A high configuration entropy thermoelectric compound and its design method and preparation method

A compound and configuration technology, applied in the field of high configuration entropy thermoelectric compounds and its design method and preparation, to achieve the effect of improving thermoelectric performance and thermal stability, low lattice thermal conductivity, and realizing synergistic regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

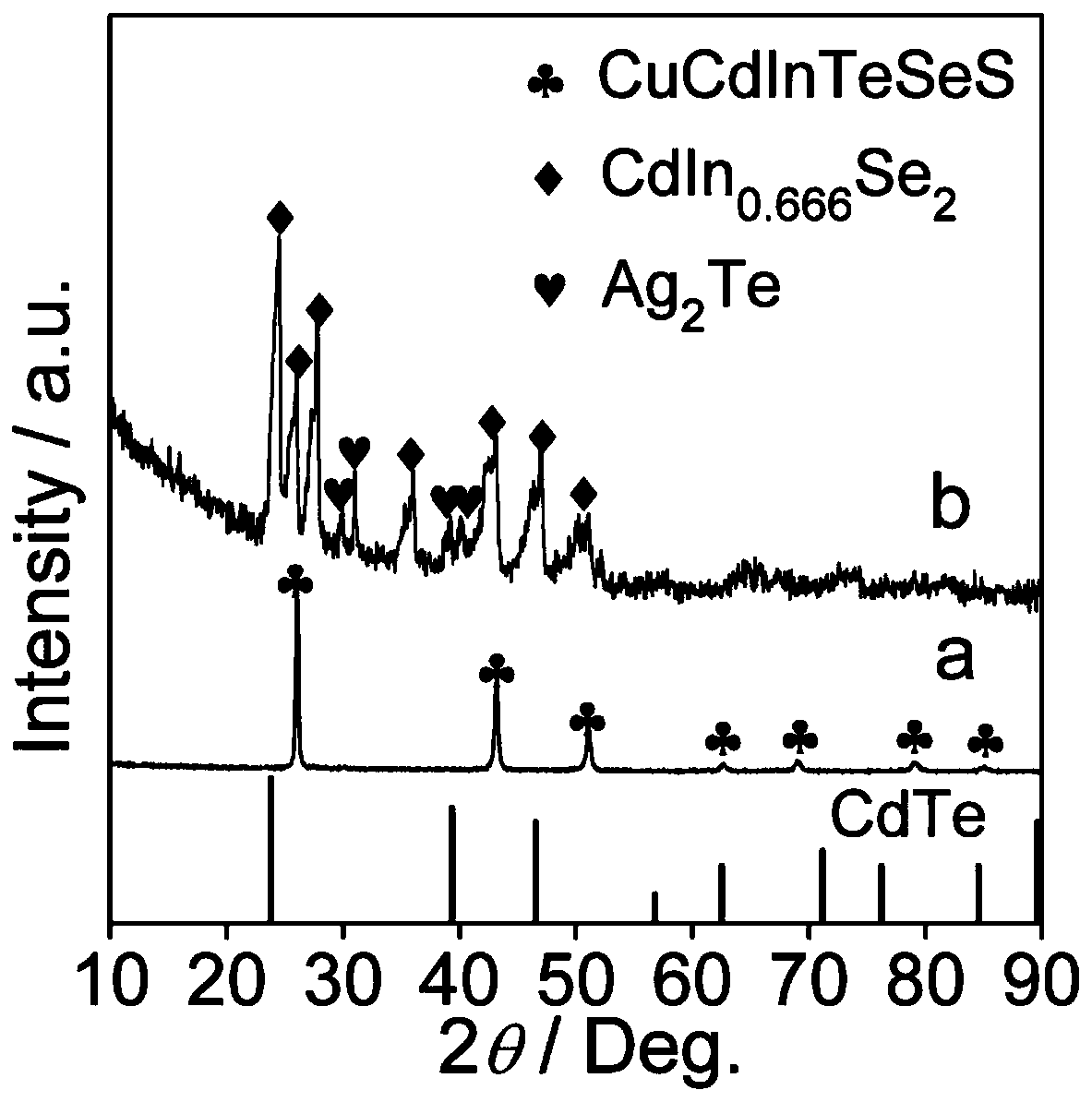

[0041] A design method for high configuration entropy thermoelectric compounds, comprising the steps of:

[0042] 1) Taking CdTe, the basic compound of diamond-like structure, as the research object, under the premise of satisfying electrical neutrality, that is, at the cation site (Cd 2+ ) to be filled with Cu + and In 3+ or Ag + and In 3+ , the anion site (Te 2- ) to fill in Se 2- and S 2- ;

[0043] 2) For the six elements of Cu, Cd, In, Te, Se, and S, calculate the ΔG (Gibbs free energy) of each substance from the first principle, including the compound CuCdInTeSeS formed by all elements, and the compound CuCdInTe formed by some elements 3 , CuCdInSe 3 , CuCdInS 3 、CuInTe 2 、CuInSe 2 、CuInS 2 、Cu 2 Te, Cu 2 Se, Cu 2 S, CdTe, CdSe, CdS, In 4 Te 3 、In 4 Se 3 、In 4 S 3 , InTe, In 2 Te 3 , InSe, In 2 Se 3 , InS, In 2 S 3 etc. Some elements form solid solutions (Cu 2 Te) 1-x (CdSe) x , (Cu 2 Te) 1-x (CdS) x , (Cu 2 Te) 1-x (In 2 Se 3 ) x , (C...

Embodiment 2

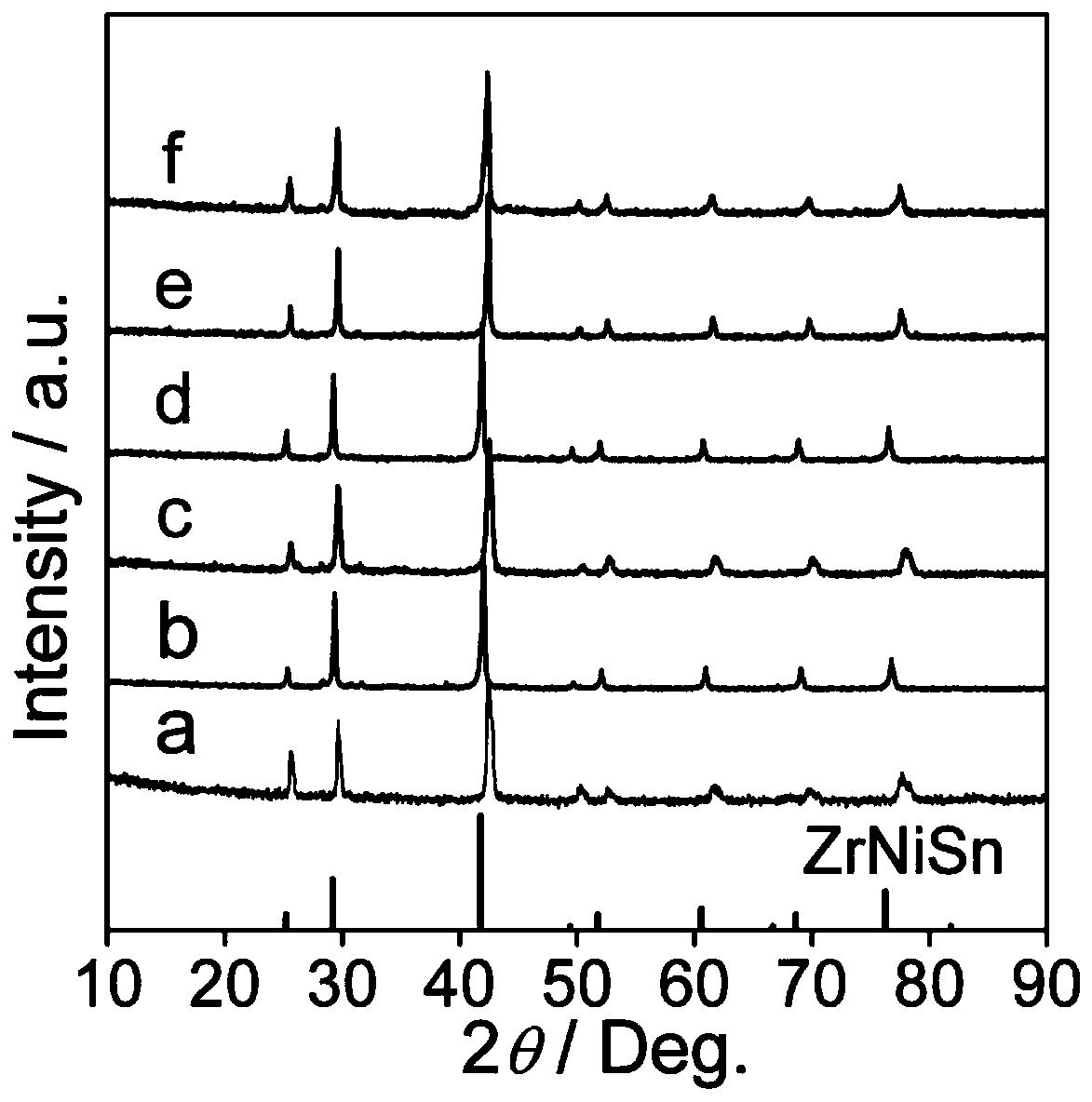

[0048] A class of Half-Heusler compound type high configuration entropy thermoelectric compounds, the stoichiometric formulas are ZrTiCoNiSnSb, ZrHfCoNiSnSb, TiHfCoNiSnSb, Zr 2 CoNiSnSb, ZrNbCo 2 SnSb, ZrNbCoNiSnSb, its preparation method comprises the steps:

[0049] 1) Using Zr powder, Ti powder, Hf powder, Co powder, Ni powder, Nb powder, Sn powder and Sb powder as raw materials, press ZrTiCoNiSnSb, ZrHfCoNiSnSb, TiHfCoNiSnSb, Zr respectively 2 CoNiSnSb, ZrNbCo 2 Stoichiometric ratios of SnSb, ZrNbCoNiSnSb high configuration entropy thermoelectric compounds are weighed, each compound uses a total of 5g of raw materials, which are sequentially numbered as a, b, c, d, e, f;

[0050] 2) Put each raw material in an agate mortar and mix evenly. The obtained mixed powder is used as a reactant, and the reactant is put into a steel mold, and the pressure of 6MPa is used on the tablet machine and the pressure is maintained for 5 minutes to obtain a Φ12mm Ingot;

[0051] 3) Vacuu...

Embodiment 3

[0056] A kind of high configuration entropy thermoelectric compound of salt rock phase structure compound type, the stoichiometric formula is respectively BiPbAgTeSeS, SbPbAgTeSeS, BiSnAgTeSeS, and its preparation method comprises the following steps:

[0057] 1) Using Bi block, Sb block, Pb grain, Sn grain, Ag wire, Te block, Se block, and S block as raw materials, weigh them according to the stoichiometric ratio of BiPbAgTeSeS, SbPbAgTeSeS, and BiSnAgTeSeS high configuration entropy thermoelectric compounds, The total amount of raw materials used for each compound is 5g, and they are numbered a, b, and c in sequence;

[0058] 2) Vacuum-seal each raw material in a quartz glass tube, then put the glass tube into a high-temperature melting furnace, raise the temperature to 1100 °C at a heating rate of 3-5 °C / min, keep it for 24 hours, and then cool it with the furnace;

[0059] 3) Grind the ingot obtained in step 2) into powder, weigh 4.6g and put it into a Φ16mm graphite mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com