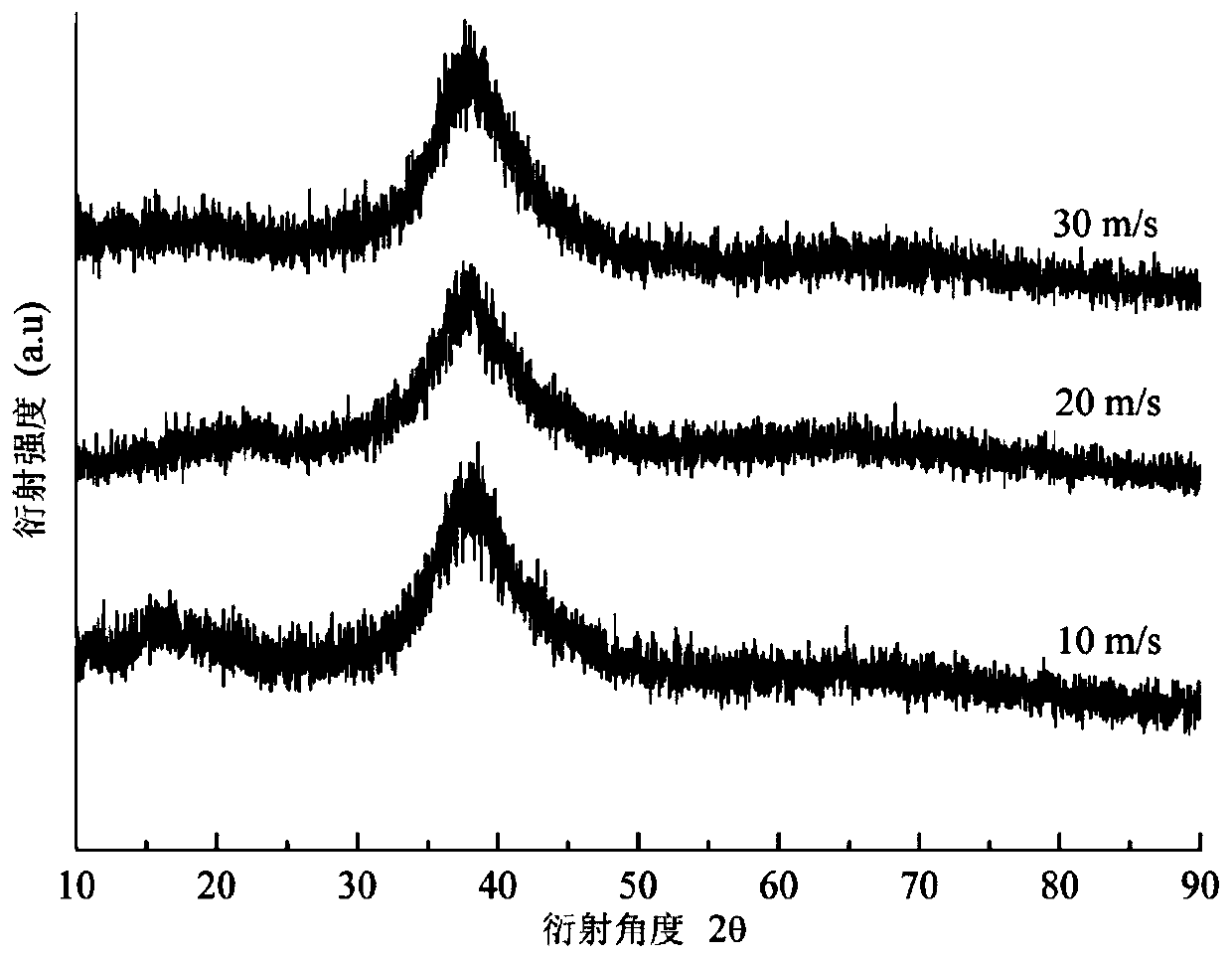

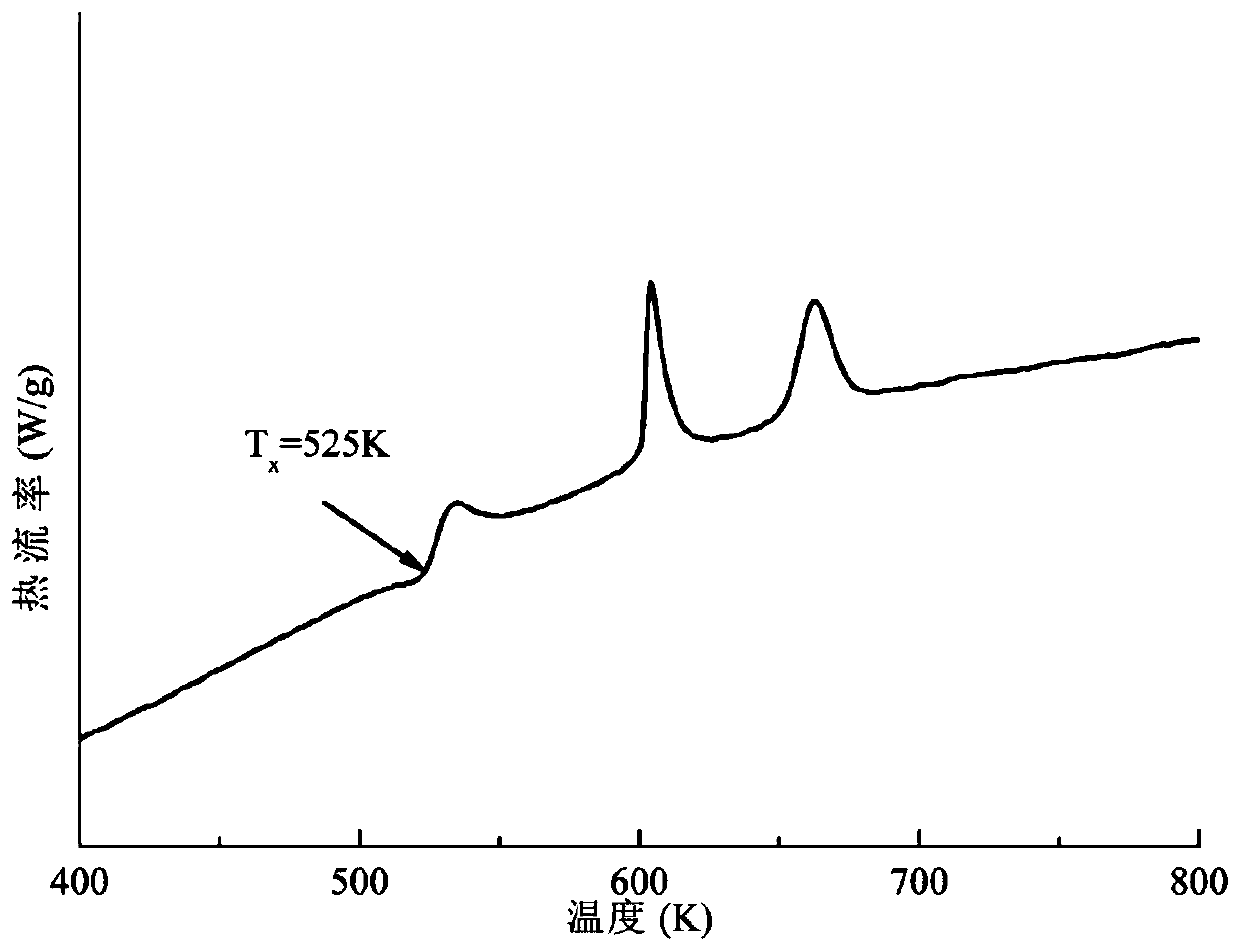

Embodiment 1

[0025] This example is a kind of atomic percentage: Al is 87.0at.%, Ni is 7.5at.%, Y is 2.5at.%, Ce is 3.0at.% Al 87 Ni 7.5 Y 2.5 Ce 3 Amorphous alloy and method for its preparation.

[0026] The first step is to prepare the raw materials for preparing the master alloy:

[0027] According to the atomic percentage of the element composition of Al-Ni-Y-Ce aluminum-based amorphous alloy: Al is 87.0at.%, Ni is 7.5at.%, Y is 2.5at.%, Ce is 3.0at.%. Get the commercial aluminum yttrium alloy that composition mass percent is Al-25%Y, the commercial aluminum cerium alloy that composition mass percent is Al-25%Ce, pure Ni and pure Al are raw materials of corresponding amount, first all above-mentioned master alloy raw materials are carried out Mechanical grinding to remove surface scale, cleaning with absolute ethanol, acetone and deionized water under ultrasonic conditions, and then air-drying to complete the preparation of raw materials for preparing master alloys;

[0028] The s...

Embodiment 2

[0033] This example is a kind of atomic percentage: Al is 87.0at.%, Ni is 7.5at.%, Y is 2.5at.%, Ce is 3.0at.% Al 87 Ni 7.5 Y 2.5 Ce 3 Amorphous alloy and method for its preparation.

[0034] The first step is to prepare the raw materials for preparing the master alloy:

[0035] With embodiment 1;

[0036] The second step is to prepare the master alloy ingot:

[0037] In a vacuum of 1×10 -3 In the vacuum electric arc furnace of Pa, the sponge titanium is first smelted to absorb the oxygen in the vacuum electric arc furnace, and the smelting atmosphere is purified, and then under the protective atmosphere of argon, the sponge titanium is used as the oxygen absorber, and the above-mentioned first step is prepared. The raw materials for preparing the master alloy are put into the vacuum electric arc furnace for 6 times of electric arc melting until the raw material components of the master alloy are melted evenly, and cooled to room temperature in an atmosphere protected by...

Embodiment 3

[0041] This example is a kind of atomic percentage: Al is 87.0at.%, Ni is 7.5at.%, Y is 2.5at.%, Ce is 3.0at.% Al 87 Ni 7.5 Y 2.5 Ce 3 Amorphous alloy and method for its preparation.

[0042] The first step is to prepare the raw materials for preparing the master alloy:

[0043] With embodiment 1;

[0044] The second step is to prepare the master alloy ingot:

[0045] In a vacuum of 1×10 -3 In the vacuum electric arc furnace of Pa, the sponge titanium is first smelted to absorb the oxygen in the vacuum electric arc furnace, and the smelting atmosphere is purified, and then under the protective atmosphere of argon, the sponge titanium is used as the oxygen absorber, and the above-mentioned first step is prepared. The raw materials for preparing the master alloy are put into the vacuum electric arc furnace for 5 times of electric arc melting until the raw material components of the master alloy are melted evenly, and then water-cooled to room temperature under an atmospher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fatigue bending times | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com