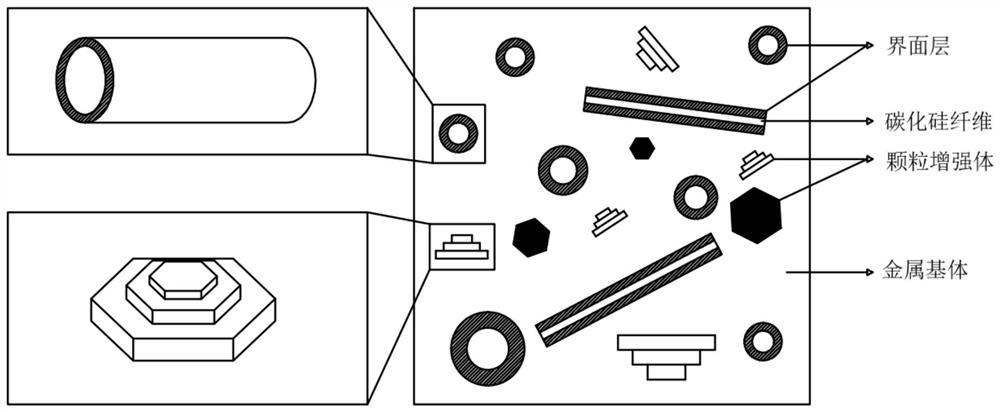

Silicon carbide fiber and medium-high entropy ceramic reinforced metal matrix composite material and preparation method thereof

A technology of silicon carbide fiber and composite materials, which is applied in the field of fiber and ceramic particle reinforced metal matrix composite materials, can solve the problems of poor product strength, reduced service performance, shortened service life, etc., and achieve extended service life, high tensile strength, The effect of low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] As another aspect of the technical solution of the present invention, it also relates to a preparation method of a silicon carbide fiber and a medium and high entropy ceramic reinforced metal matrix composite material, comprising:

[0037] Mixing silicon carbide fiber, medium and high entropy rare earth boron carbon compound material and metal or alloy material uniformly to obtain a mixture;

[0038] The mixture is heat treated to prepare the silicon carbide fiber and the medium and high entropy ceramic reinforced metal matrix composite material.

[0039] In some preferred embodiments, the preparation method specifically includes:

[0040] Prepare an interface layer on the surface of the silicon carbide fiber to obtain a silicon carbide fiber with an interface layer;

[0041] Mixing the silicon carbide fiber with the interface layer, the medium and high entropy rare earth boron carbon compound material and the metal or alloy material uniformly to obtain a mixture;

[...

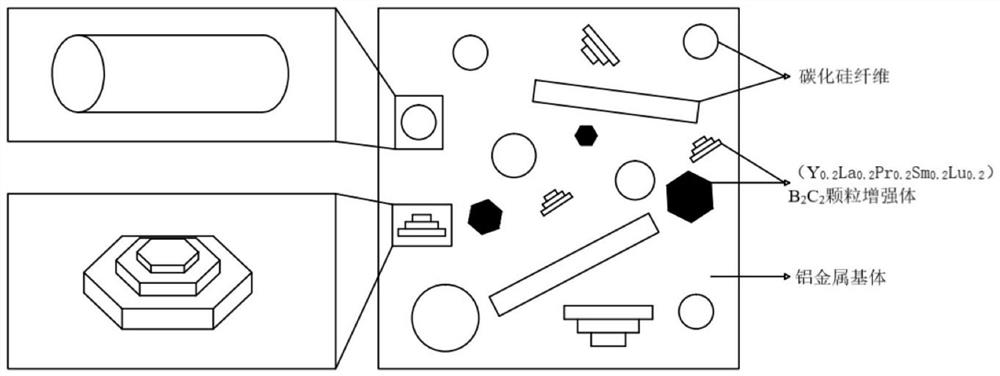

Embodiment 1

[0056] In this embodiment, the metal matrix composite material is a silicon carbide fiber reinforced aluminum metal matrix composite material as an example, and the ceramic particle reinforcement is (Y 0.2 La 0.2 Pr 0.2 Sm 0.2 Lu 0.2 )B 2 C 2 , the specific preparation steps are as follows:

[0057] (1) Grind silicon carbide fibers and control their volume fraction to 40%; regrind (Y 0.2 La 0.2 Pr 0.2 Sm 0.2 Lu0.2 )B 2 C 2 Particles, the particle size is controlled at 2μm, and the volume fraction is controlled at 10%;

[0058] (2) Using a high-energy ball mill to grind the aluminum powder and the above-mentioned ground silicon carbide fibers and (Y) 0.2 La 0.2 Pr 0.2 Sm 0.2 Lu 0.2 )B 2 C 2 The particles are mixed evenly, the rotation speed is 150r / min, and the duration is 3h;

[0059] (3) The final product is prepared by the hot pressing sintering method, and the reinforcing phase is obtained after sintering at a high temperature of 1000 ° C for 10 hours, wh...

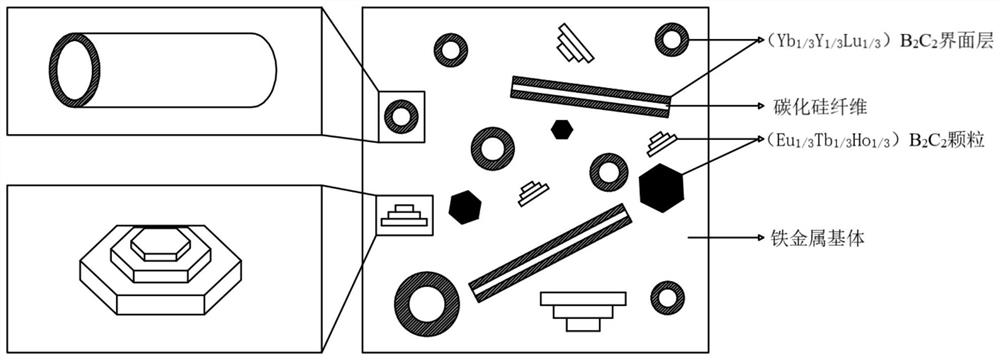

Embodiment 2

[0061] In this embodiment, the metal matrix composite material is a silicon carbide fiber reinforced titanium metal matrix composite material as an example, and the ceramic particle reinforcement is (Pr 0.2 Eu 0.2 Ho 0.2 Pm 0.2 Lu 0.2 )B 2 C 2 , the specific preparation steps are as follows:

[0062] (1) Grind silicon carbide fibers and control their volume fraction to 10%; regrind (Pr 0.2 Eu 0.2 Ho 0.2 Pm 0.2 Lu 0.2 )B 2 C 2 Particles, the particle size is controlled at 5μm, and the volume fraction is controlled at 15%;

[0063] (2) Using a high-energy ball mill to grind the titanium powder and the above ground silicon carbide fibers and (Pr 0.2 Eu 0.2 Ho 0.2 Pm 0.2 Lu 0.2 )B 2 C 2 The particles are mixed evenly, the rotation speed is 200r / min, and the duration is 4h;

[0064] (3) The final product is prepared by hot pressing sintering method, and the reinforcing phase is obtained after sintering at 1500 ℃ for 8 hours and the reinforcing phase is silicon c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com