Colorful rubber composition for tire sidewall and preparation method of colorful rubber composition

A rubber composition and color technology, applied in the fields of rubber tires and chemical manufacturing, can solve the problems of low sidewall flex resistance, easy fading of sidewalls, and low aging resistance, so as to improve compatibility and shorten mixing time, performance-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

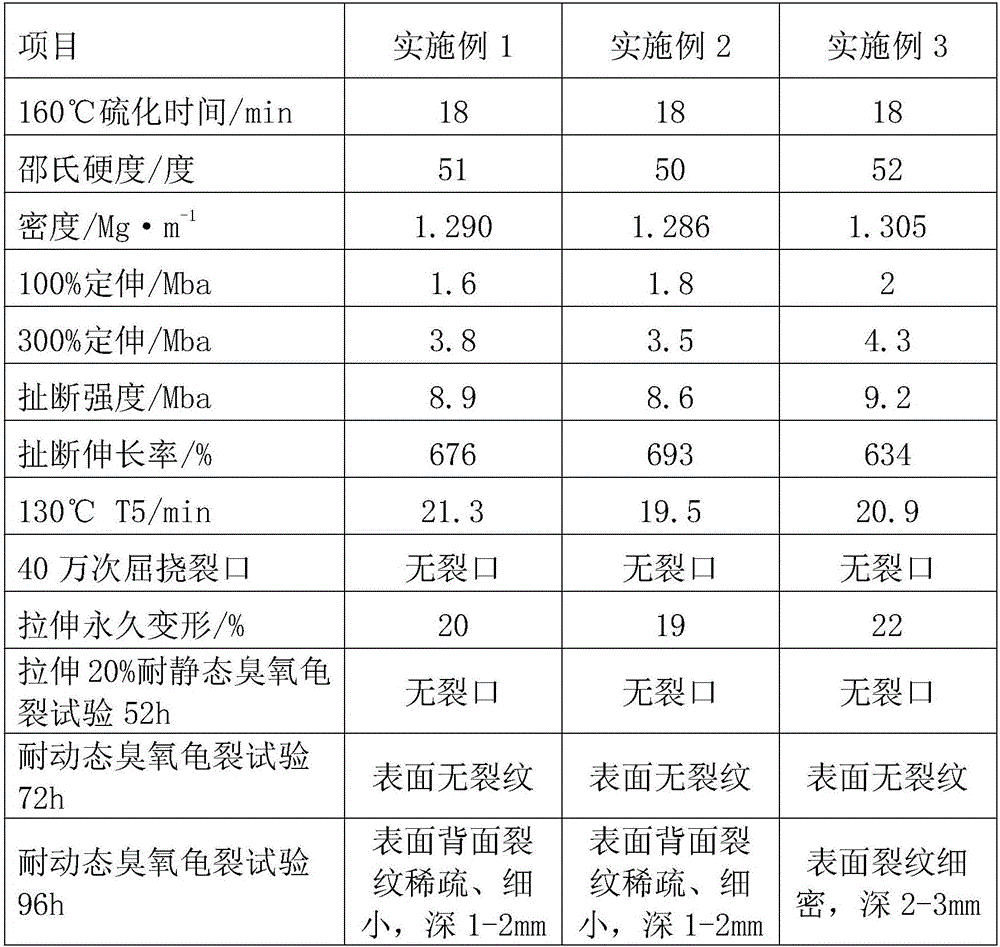

Examples

Embodiment 1

[0020] The colored rubber composition used in the sidewall of the tire involved in this embodiment, its raw material components and parts by weight of each component are: 35 parts of SVR-3L type rubber, 15 parts of KEP-350 type rubber, and 15 parts of CIIR-1066 type rubber 50 parts, tackifying resin 1.5 parts, stearic acid 2 parts, dispersant 1.5 parts, non-polluting anti-aging agent 0.5 parts, kaolin 28 parts, titanium dioxide 35 parts, benzidine yellow 20 parts, rubber scarlet 2 parts, promote 0.8 parts of agent DM, 0.5 parts of accelerator RPS-710, 0.5 parts of sulfur, 0.1 parts of anti-scorch agent;

[0021] The preparation method of the colored rubber composition that this embodiment relates to is used for tire sidewall, and its specific preparation process comprises the following steps:

[0022] (1) Batching and compounding: carry out compounding and compounding according to the raw material components and parts by weight of the colored rubber compositions used for tire ...

Embodiment 2

[0029] The colored rubber composition used in the tire sidewall involved in this embodiment, its raw material components and parts by weight of each component are: 30 parts of SVR-3L type rubber, 20 parts of KEP-350 type rubber, 20 parts of CIIR-1066 type rubber 50 parts, 2 parts of tackifying resin, 1.5 parts of stearic acid, 1 part of dispersant, 0.7 parts of non-polluting anti-aging agent, 25 parts of kaolin, 35 parts of titanium dioxide, 20 parts of benzidine yellow, 2 parts of rubber red, promote 0.8 parts of agent DM, 0.6 parts of accelerator RPS-710, 0.8 parts of sulfur, 0.1 parts of anti-scorch agent;

[0030] The preparation method of the colored rubber composition that this embodiment relates to is used for tire sidewall, and its specific preparation process comprises the following steps:

[0031] (1) Batching and compounding: carry out compounding and compounding according to the raw material components and parts by weight of the colored rubber compositions used for...

Embodiment 3

[0038] The colored rubber composition used in the sidewall of the tire involved in this embodiment, its raw material components and parts by weight of each component are: 40 parts of SVR-3L type rubber, 15 parts of KEP-350 type rubber, and 15 parts of CIIR-1066 type rubber 45 parts, tackifying resin 1.5 parts, stearic acid 2 parts, dispersant 2 parts, non-polluting anti-aging agent 1 part, kaolin 30 parts, titanium dioxide 35 parts, benzidine yellow 20 parts, rubber scarlet 2 parts, promote 0.9 parts of agent DM, 0.5 parts of accelerator RPS-710, 0.6 parts of sulfur, 0.1 parts of anti-scorch agent;

[0039] The preparation method of the colored rubber composition that this embodiment relates to is used for tire sidewall, and its specific preparation process comprises the following steps:

[0040] (1) Batching and compounding: carry out compounding and compounding according to the raw material components and parts by weight of the colored rubber compositions used for tire sidew...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com