Patents

Literature

69results about How to "Good extrudability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Staged reactor process

In a process for the in situ blending of polymers comprising contacting ethylene and one or more comonomers in two or more fluidized bed reactors with a catalyst system comprising (i) a magnesium / titanium based precursor containing an electron donor and (ii) a hydrocarbyl aluminum cocatalyst, the improvement comprising (A) increasing or decreasing the melt flow ratio and / or molecular weight of the blend by, respectively, decreasing or increasing the mole ratio of a precursor activator compound to the electron donor or (B) increasing or decreasing the bulk density of the blend by, respectively, increasing or decreasing the mole ratio of a precursor activator compound to the electron donor, both (A) and (B) subject to defined provisos including partial pre-activation of the precursor.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Melt-fabricable core/shell perfluoropolymer

InactiveUS7763680B2High viscosityIncrease in critical shear rateFibre treatmentCoatingsPolymer sciencePolymer

Owner:THE CHEMOURS CO FC LLC

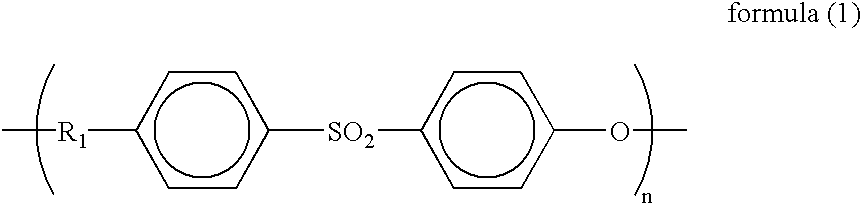

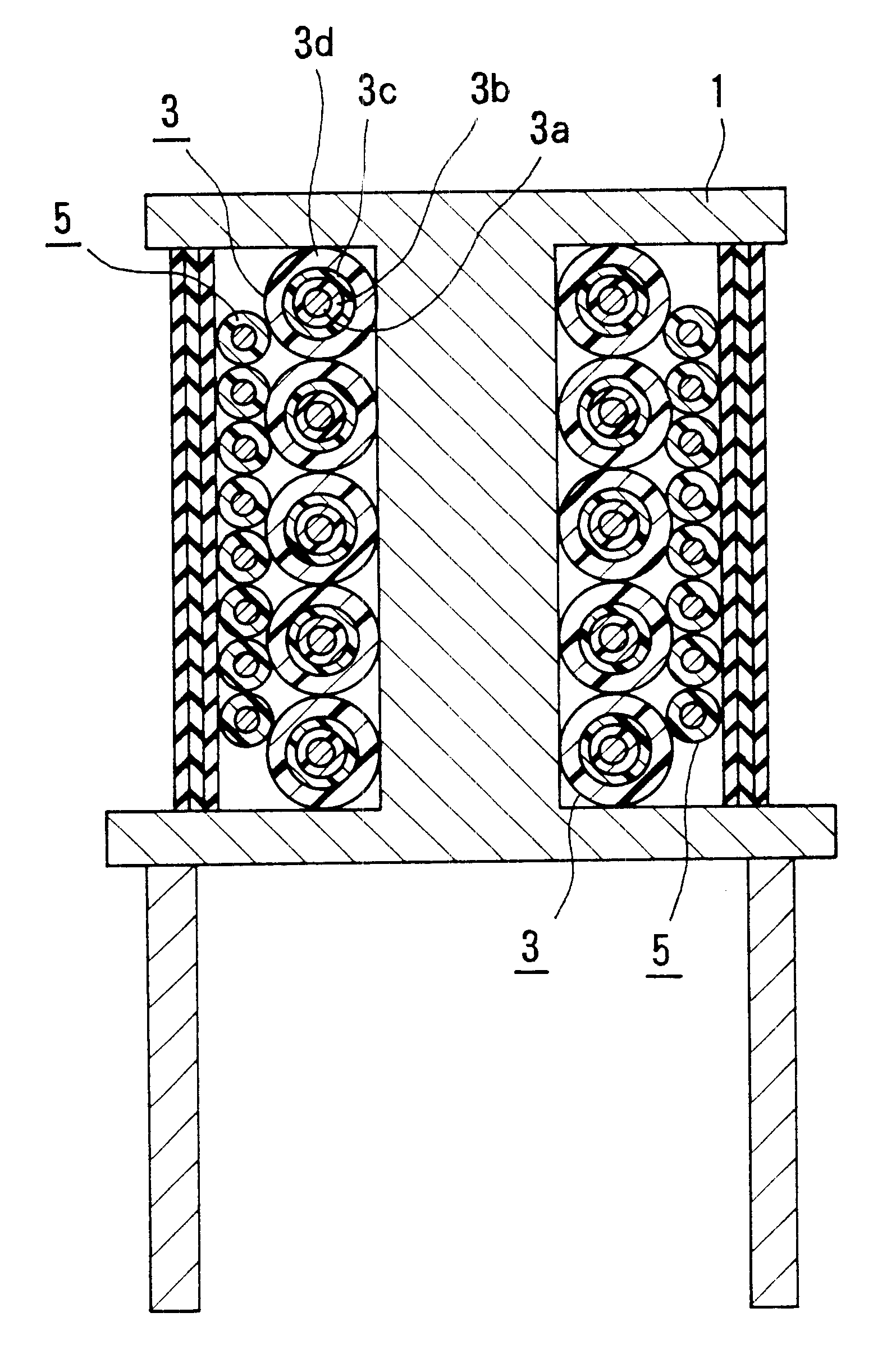

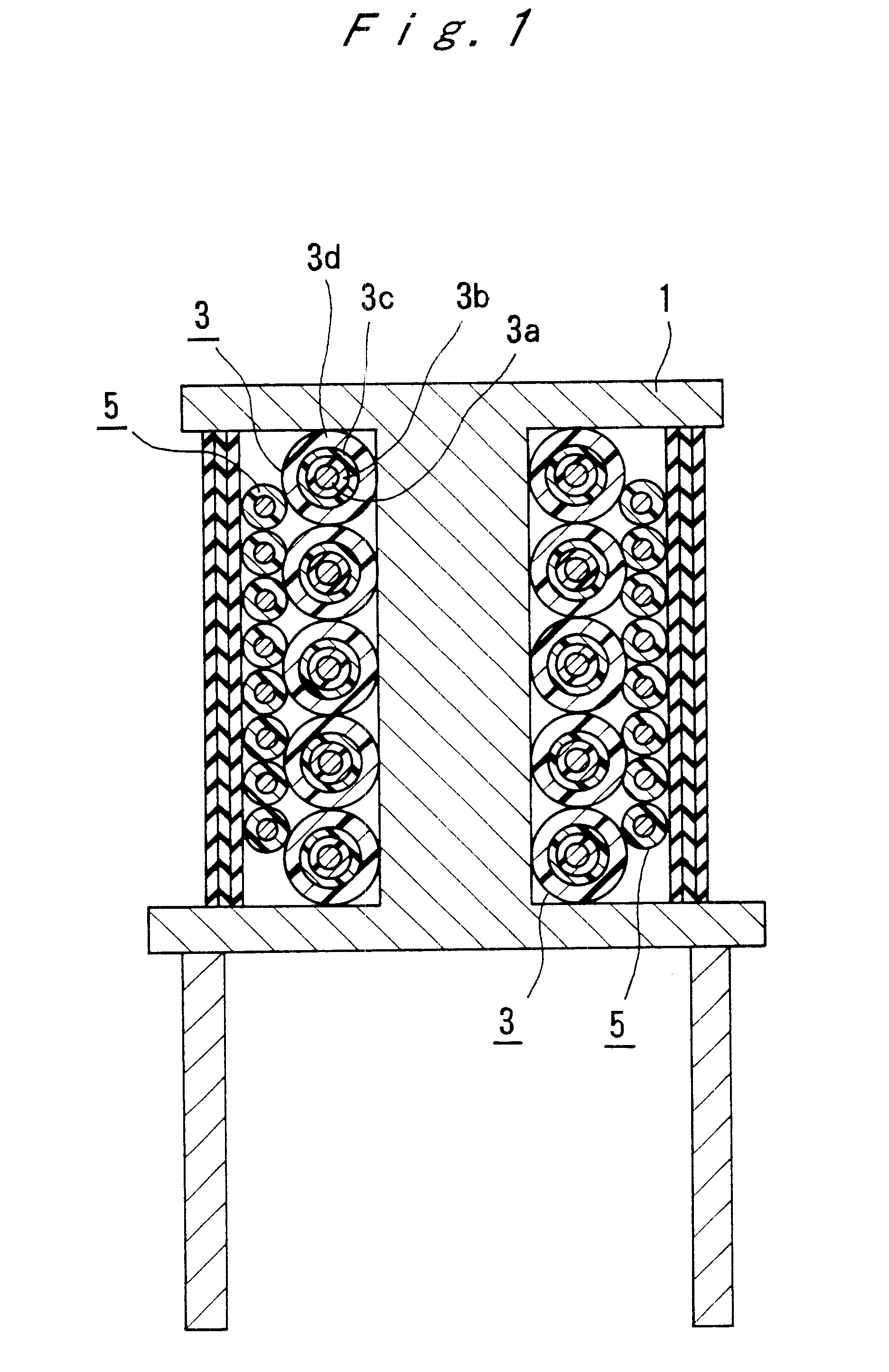

Multilayer insulated wire and transformer using the same

InactiveUS6437249B1High enough heat-resistanceGood effectPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsElectricityElectrical conductor

A multilayer insulated wire has two or more extrusion-coating insulating layers provided on a conductor directly or via some other layer, or provided on the outside of a multicore wire composed of conductor cores or insulated cores that are collected together, wherein at least one of the insulating layers is made of a mixture prepared by mixing 100 parts by weight of a polyethersulfone resin and 10 to 100 parts by weight of an inorganic filler. A transformer utilizes the multilayer insulated wire. The multilayer insulated wire can realize such high heat resistance as heat resistance F class (155° C.), which satisfies IEC 950 standards, or higher heat resistance, in transformers; and can exhibit excellent electrical properties even at high frequencies. Further, when the transformer is used at high frequencies, the electric properties are not lowered, and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

Flame retardant polymer compositions

InactiveUS6025422AReduce the amount requiredIncrease resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsPolymer sciencePolyketone

A composition that includes a hydrated inorganic filler and a polymer blend is disclosed. The polymer blend includes a polymerization or copolymerization product of one or more ethylenically unsaturated monomers. In addition, the polymer blend includes an aliphatic polyketone. The incorporation of aliphatic polyketone with polyethylene based polymers or copolymers results in dramatic improvements in both drip resistance and char strength; moreover, the composition of the present invention can use reduced amounts of hydrated inorganic filler relative to conventional polyethylene based compositions. This reduction in the amount of hydrated filler is expected to lead to improvements in physical properties and extrudability not otherwise possible. These properties make the compositions of the present invention particularly useful as an outer layer for electrical wires, optical fibers, or cables containing at least one wire, optical fiber, or both.

Owner:CORNING OPTICAL COMM LLC

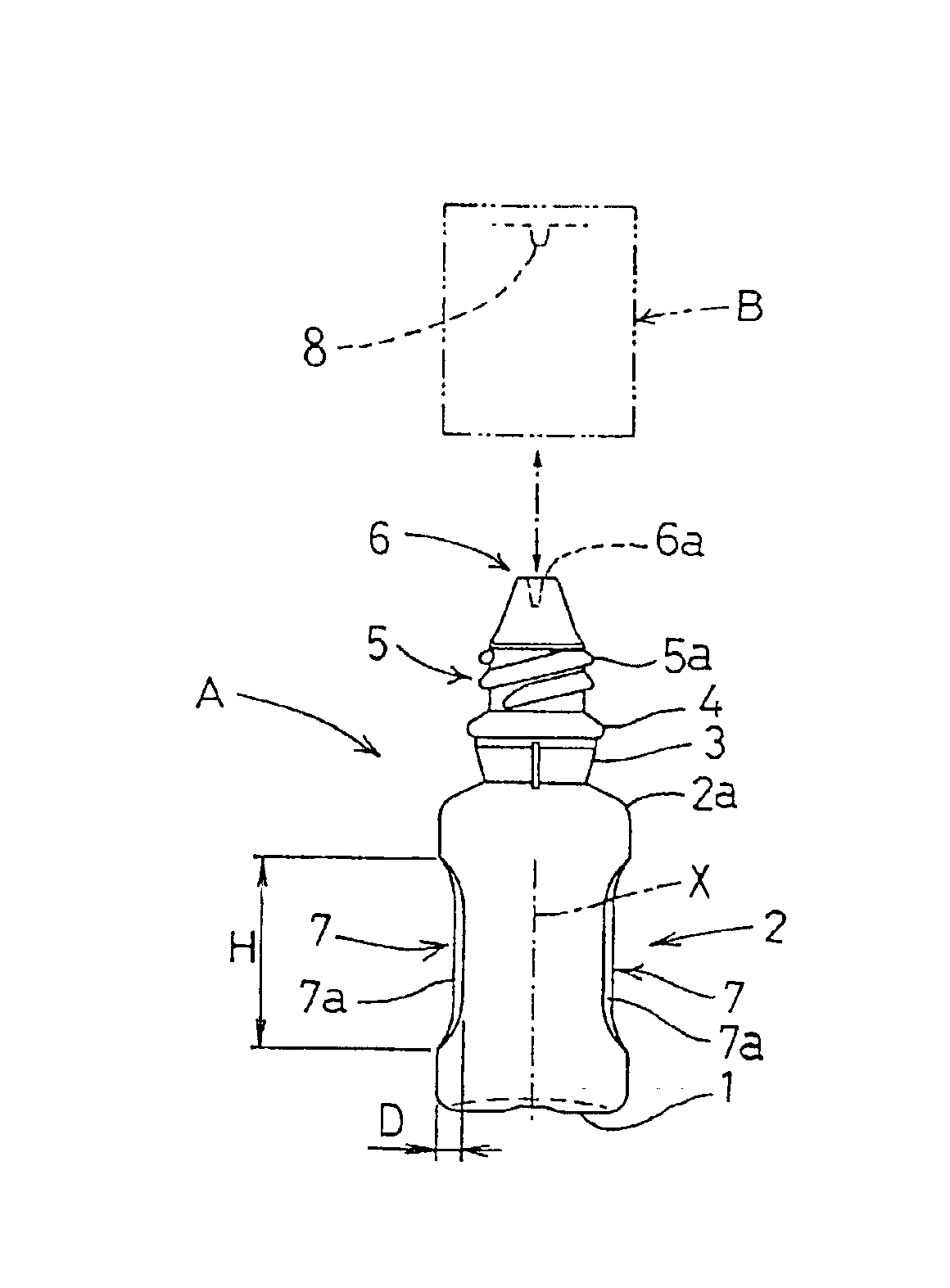

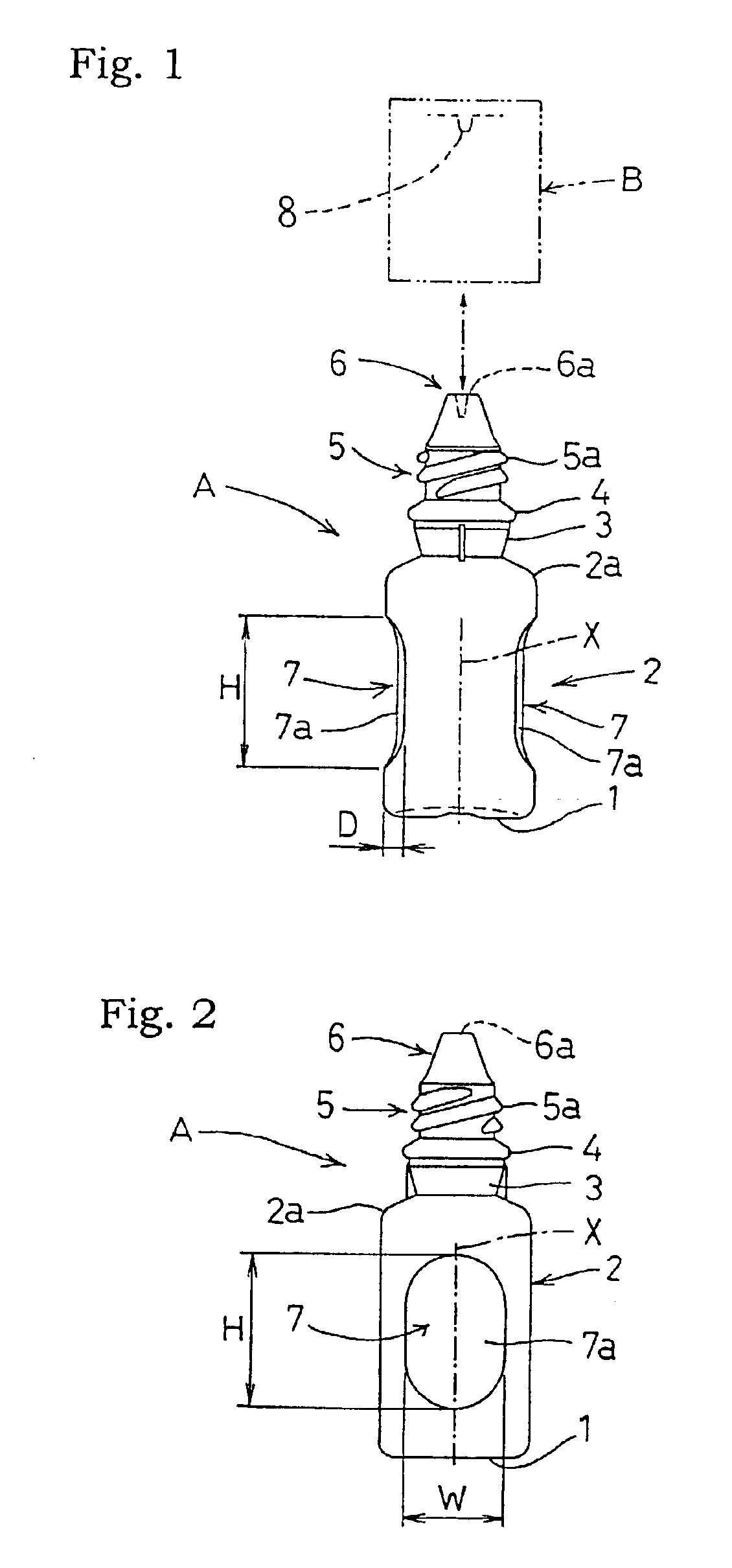

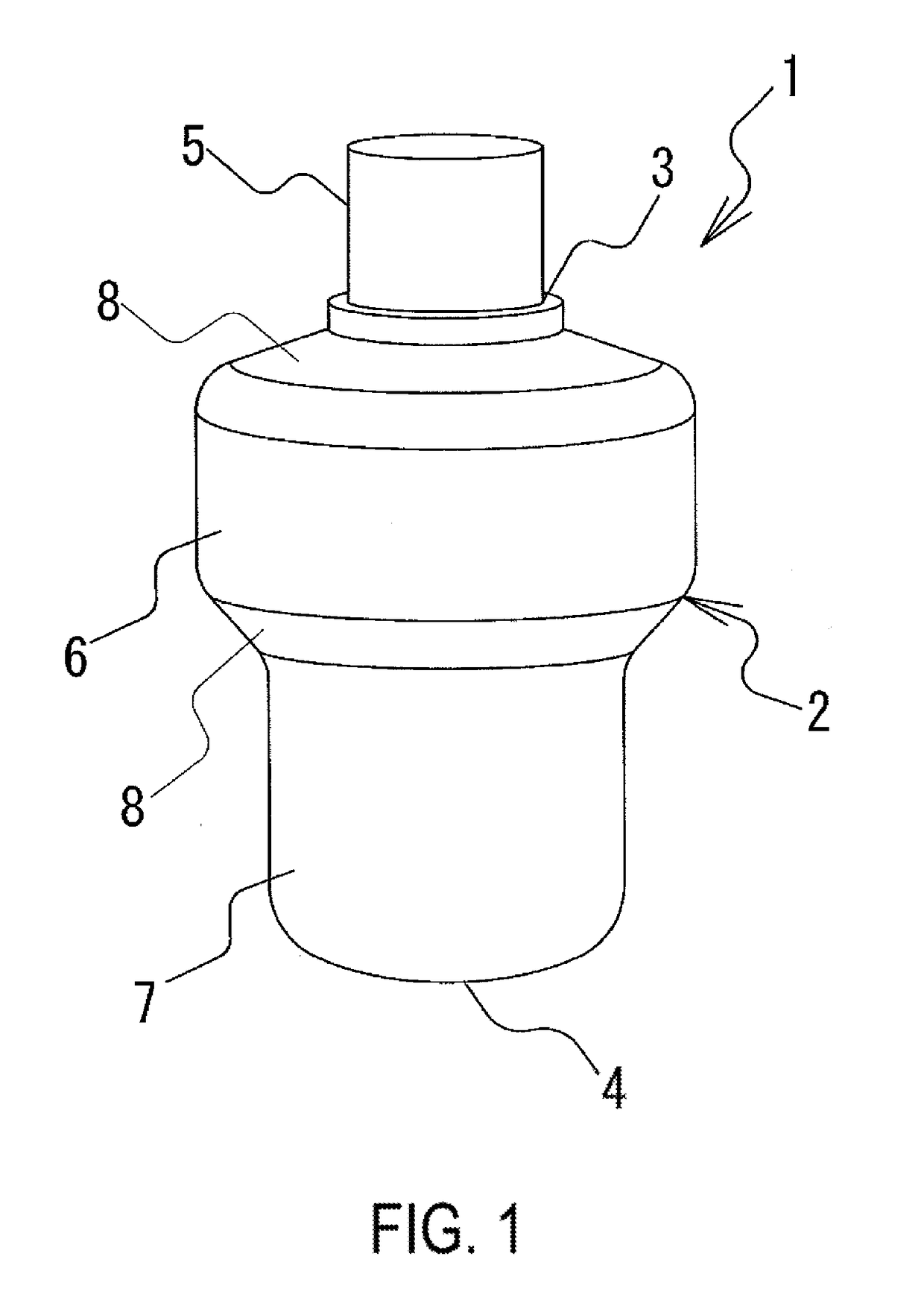

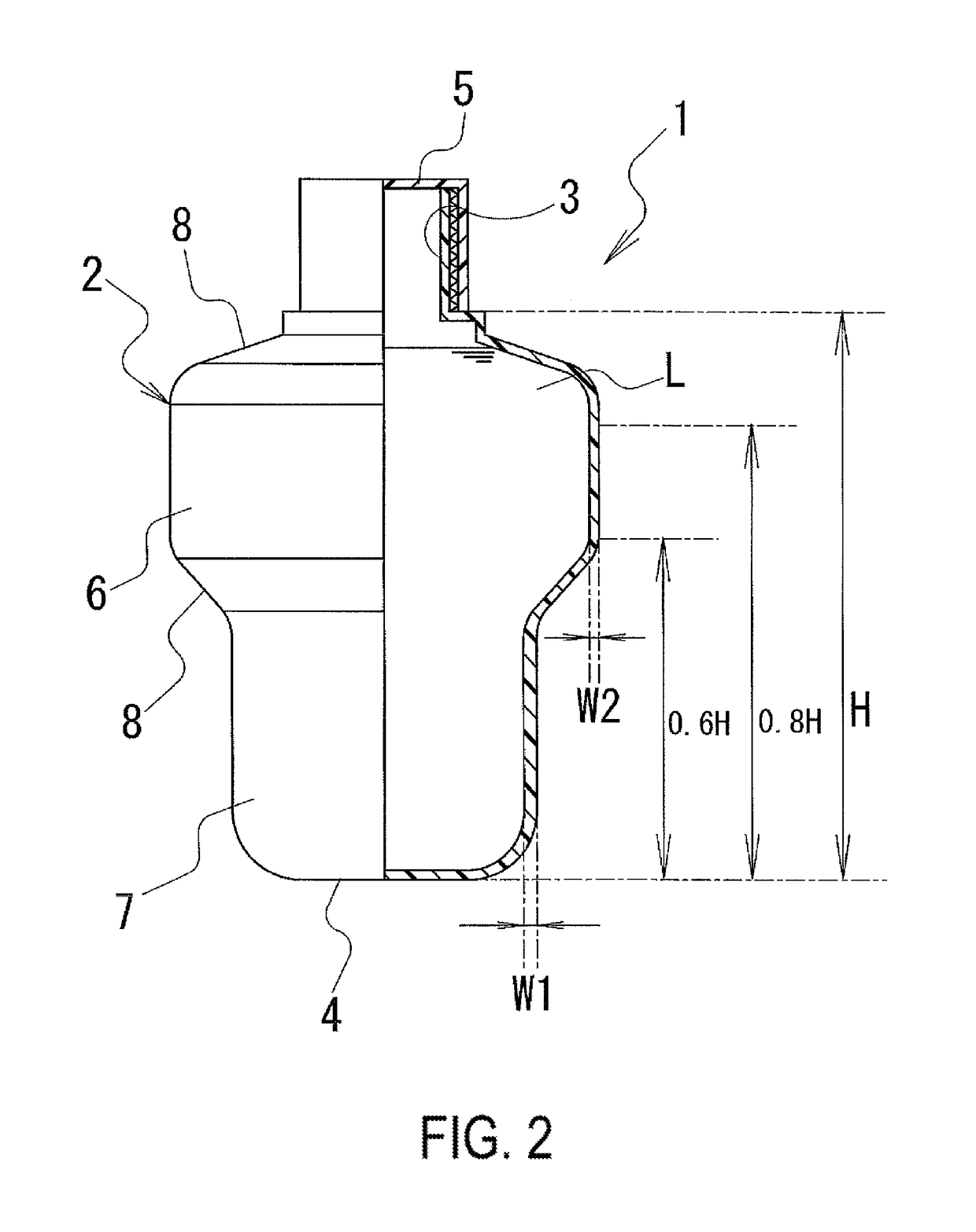

Recessed part forming instillation container

InactiveUS6875201B1Reduce manufacturing costLittle strengthBottlesLarge containersHollow cylinderEngineering

In an eye drops container, a barrel portion 2 in the form of a flexible hollow cylinder defines a dent portion 7 which can be gripped with two fingers.

Owner:SANTEN PHARMA CO LTD

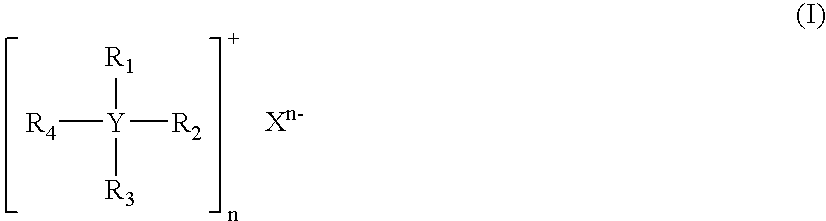

Core/shell polymer

InactiveUS20070117935A1Increase melt viscosityGood extrudabilityFibre treatmentCoatingsPolymer chemistryPolymer

Owner:THE CHEMOURS CO FC LLC

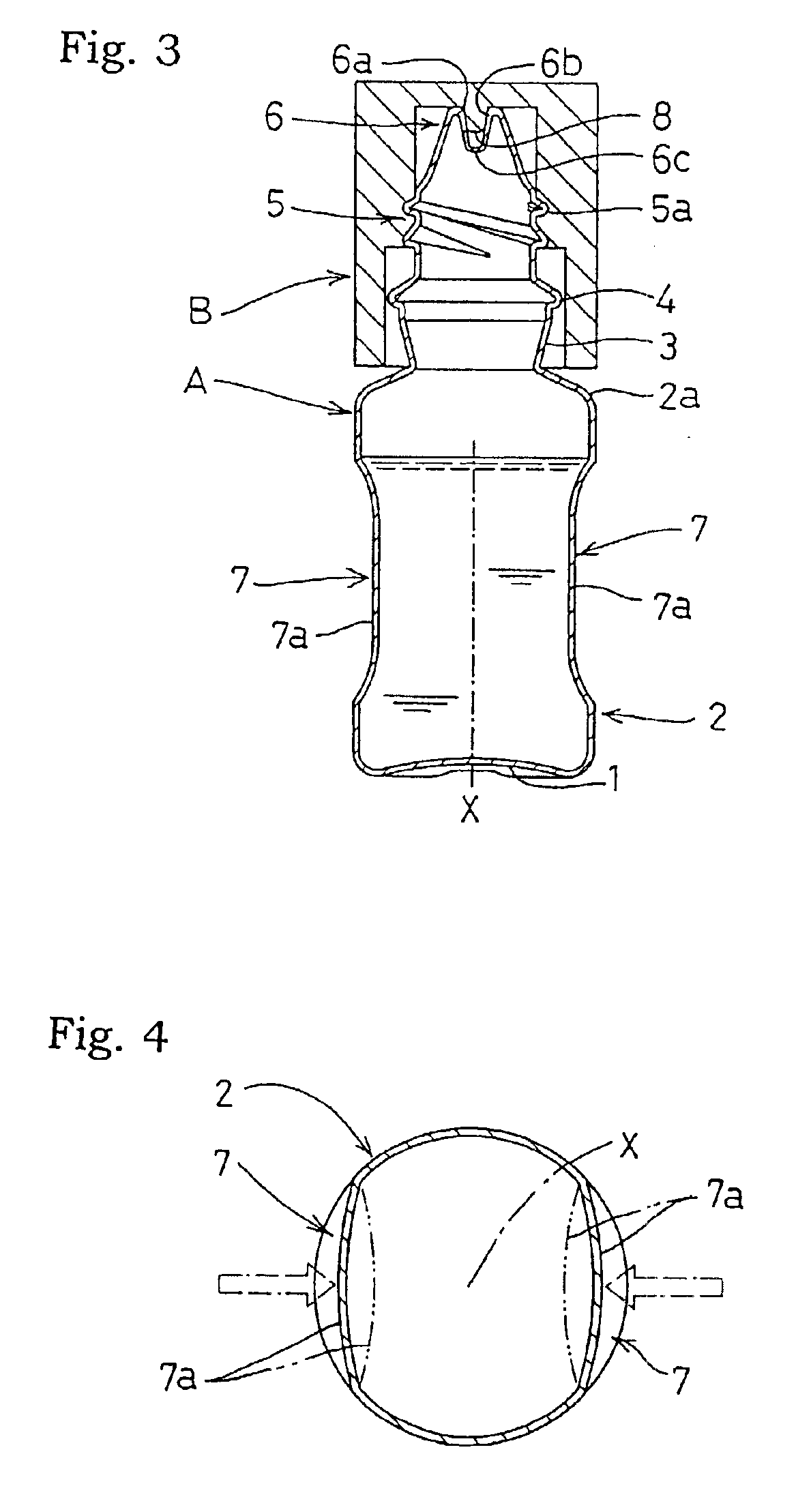

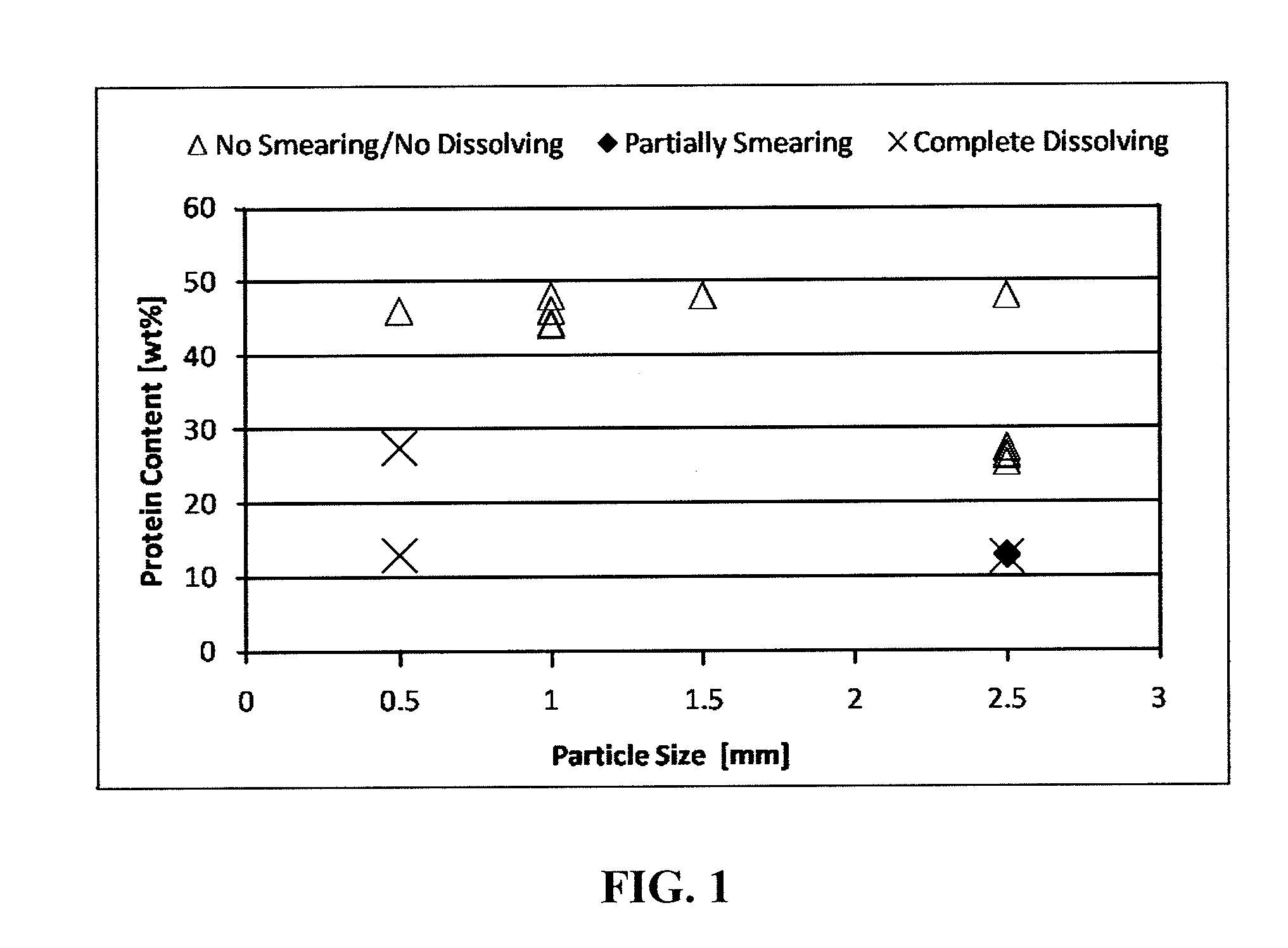

Encapsulated omega-3 fatty acids for baked goods production

InactiveUS20100310728A1Prevents substantial smearing and dissolutionHardens the encapsulated productReady-for-oven doughsDough treatmentCooking & bakingAntioxidant

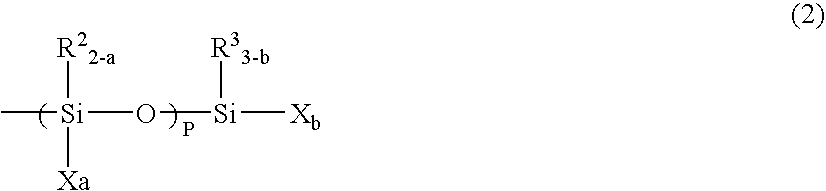

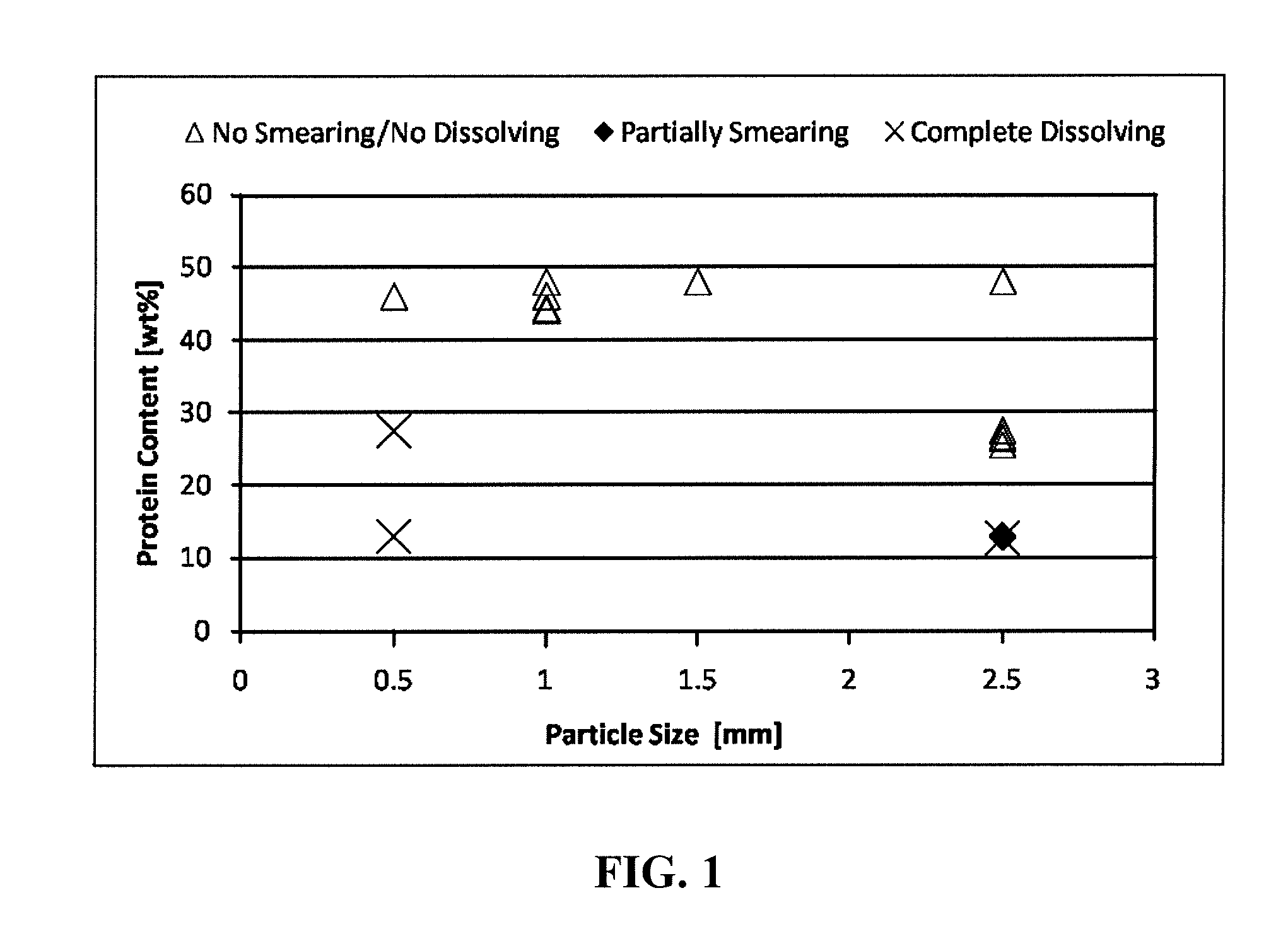

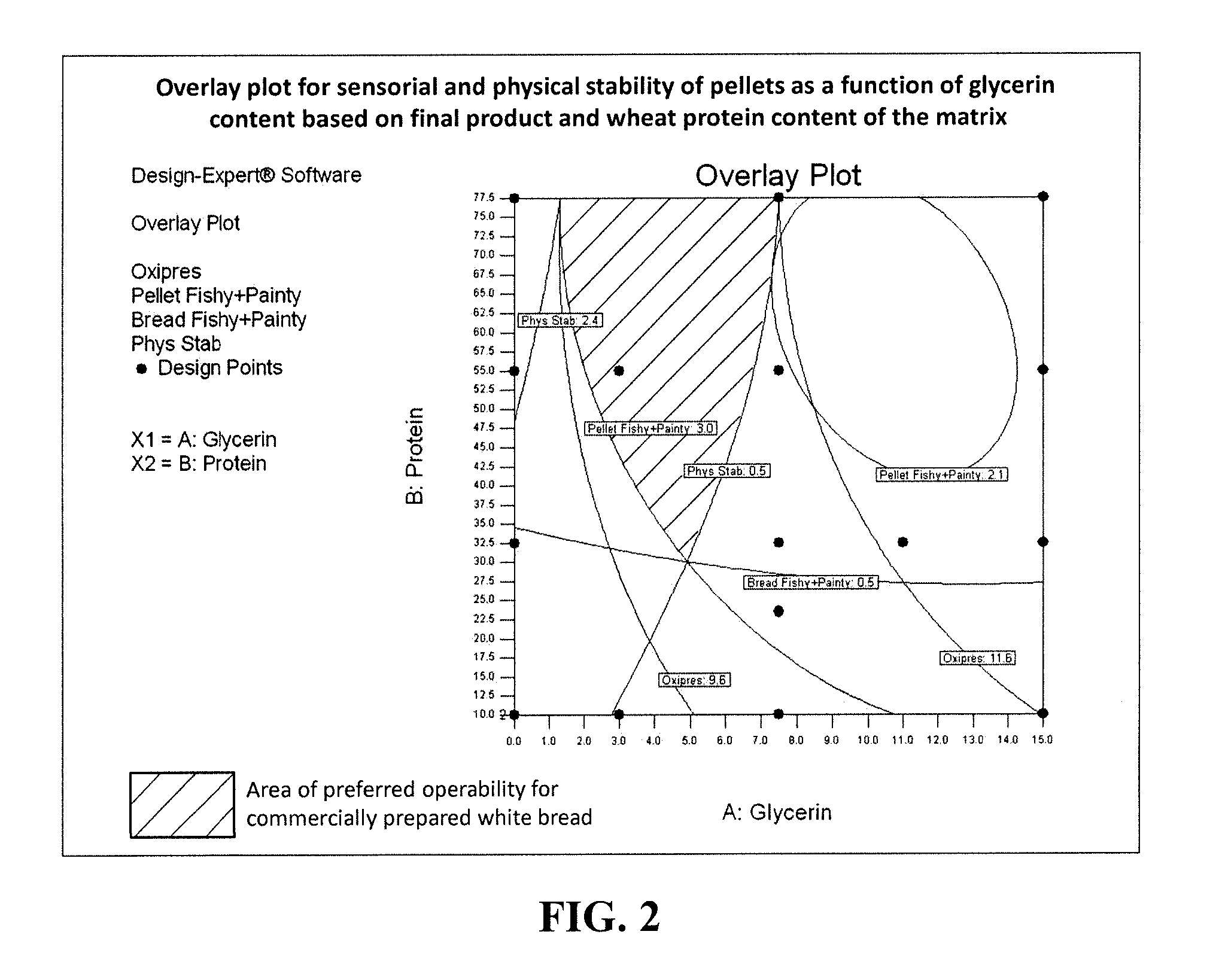

Encapsulated polyunsaturated fatty acids which can be incorporated into a baked good dough or batter without smearing or dissolution of the encapsulated product contains film-coated oil droplets encapsulated by a matrix material, a liquid plasticizer which plasticizes the matrix material, and an acidic antioxidant dispersed throughout the plasticized matrix material which helps to prevent oxidation of the polyunsaturated fatty acids; and the production of a fishy taint or malodors and mal-flavors. The matrix material includes a starch component which helps to avoid a rubbery consistency and texture and promotes extrudability, and a protein component, which hardens the encapsulated product and prevents substantial smearing and dissolution during dough or batter mixing and baking. The matrix material protein content is from about 25% to about 77.5% by weight of the matrix material. The protein content of the encapsulated product is from about 15% to about 65% by weight, of the encapsulated product.

Owner:GEN MILLS IP HLDG II

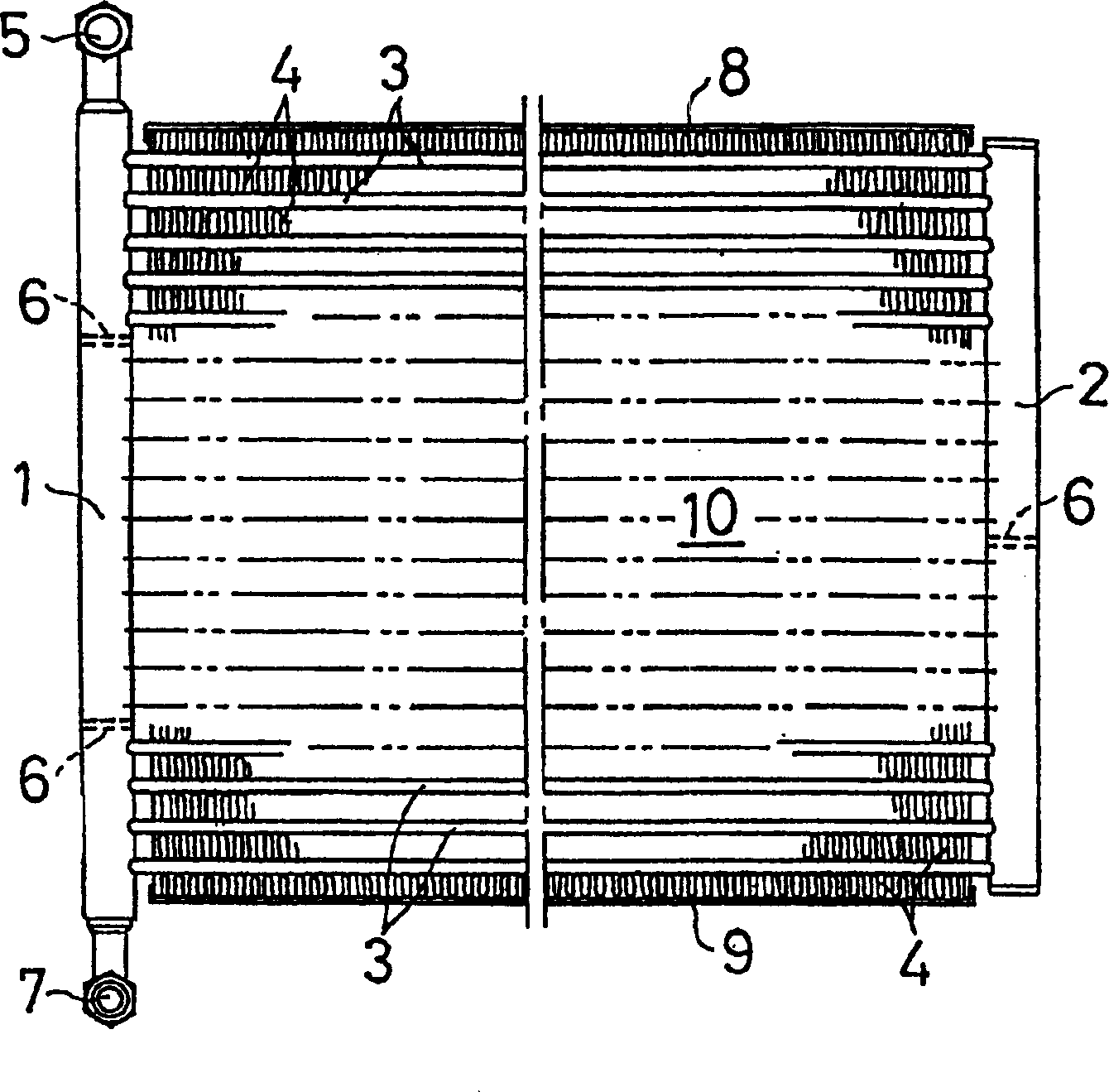

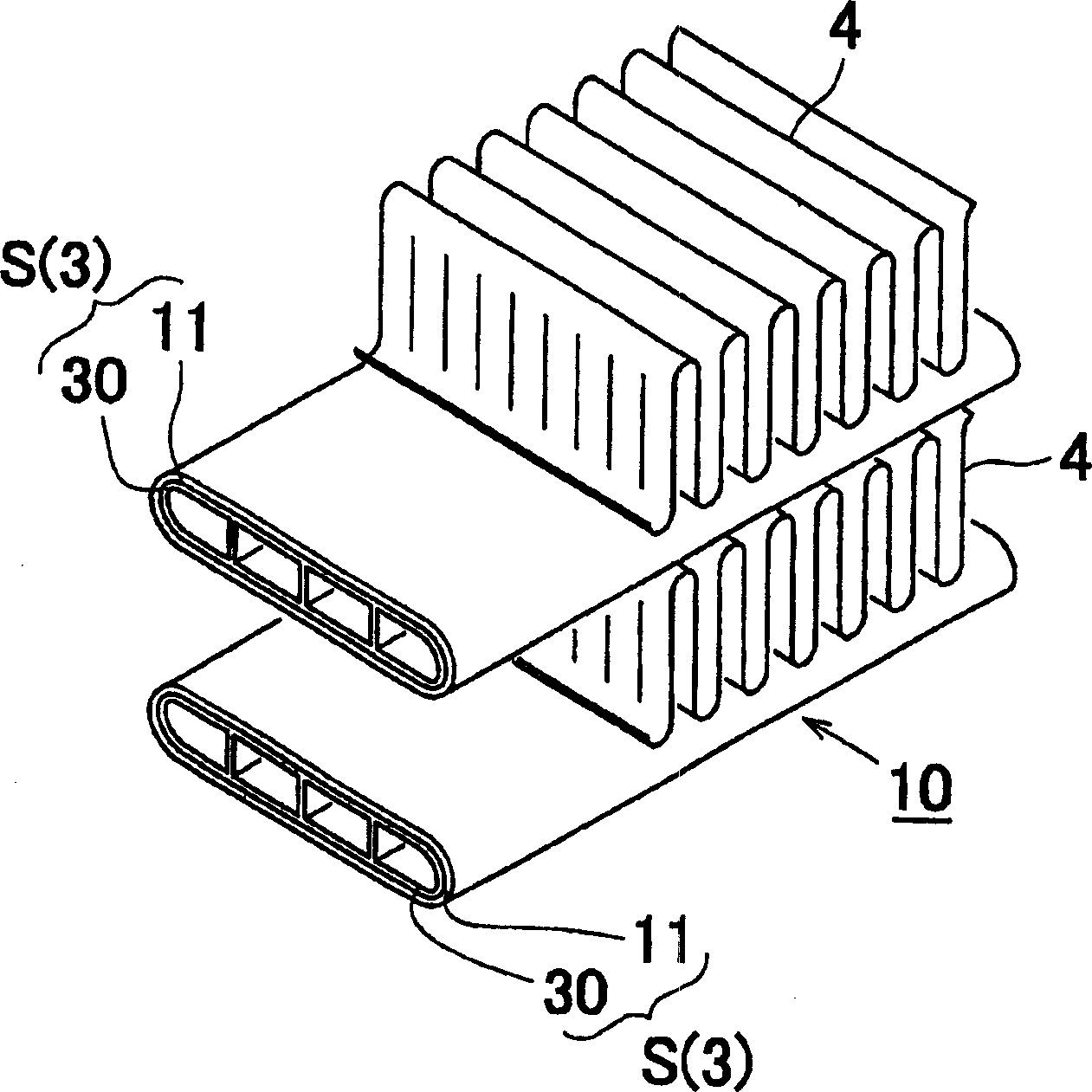

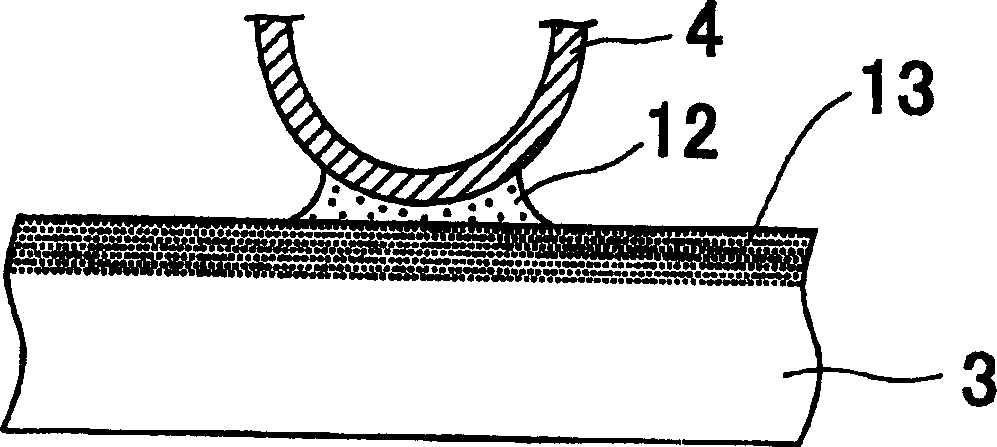

Aluminum alloy brazing material, brazing member, brazed article and brazinh method therefor using said material, brazing heat exchanging tube, heat exchanger and manufacturing method thereof using sai

InactiveCN1726114AAvoid excessive corrosionReduce the predetermined thicknessWelding/cutting media/materialsHeat exchange apparatusPlate heat exchangerImpurity

A heat exchanger 10 includes a brazing heat exchanging tube S and a fin 4. The heat exchanging tube S and the fin 4 are brazed with each other via the brazing layer 11 of the heat exchanging tube S. The brazing layer 11 is formed by spraying of a brazing material consisting of Si: 6 to 15 mass%, Zn :1 to 20 mass%, at least one of Cu: 0.3 to 0.6 mass% and Mn: 0.3 to 1. 5 mass, and the balance being aluminum and inevitable impurities.

Owner:SHOWA DENKO KK

Bone void fillers

InactiveCN103313733AEasy to keepGood extrudabilitySurgical adhesivesSkeletal disorderFiller ExcipientMedicine

A bone void filler composition containing an acidic mineral component that contains a calcium source and a phosphate source or a lower alkyl carboxylate source; an osteoinductive component that contains demineralized bone; and a three-dimensional, osteoconductive biologically acceptable carrier component that contains a collagenous material, and methods of making and using the composition, are described. The bone void filler composition may be in the form of a sponge of any desired shape or in the form of a paste or putty that is used to form a sponge or is obtained from particulated sponge, or a paste or putty that forms after a sponge is rehydrated. A pre-mixed bone void filler composition containing an acidic mineral component that contains a calcium source and a phosphate source or a lower alkyl carboxylate source; an osteoinductive component that contains demineralized bone; and a biologically acceptable carrier component that contains a liquid carrier, and methods of making and using the composition, are also described. The ratio of demineralized bone component to acidic mineral component may range from about 0.5:1 to about 80:1.

Owner:ZIMMER ORTHOBIOLOGICS

Wo2010007950

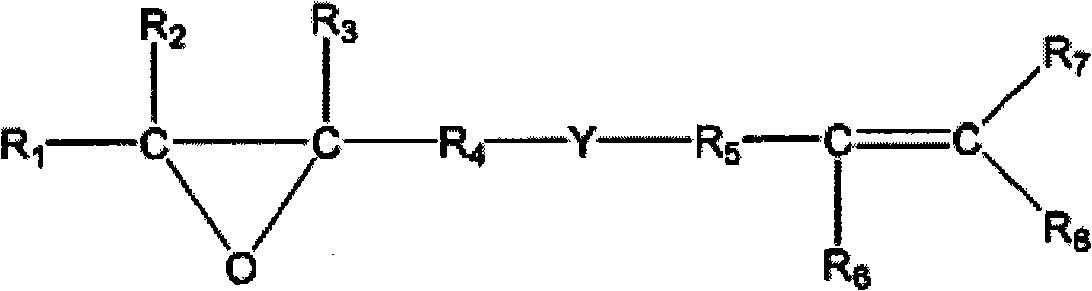

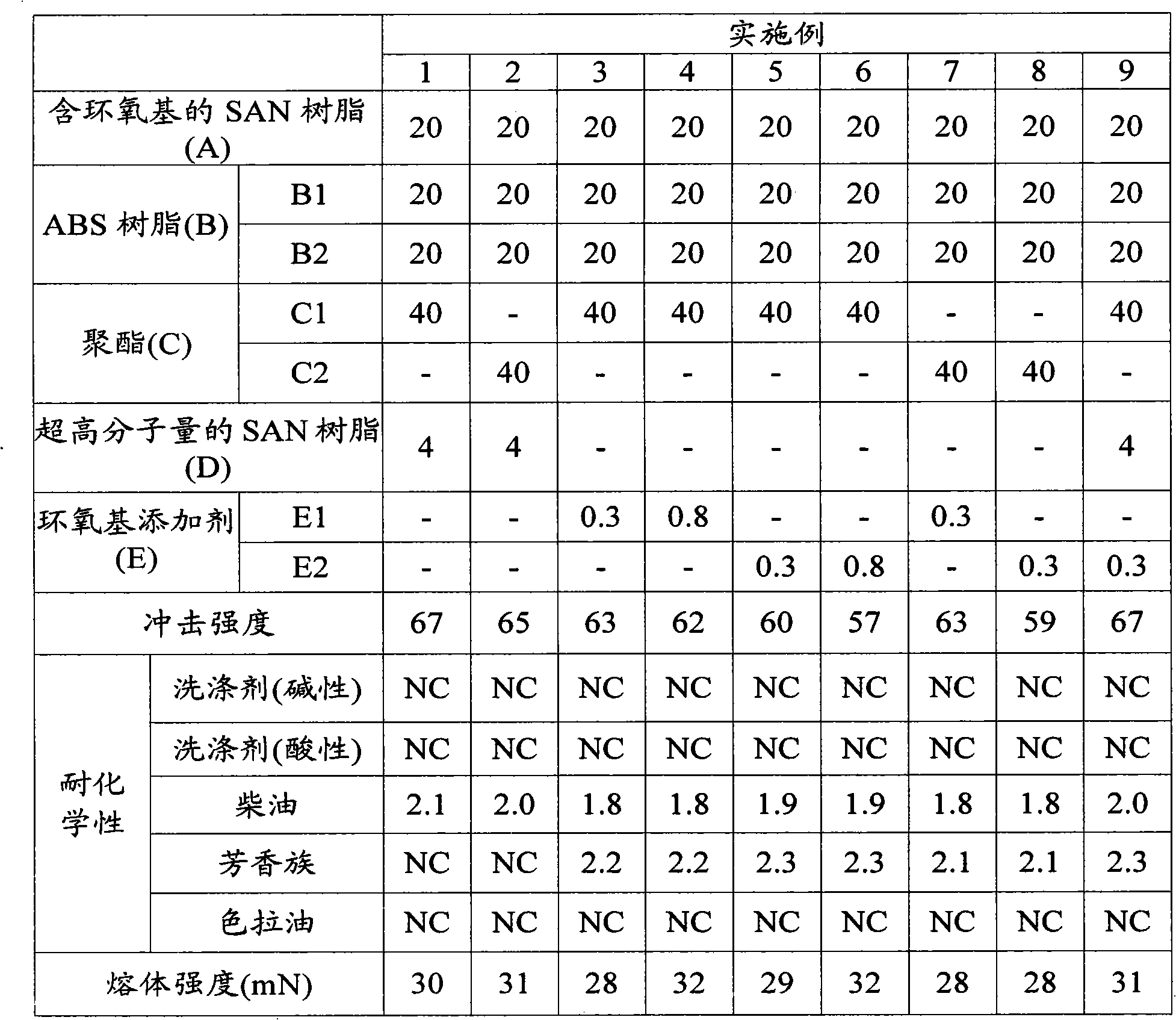

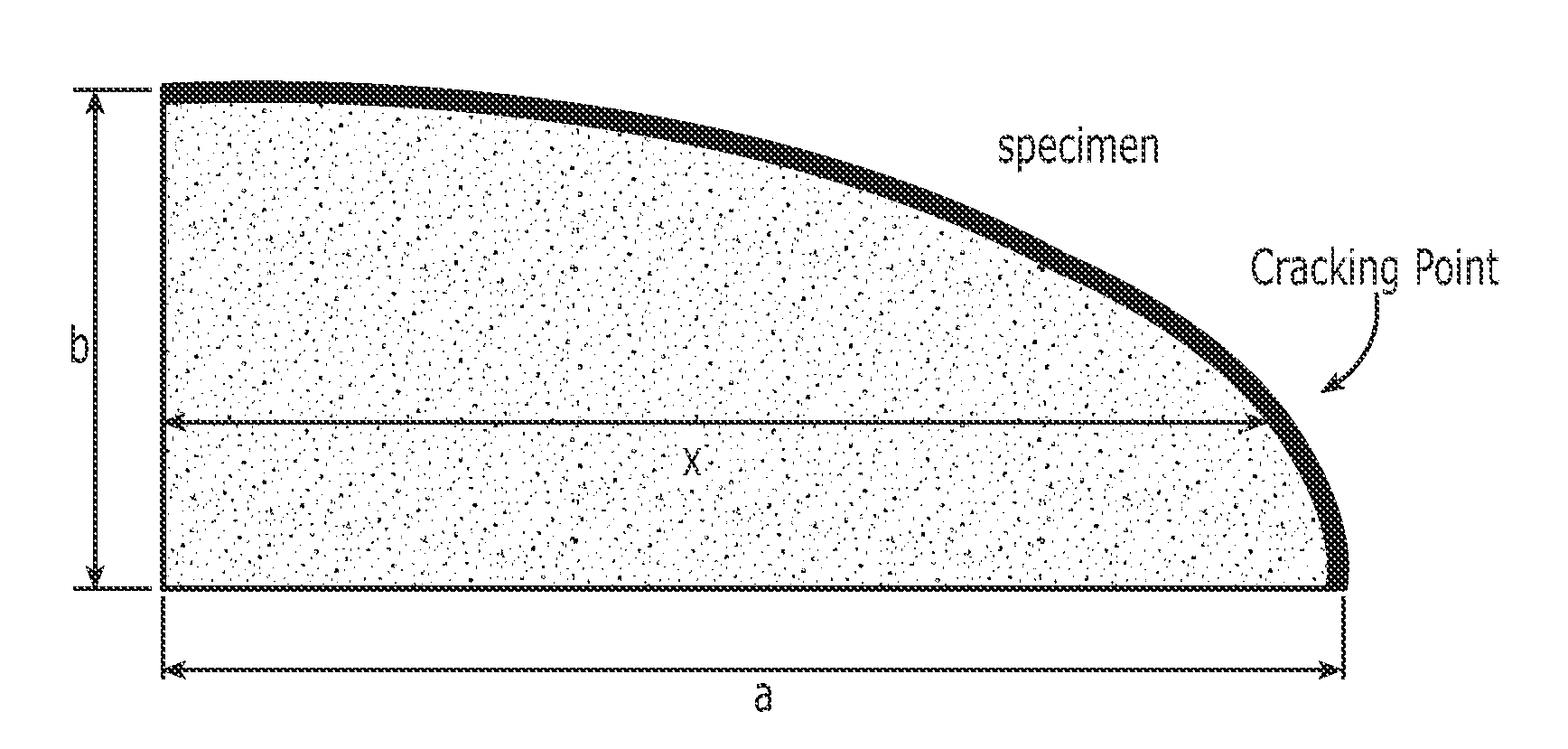

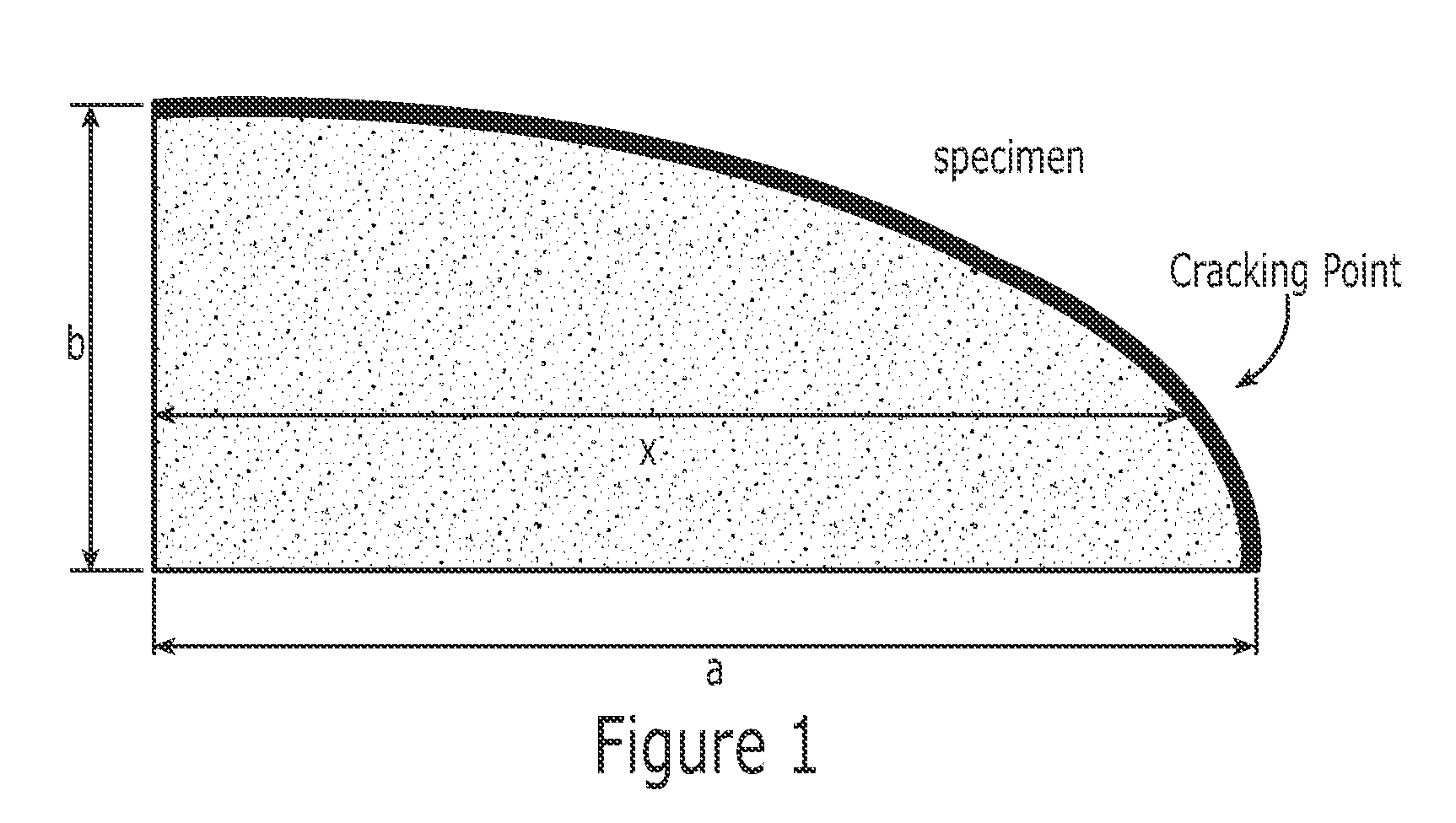

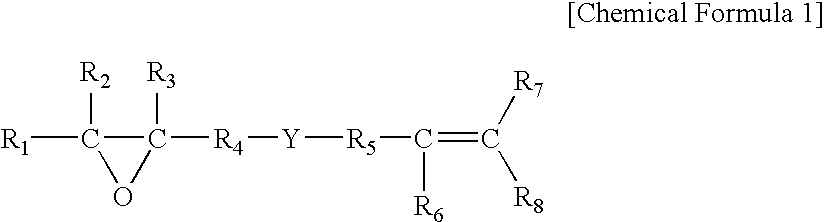

The present invention provides a chemical and impact resistant thermoplastic resin composition having improved extrudability. In one embodiment, the thermoplastic resin composition comprises (A) about 1 to about 98 % by weight of an epoxy group-containing vinyl copolymer resin; (B) about 1 to about 98 % by weight of a rubber modified styrene copolymer resin; (C) about 1 to about 98 % by weight of a polyester resin; and about 1 to about 6 parts by weight of an aromatic vinyl-vinyl cyanide copolymer resin having a weight average molecular weight of about 1,000,000 to about 5,000,000, per 100 parts by weight of a base resin comprising (A)+(B)+(C). In another embodiment, the thermoplastic resin composition comprises (A) about 1 to about 98 % by weight of an epoxy group-containing vinyl copolymer resin; (B) about 1 to about 98 % by weight of a rubber modified styrene copolymer resin; (C) about 1 to about 98 % by weight of a polyester resin; and (E) about QOl to about 1 part by weight of an epoxy-based additive, per 100 parts by weight of a base resin comprising (A)+(B)+(C).

Owner:CHEIL IND INC

Chemical and Impact Resistant Thermoplastic Resin Composition Having Improved Extrudability

The present invention provides a chemical and impact resistant thermoplastic resin composition that can have improved extrudability. In one embodiment, the thermoplastic resin composition comprises a base resin including (A) about 1 to about 98% by weight of an epoxy group-containing vinyl copolymer resin; (B) about 1 to about 98% by weight of a rubber modified styrene copolymer resin; and (C) about 1 to about 98% by weight of a polyester resin; and about 1 to about 6 parts by weight of an aromatic vinyl-vinyl cyanide copolymer resin having a weight average molecular weight of about 1,000,000 to about 5,000,000, per 100 parts by weight of the base resin comprising (A)+(B)+(C). In another embodiment, the thermoplastic resin composition comprises a base resin including (A) about 1 to about 98% by weight of an epoxy group-containing vinyl copolymer resin; (B) about 1 to about 98% by weight of a rubber modified styrene copolymer resin; and (C) about 1 to about 98% by weight of a polyester resin; and (E) about 0.01 to about 1 part by weight of an epoxy-based additive, per 100 parts by weight of the base resin comprising (A)+(B)+(C).

Owner:LOTTE ADVANCED MATERIALS CO LTD

Flame retardant polyamide resin composition and molded article

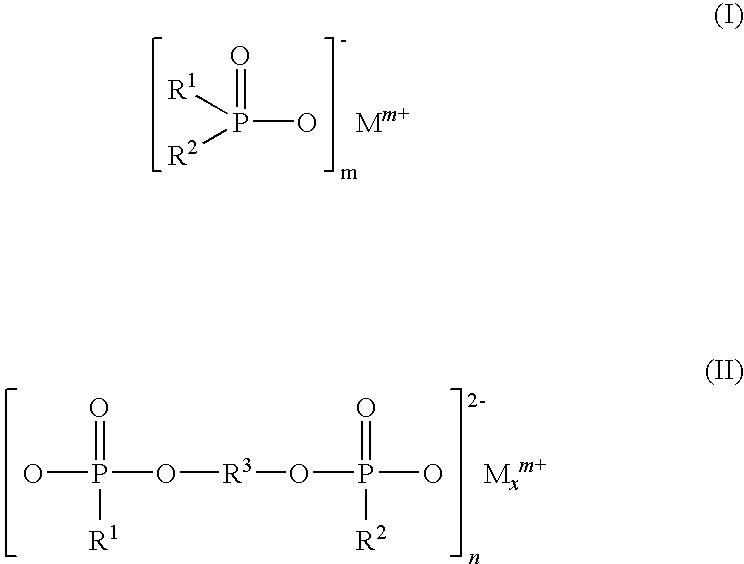

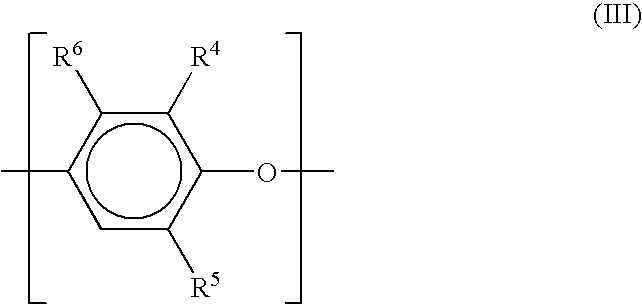

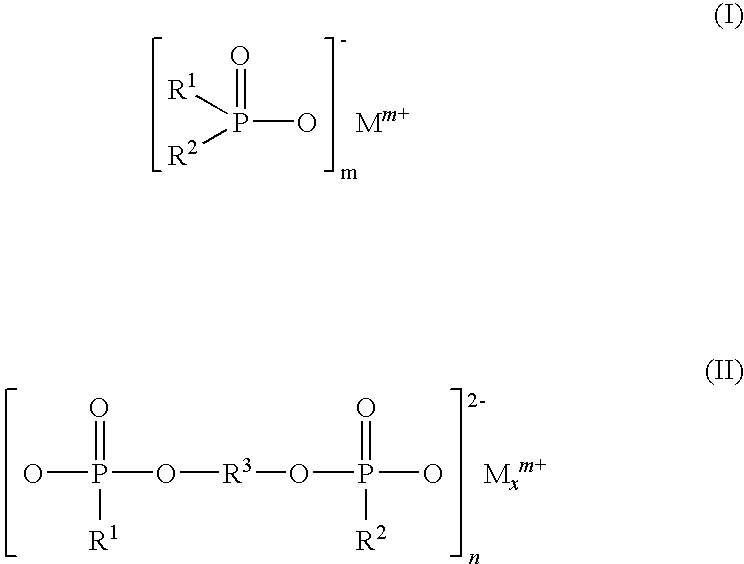

ActiveUS20090312468A1Reduce generationGood extrudabilityGroup 5/15 element organic compoundsHydrogen halidePolymer science

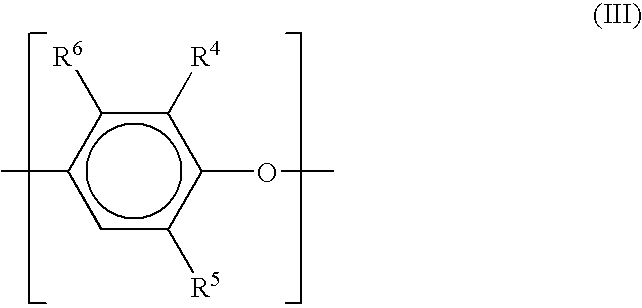

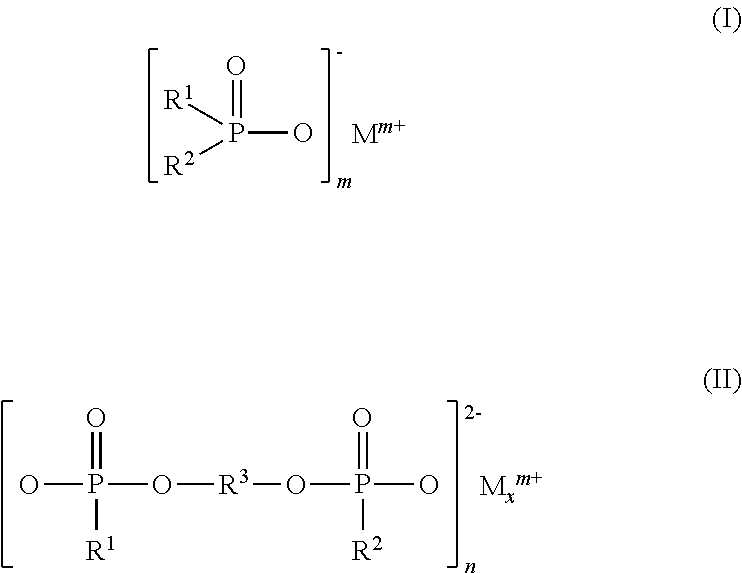

A flame retardant polyamide resin composition having excellent extrudability and moldability, being free of generating a highly corrosive hydrogen halide gas upon combustion, exhibiting very high flame retardancy, having excellent mechanical properties and electrical properties and being suited for use in electrical and electronic parts and parts for automobile electrical equipments, and a molded article thereof are provided. A polyamide resin composition comprising 100 parts by weight of an aliphatic polyamide resin (A) having a viscosity number of 70 to 200 ml / g, 0.1 to 30 parts by weight of a polyphenylene ether-based resin (B), and 5 to 100 parts by weight of flame retardant agent (C) comprising at least the following components (a), (b) and (c); (a) a reaction product of a melamine and a phosphoric acid, (b) a phosphinic acid salt and / or a diphosphinic acid salt, and (c) a metal salt of boric acid, wherein a compounding weight ratio (a):(b):(c) of the flame retardant agent components is 1:(0.5 to 2.5):(0.01 to 1).

Owner:MITSUBISHI ENG PLASTICS CORP

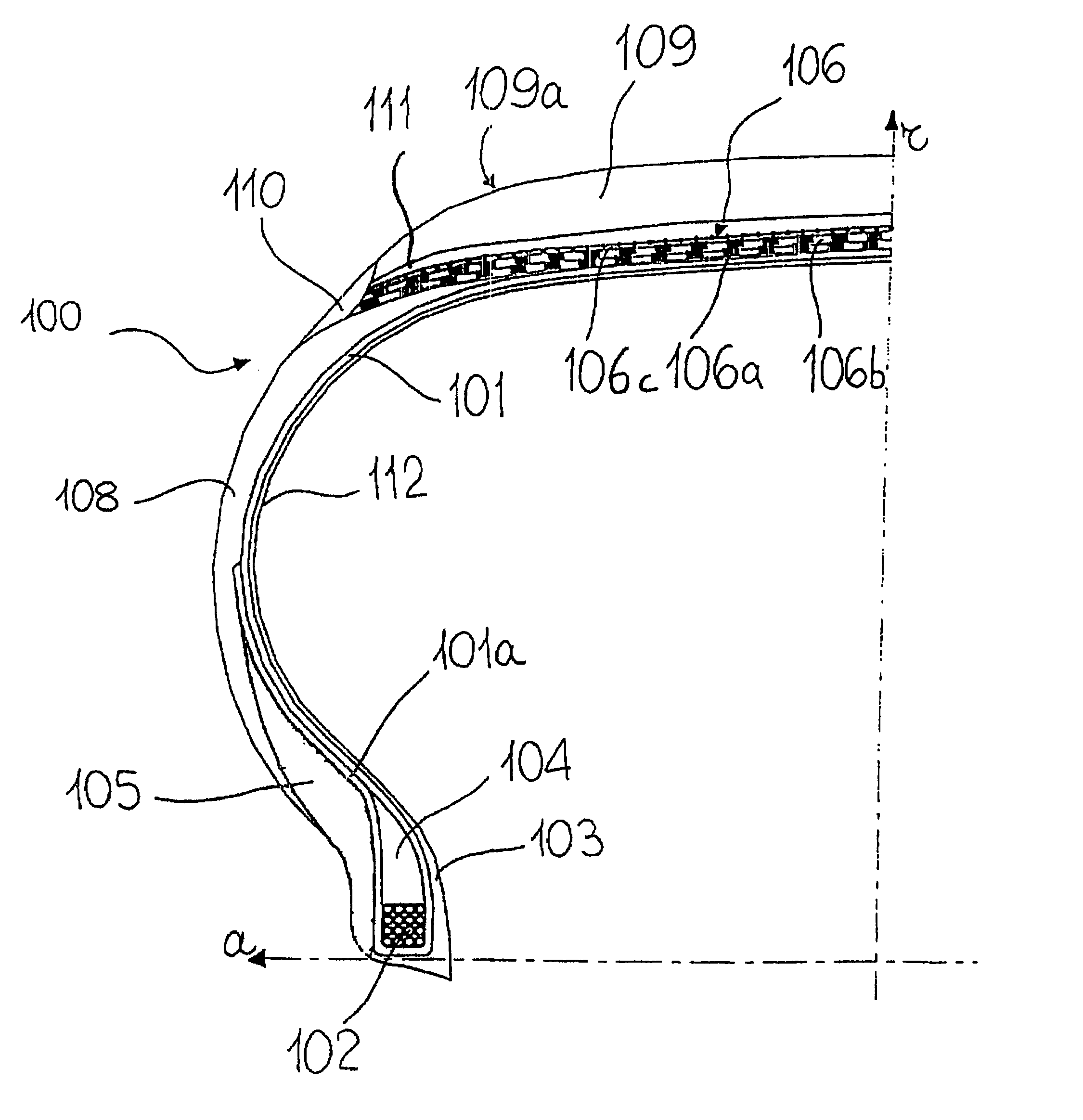

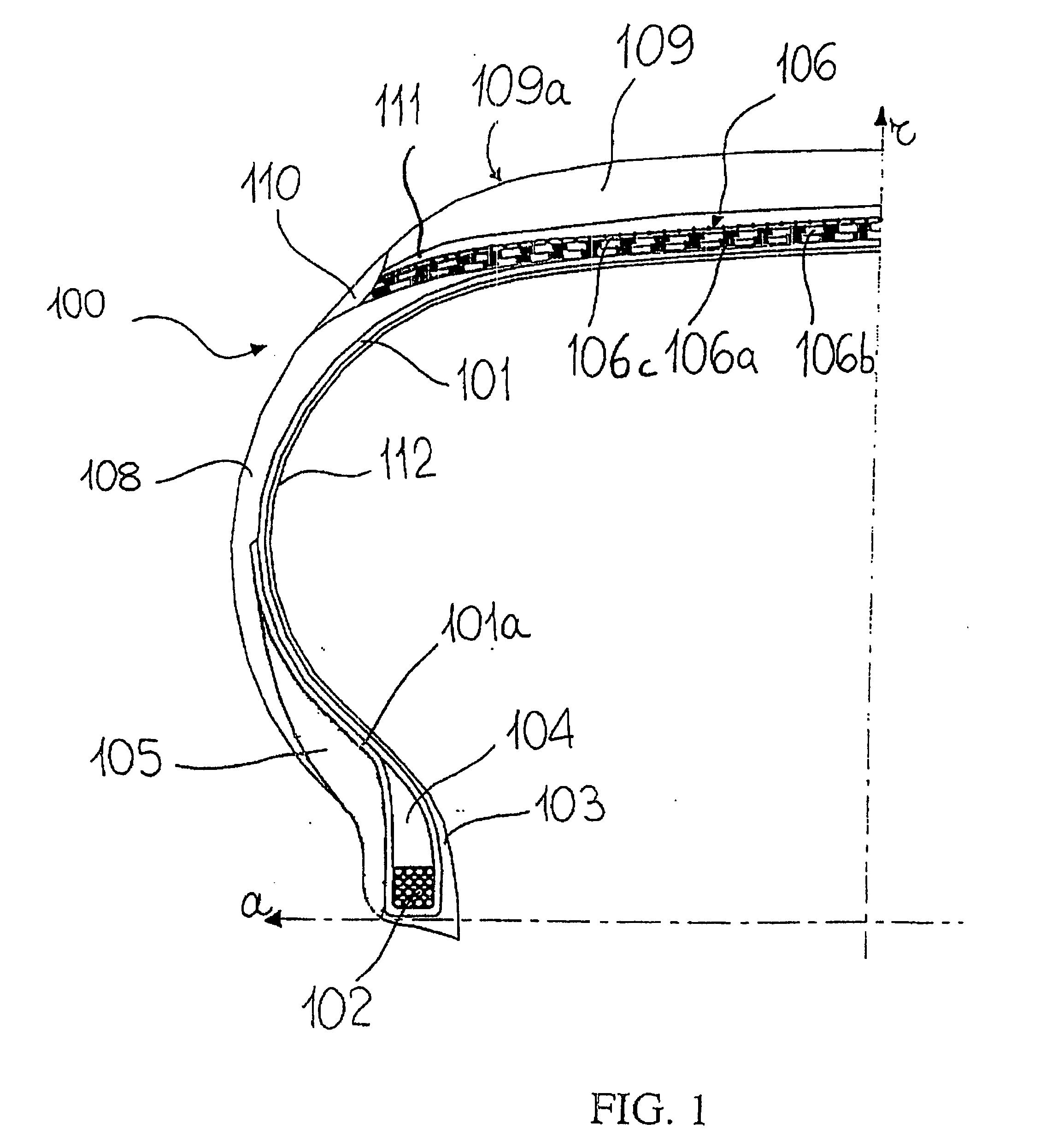

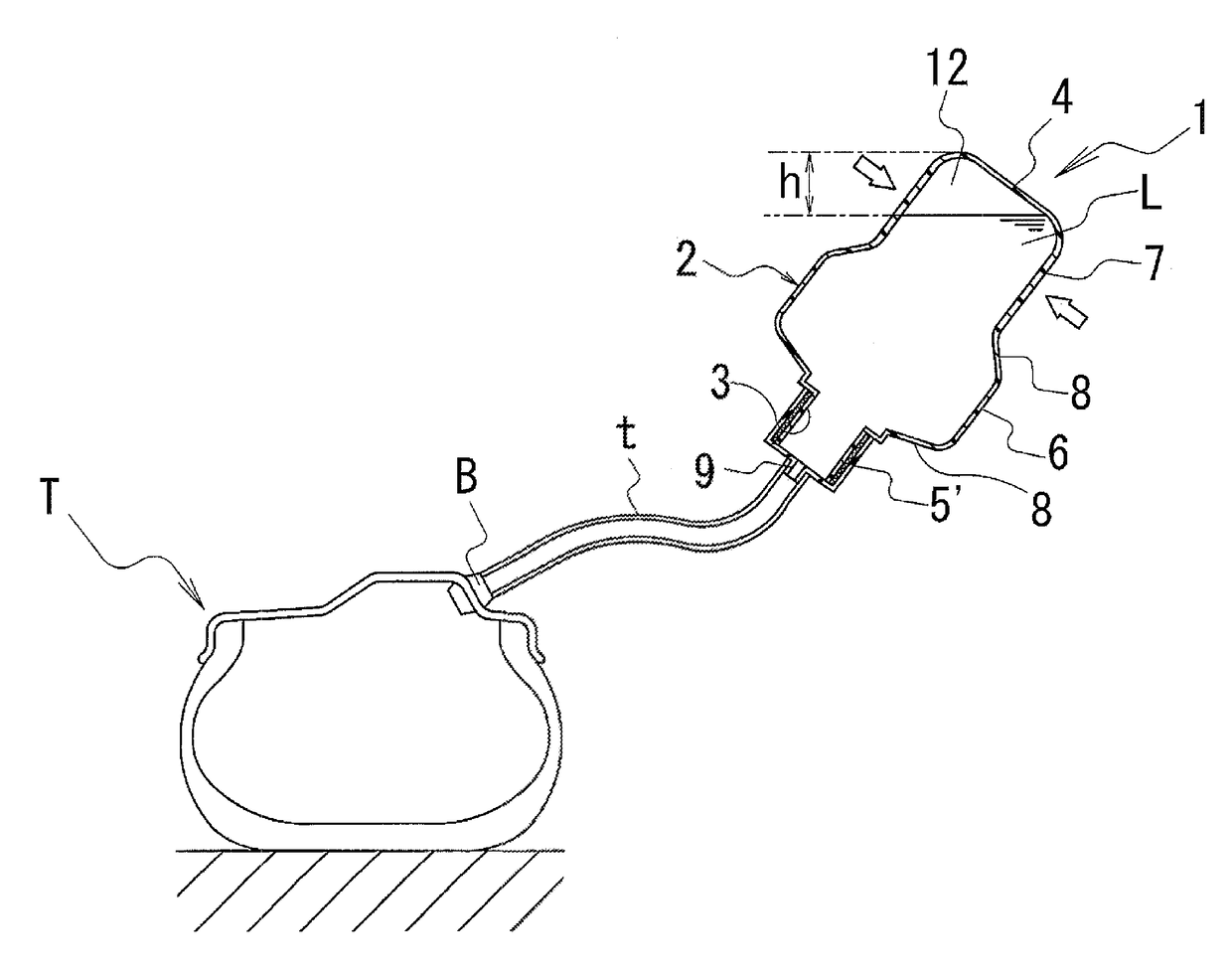

Tire and Crosslinkable Elastomeric Composition

InactiveUS20080185087A1Easy to manufactureImprove adhesionWithout separate inflatable insertsWith separate inflatable insertsElastomerEngineering

A tire, including a carcass structure, includes at least one carcass ply of a substantially toroidal shape, having opposite lateral edges associated with respective right-hand and left-hand bead structures, the bead structures including at least one bead core and at least one bead filler; a belt structure applied in a radially external position with respect to the carcass structure; a tread band radially superimposed on the belt structure; a pair of sidewalls applied laterally on opposite sides with respect to the carcass structure; and at least one layer including a crosslinked elastomeric material applied in a radially inner position with respect to the carcass structure. The crosslinked elastomeric material is obtained by crosslinking a crosslinkable elastomeric composition including (a) less than 50 phr, preferably 15 phr to 40 phr, of at least one butyl rubber; (b) not less than 50 phr, preferably 60 phr to 85 phr, of at least one polyisoprene rubber; and (c) 2 phr to 50 phr, preferably 5 phr to 35 phr, of at least one layered material. Preferably, the layer including a crosslinked elastomeric material is a tire innerliner.

Owner:PIRELLI TYRE SPA

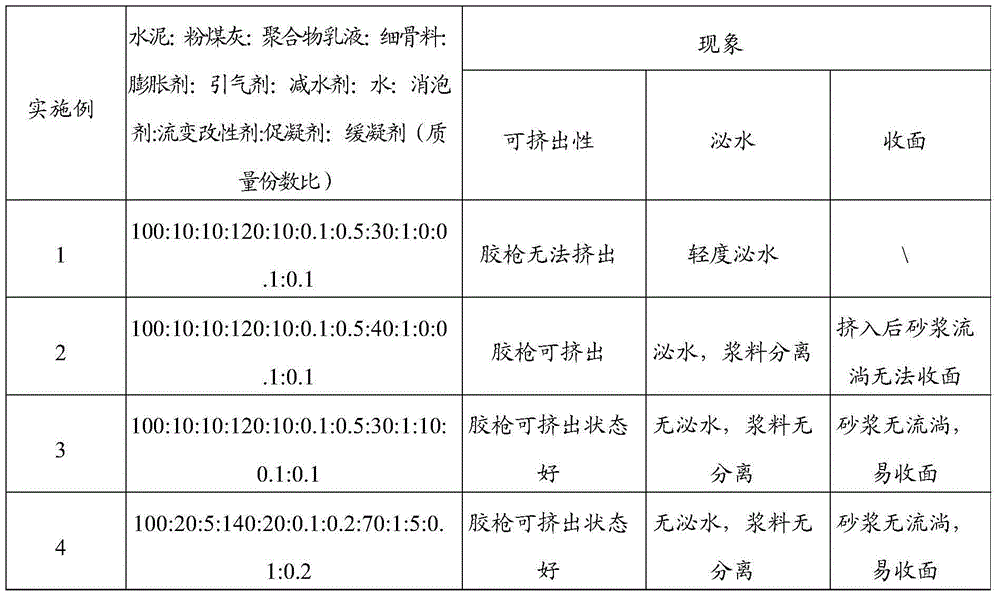

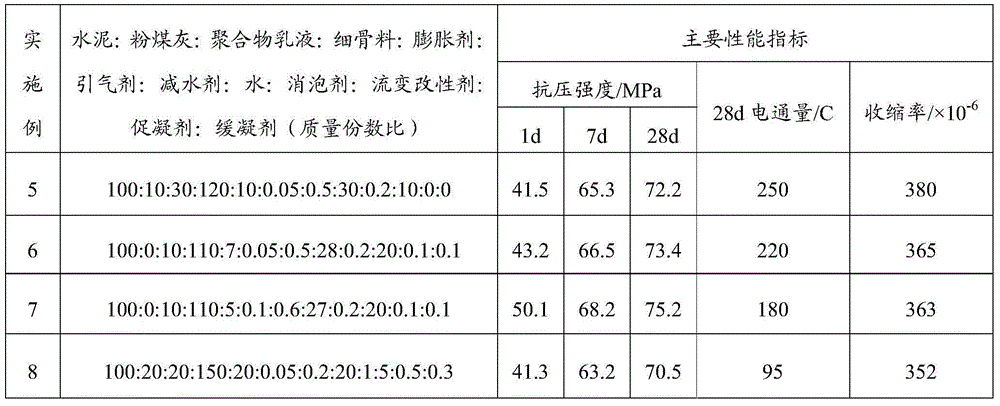

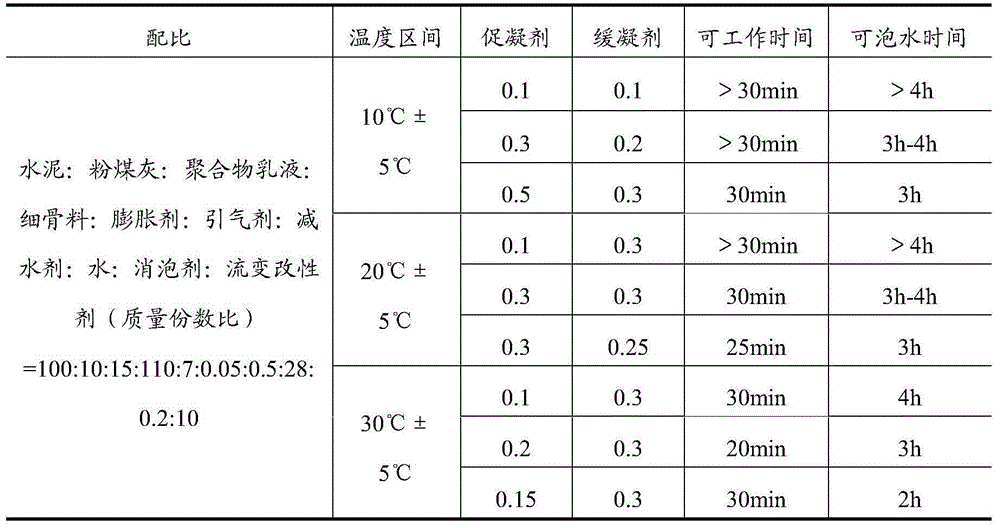

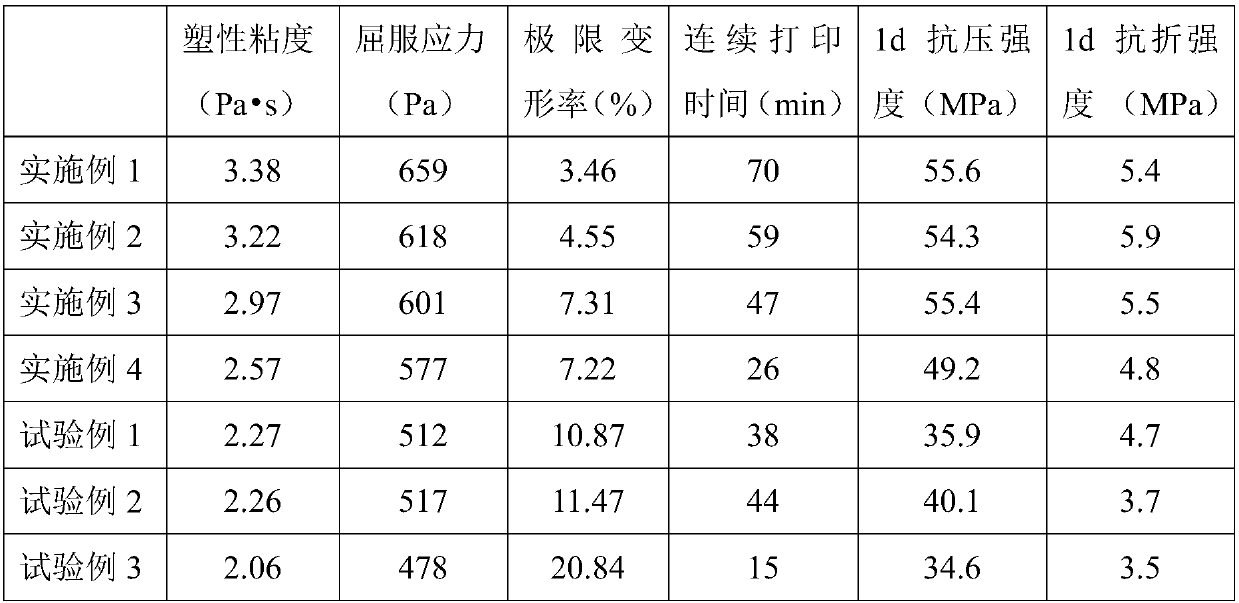

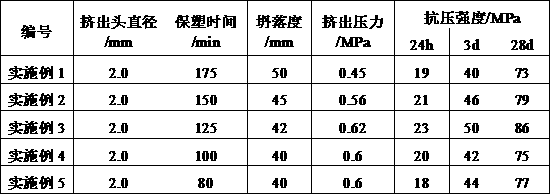

Track board sealing anchor mortar and preparation method thereof

The invention provides track board sealing anchor mortar and a preparation method thereof. The track board sealing anchor mortar comprises the following components in parts by weight: 100 parts of cement, 0-20 parts of coal ashes, 5-30 parts of polymer emulsion, 50-150 parts of fine aggregates, 1-20 parts of expanding agent, 0.05-0.5 part of air entraining agent, 0.2-3 parts of water reducing agent, 10-70 parts of water, 0.05-1 part of antifoaming agent, 5-20 parts of rheology modifier, 0-1 part of coagulant and 0-1 part of retarder. The mortar has excellent characteristics of extrudability, easiness in surface finishing, high construction efficiency, compaction, permeability resistance, durability and freezing resistance.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +2

Composition for wire coating material, insulated wire, and wiring harness

InactiveUS20130273367A1Improve heat resistanceGood peeling effectOrganic chemistryPlastic/resin/waxes insulatorsPolymer sciencePtru catalyst

To provide a composition for a wire coating material, requiring no electron irradiation crosslinking and a less filler, that can produce a crosslinked coat having a high heat resistance, gel fraction and peel property at high temperature, and provide an insulated wire, and a wiring harness. A wire coating material composition contains (A) silane-grafted polyolefin, (B) undenatured polyolefin, (C) functional-group modified polyolefin modified by functional groups of a carboxylic acid group, an acid anhydride group, an amino group and an epoxy group, (D) a bromine flame retardant having a phthalimide structure or the flame retardant and an antimony trioxide, (E) a crosslinking catalyst batch containing a resin containing a crosslinking catalyst, and (F) a zinc oxide and an imidazole compound or a zinc sulfide, (G) a triazine hindered phenolic antioxidant having a melting point of 150 degrees C. or more, and (H) a triazole derivative or a hydrazide metal deactivator.

Owner:AUTONETWORKS TECH LTD +2

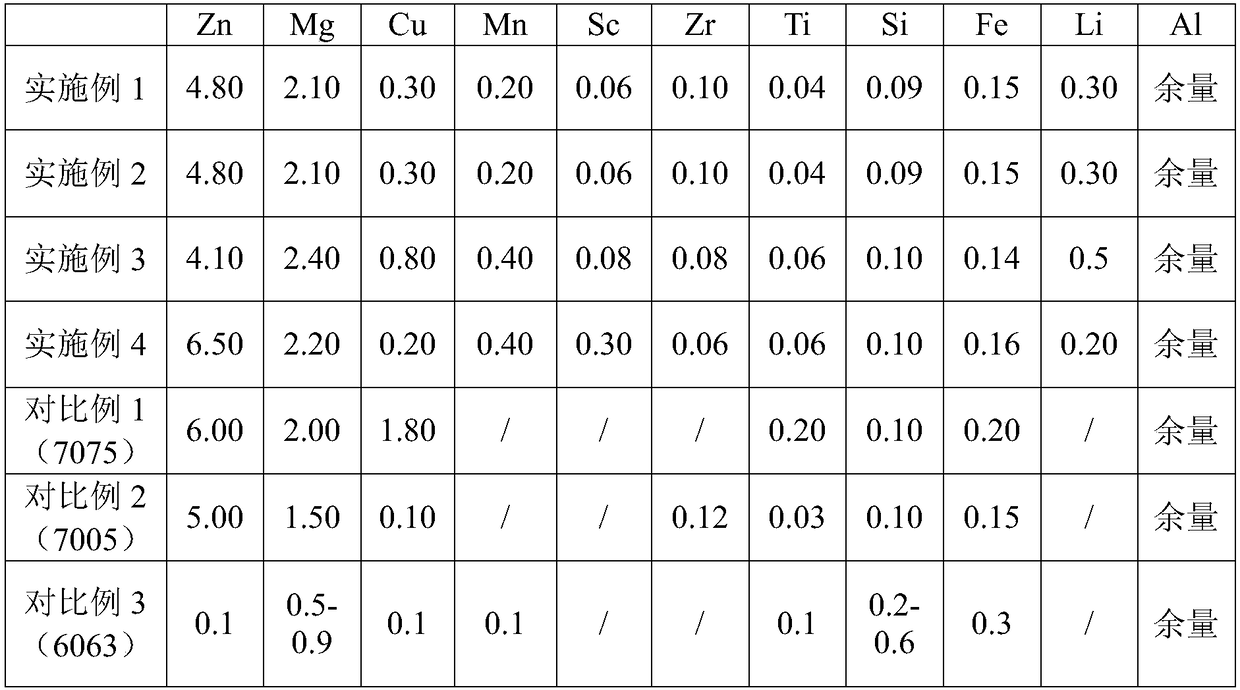

Al-Zn-Mg series aluminum alloy profile material and preparing method thereof

The invention provides an Al-Zn-Mg series aluminum alloy profile material and a preparing method thereof. Aluminum alloy comprises the following components in a percent by mass: 4.5-5.8% of Zn, 1.8-2.5% of Mg, 0.3-0.8% of Cu, 0.1-0.5% of Li, 0.05-0.2% of Zr, 0.03-0.3% of Sc, 0.2-0.4% of Mn, 0.03-0.06% of Ti and the balance of Al and unavoidable impurities, wherein the mass ratio of Zn to Mg is 1.8-3.2. The aluminum alloy obtained by the application has excellent comprehensive properties. After heat treatment, the tensile strength (Rm) of the aluminum alloy is 500-560MPa, the yield strength (Rp0.2) is 450-520MPa, and the elongation after fracture (As) is 10-17%; and at the same time, the weldability, the extrudable processability and the corrosion resistance are all great.

Owner:HUNAN ORIENTAL SCANDIUM

Desulfurized gypsum 3D (three dimensional) printing alkali-activated cementing material and use method thereof

ActiveCN109678445ARegulating the rate of setting and hardeningImprove mechanical propertiesAdditive manufacturing apparatusSolid componentAlkali activated

The invention belongs to the field of 3D (three dimensional) printing building materials and particularly relates to a desulfurized gypsum 3D printing alkali-activated cementing material and a use method thereof. The alkali-activated cementing material is prepared from a solid component and a liquid component which are separately stored, wherein, in parts by weight, the solid component comprises 40 to 60 parts of slag, 20 to 50 parts of desulfurized gypsum, 0.02 to 0.05 part of an activator, 3 to 10 parts of attapulgite clay, 0.1 to 0.5 part of a thickening agent and 1 to 5 parts of water absorbent resin; the liquid component comprises 20 to 40 parts of water. According to the invention, the desulfurized gypsum is taken as a main raw material; the extrusion requirements necessary for 3D printing are met by adding an admixture to synergistically regulate the setting and hardening rate and rheological property of the alkali-activated cementing material. The desulfurized gypsum can be recycled, and the use amount of the slag is reduced, so that the cost is reduced; in addition, the alkali-activated cementing material can be applied to 3D printing on a large scale to develop high-efficiency and green building materials.

Owner:UNIV OF JINAN

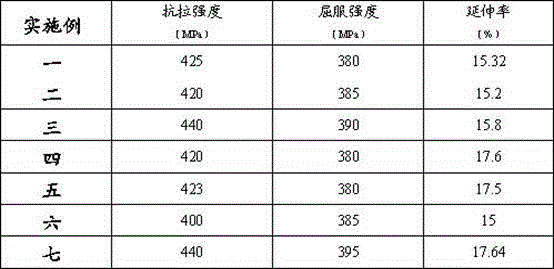

High-strength alloy with excellent extruding property

The invention discloses a high-strength alloy with excellent extruding property. The high-strength alloy is characterized by comprising the following components in percentage by weight: not more than 0.15% of silicon, not more than 0.3% of iron, 0.45%-0.7% of copper, not more than 0.1% of manganese, 0.8%-1.5% of magnesium, 0.05%-0.25% of chrome, 5.0%-6.5% of zinc, not more than 0.1% of titanium, 0.05%-0.1% of zirconium and the balance of aluminum and impurities of which the content is not more than 0.1%, wherein the content of a single component in the impurities is not more than 0.03%; the ratio of copper to magnesium is controlled to 100 : (114-333); and the ratio of magnesium to zinc is controlled to 100 : (333-813). The high-strength alloy is excellent in extruding property; the tensile strength is greater than or equal to 400MPa; the yield strength is greater than or equal to 380MPa; the ductility is greater than or equal to 15%; the high-strength alloy is easily to extrude and process when applied to a hinge, and is free of cracking in cold working and molding; and the whole ladder load test after the alloy is assembled into a whole ladder can smoothly pass.

Owner:苏州莱恩精工合金股份有限公司

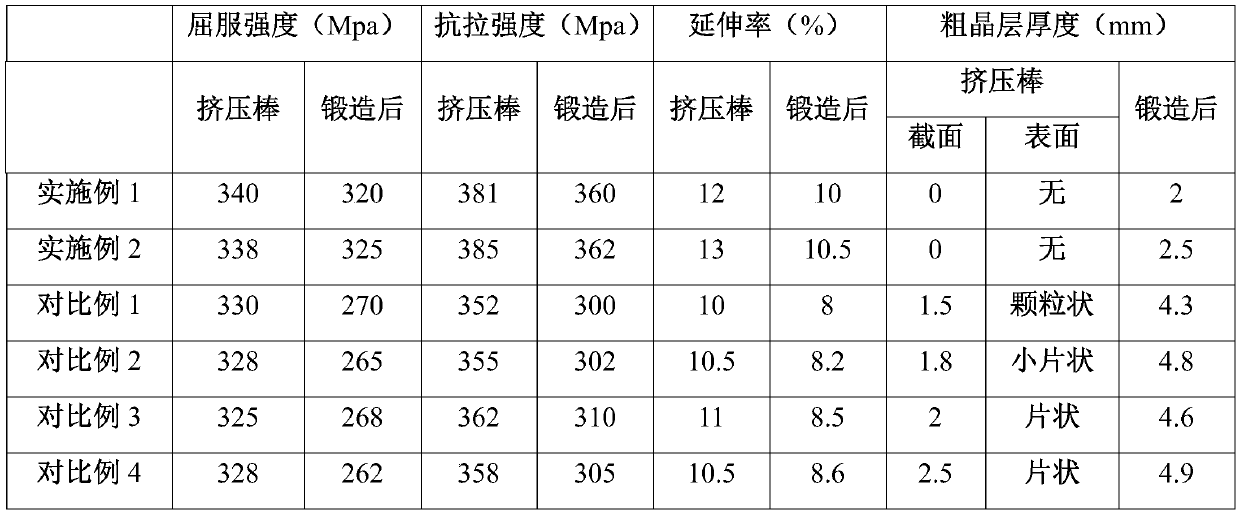

Technology capable of reducing generation of coarse grains on surface of vehicle extrusion-forged bar

InactiveCN110983216AImprove mechanical propertiesRaise the recrystallization temperatureExtrusion diesExtrusion control devicesIngotUltimate tensile strength

The invention belongs to the field of aluminum alloy production technologies, and relates to a technology capable of reducing generation of coarse grains on the surface of a vehicle extrusion-forged bar. An aluminum alloy is prepared from the raw materials in percentage by weight: 1.07-1.12% of Si, less than or equal to 0.1% of Fe, 0.01-0.04% of Cu, 0.62-0.65% of Mn, 0.88-0.93% of Mg, 0.15-0.18% of Cr, less than or equal to 0.03% of Zn, 0.02-0.05% of Ti, less than or equal to 0.03% of a single impurity, less than or equal to 0.1% of an impurity total, and the balance of Al, wherein the ratio of the Mg to the Si is 0.79-0.87. An aluminum alloy cast ingot prepared through the formula is subjected to solid solution heat treatment after extrusion, on-line water spray quenching treatment and stretch straightening, each technological parameter is controlled seriously, after an aluminum alloy extrusion bar is subjected to 545 DEG C*1 h solid solution heat treatment, the section has no the coarse grains, and the surface has no the coarse grains; and after the bar is forged, the thickness of a coarse grain layer of the section is less than or equal to 3 mm, and mechanical performance after170 DEG C*8.5 h can reach: the yield strength RP 0.2 is greater than or equal to 320 Mpa, the tensile strength Rm is greater than or equal to 360 Mpa, and the elongation percentage A is greater than or equal to 10%.

Owner:CHINA ZHONGWANG

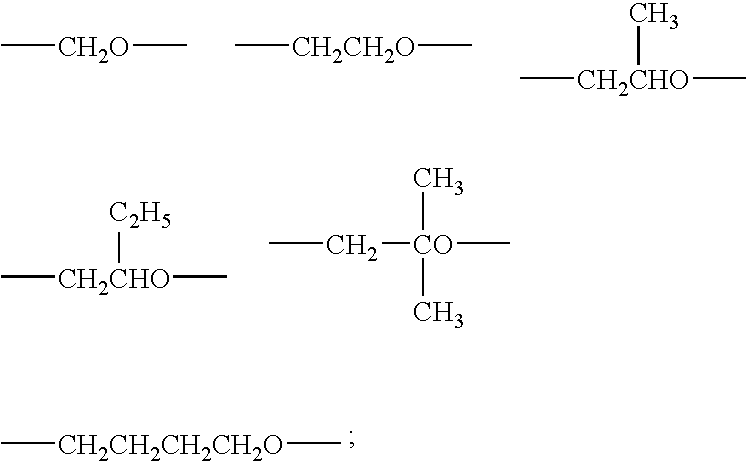

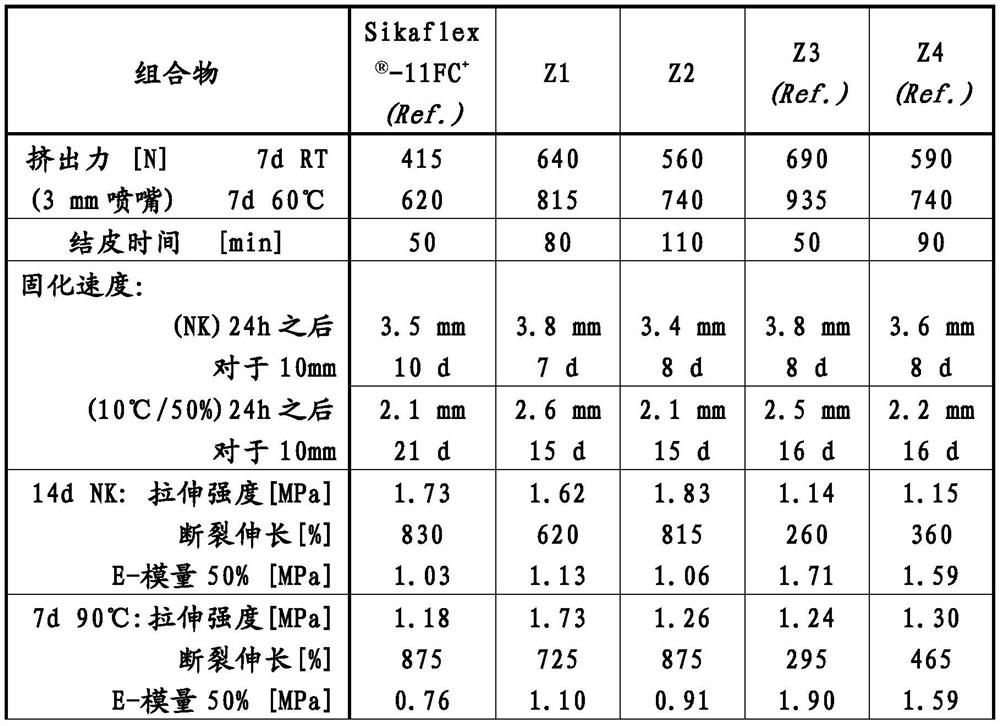

Hardening Resin Composition

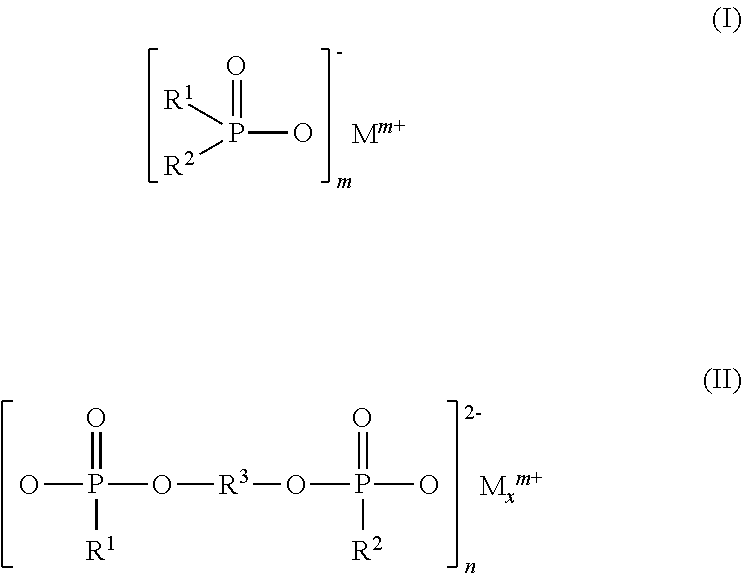

InactiveUS20070265380A1Good extrudabilityGood initial fixabilityOther chemical processesRecord information storageSilylenePlasticizer

The present invention provides a curable resin composition which comprises a reactive silyl group-containing organic polymer, is highly capable of being extruded from a cartridge and, even upon application thereof to vertical adherend surfaces, can exercise its initial fixability to fix the substrates in an instant. The present invention relates to a curable resin composition which comprises a polyoxyalkylene polymer (a) containing at least one reactive silyl group in each molecule, 5 to 50 parts by weight of a hydrocarbon-based plasticizer (b) per 100 parts by weight of (a) and 10 to 200 parts by weight of a needle crystal filler (c) on the same basis.

Owner:KANEKA CORP +1

A low-smoke pyrotechnic composition for producing colored flames

ActiveCN101679138AHigh extrudabilityGood burning rateNitrocellulose explosive compositionsPyrophoric compositionsColourantPerchlorate ion

The present invention provides a chiorine-containing pyrotechnic composition which is substantially free of perchlorate which composition comprises a nitrocellulose which is derived from a fibrous nitrocellulose starting material that has at least partially been dissolved during the process of preparing the pyrotechnic composition, and a colourant. The invention further provides a firework article comprising said pyrotechnic composition, and a method for preparing the same.

Owner:CLEARSPARK

Encapsulated Omega-3 Fatty Acids for Baked Goods Production

InactiveUS20160165931A1Prevents substantial smearing and dissolutionHardens the encapsulated productReady-for-oven doughsDough treatmentFlavorAntioxidant

Encapsulated polyunsaturated fatty acids which can be incorporated into a baked good dough or batter without smearing or dissolution of the encapsulated product contains film-coated oil droplets encapsulated by a matrix material, a liquid plasticizer which plasticizes the matrix material, and an acidic antioxidant dispersed throughout the plasticized matrix material which helps to prevent oxidation of the polyunsaturated fatty acids; and the production of a fishy taint or malodors and mal-flavors. The matrix material includes a starch component which helps to avoid a rubbery consistency and texture and promotes extrudability, and a protein component, which hardens the encapsulated product and prevents substantial smearing and dissolution during dough or batter mixing and baking. The matrix material protein content is from about 25% to about 77.5% by weight of the matrix material. The protein content of the encapsulated product is from about 15% to about 65% by weight, of the encapsulated product.

Owner:GENERAL MILLS INC

Flame retardant polyamide resin composition and molded article

ActiveUS7968629B2Reduce generationGood extrudabilityGroup 5/15 element organic compoundsHydrogen halidePhosphoric acid

A flame retardant polyamide resin composition having excellent extrudability and moldability, being free of generating a highly corrosive hydrogen halide gas upon combustion, exhibiting very high flame retardancy, having excellent mechanical properties and electrical properties and being suited for use in electrical and electronic parts and parts for automobile electrical equipments, and a molded article thereof are provided. A polyamide resin composition comprising 100 parts by weight of an aliphatic polyamide resin (A) having a viscosity number of 70 to 200 ml / g, 0.1 to 30 parts by weight of a polyphenylene ether-based resin (B), and 5 to 100 parts by weight of flame retardant agent (C) comprising at least the following components (a), (b) and (c); (a) a reaction product of a melamine and a phosphoric acid, (b) a phosphinic acid salt and / or a diphosphinic acid salt, and (c) a metal salt of boric acid, wherein a compounding weight ratio (a):(b):(c) of the flame retardant agent components is 1:(0.5 to 2.5):(0.01 to 1).

Owner:MITSUBISHI ENG PLASTICS CORP

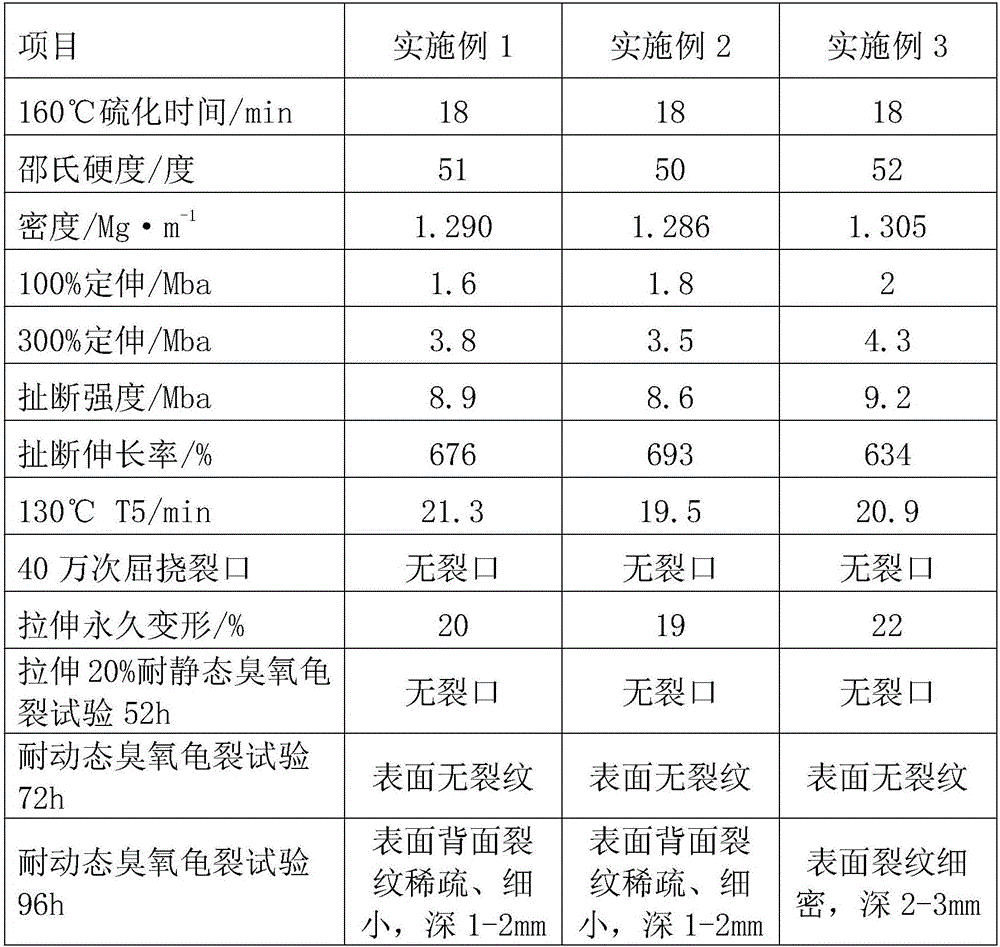

Colorful rubber composition for tire sidewall and preparation method of colorful rubber composition

The invention belongs to the technical fields of rubber tires and chemical manufacturing, and relates to a colorful rubber composition for a tire sidewall and a preparation method of the colorful rubber composition. The colorful rubber composition for the tire sidewall is prepared from the following raw material ingredients in parts by weight: 30-40 parts of natural rubber, 10-20 parts of ethylene propylene terpolymer, 45-55 parts of chlorinated butyl rubber, 1-2 parts of tackifying resin, 1.5-2.5 parts of an activating agent without carbon black, 1-2 parts of a dispersant, 0.5-1 part of a no-pollution anti-aging agent, 25-30 parts of kaolin, 30-40 parts of titanium pigment, 19-24 parts of a coloring agent, 1-1.5 parts of an accelerant, 0.4-1 part of sulphur and 0.1 part of an anti-scorching agent. In combination with a three-phase mixing process in the preparation process, the problems of low flexing resistance, low aging resistance and high color fading possibility of a colorful rubber tire sidewall in the prior art are solved. The rubber composition not only meets the requirements of tire sidewall rubber for high flexing resistance and high aging resistance, but also meets the aesthetic vision for a user to modify tire appearance.

Owner:山东新大陆橡胶科技有限公司

All-directional conductive polyurethane foam and preparation method thereof

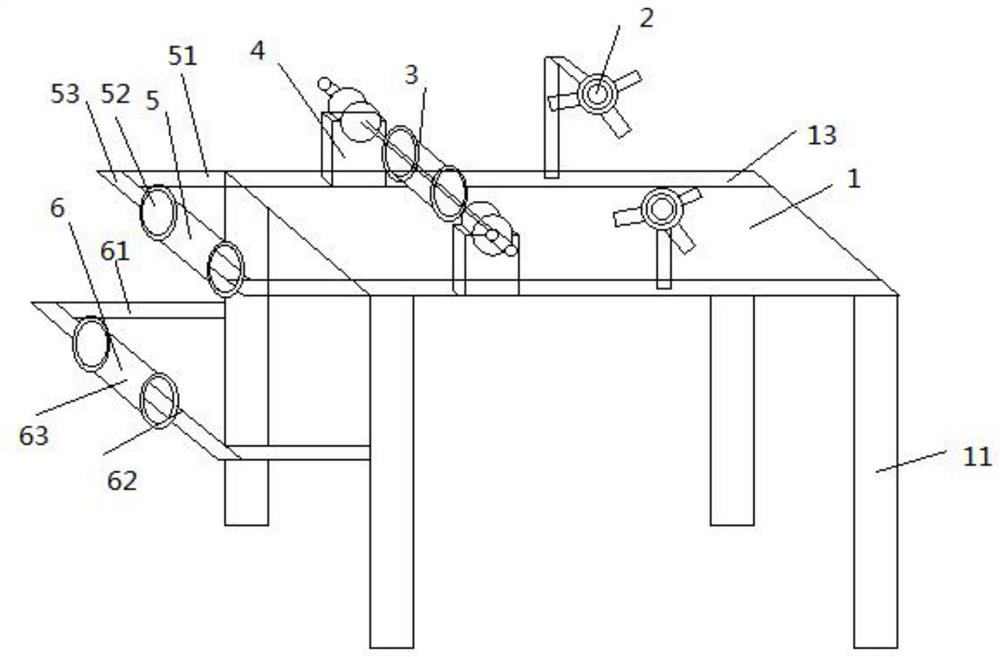

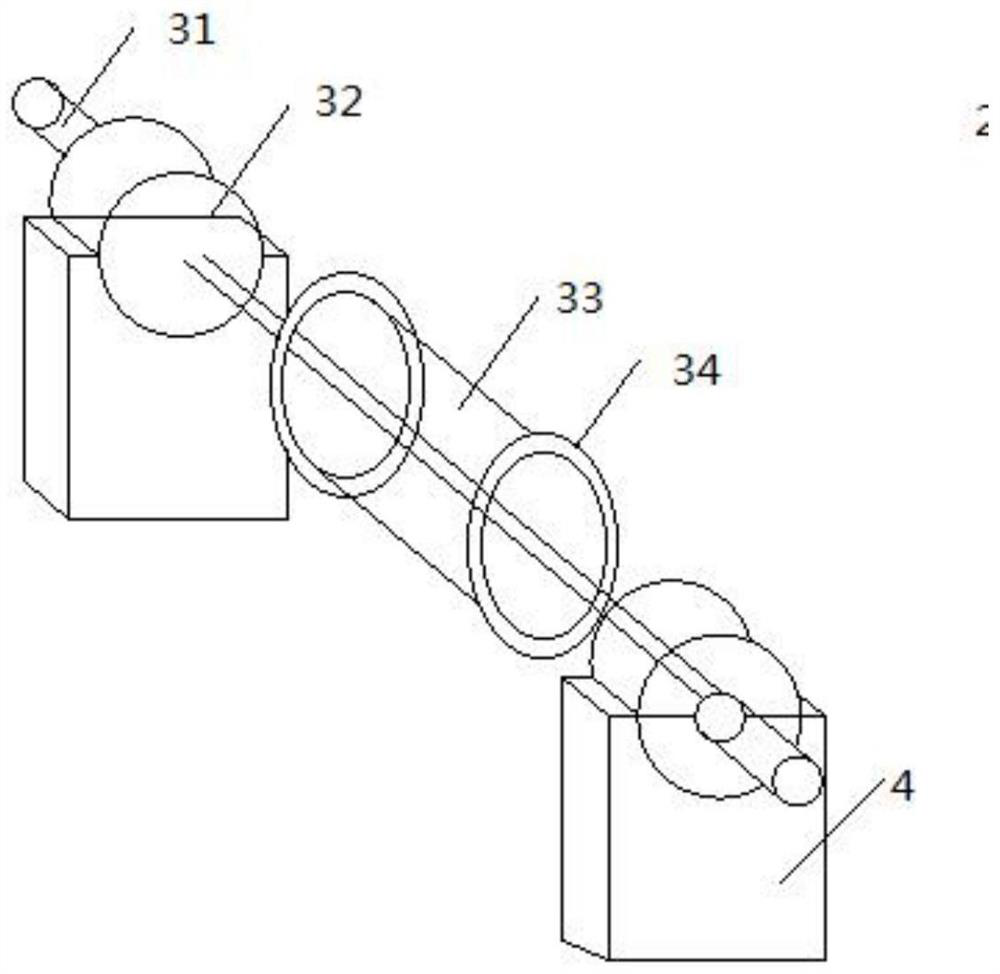

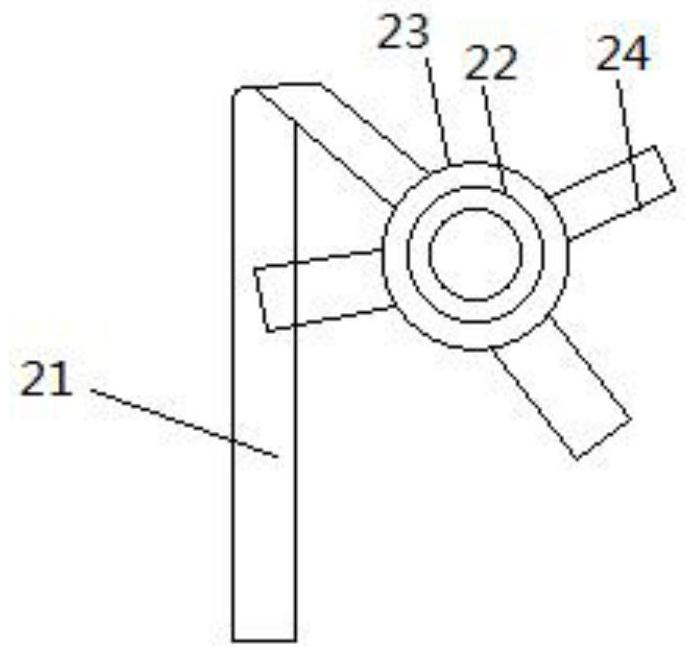

ActiveCN111805920AIncrease elasticityGood flexibilityVacuum evaporation coatingSputtering coatingFiberPolymer science

The invention discloses all-directional conductive polyurethane foam and a preparation method thereof. The method comprises the following specific steps that S1, foam is prepared, wherein a foamed sponge taking polyurethane as the main component is cut into sheets; S2, conductive cloth is prepared, wherein polyurethane fiber plaid cloth is put into a vacuum chamber, and the plaid cloth is subjected to copper plating through multi-arc ion plating to form a conductive cloth; S3, the foam is cleaned; and S4, glue spraying and cloth pasting are carried out on the foam, wherein the cut foam is subjected to liquid glue spraying and conductive cloth pasting through a glue spraying and cloth pasting device. The polyurethane foam has the advantages of high conductivity, high softness, large extrusion degree, good shielding effect and the like, and has extremely high cost performance; and a cloth winding mechanism of the glue spraying and cloth pasting device can be disassembled, the replaceableproperty of the conductive cloth is ensured, and the all-directional conductive polyurethane foam with different sizes can be produced in large batches. The device has the advantages of being convenient to operate, firm in conductive cloth pasting, time-saving, labor-saving and the like.

Owner:SUZHOU AOYU RUBBER & PLASTIC TECH CO LTD

Preparing method for automobile air conditioner pipe

InactiveCN106756273AReduce porosityReduce tensionFoundry mouldsFoundry coresAutomobile air conditioningCorrosion

Owner:苏州富艾姆工业设备有限公司

Isocyanate-group-containing polymer having a low content of monomeric diisocyanates

PendingCN112543779AHigh molecular weightImprove responseAdhesive processesPolyureas/polyurethane adhesivesPolymer sciencePolyether polyurethane

The invention relates to an isocyanate group-containing polyether urethane polymer having an NCO content in the range from 1.3 to 1.9 wt% and a content of monomeric diisocyanates of not more than 0.5wt%, derived from the reaction of at least one monomeric aromatic diisocyanate and a polyether triol having an average OH functionality in the range from 2.2 to 2.6, an OH number in the range from 25to 32 mg KOH / g in an NCO / OH ratio of at least 3:1 and subsequent removal of a majority of the monomeric diisocyanates by means of a suitable separation process, and moisture-curing polyurethane compositions having a content of monomeric diisocyanates of less than 0.1 wt% containing said polymer. The polymer according to the invention allows very storage-stable moisture-curing polyurethane compositions, which are safe to handle even without special protective measures, are easy to process, have a long open time, cure rapidly to provide an elastic material of high extensibility and elasticity with high strength, high tear propagation resistance, good low-temperature flexibility, good adhesion properties and high resistance, in particular with respect to heat and UV radiation. Such polyurethane compositions are in particular suitable as elastic adhesives, sealants, and coatings.

Owner:SIKA TECH AG

Composite magnesium oxysulfate cementing material used for 3D printing as well as preparation method and application of composite magnesium oxysulfate cementing material

ActiveCN110342898AImprove adhesionImprove plasticityAdditive manufacturing apparatusCarbonizationDolomite

The invention belongs to the technical field of gel materials, in particular relates to a composite magnesium oxysulfate cementing material used for 3D printing, and further discloses a preparation method and application of the composite magnesium oxysulfate cementing material. The composite magnesium oxysulfate cementing material is formed by adopting a magnesium oxysulfate cementing material (MOS) and aggregate, wherein the magnesium oxysulfate cementing material is composed of magnesium oxysulfate cement, a water reducing agent, a binder, a reinforcing agent, a retarder, a water repellent and glass fibers, and the aggregate is fine aggregate composed of talc powder and dolomite powder. Compared with an ordinary Portland cement material for 3D printing, the composite magnesium oxysulfatecementing material provided by the invention has good cohesiveness, plasticity, extrudability and continuity, and the advantages of good mechanical properties, a light weight, high strength, high early strength, good later strength, good cohesiveness, good carbonization resistance and strong resistance to erosion of various soluble salts, can meet the performance requirements of 3D printing products and can be applied to a 3D printing technology.

Owner:辽宁科大中驰镁建材科技有限公司 +1

Magnesium aluminum alloy and preparation method thereof

The invention discloses magnesium aluminum alloy and a preparation method thereof. The magnesium aluminum cast alloy comprises, by weight, 7-12% of aluminum, 0.1-0.8% of manganese, 0.1-1.0% of cerium,3-6% of chromium, 0.2-0.4% of zinc, 0.5-1.2% of strontium, 0.7-1.0% of titanium and the balance magnesium and inevitable impurities. The impurities comprises, by mass, 1-3% of cobalt, less than or equal to 5% of tungsten, less than or equal to 2% of niobium, less than or equal to 2% of vanadium. The content of magnesium is no less than 65%. According to the magnesium aluminum alloy preparation method, through melting, refining and liquid surface scum removing, a mixed melt is fed into an intermediate frequency furnace and deposited on a substrate after atomizing through high-pressure argon, alloy ingots are formed, then the alloy ingots are cooled to the room temperature, and a finished magnesium aluminum alloy product is obtained. According to the technical scheme, the magnesium aluminumalloy has good mechanical properties and structure uniformity, the corrosion resistance is improved, the material utilization rate is high, the yield of products is increased, and the production costis reduced.

Owner:安徽金兰压铸有限公司

Puncture repair liquid-holding container

Owner:THE YOKOHAMA RUBBER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com