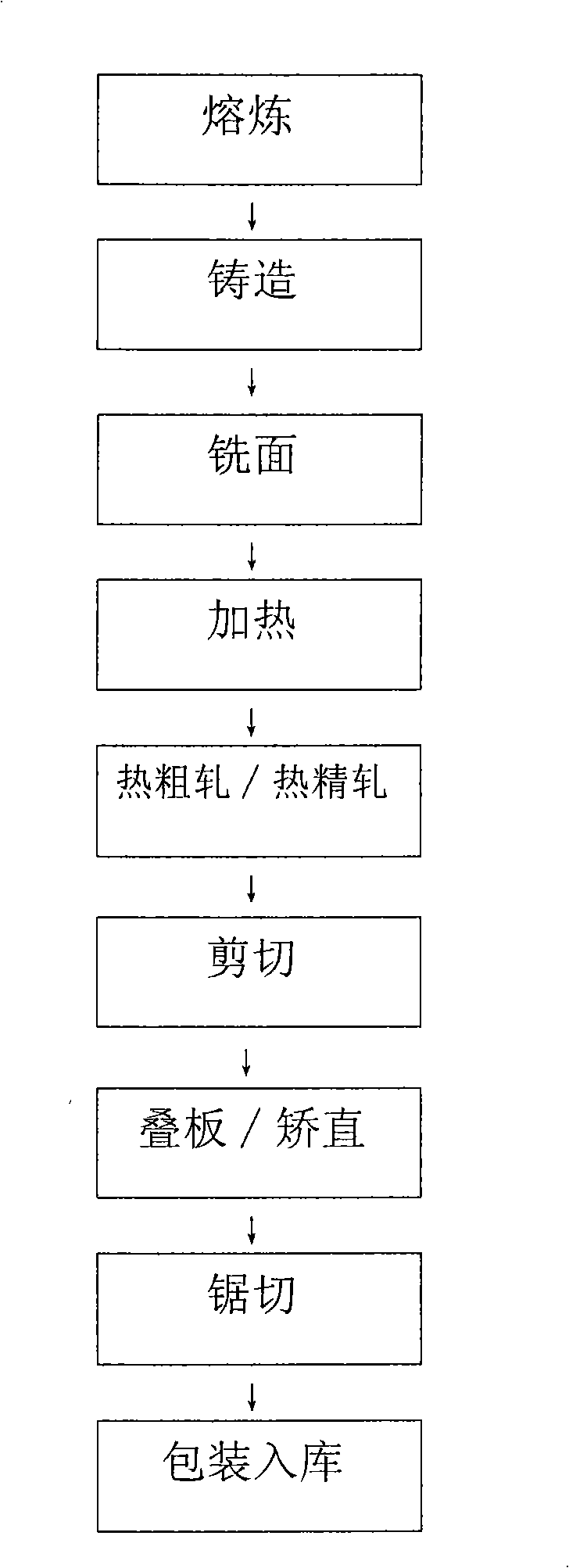

Production process of aluminum alloy hot rolling medium plate

A production process, aluminum alloy technology, applied in the direction of temperature control, etc., can solve the problems of difficult to control thickness and plate shape, easy cracking edge, long production cycle, etc., to achieve the effect of perfecting the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 5083 aluminum alloy plate 20*1500*6000mm

[0030]Melting: Firstly, inspect the prepared raw materials; configure the qualified raw materials, and the composition of alloy materials is as follows: Fe≤0.35%, Si≤0.25%, Cu≤0.10%, Mn: 0.70~0.90%, Mg: 4.50~4.80% , Cr: 0.10~0.20%, Zn≤0.20%, Ti≤0.10%, the total of other impurities≤0.15%, Na≤5ppm, Ca≤5ppm, Al: the balance, put into the smelting furnace successively; Pre-analysis, composition adjustment, guide furnace, refining degassing, slag removal, temperature adjustment.

[0031] Casting: use semi-continuous casting, and check whether the ingot meets the production requirements according to the relevant inspection standards.

[0032] Face milling: the milling amount of the large face: 15~20mm, the milling amount of the small face: 10~15mm; the roughness Ra(um) after milling of the large face is required to be less than 3.2, and the roughness Ra(um) after milling of the small face is less than 6.4.

[0033] Heating: 5083 he...

Embodiment 2

[0041] 5083 aluminum alloy hot rolled plate 8*1500*6000.

[0042] Melting: Firstly, inspect the prepared raw materials; configure the qualified raw materials, and the composition of alloy materials is as follows: Fe≤0.35%, Si≤0.25%, Cu≤0.10%, Mn: 0.70~0.90%, Mg: 4.50~4.80% , Cr: 0.10~0.20%, Zn≤0.20%, Ti≤0.10%, the total of other impurities≤0.15%, Na≤5ppm, Ca≤5ppm, Al: the balance, put into the smelting furnace successively; Pre-analysis, composition adjustment, guide furnace, refining degassing, slag removal, temperature adjustment.

[0043] Casting: use semi-continuous casting, and check whether the ingot meets the production requirements according to the relevant inspection standards.

[0044] Face milling: the milling amount of the large face: 15~20mm, the milling amount of the small face: 10~15mm; the roughness Ra(um) after milling of the large face is required to be less than 3.2, and the roughness Ra(um) after milling of the small face is less than 6.4.

[0045] Heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com