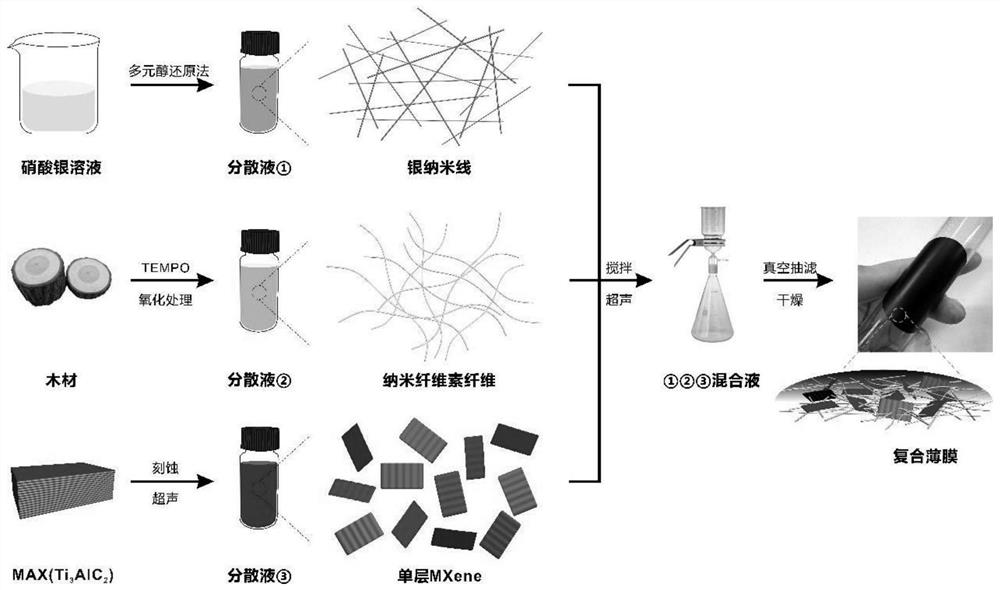

MXene/silver nanowire/nanocellulose composite film and preparation method thereof

A technology of nanocellulose and silver nanowires, which is applied in the direction of nanotechnology, nanotechnology, cable/conductor manufacturing, etc., can solve the problems that electrochemical performance and mechanical performance cannot be combined, performance cannot be further improved, and preparation is complicated, etc., to achieve excellent Electrochemical performance and electromagnetic shielding performance, expanding the scope of use, and the effect of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

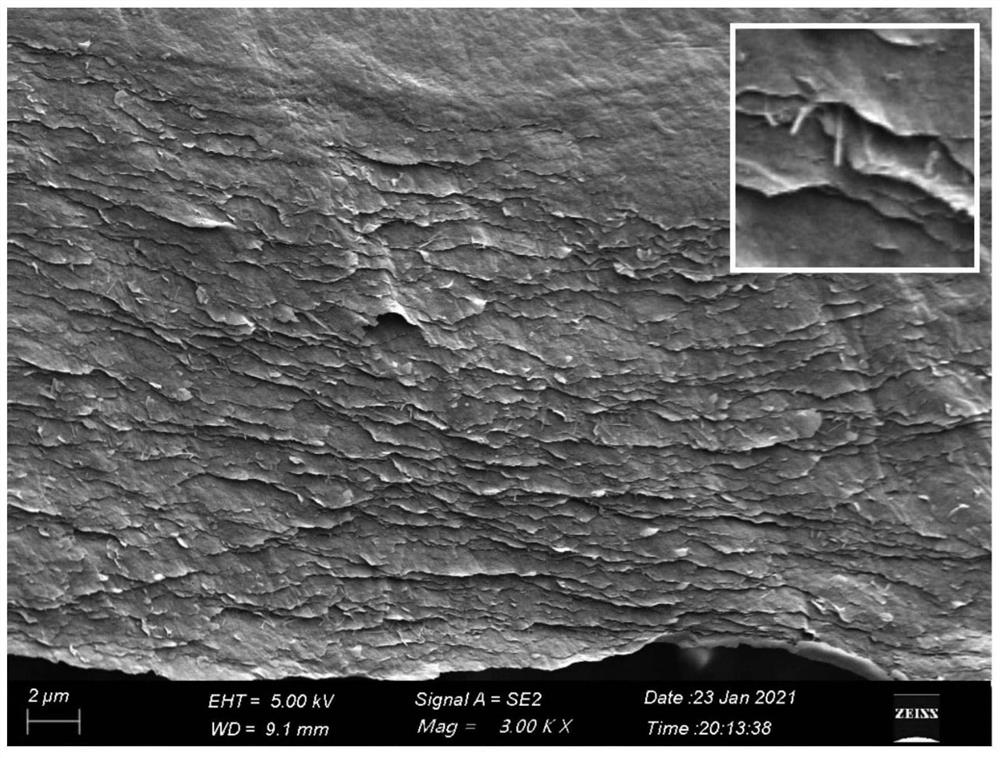

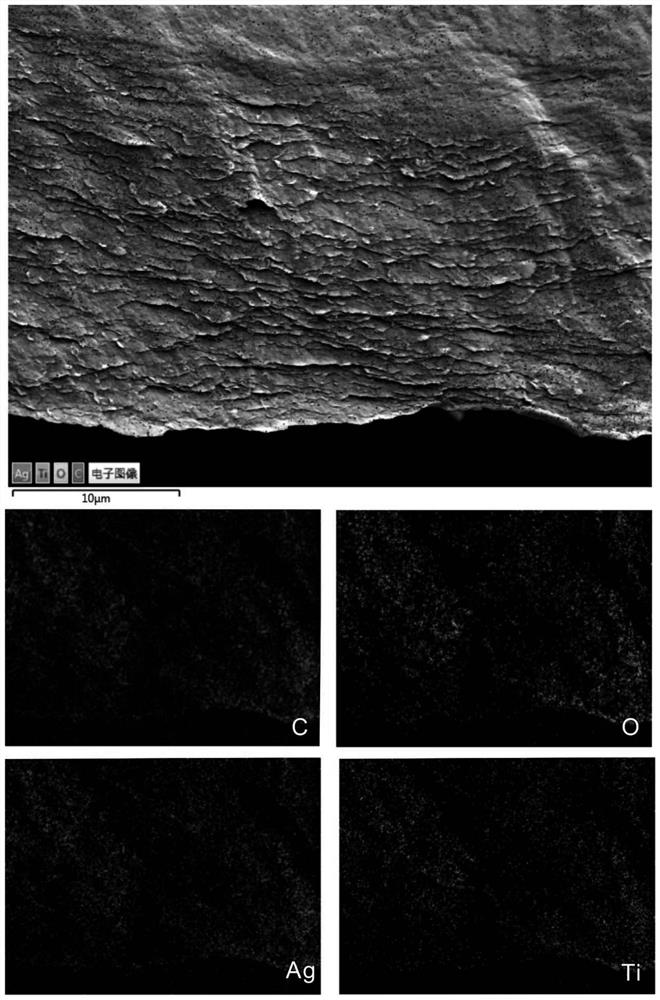

[0047] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0048] (1) Slowly dissolve 1.6g of lithium fluoride in 20mL of 9M hydrochloric acid, stir for 10min to obtain a clear corrosion solution; slowly add 1g of Ti to the corrosion solution 3 AlC 2 , stirred at 45°C for 24 hours, washed with deionized water and centrifuged 7 times at a centrifugal speed of 3500rpm, centrifuged for 5min each time, until the pH value of the supernatant was greater than 6; collected the precipitate, dissolved in 100mL deionized water, and placed in an argon atmosphere Ultrasound for 3 hours; centrifuge the ultrasonic solution for 1.5 hours at a speed of 3500 rpm, and collect the supernatant as a single-layer MXene colloidal solution; take a certain amount of the obtained solution, vacuum-assisted suction filtration through a 0.22 μm microporous filter membrane, and Dry under nitrogen protection, weigh the qualit...

Embodiment 2

[0055] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0056] (1) Slowly dissolve 1.8g lithium fluoride in 25mL 9M hydrochloric acid, stir for 10min to obtain a clear corrosion solution; slowly add 1.2g Ti to the corrosion solution 3 AlC 2 , stirred at 45°C for 28 hours, washed with deionized water and centrifuged 8 times at a centrifugal speed of 3500rpm, centrifuged for 5min each time, until the pH value of the supernatant was greater than 6; collected the precipitate, dissolved in 100mL deionized water, and placed in an argon atmosphere Ultrasound for 3.5 hours; centrifuge the ultrasonic solution for 1.5 hours at a speed of 3500 rpm, and collect the supernatant as a single-layer MXene colloidal solution; take a certain amount of the obtained solution, vacuum-assisted suction filtration through a 0.22 μm microporous filter membrane, and Dry under nitrogen protection, weigh the quality dif...

Embodiment 3

[0063] A kind of MXene / silver nanowire / nanocellulose composite film and preparation method thereof, comprising the following process steps:

[0064] (1) Slowly dissolve 1.5g of lithium fluoride in 15mL of 9M hydrochloric acid, stir for 10min to obtain a clear corrosion solution; slowly add 0.8g of Ti to the corrosion solution 3 AlC 2 , stirred at 45°C for 20 hours, washed and centrifuged 6 times with deionized water at 4000rpm, centrifuged for 5 minutes each time, until the pH value of the supernatant was greater than 6; collected the precipitate, dissolved in 80mL deionized water, and placed in an argon atmosphere Sonicate for 3 hours; centrifuge the ultrasonic solution for 1 hour at a speed of 4000 rpm, and collect the supernatant as a single-layer MXene colloidal solution; take a certain amount of the obtained solution, vacuum-assisted filtration through a 0.22 μm microporous filter membrane, and store in nitrogen Dry under protection, weigh the quality difference before a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com