Method for manufacturing electromagnetic shielding curved surface optical window with metal mesh structure

An electromagnetic shielding and metal mesh grid technology, applied in the field of optical windows, can solve the problems of uneven distribution of high-order diffraction energy, reduce the light transmission performance of optical windows, reduce the light transmission performance and electromagnetic shielding performance of optical windows, etc., and achieve good electromagnetic shielding performance. The effect of shielding performance, expanding universality, and good light transmission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

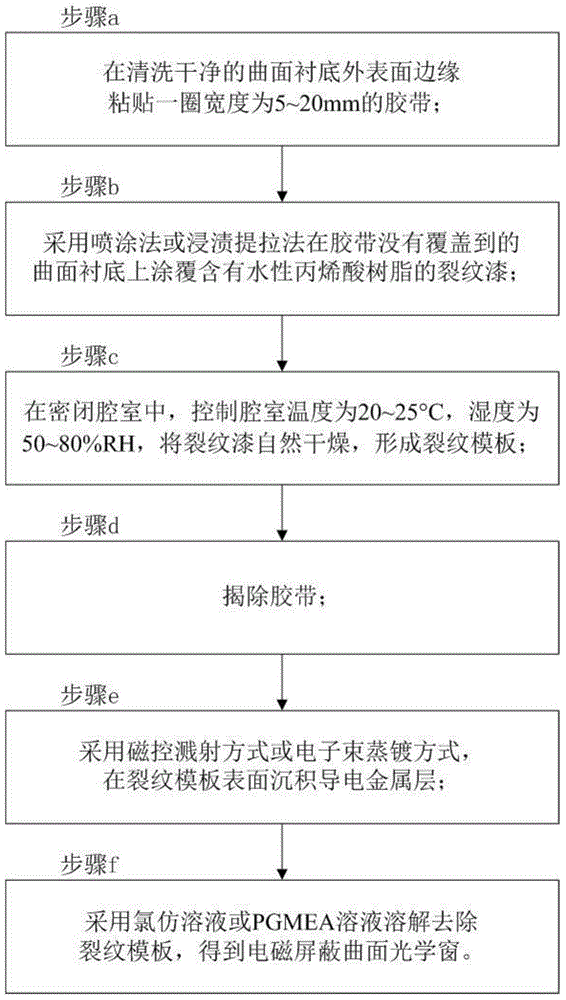

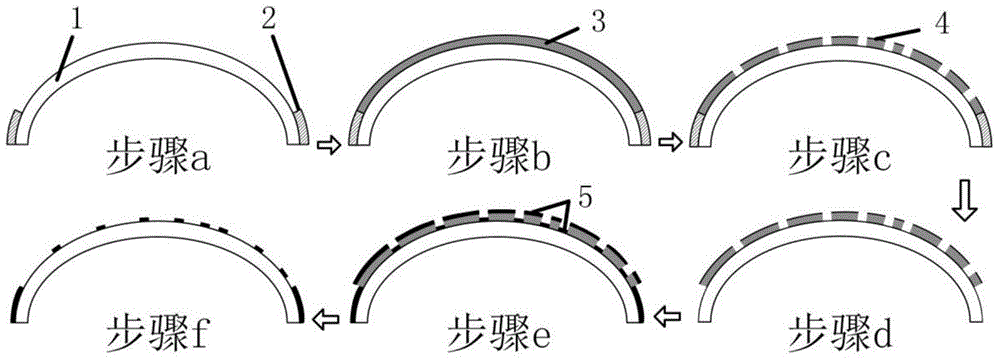

[0044] The manufacturing method of the electromagnetic shielding curved surface optical window with metal grid structure in this embodiment, the flow chart is as follows figure 1 As shown, the method includes the following steps:

[0045] Step a, paste a circle of adhesive tape 2 with a width of 5-20mm on the edge of the outer surface of the cleaned curved substrate 1;

[0046]Step b, coating the cracked paint 3 containing water-based acrylic resin on the curved substrate 1 not covered by the adhesive tape 2 by spraying or dipping;

[0047] Step c, in a closed chamber, control the temperature of the chamber to 20-25°C and the humidity to 50-80% RH, and dry the crack paint 3 naturally to form the crack template 4;

[0048] Step d, remove the adhesive tape 2;

[0049] Step e, using magnetron sputtering or electron beam evaporation to deposit a conductive metal layer 5 on the surface of the cracked template 4;

[0050] Step f, using chloroform solution or PGMEA solution to dis...

specific Embodiment 2

[0053] The manufacturing method of the electromagnetic shielding curved surface optical window with a metal grid structure in this embodiment, the method flow and process flow are exactly the same as the specific embodiment 1, the difference is that the crack paint is diluted with a diluent, and the dilution ratio k is defined as the diluent and the crack The volume ratio of paint, and 2≤k≤5.

[0054] Under the above ratio conditions, it is found that:

[0055] The relationship between the average crack width w of the crack template 4 and the thickness h of the crack paint 3 is:

[0056] w=0.342e 0.266h

[0057] In the formula, w is the average crack width of the crack template 4 in μm; h is the thickness of the crack paint 3 in μm.

[0058] The relationship between the average crack interval d of the crack template 4 and the thickness h of the crack paint 3 is:

[0059] d=15.8e 0.169h

[0060] In the formula, d is the average crack interval of the crack template 4 in μm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com