A kind of cu-based amorphous powder for cold spraying and its preparation method and application

A technology of amorphous powder and cold spraying, applied in the direction of pressure inorganic powder plating, coating, metal material coating process, etc., can solve the problems of low deposition temperature, oxidation, high particle speed, etc., and achieve high coating density, The effect of increasing the degree of mismatch and improving the configuration entropy value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

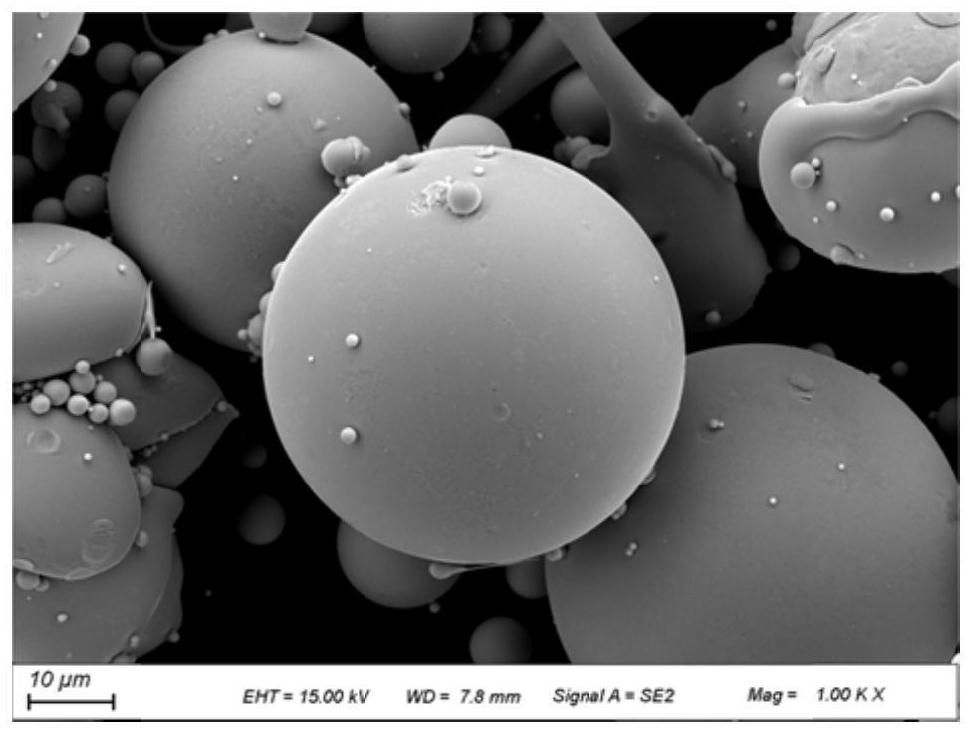

[0026] A Cu-based amorphous powder for cold spraying is composed of the following elements, and the atomic percentage of each element is as follows: 13.0at% Zr, 27.7wt% Ti, 5.0at% Ni, 4.0at% Al, 0.5at% Sn, and the rest The amount is Cu, the powder is nearly spherical, and the particle size is 10-45 μm.

[0027] The above-mentioned preparation method of Cu-based amorphous powder for cold spraying comprises the following steps:

[0028] 1)Accurately calculate and weigh CuZr alloy, pure Cu, Ti powder, pure Ni, pure Al, pure Sn according to the composition ratio of 6 elements;

[0029] 2) Add pure Ti powder, pure Ni, CuZr alloy, pure Cu, pure Al and pure Sn into the vacuum induction induction furnace in order of melting point from high to low, then heat up to 1670±5°C at 50°C / s and keep warm 30min to make it all melted. During the heat preservation period, argon gas was continuously introduced into the vacuum furnace, and the metal liquid was continuously stirred by the electrom...

Embodiment 2

[0034] A Cu-based amorphous powder for cold spraying is composed of the following elements, and the atomic percentage of each element is as follows: 14.2at% Zr, 25.7at% Ti, 5.4at% Ni, 4.5at% Al, 0.7at% Sn, and the rest The amount is Cu, the powder is nearly spherical, and the particle size is 10-45 μm.

[0035] The preparation method and the steps of preparing the protective coating are the same as those in Example 1.

Embodiment 3

[0037] A Cu-based amorphous powder for cold spraying is composed of the following elements, and the atomic percentages of each element are as follows: 15.5at% Zr, 25.3at% Ti, 6.2at% Ni, 5.4at% Al, 1.2at% Sn, and the rest The amount is Cu, the powder is nearly spherical, and the particle size is 10-45 μm.

[0038] In the preparation method, except that the drying temperature in step 2) was changed to 80° C. and the drying time was 2 h, the rest were the same as those in Example 1.

[0039] In the step of preparing the protective coating, except that the carrier gas preheating temperature is 800°C, the spraying pressure is 6MPa, the spray gun moving speed is 0.20m / s, the spraying distance is 30mm, the powder feeder rotation speed is 5rpm, and the spraying thickness is 250μm, the rest are the same as in Example 1.

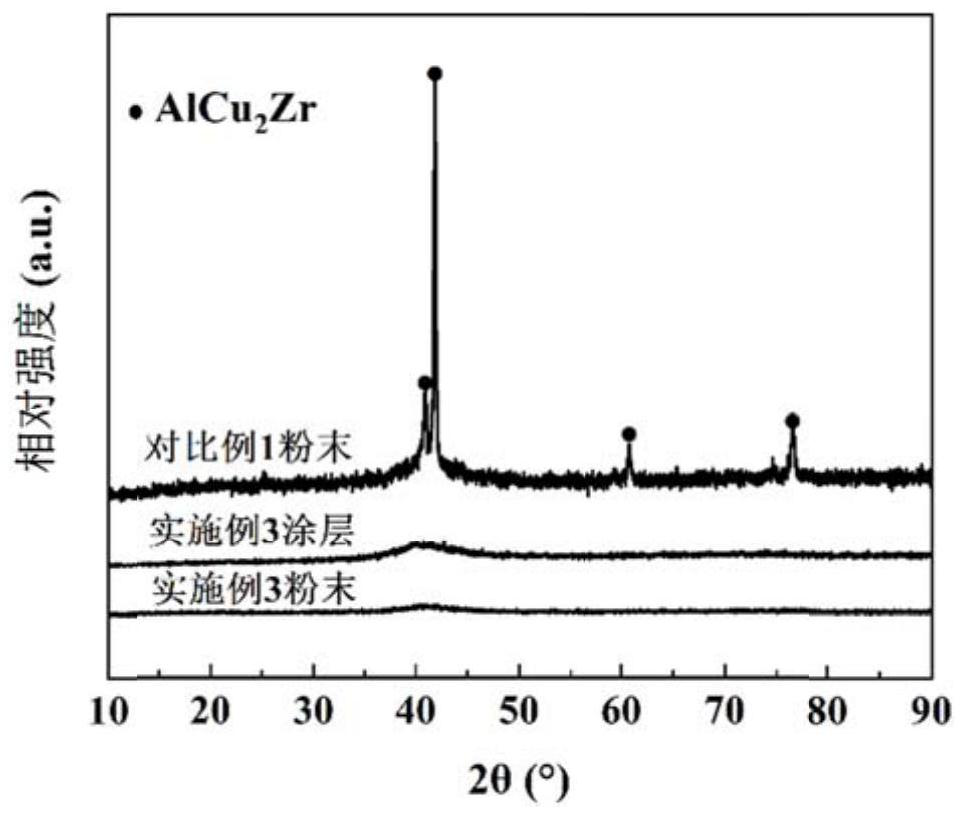

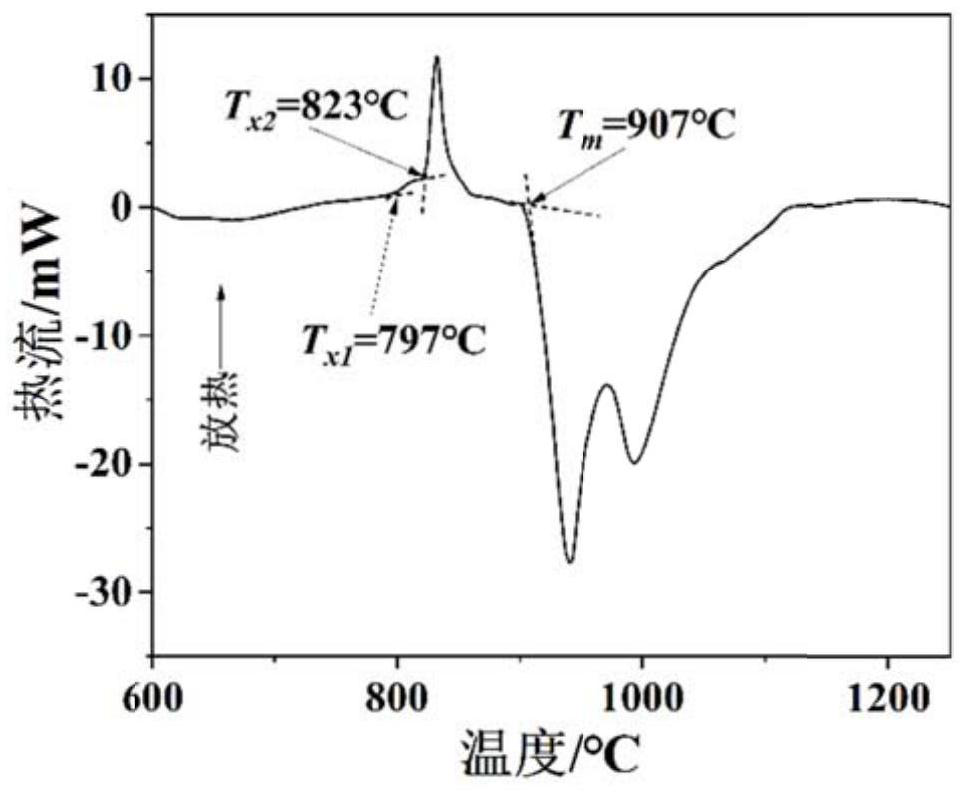

[0040] Depend on figure 1 It can be seen that both the prepared Cu-based amorphous powder and coating have only one broadened steamed bread peak, showing a typical a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystallization temperature | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com