Patents

Literature

602 results about "Perchlorate ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A perchlorate is the name for a chemical compound containing the perchlorate ion, ClO− 4. The majority of perchlorates are produced commercially.

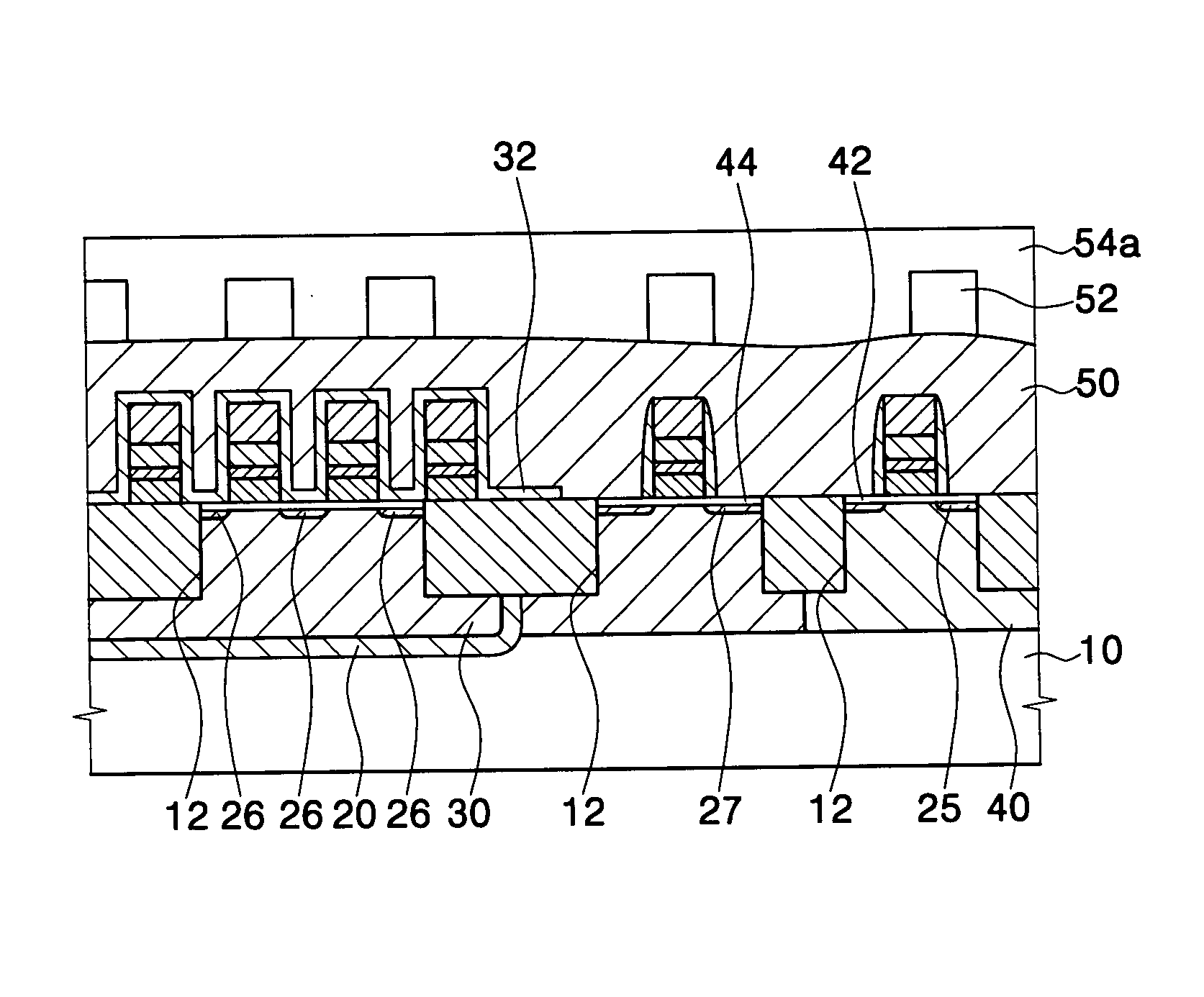

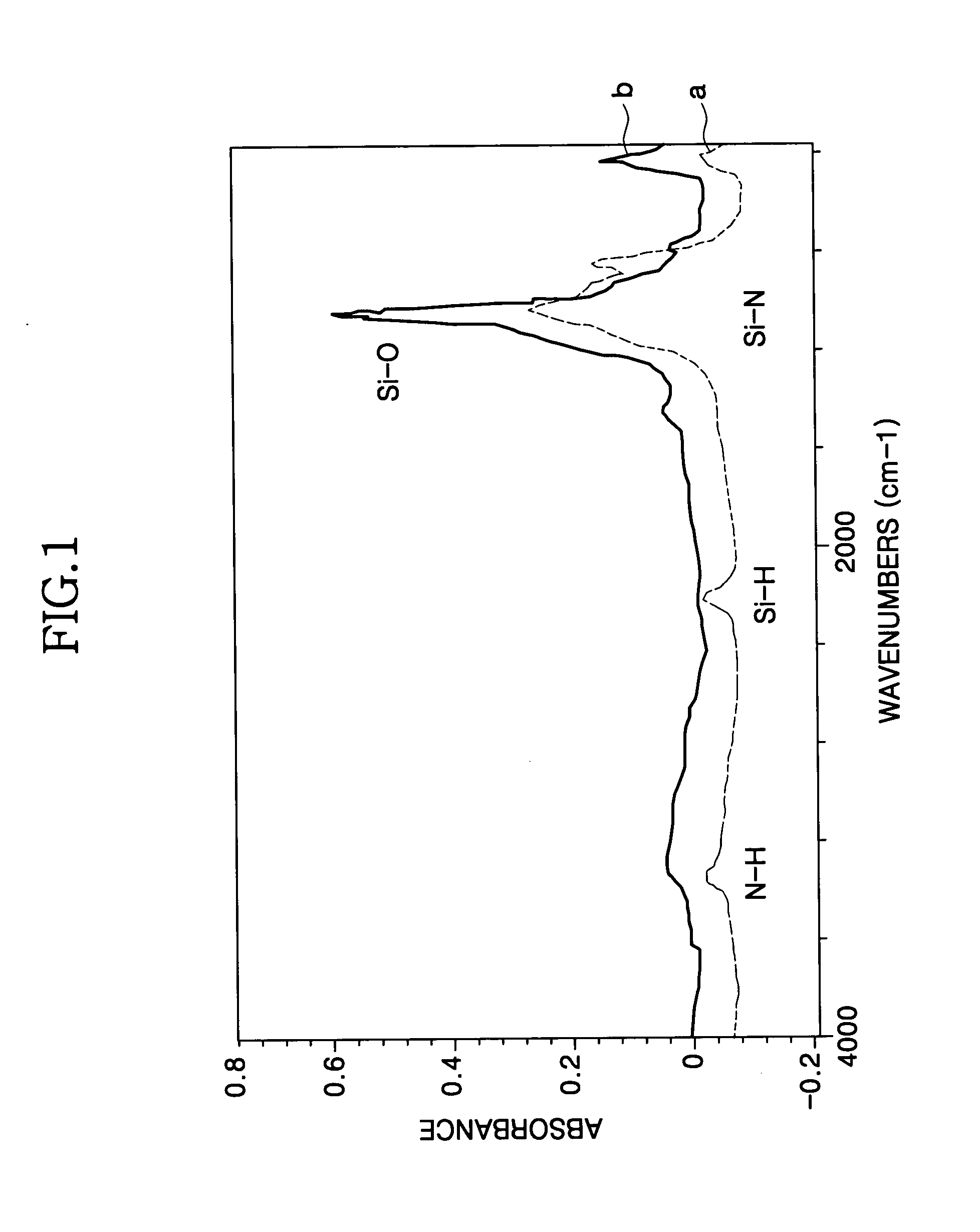

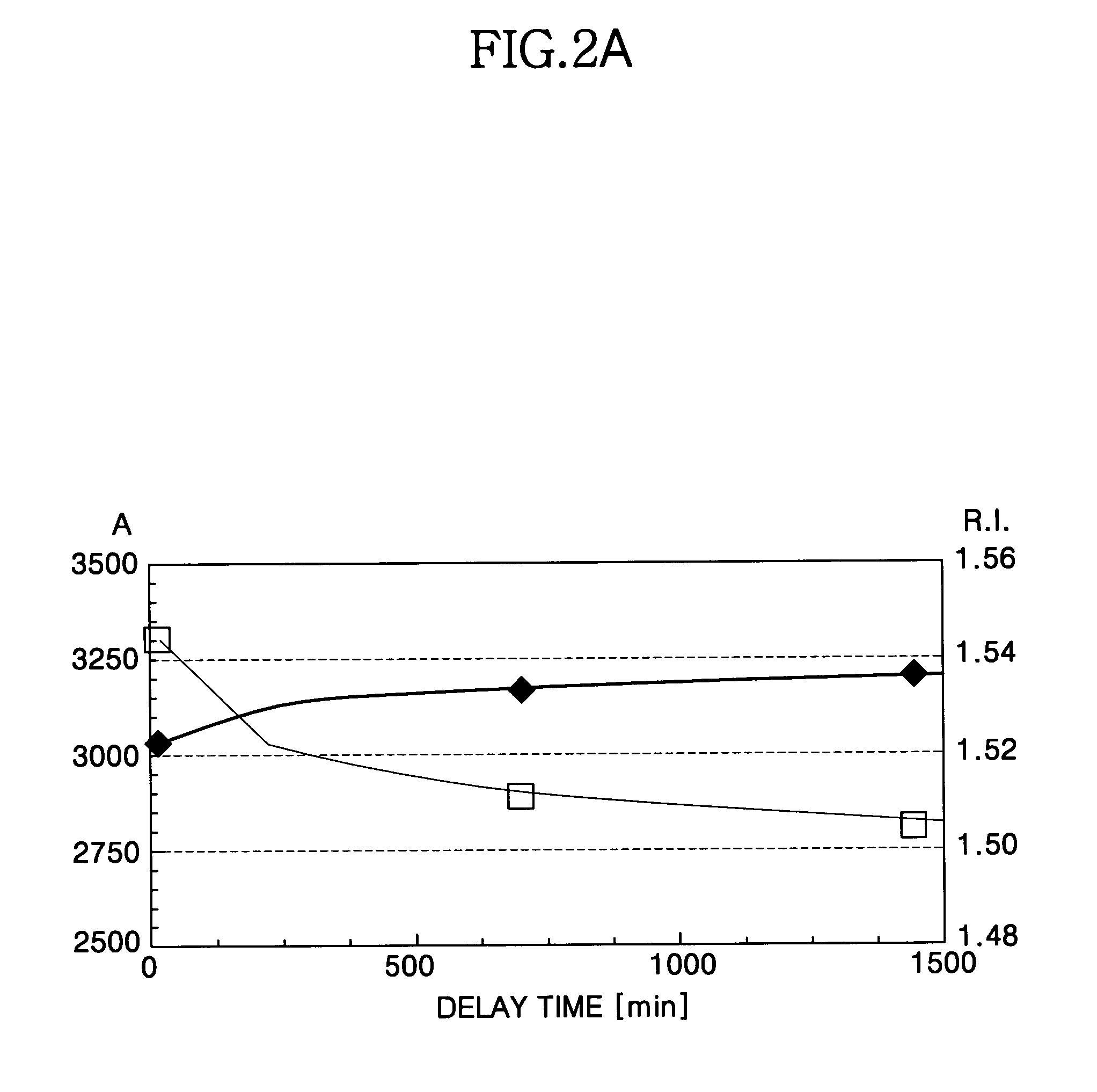

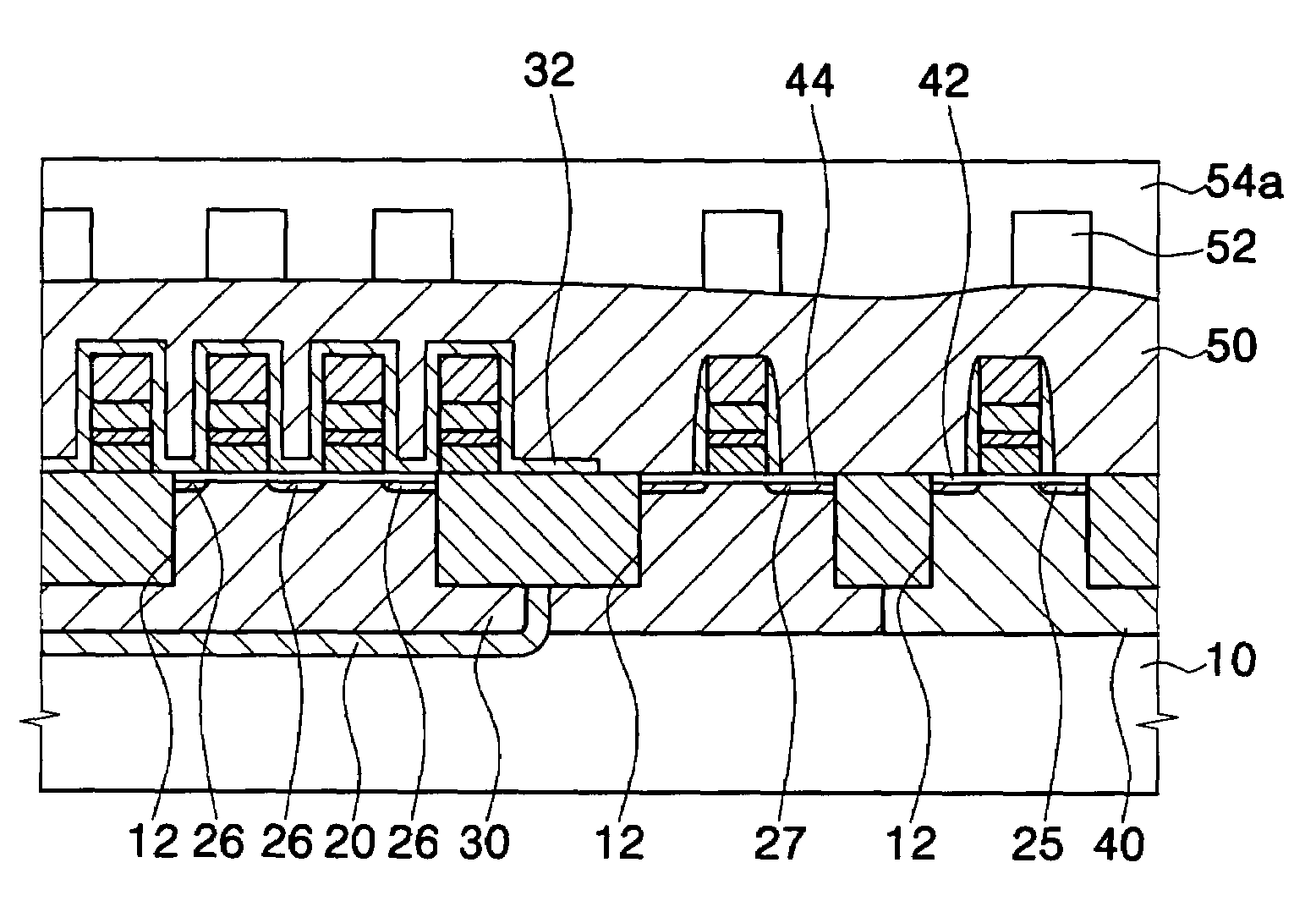

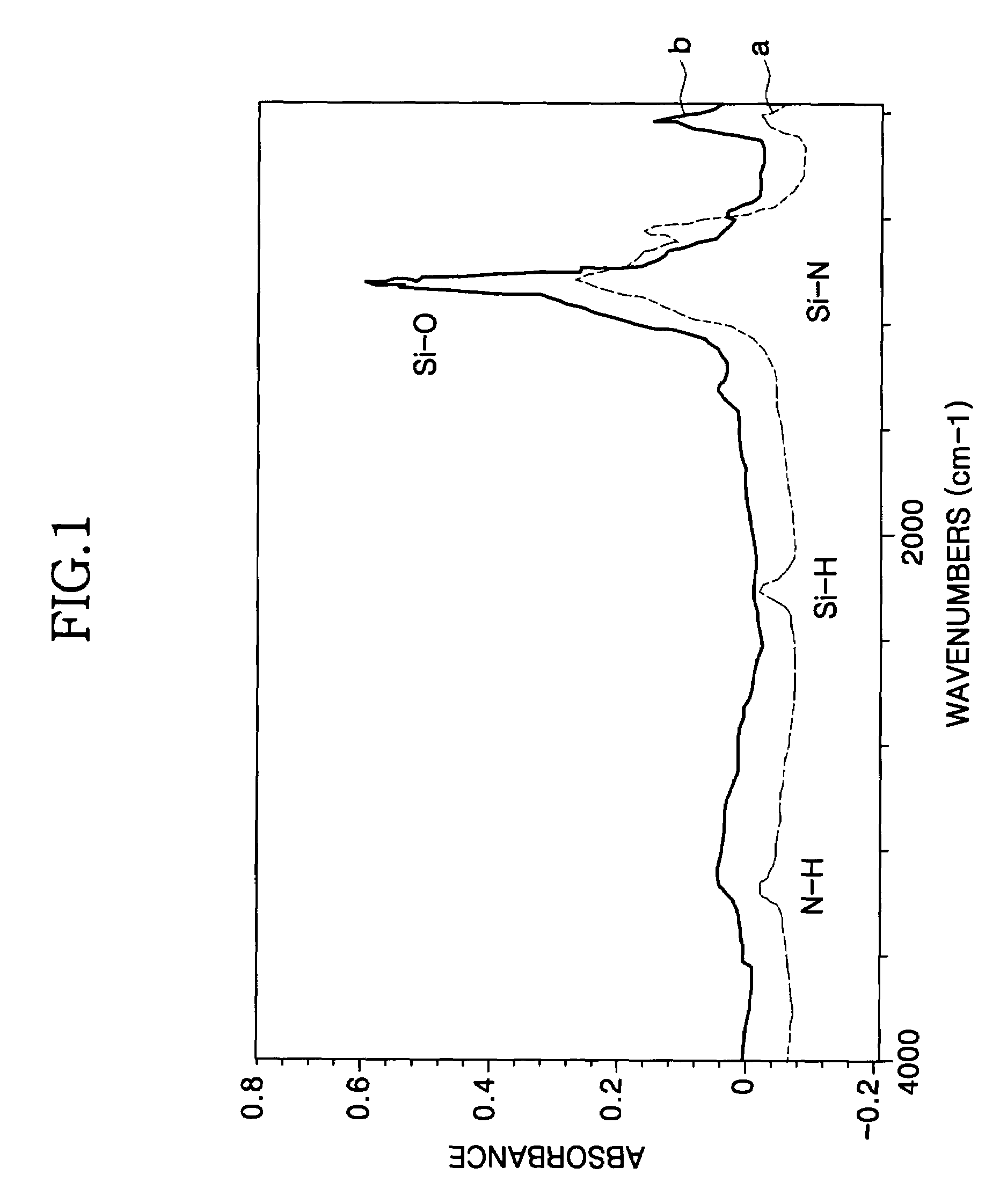

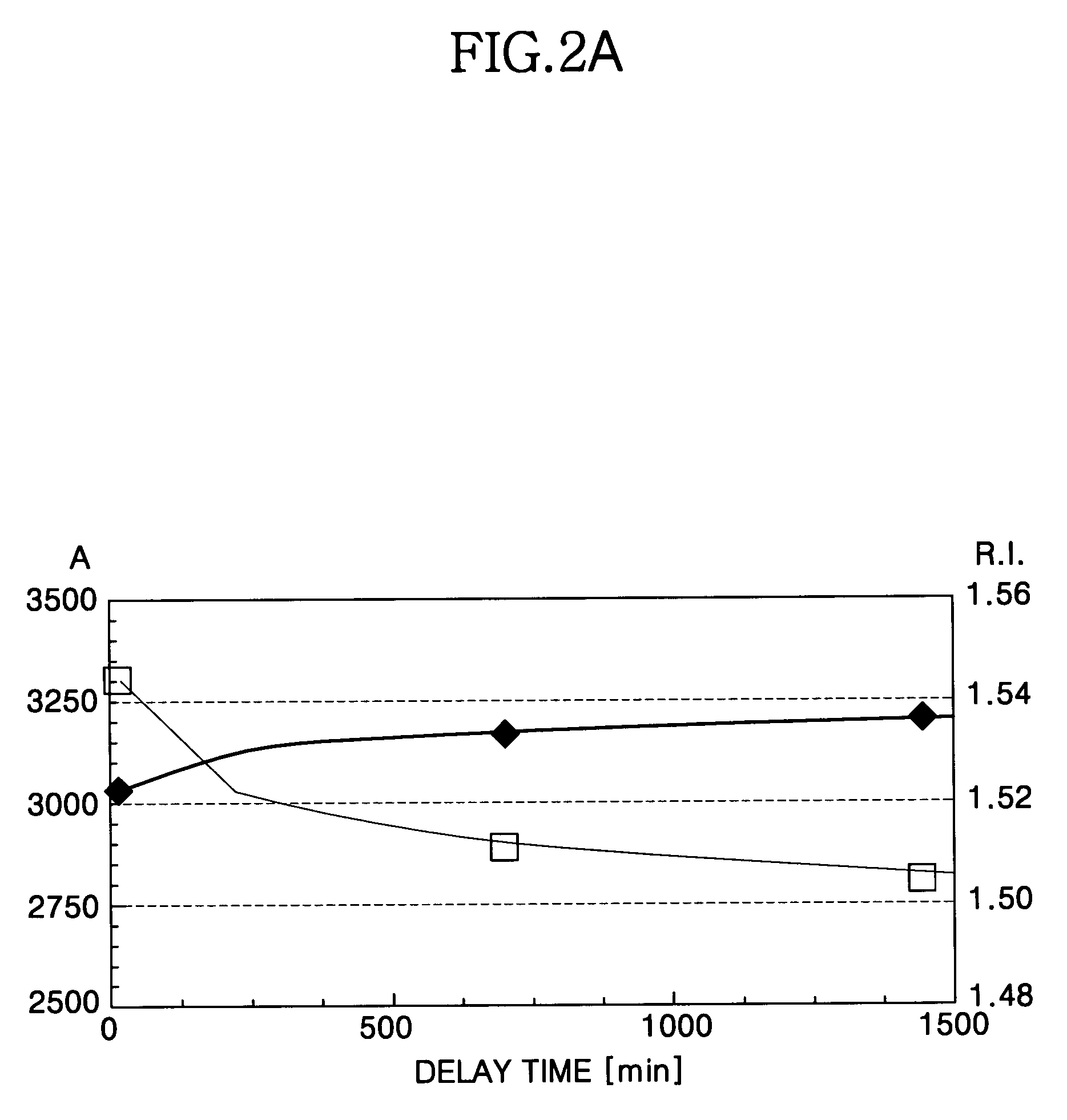

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

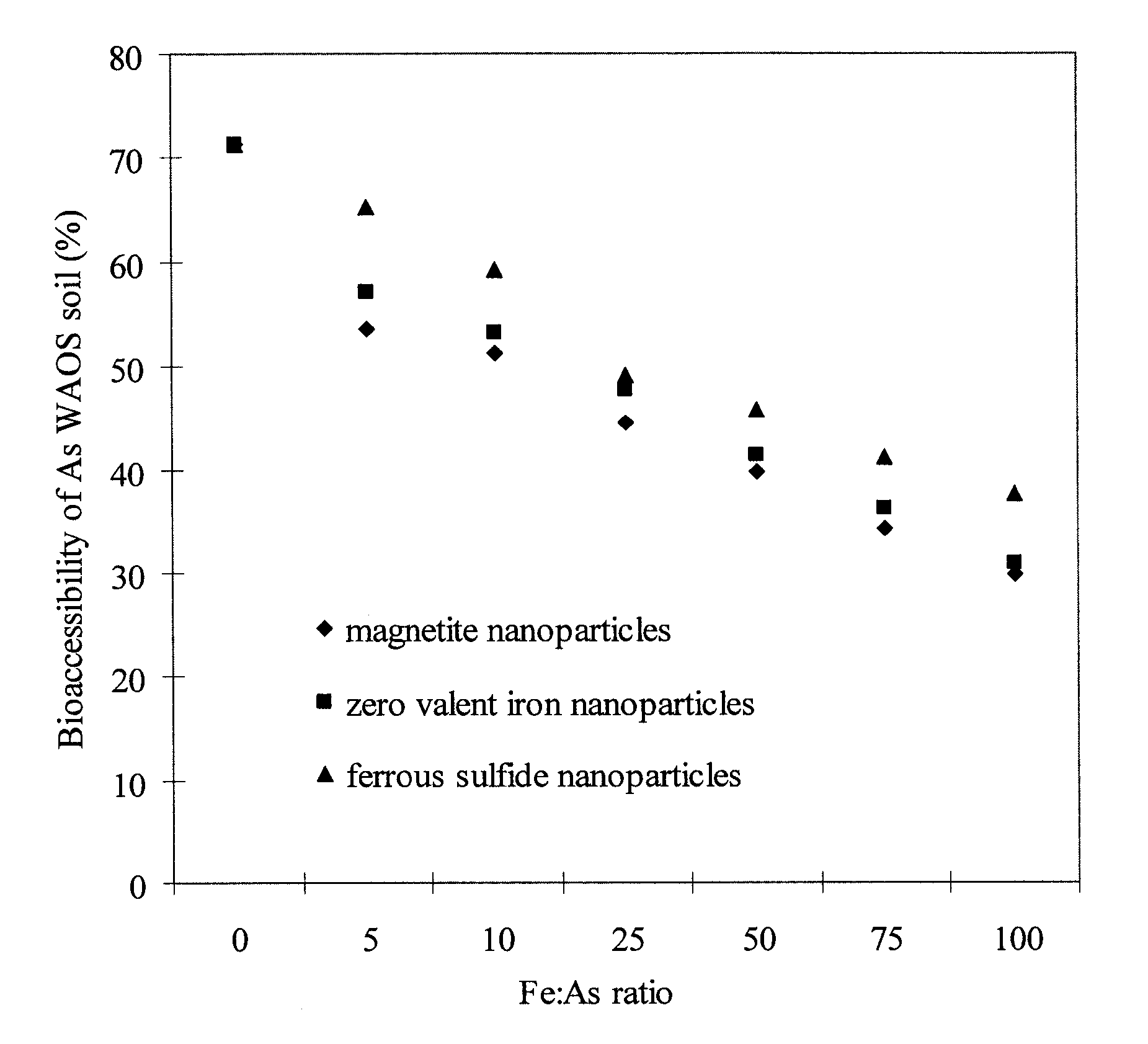

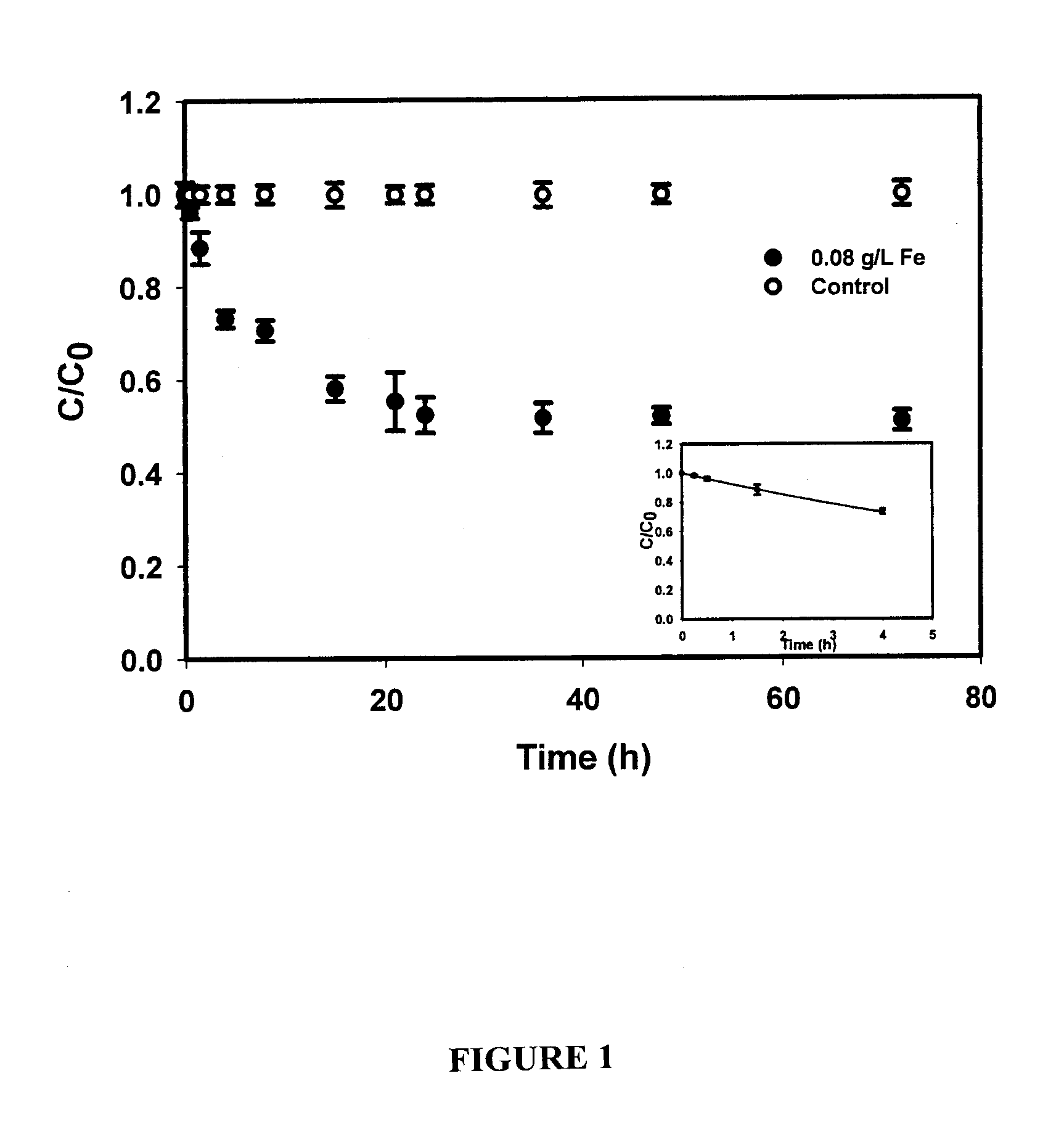

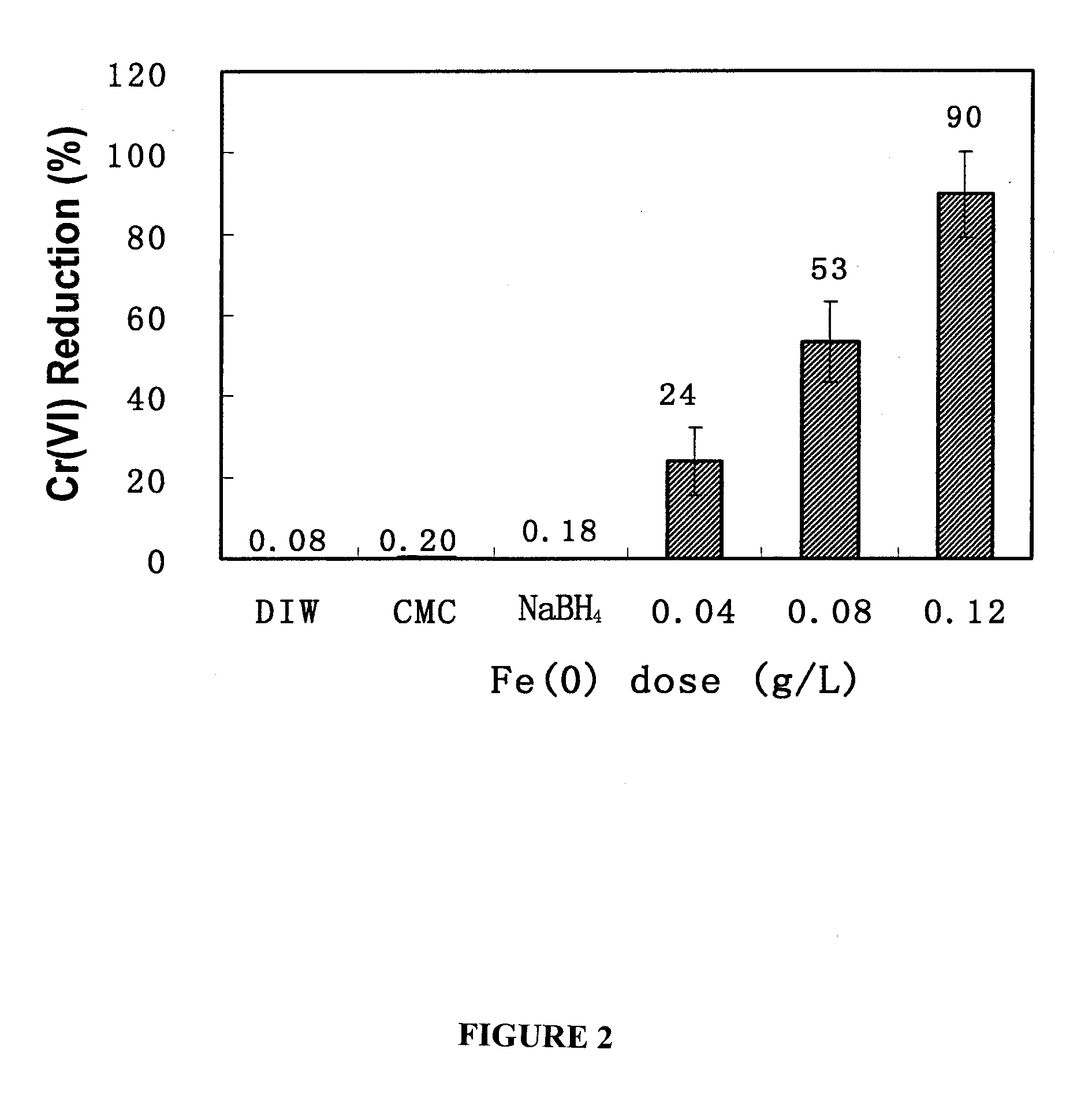

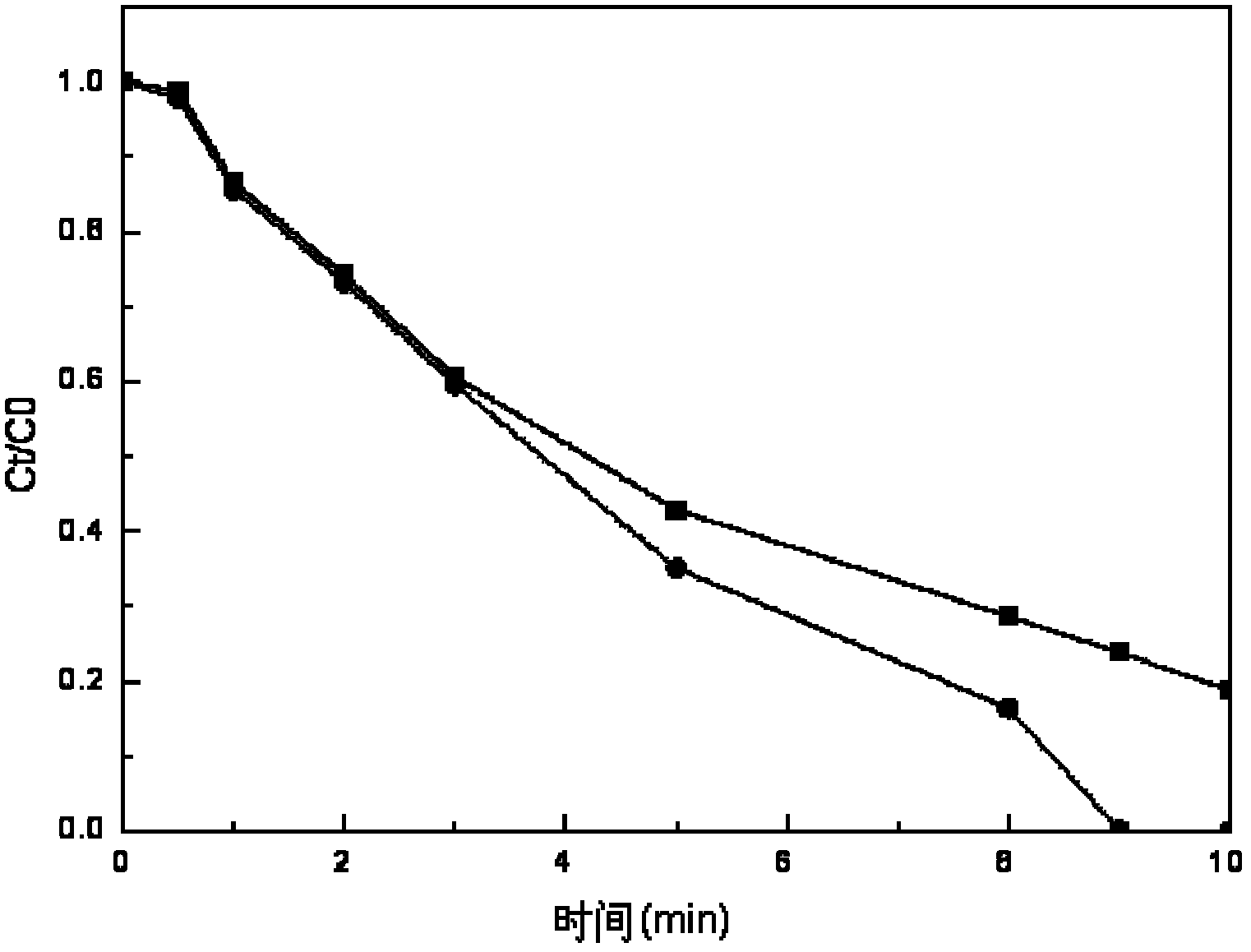

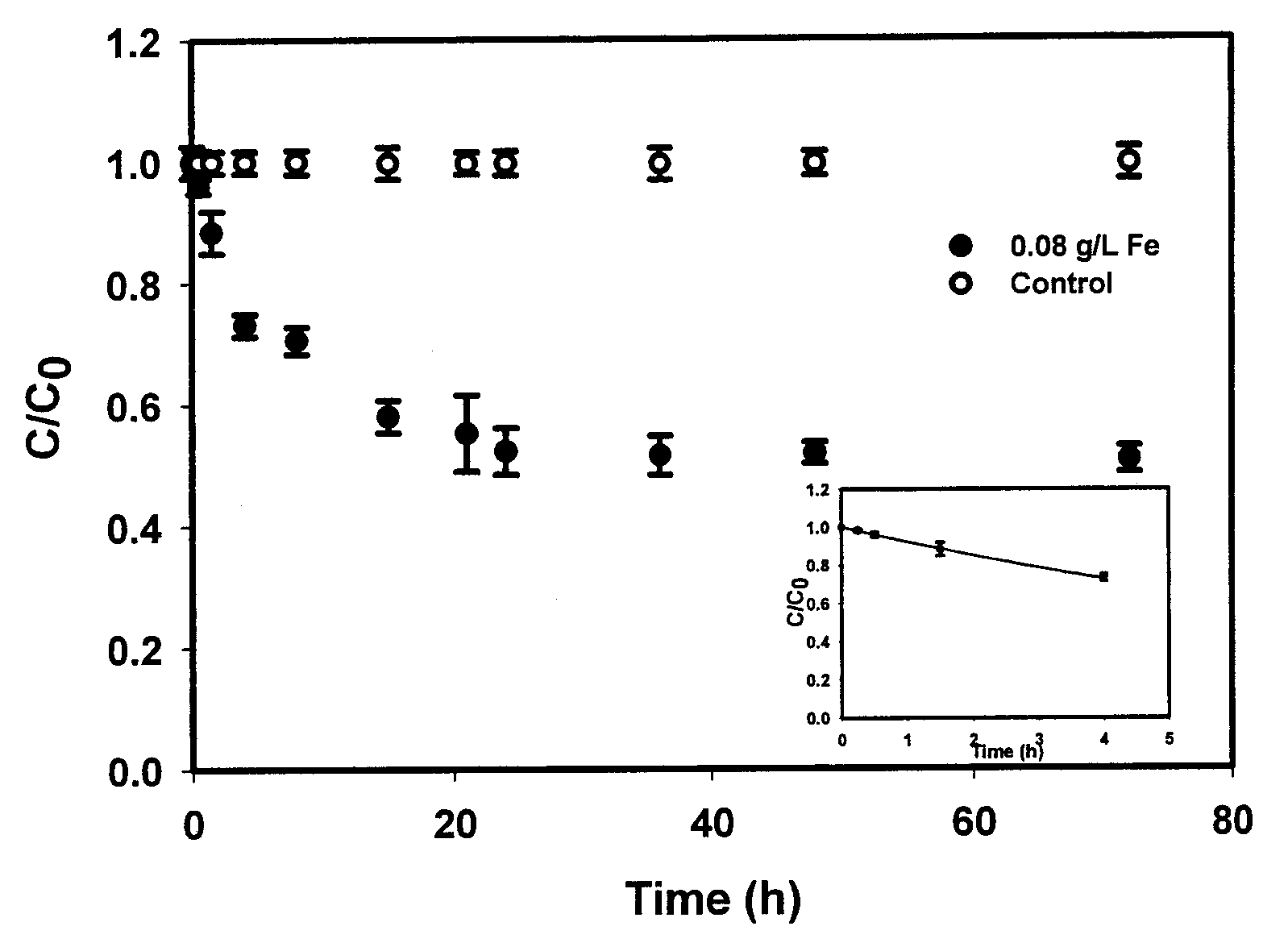

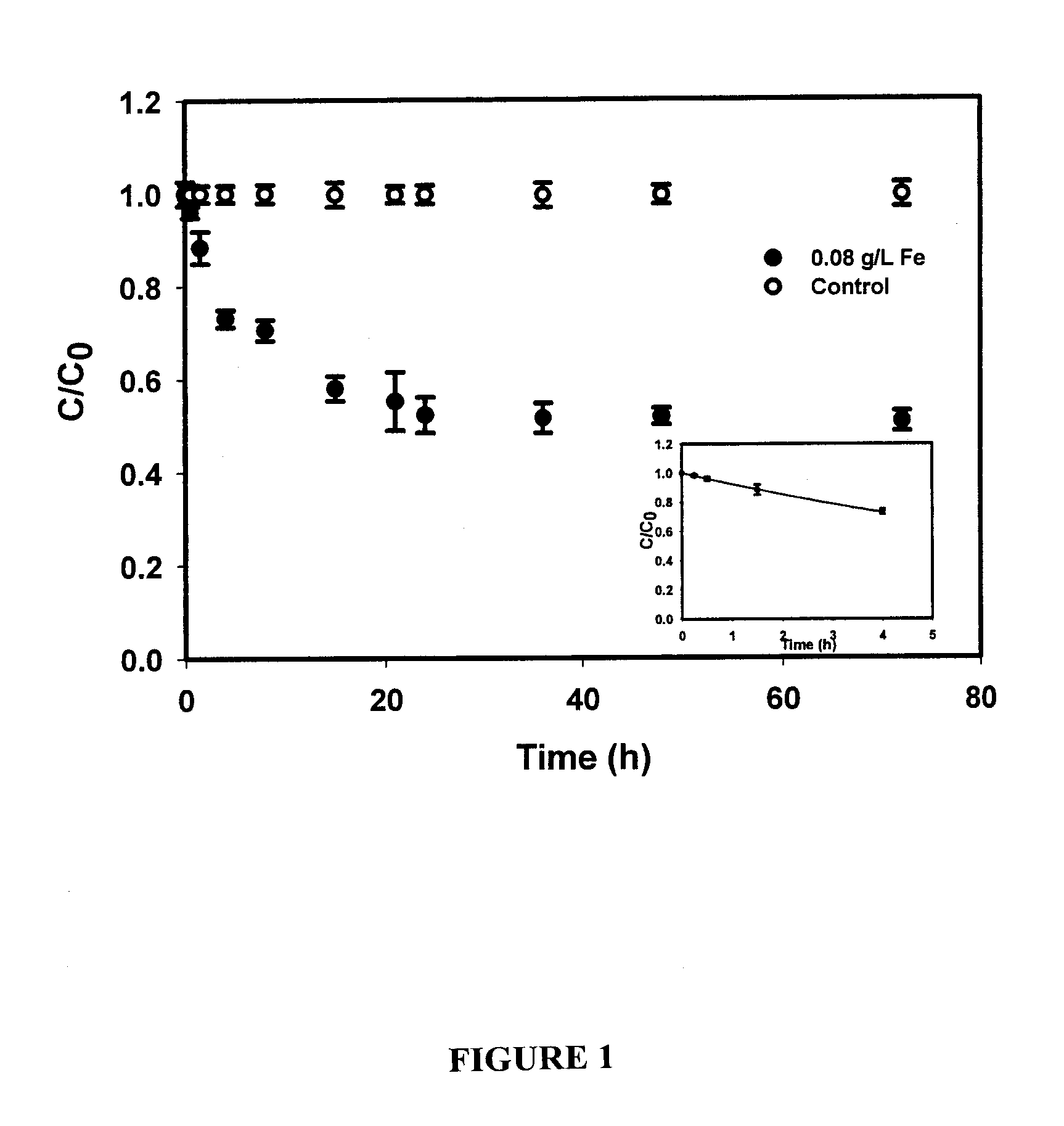

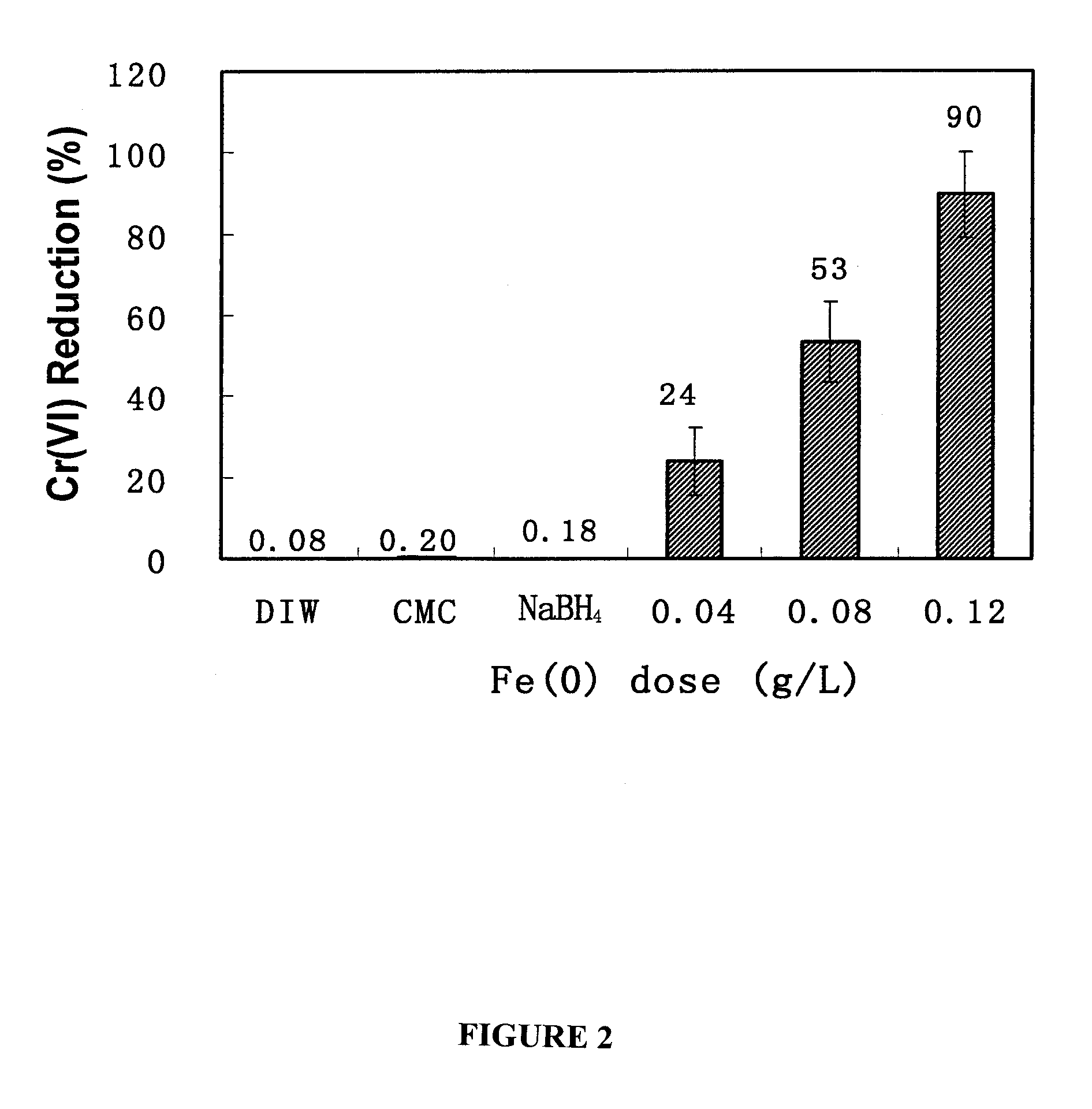

In Situ Remediation of Inorganic Contaminants Using Stabilized Zero-Valent Iron Nanoparticles

InactiveUS20070256985A1Low costProcess environmental protectionMaterial nanotechnologyWater treatment compoundsCelluloseMaterials science

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

Transformation liquid for preparation of corrosion-resistant oxidation film on aluminium alloy surface and method of use thereof

InactiveCN101139708AImprove corrosion resistanceGood adhesionMetallic material coating processesHigh resistancePersulfate

The invention discloses a transforming solution for preparing anti-corrosion compound oxidation film on an aluminum alloy surface and a using method for the oxidation film. The invention is characterized in that, the transforming solution is a film-forming promoter containing rare-earth salt (nitrate or sulfate and compound salt of cerium, praseodymium, and neodymium), such compound oxidant as radical of permanganate, nitrate and perchlorate, etc., film-forming promoter of vanadium salt and strontium salt, etc.; the transforming solution contains no sexavalent chromium, is environmental friendly; the reaction speed is improved by the compound oxidant and the film-forming promoter, no heating is needed for the chemical transforming, the treating time is 1-5 min. The invention can rapidly prepare under room temperature compound oxidation film comprising compound rare-earth oxide, alumina and manganese oxide with good resistance to corrosion on aluminum alloy surface. The treating solution from the invention is of rapid film-forming speed, simple process, even film layer, high resistance to corrosion, and low environmental pollution, etc.

Owner:陈东初 +2

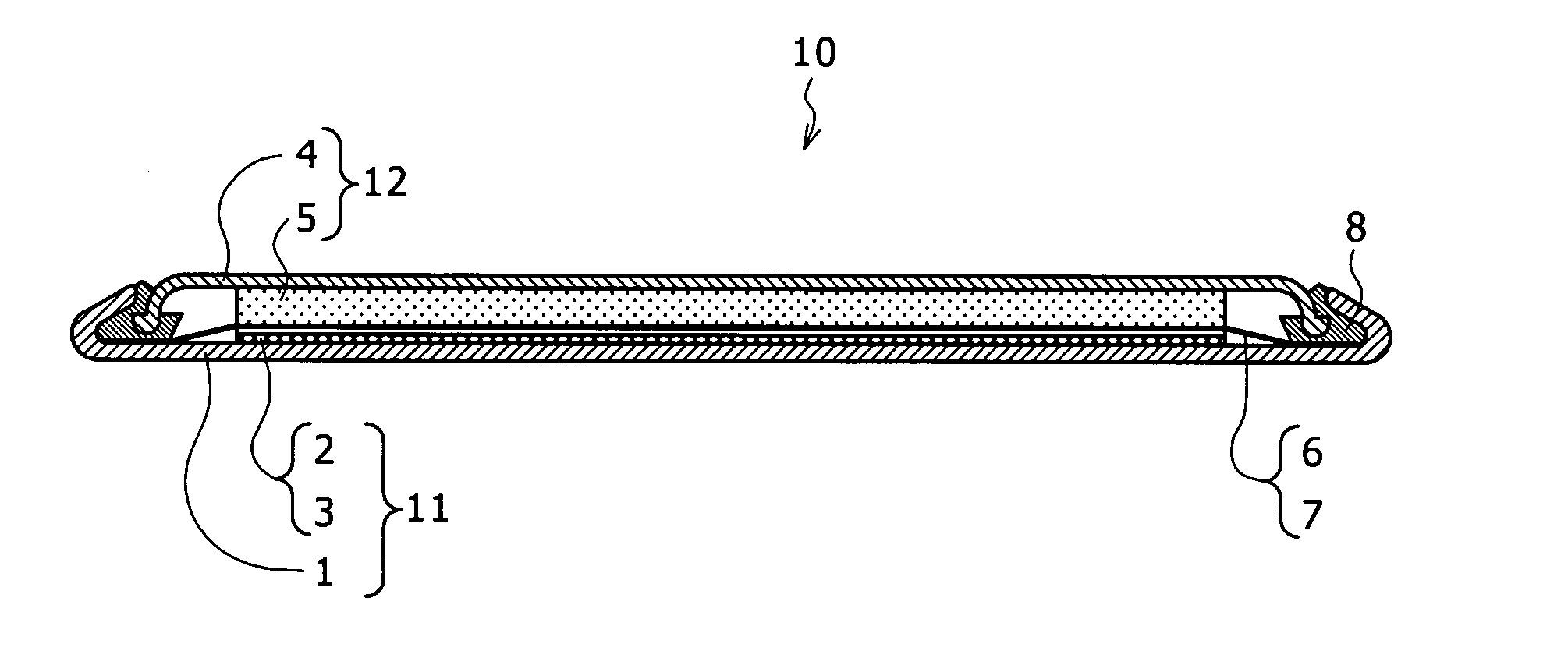

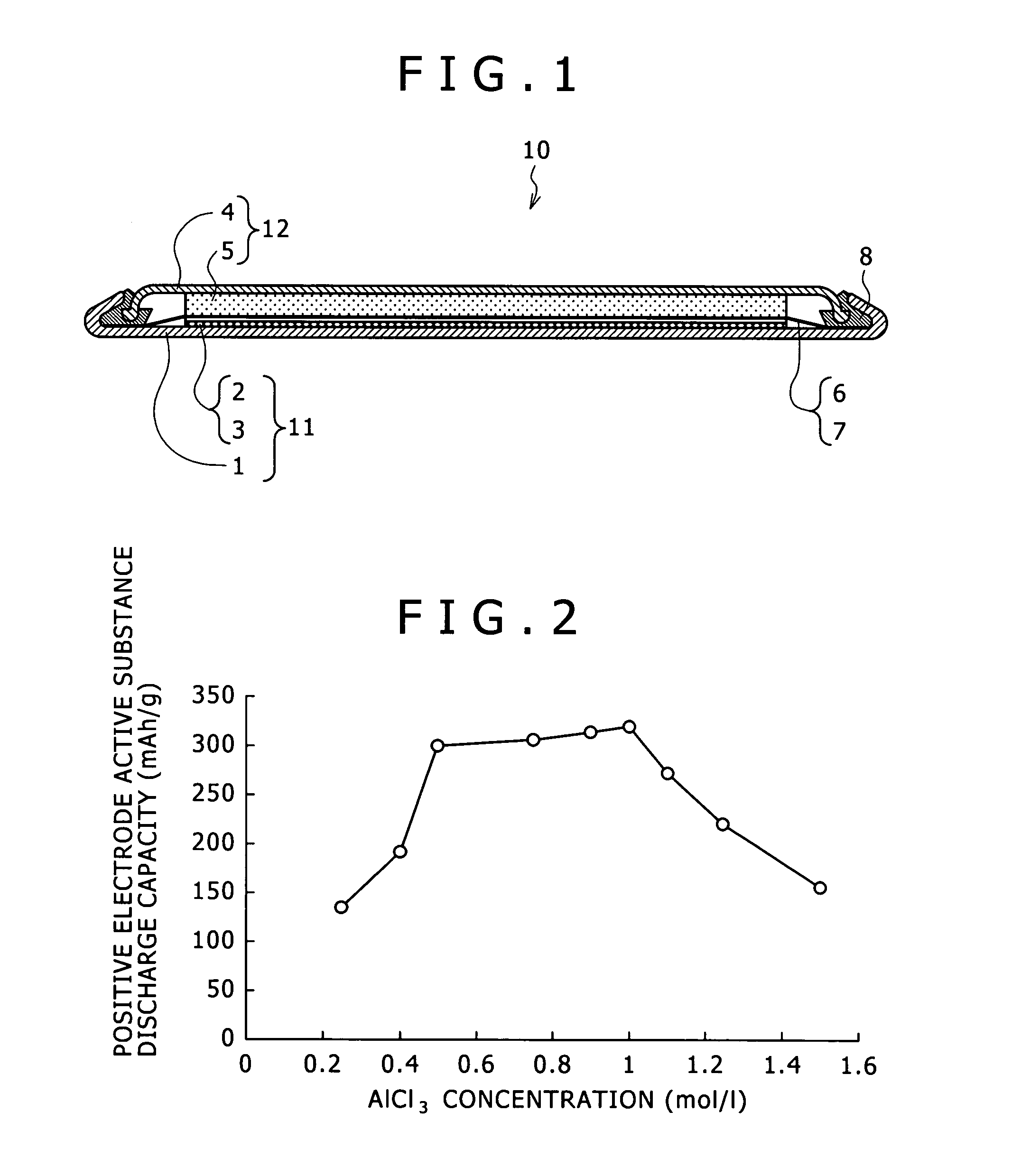

Magnesium ion-containing non-aqueous electrolyte and a production process thereof, as well as electrochemical device

ActiveUS20090068568A1Effective resourcesEfficient use ofCell electrodesOrganic electrolyte cellsAluminum IonPhosphate ion

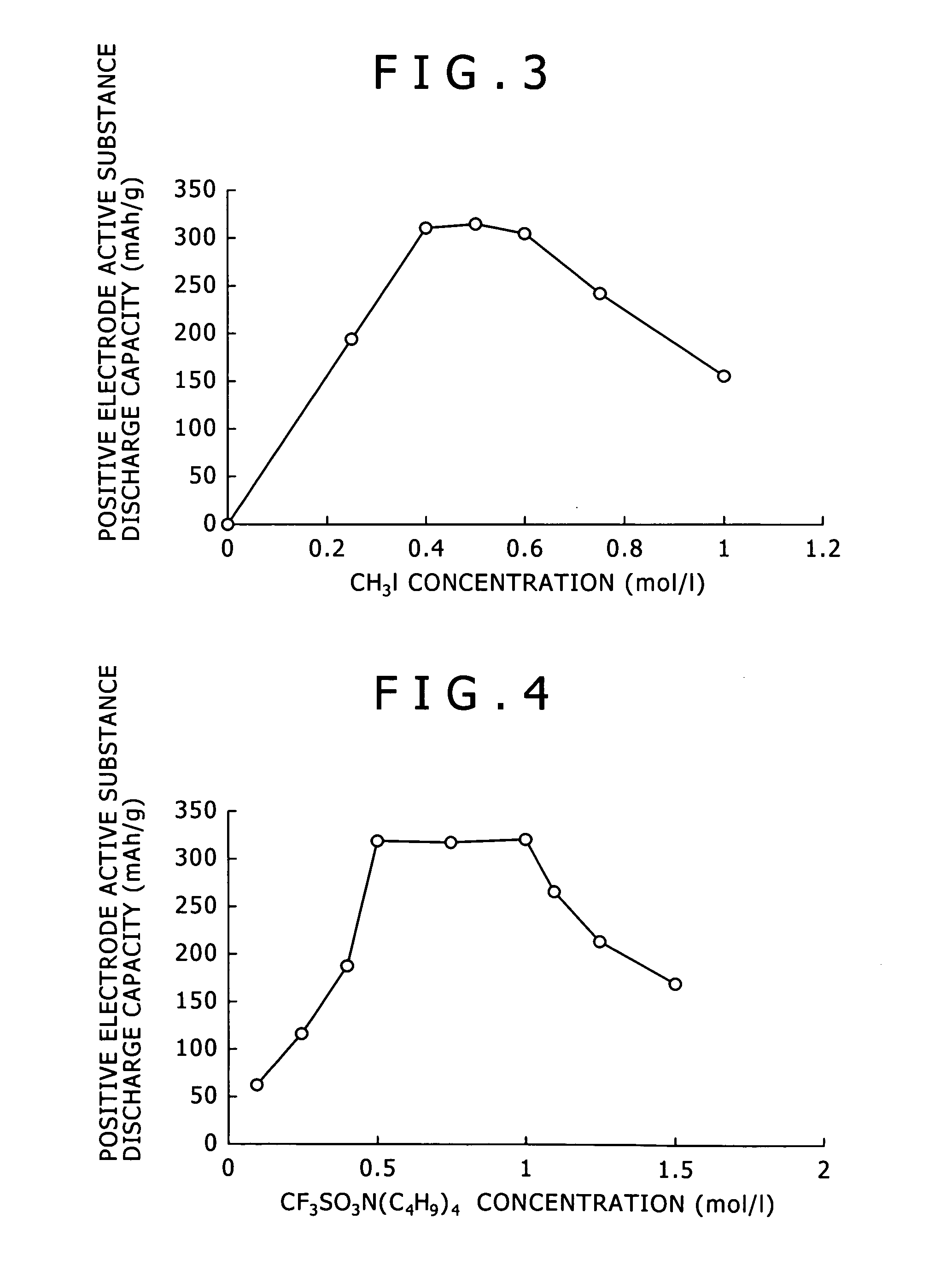

A magnesium ion containing non-aqueous electrolyte in which magnesium ions and aluminum ions are dissolved in an organic etheric solvent, and which is formed by: adding metal magnesium, a halogenated hydrocarbon RX, an aluminum halide AlY3, and a quaternary ammonium salt R1R2R3R4N+Z− to an organic etheric solvent; and applying a heating treatment while stirring them (in the general formula RX representing the halogenated hydrocarbon, R is an alkyl group or an aryl group, X is chlorine, bromine, or iodine, in the general formula AlY3 representing the aluminum halide, Y is chlorine, bromine, or iodine, in the general formula R1R2R3R4N+Z− representing the quaternary ammonium salt, R1, R2, R3, and R4 represent each an alkyl group or an aryl group, and Z− represents chloride ion, bromide ion, iodide ion, acetate ion, perchlorate ion, tetrafluoro borate ion, hexafluoro phosphate ion, hexafluoro arsenate ion, perfluoroalkyl sulfonate ion, or perfluoroalkyl sulfonylimide ion.

Owner:MURATA MFG CO LTD

Gas generating system and composition

InactiveUS20080078486A1Easy to manufactureLoomsPedestrian/occupant safety arrangementCarboxylic acidDicarboxylic acid

A gas generating system devoid of a booster chamber. The inflator includes a composition having a metal chlorate as a first oxidizer, a primary fuel selected from carboxylic acids, dicarboxylic acids, and mixtures thereof, and a second oxidizer not having perchlorate character. The metal chlorate is provided at about 10-20 wt %, the primary fuel is provided at about 15-45 wt %, and the second oxidizer is provided at about 30-50 wt % stated by weight of the total composition.

Owner:TK HLDG

Etching liquid composition and etching method

The invention relates to an etchant composition and an etching method, wherein, the etchant composition comprises any two components of oxidants, acid and salt, and the pH value of the etchant composition is between 1 and 7. The oxidant components are selected from hydrogen peroxide, ammonium persulfate, potassium persulfate and ceric ammonium nitrate; the acid components are selected from chloric acid, perchlorate, acetic acid, nitric acid, hydrofluoric acid, sulfuric acid and oxalic acid, and the salt components are selected from ammonium fluoride, ammonium bifluoride, diammonium phosphate, ammonium phosphate, ammonium chloride and perfluorinated octyl sulfanilic acid (C8F17SO3NH4).

Gradient Ozone Catalytic Oxidation Method for Degrading Organic Pollutants in Water

ActiveCN102276095AAchieving Gradient OxidationControl contentMultistage water/sewage treatmentWater/sewage treatment by oxidationNitrosoCatalytic oxidation

The invention relates to a method for degrading organic pollutants in water by gradient ozone catalytic oxidation, and relates to a gradient ozone catalytic oxidation combination method for degrading organic pollutants in water. By the method, the problem that the conventional advanced oxidation technology has defects during individual use, the problem that the organic pollutants in the water cannot be removed efficiently, the problem that the influence of the pH value and temperature of the water on the method is large, and the problem that high-toxicity byproducts are formed are solved. In the method, water treatment is realized by combining two or three of a process for treating O3 individually, an enhanced catalytic oxidation process for O3 and an O3 / ultraviolet (UV) process sequentially. By the reasonable optimizing and gradient combination of the three treatment modes, the method is suitable for wide pH values and a wide temperature range, the pollutants with intermediate toxicity are controlled to be formed, the toxicity of the pollutants is reduced, the pollutants in the water is degraded efficiently and completely, and the content of oxidative species in effluent is controlled. An efficient oxidation treatment effect is kept at low temperature, and the generation of bromate, nitroso dimethylamine, chlorate, perchlorate, iodate and periodate can be controlled greatly.

Owner:哈尔滨工投环保产业有限公司

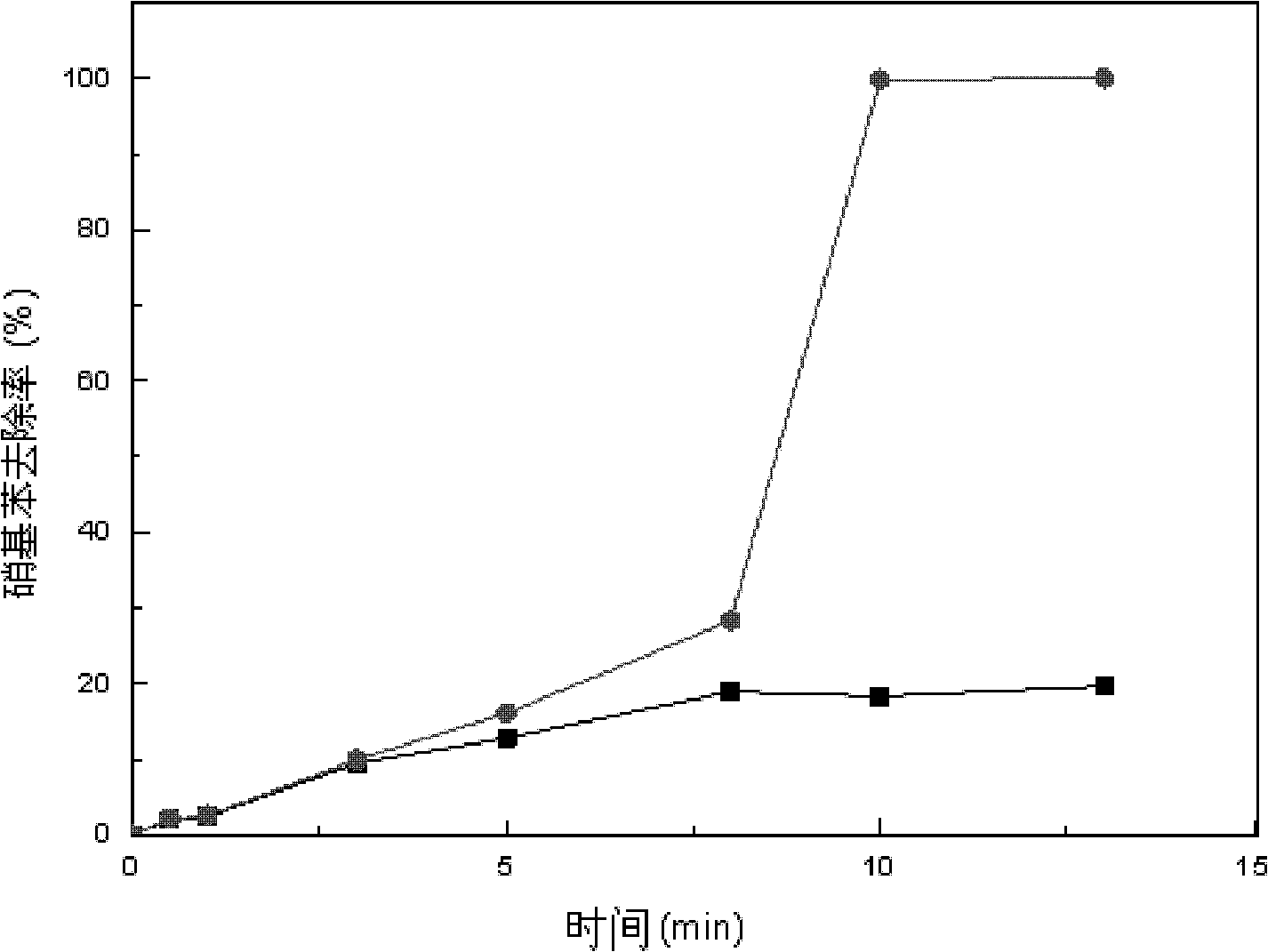

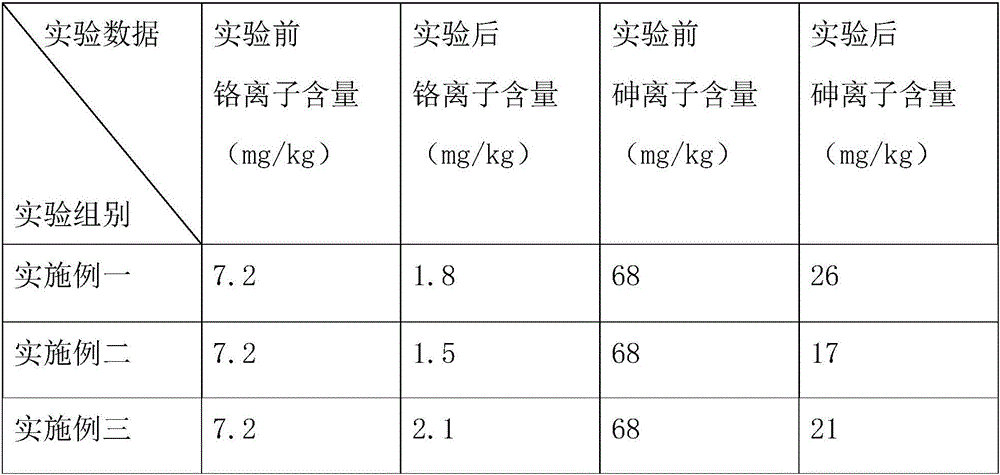

Preparation method of modified micron zero-valent iron and application method of modified micron zero-valent iron in remediation of heavy metal contaminated soil

ActiveCN106180735AAvoid secondary pollutionGood dispersionContaminated soil reclamationSoil treatmentSlag

The invention discloses a preparation method of modified micron zero-valent iron and an application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil. The preparation method of the modified micron zero-valent iron comprises the steps of cleaning of iron raw materials, preparation of micro iron, ultrafine grinding and modifying treatment. A modifying agent composed of water, xanthan gum, sulfide, a stabilizing agent, zeolite and blast furnace slag is adopted in the step of modifying treatment. The preparation method of the modified micron zero-valent iron has the beneficial effects that the production process of the modified micron zero-valent iron is simple, and the effect similar or superior to micron zero-valent iron is achieved while the cost is reduced; and in addition, the reaction activity is controlled, the oxidation rate is decreased, excellent stability is obtained, and the acting time of the micron zero-valent iron is longer. By the adoption of the application method of the modified micron zero-valent iron, the remediation cost of heavy metal contaminated underground water is further reduced. According to the preparation method of the modified micron zero-valent iron and the application method of the modified micron zero-valent iron in remediation of heavy metal contaminated soil, organic fertilizer is added in the soil treatment process so that the fertility of soil can be improved, the structure of soil can be improved through humic acid produced by the organic fertilizer, heavy metal elements, such as lead, chromium and arsenic, in underground water can be removed, and the concentration of pollutants such as nitrate and perchlorate can be reduced.

Owner:CHINESE ACADEMY FOR ENVIRONMENTAL PLANNING

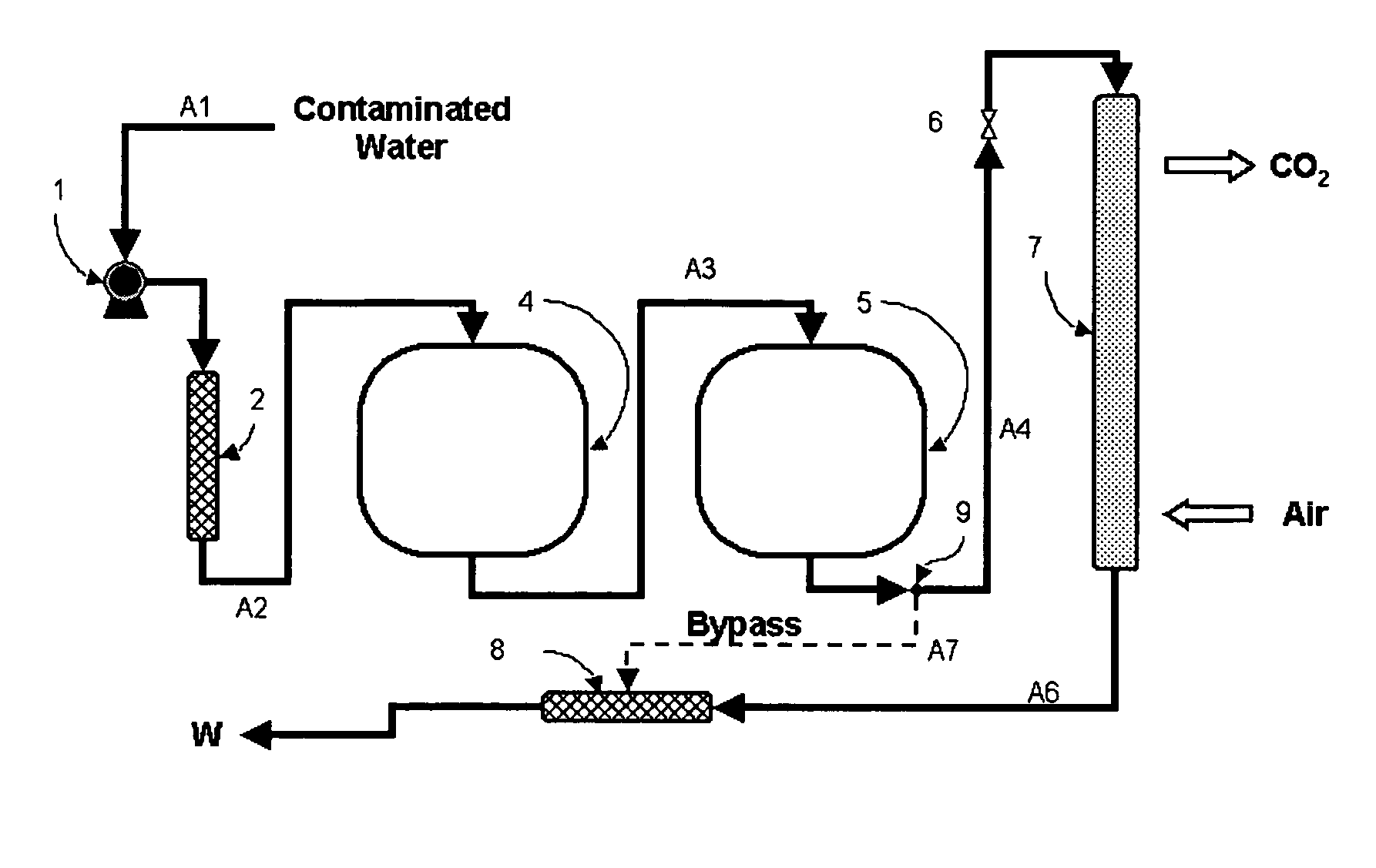

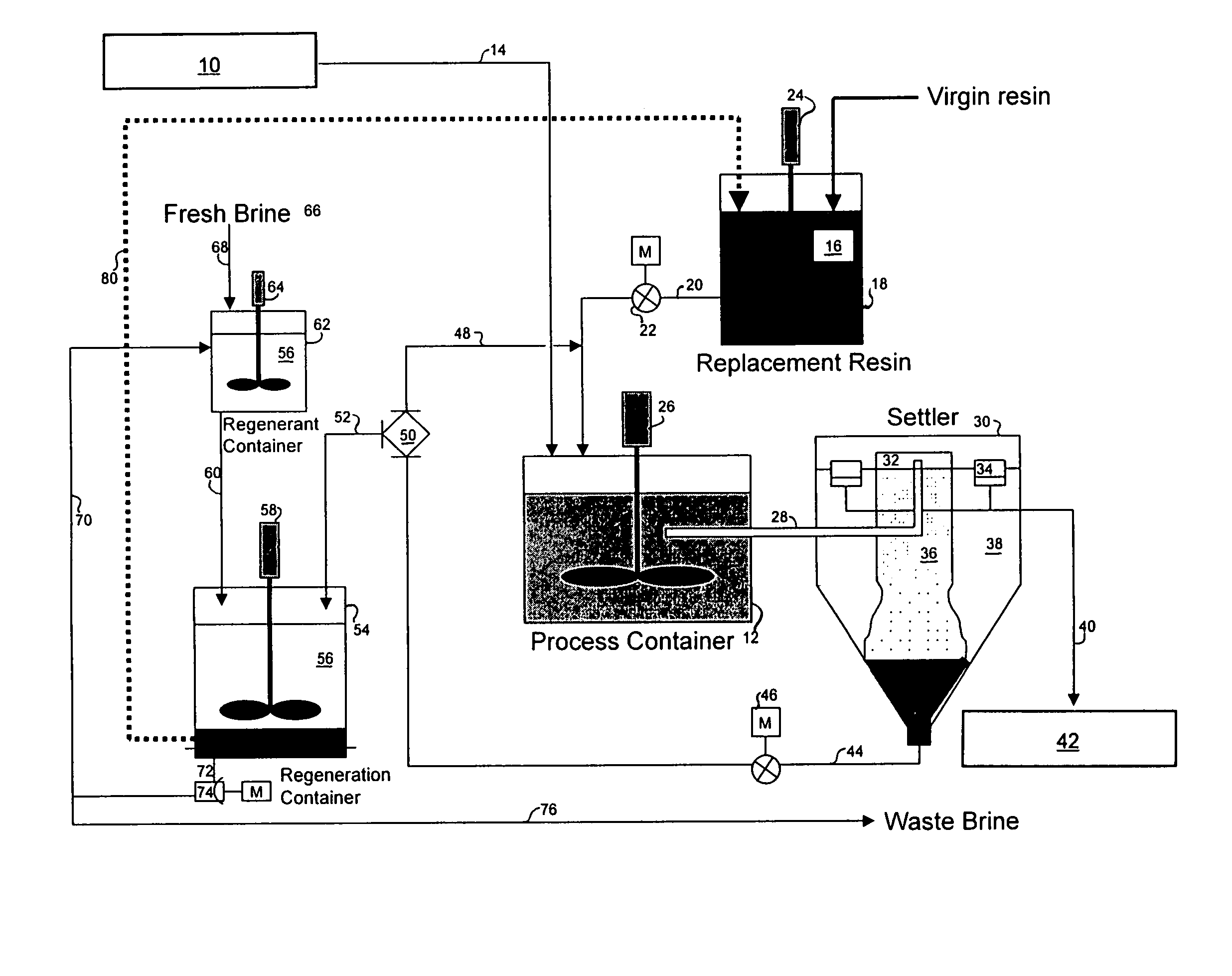

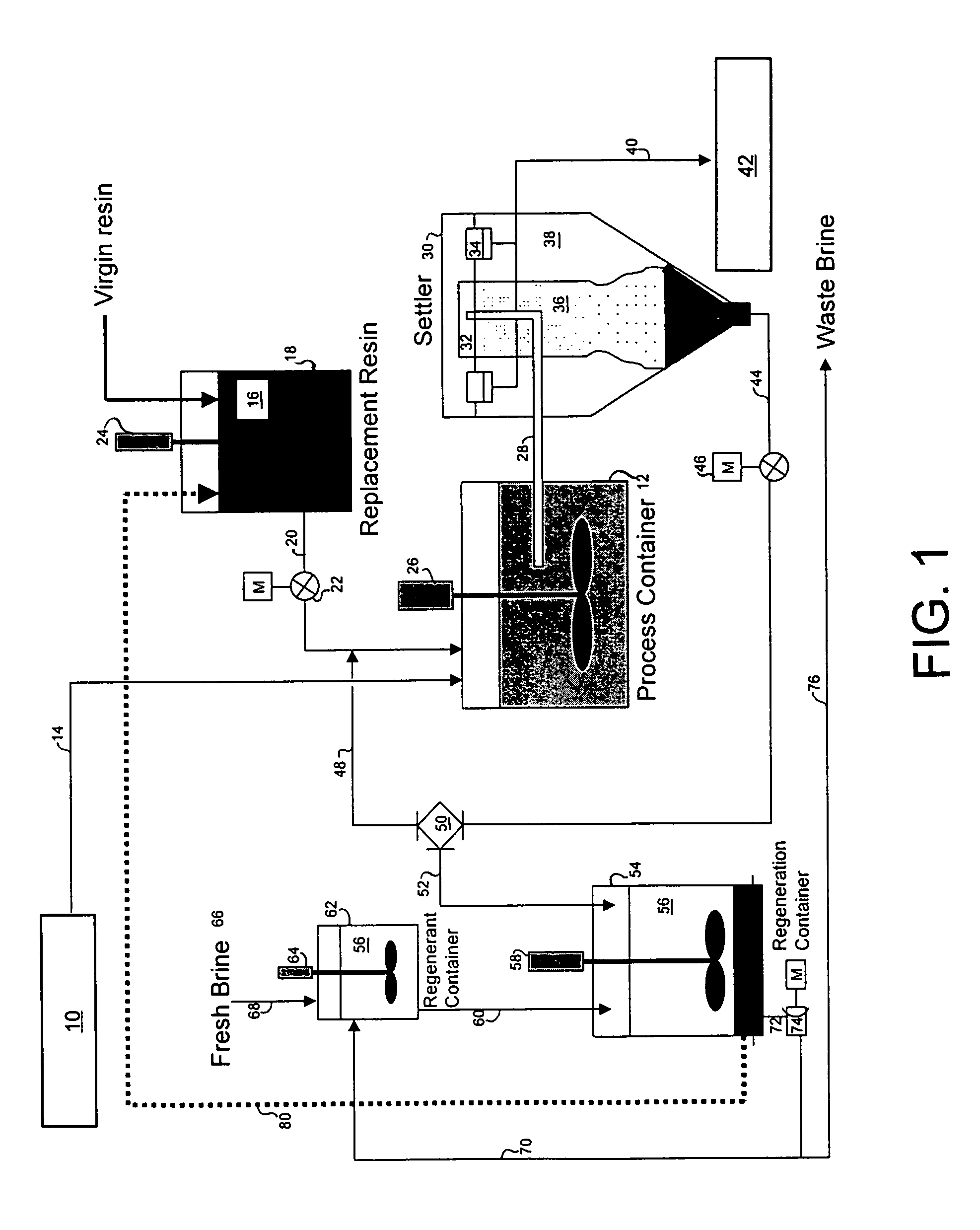

Water treatment process for perchlorate, nitrate, chromate, arsenate and other oxyanions for using weak-base anion exchange resins

ActiveUS20070114178A1Reduce pumping costsImprove chemical efficiencyOrganic anion exchangersIon-exchanger regenerationSelenateIon exchange

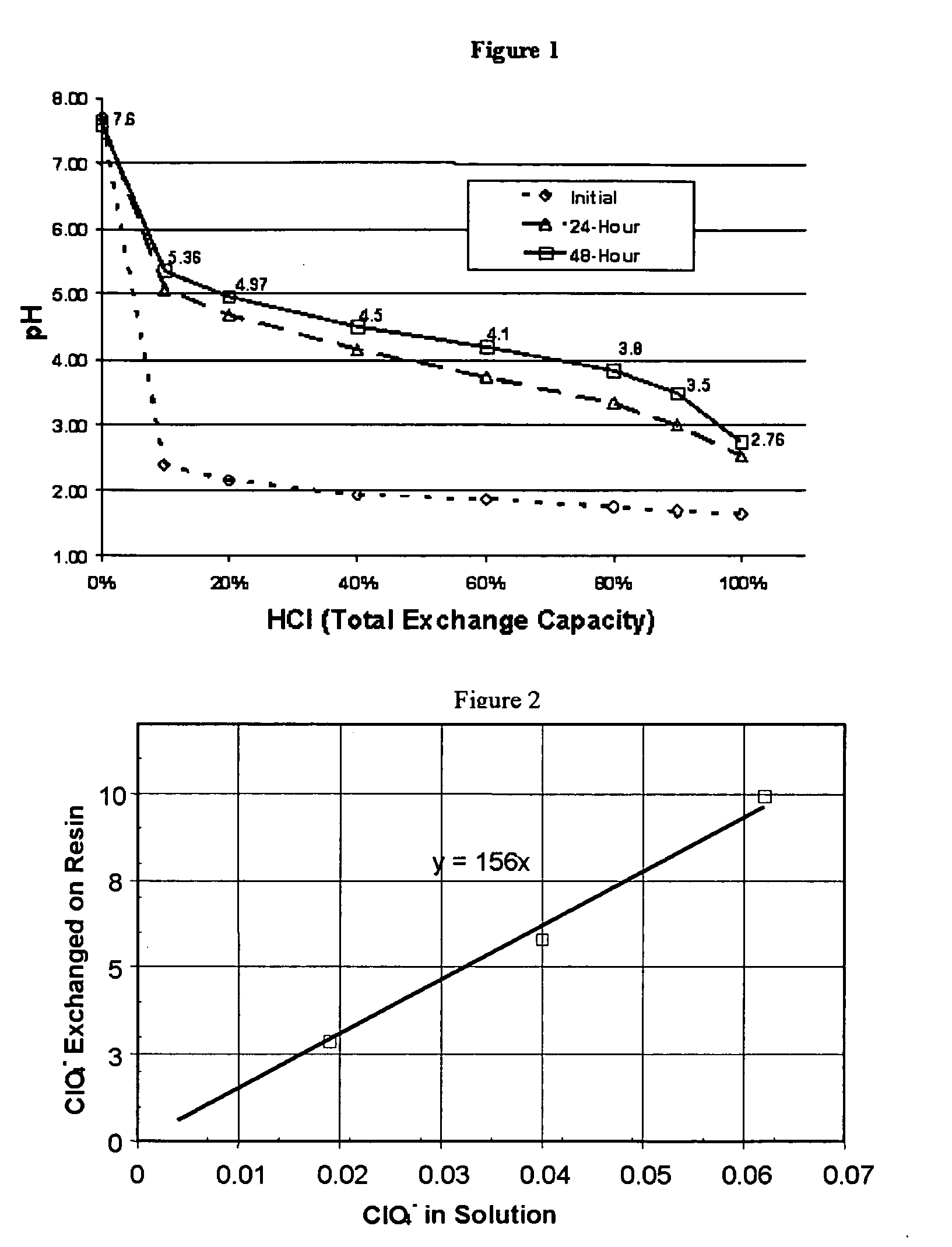

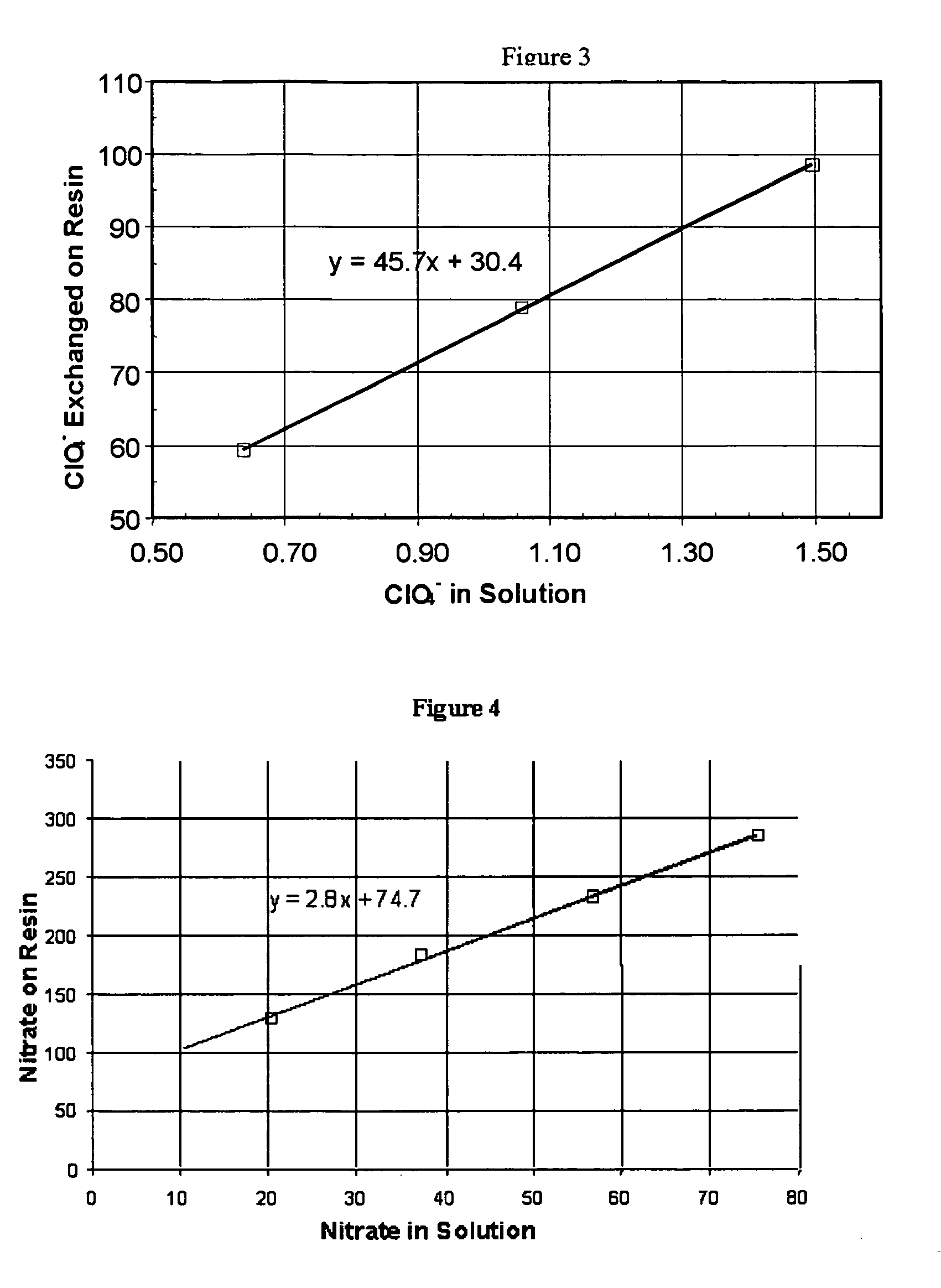

The invention consists of a water treatment process using selective and regenerable weak base anion exchange resins to remove any number of complex anions, especially oxyanions including perchlorate, nitrate, chlorate, arsenate, selenate, and chromate, from aqueous solutions. The treatment process is comprised of three key processes including 1) pretreatment to lower pH, 2) ion exchange, and 3) post treatment to adjust pH and alkalinity. The invention also includes processes for regenerating weak base anion resins and treatment of the residuals generated. This invention employs pressurized treatment, carbon dioxide management, and reuse of regenerating solution to minimize pumping and treatment costs.

Owner:APPLIED RES ASSOCS INC +1

Method for perchlorate removal from ground water

InactiveUS6881348B2Water treatment parameter controlOther chemical processesActivated carbonGroundwater

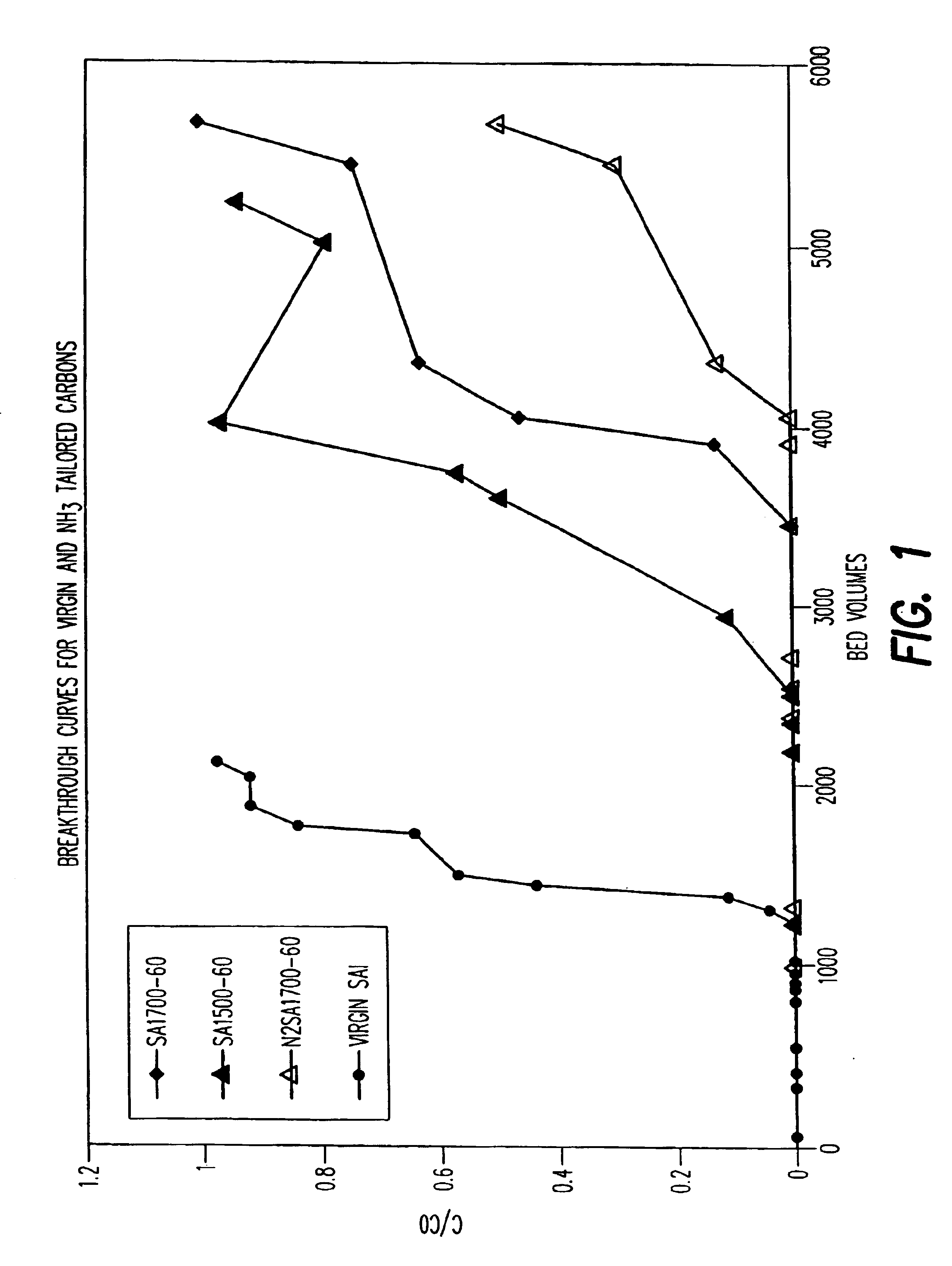

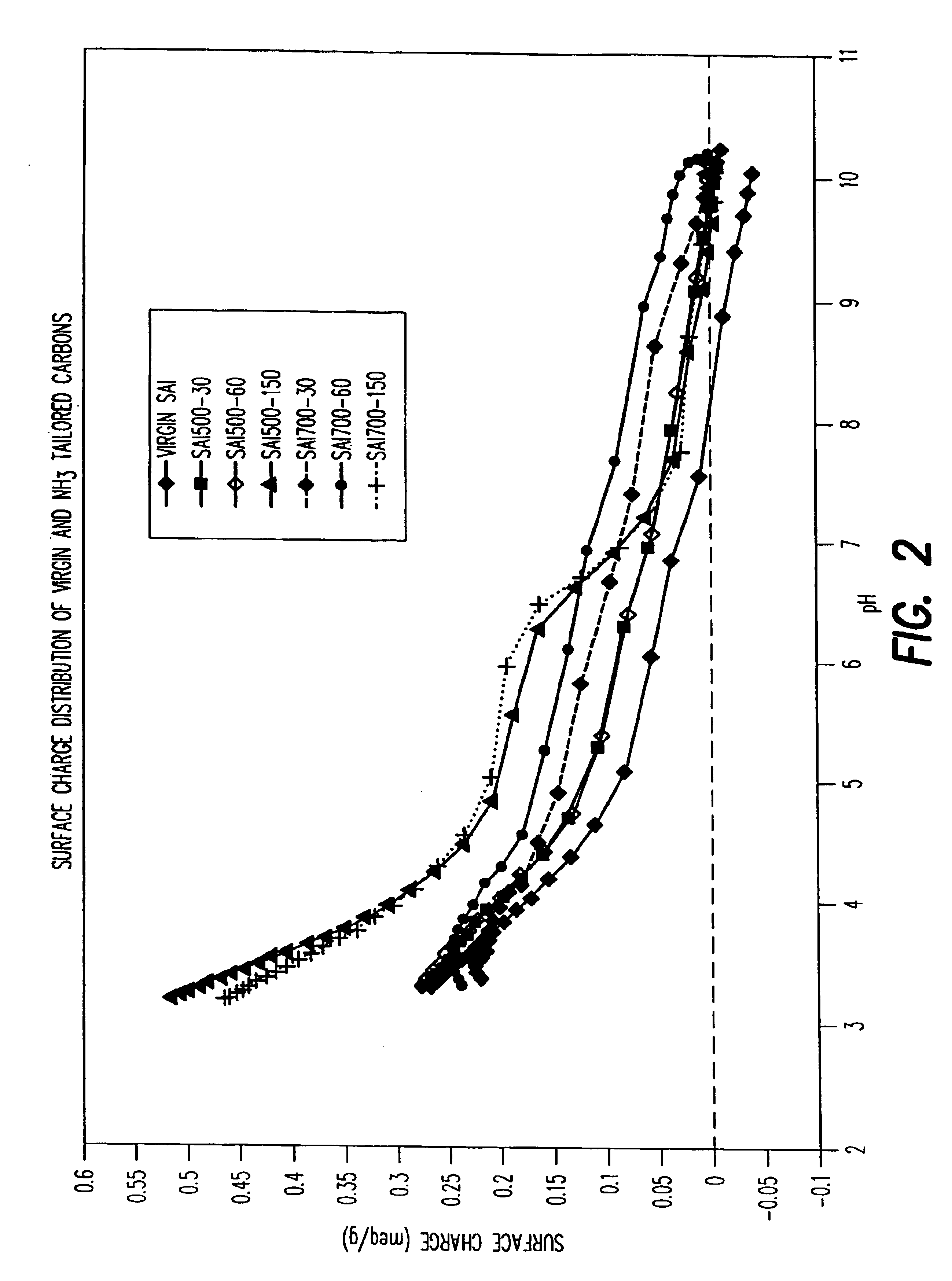

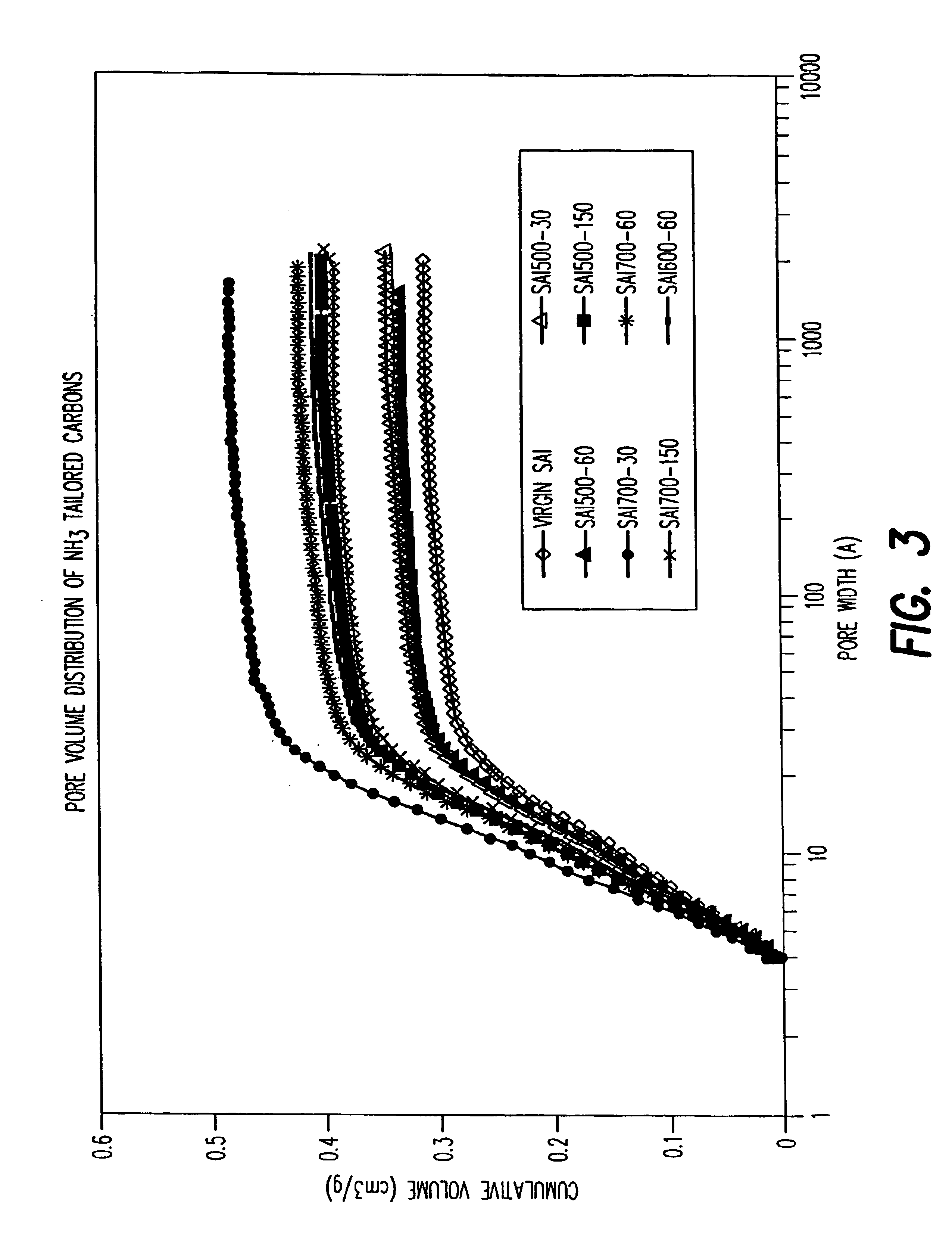

A method for removing perchlorate or other anionic contaminates from ground water which comprises the step of passing the ground water over activated carbon, wherein the activated carbon has been either preloaded with an organic cation functional group or organic cation polymer or cationic monomer, or tailored with ammonium or other reduced nitrogen-containing compound.

Owner:PENN STATE RES FOUND

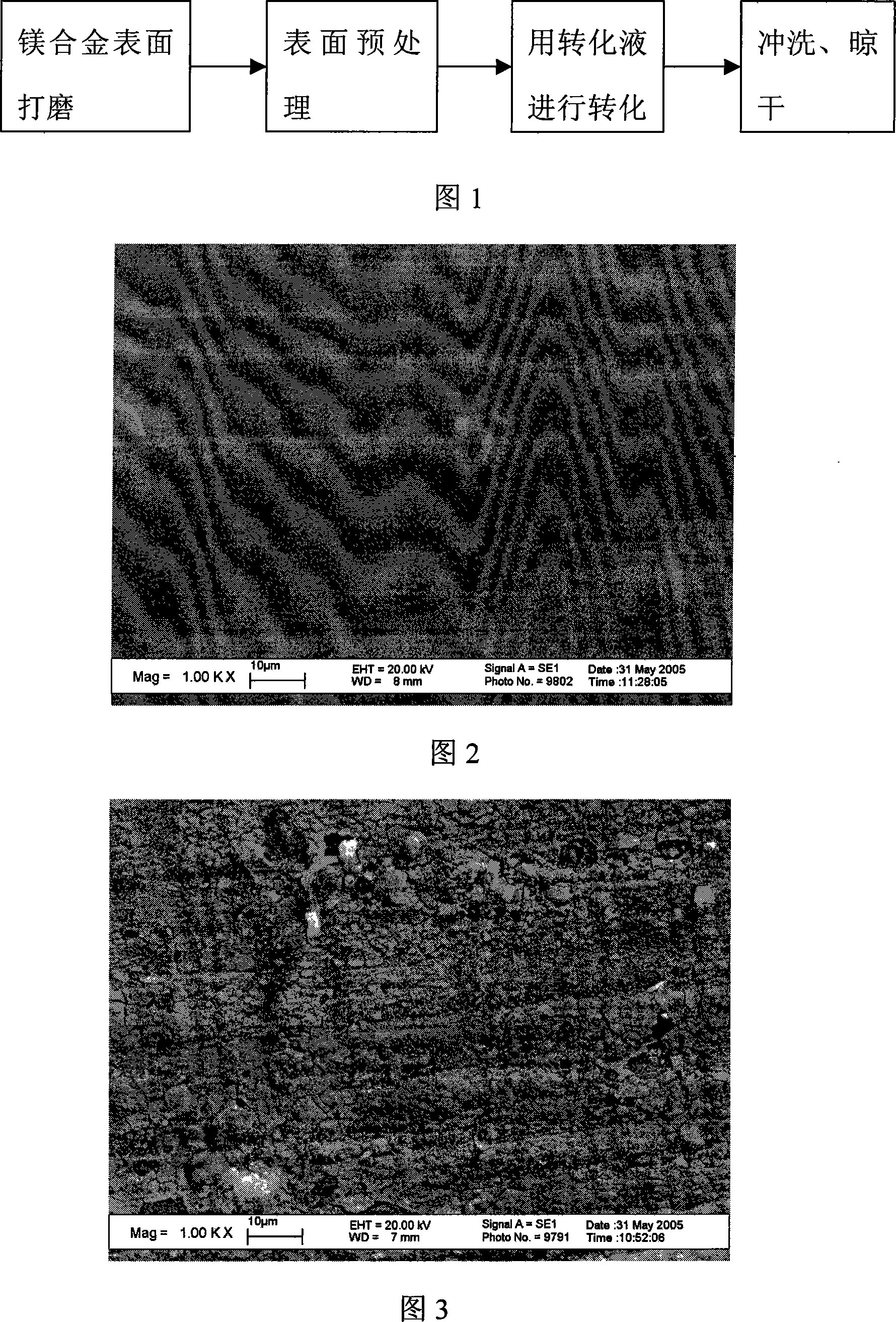

Non-chromium treatment fluid for preparation of corrosion-resistant oxidation film on magnesium alloy surface and method of use thereof

InactiveCN101225517AImprove corrosion resistanceGood adhesionMetallic material coating processesPersulfatePhytic acid

The invention discloses a preparation and application method for conversion liquid of a corrosion resistant oxide film on magnesium alloy surface, which is characterized in that: the conversion liquid adopts rare-earth-containing salt, permanganate, persulphate, nitrate and perchlorate as composite oxidant, zirconium salt, vanadic salt and strontium salt as film forming promoter, boric acid, aminoacetic acid-hydrochloric acid solution as pH buffer regulator, pyridine, thiourea and derivatives, tannins, phytic acid and the salt compound as corrosion inhibitor, sodium dodecyl benzene sulfonate and dodecyl phenol polyoxyethlene ether (OP-10) as wetting agent; the conversion liquid is free from hexavalent chromium and environment-friendly; heating is not required for chemical conversion treatment, and the treatment time is 1 to 5min; composite oxide film with good corrosion resistance performance comprising rare-earth composite oxide, magnesia and manganese oxide can be rapidly prepared at on magnesium alloy surface at ambient temperature. The preparation method for conversion liquid of a corrosion resistant oxide film on magnesium alloy surface has the advantages of fast film forming, simple process, uniform film, strong corrosion resistance and less environmental pollution.

Owner:广州市宏盈机械设备有限公司

In situ remediation of inorganic contaminants using stabilized zero-valent iron nanoparticles

InactiveUS7635236B2Good dispersionEasy to remedyMaterial nanotechnologyWater treatment compoundsMaterials scienceChromic Ion

A method for preparing highly stabilized and dispersible zero valent iron nanoparticles and using the nanoparticles as a remediation technology against inorganic chemical toxins in contaminated sites. The method employs a composition containing select polysaccharides (starch or cellulose) as a stabilizer for the iron nanoparticles in a liquid carrier, and results in suspensions of iron nanoparticles of desired size and mobility in water, brine, soils or sediments. The stabilizer facilitates controlling the dispersibility of the iron nanoparticles in the liquid carrier. An effective amount of the composition is delivered to a contaminated site so that the zero valent iron nanoparticles can remediate one or more toxins such as an arsenate, a nitrate, a chromate, or a perchlorate in the contaminated site.

Owner:AUBURN UNIV

Toner particles of controlled morphology

The present invention is a method for the preparation of electrostatographic toner including the following steps. A polymer material is dissolved in an organic solvent to form an organic phase. The organic phase is dispersed in an aqueous phase that includes a particulate stabilizer and a salt including an anion selected from chloride, oxychloride, sulfate, perchlorate, nitrate, dihydrogen phosphate, lactate, trifluoromethylsulfonate, and trifluromethylhydrate and a cation selected from aluminum, iron (III), tin (II) and zirconium (IV), to form a dispersion. The dispersion is homogenized. The organic solvent is evaporated from the dispersion and the resultant product is recovered, washed and dried. In an alternate method the salt is added directly to the dispersion.

Owner:EASTMAN KODAK CO

Explosive composition and its use

InactiveUS6984274B2Improve structural strengthLess-expensive productionBelt retractorsPedestrian/occupant safety arrangementNitro compoundPorosity

An explosive composition comprises a porous fuel and an oxidizer. The porous fuel is a solid with a structure size measuring between about 2 nm and 1000 nm and has a porosity that lies between 10% and 98%. The oxidizer is solid or liquid at room temperature and is incorporated into the pores of the porous fuel. The oxidizer is selected, in an amount of at least 50% by weight relative to a total quantity of the oxidizer, from the group consisting of hydrogen peroxide, hydroxyl ammonium nitrate, organic nitro compounds or nitrates, alkali metal nitrates or earth alkali metal nitrates as well as metal nitrites, metal chlorates, metal perchlorates, metal bromates, metal iodates, metal oxides, metal peroxides, ammonium perchlorate, ammonium nitrate and mixtures thereof.

Owner:TRW AIRBAG SYST

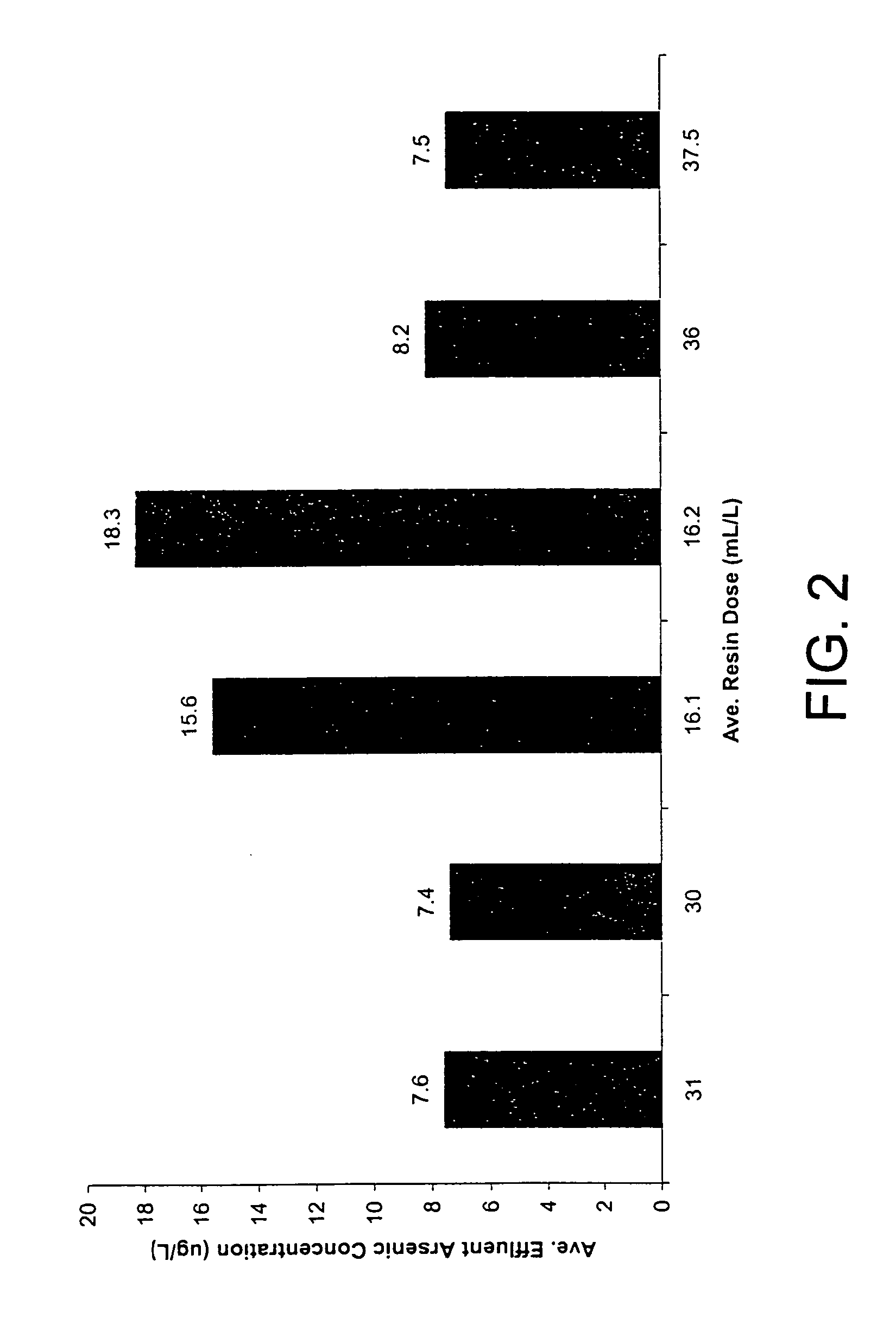

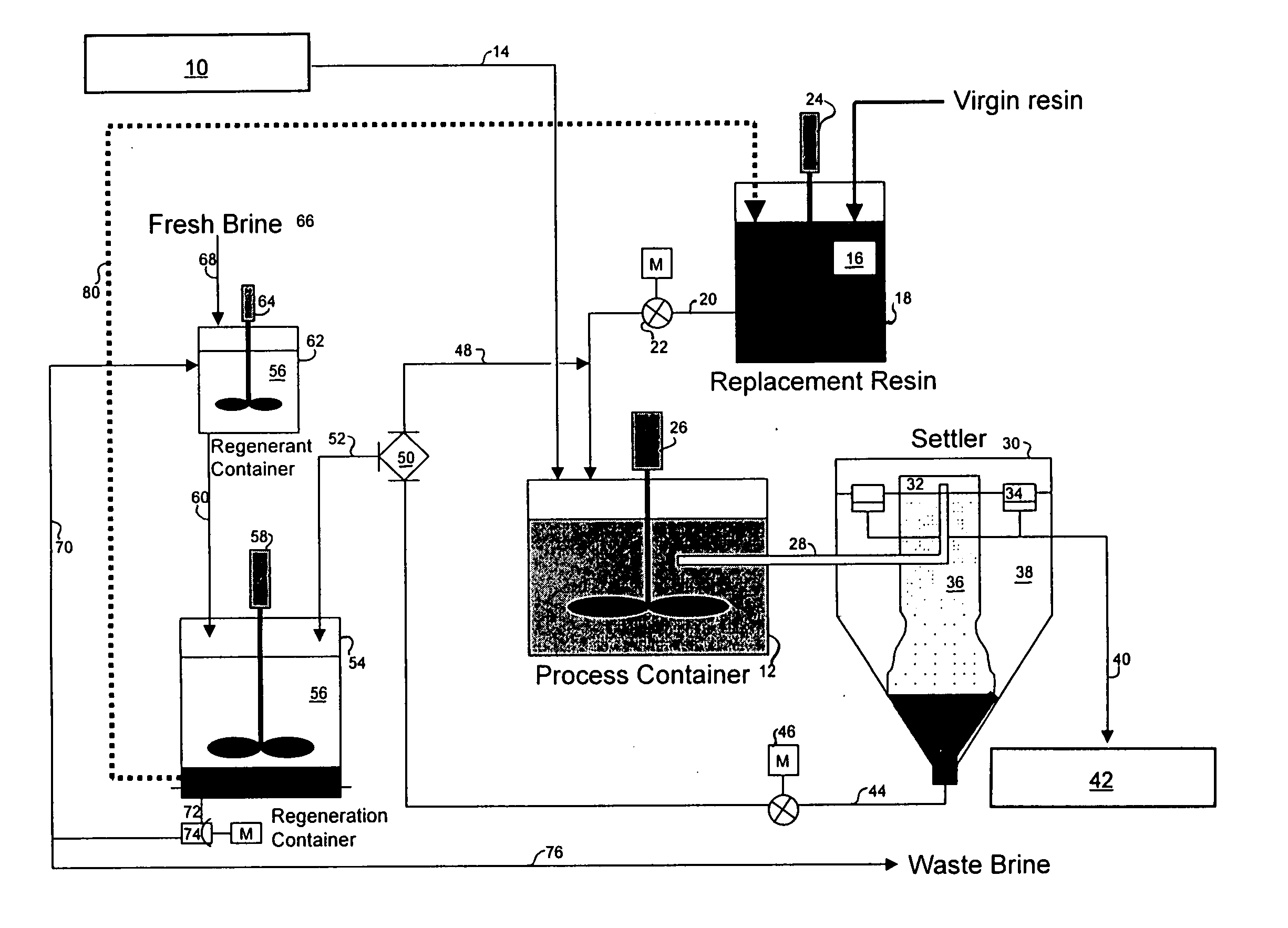

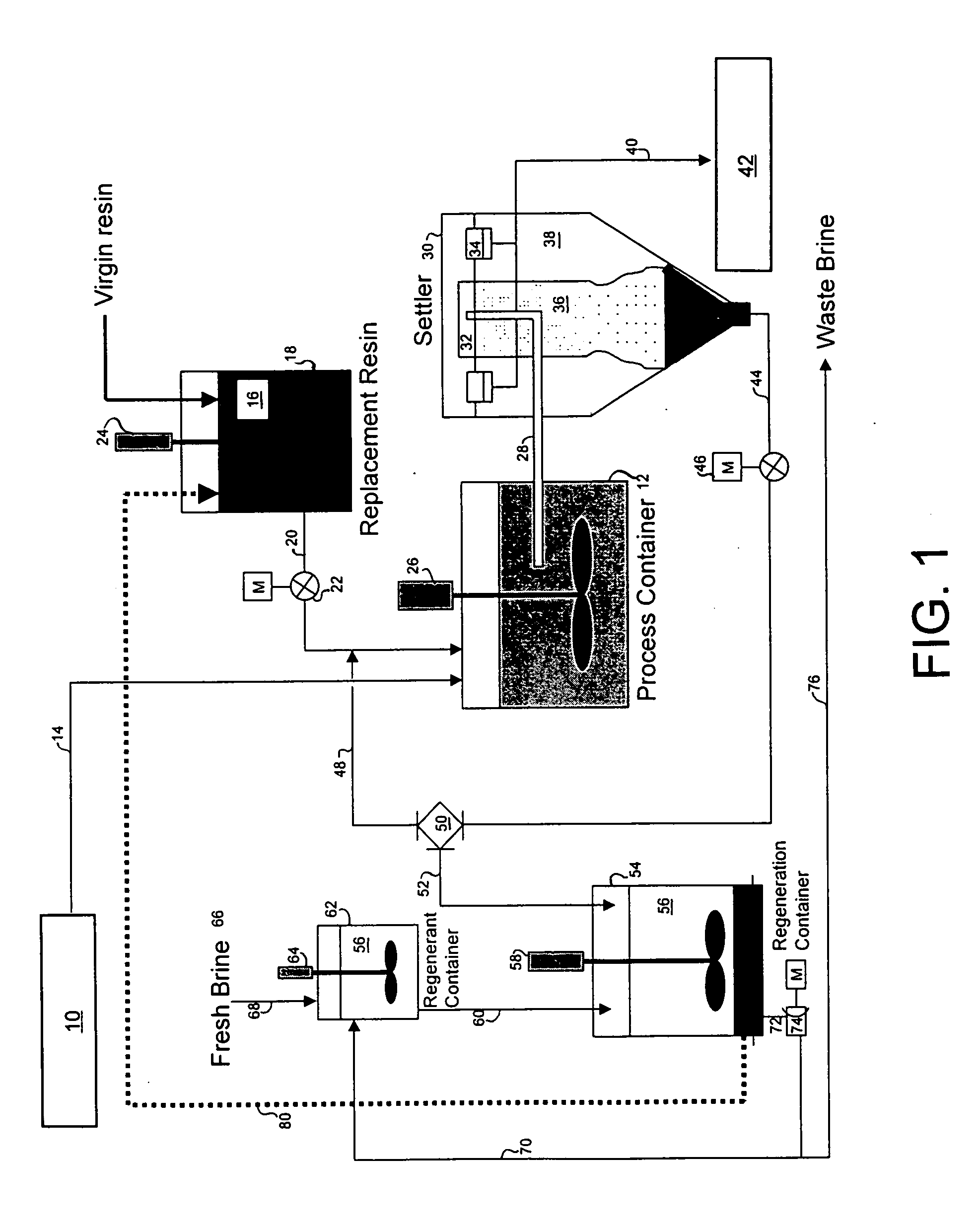

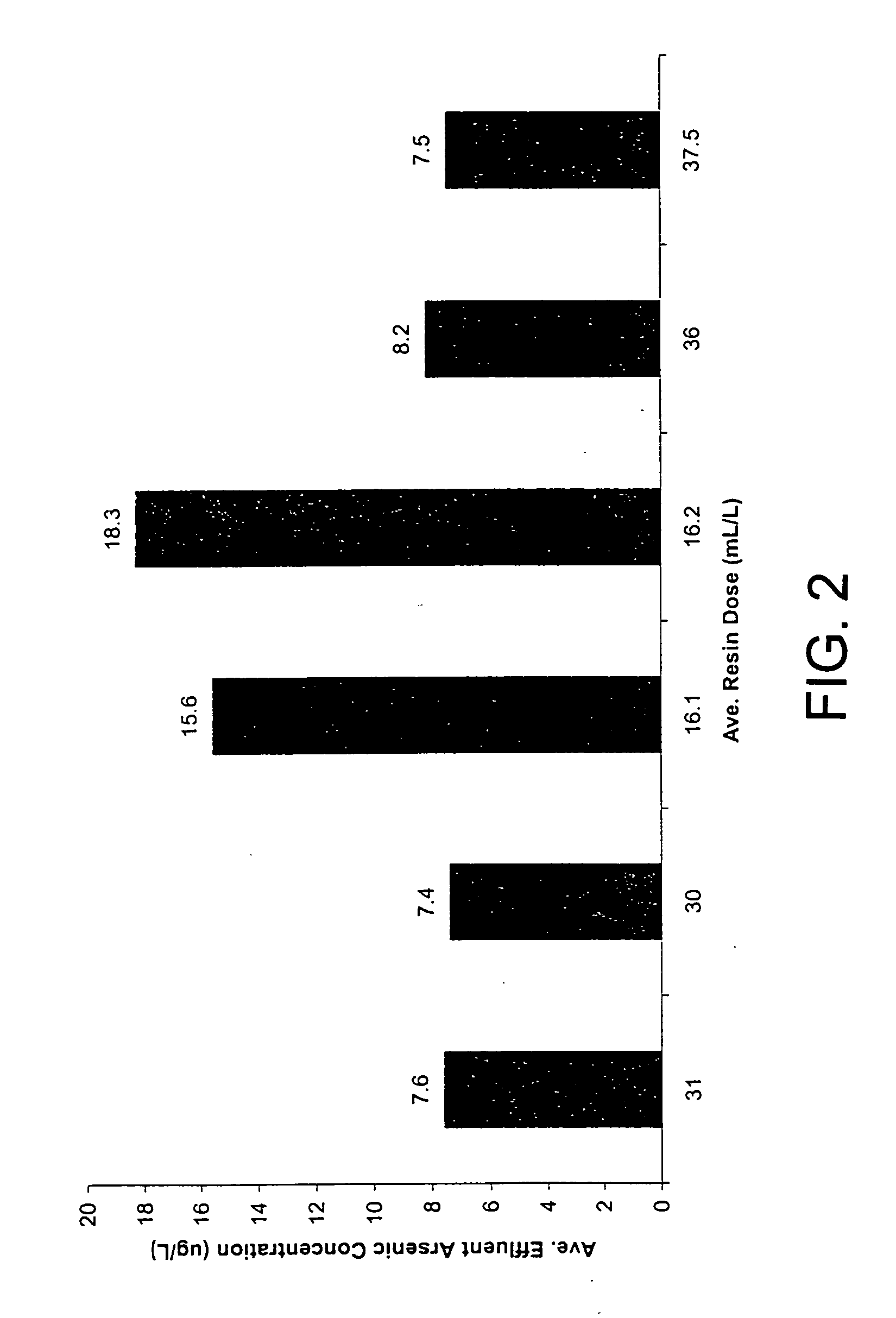

Inorganic contaminant removal from water

A method is provided for removing an inorganic ionic species or organometallic ion contaminant, or combination contaminants, including such as arsenic, chromium, bromide, bromate, perchlorate, and / or others from water which contains an unacceptably high concentration of the contaminant(s). The method includes treating the water with an ion exchange resin, preferably a magnetic ion exchange resin such as MIEX® Resin, which is capable of adsorbing the inorganic ionic species contaminant(s), and regenerating and recycling the ion exchange resin back to the process. The method produces potable water from ground water containing such contaminants and eliminates breakthrough and chromatographic peaking problems observed with conventional ion exchange systems.

Owner:IXOM OPERATIONS

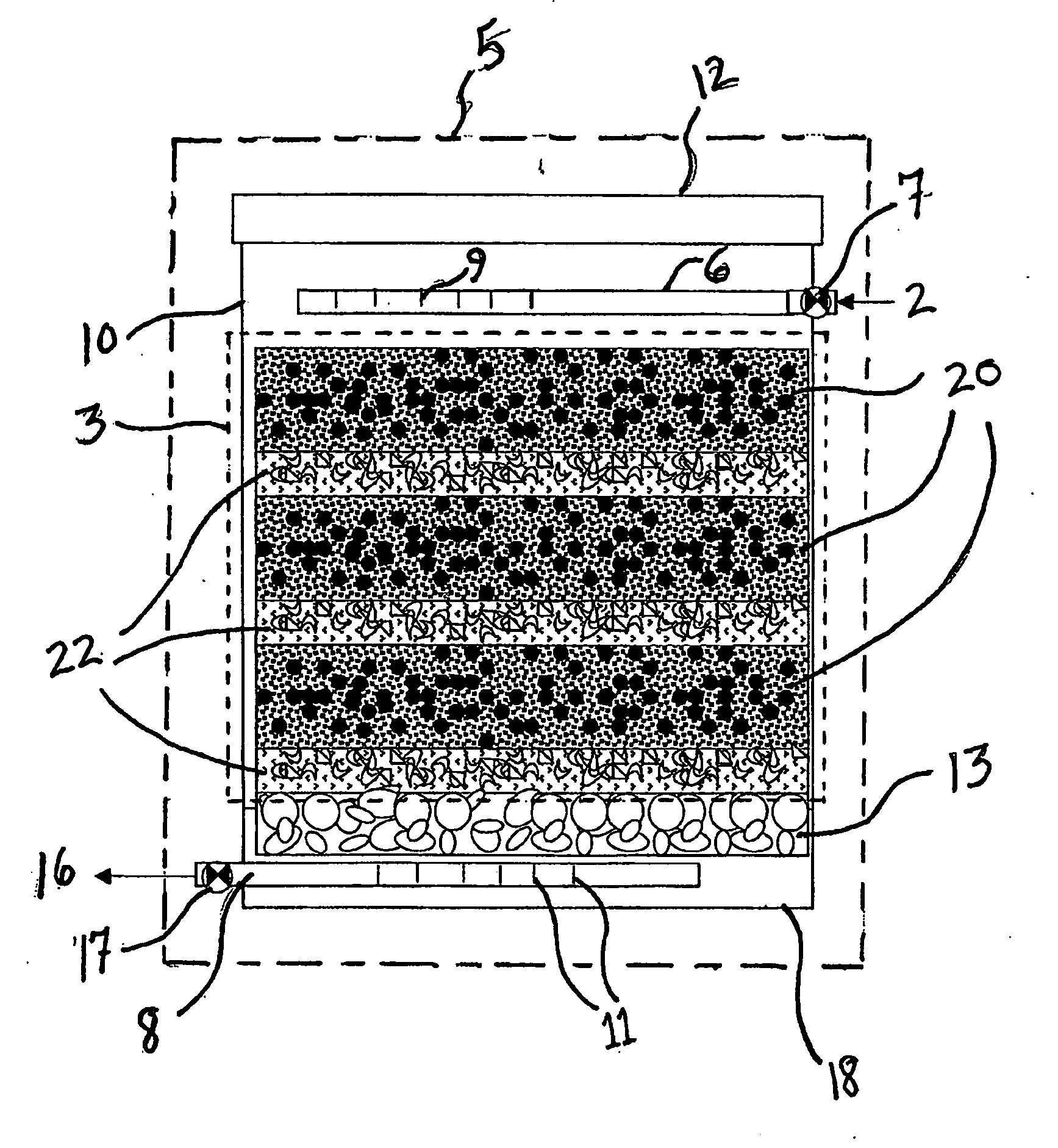

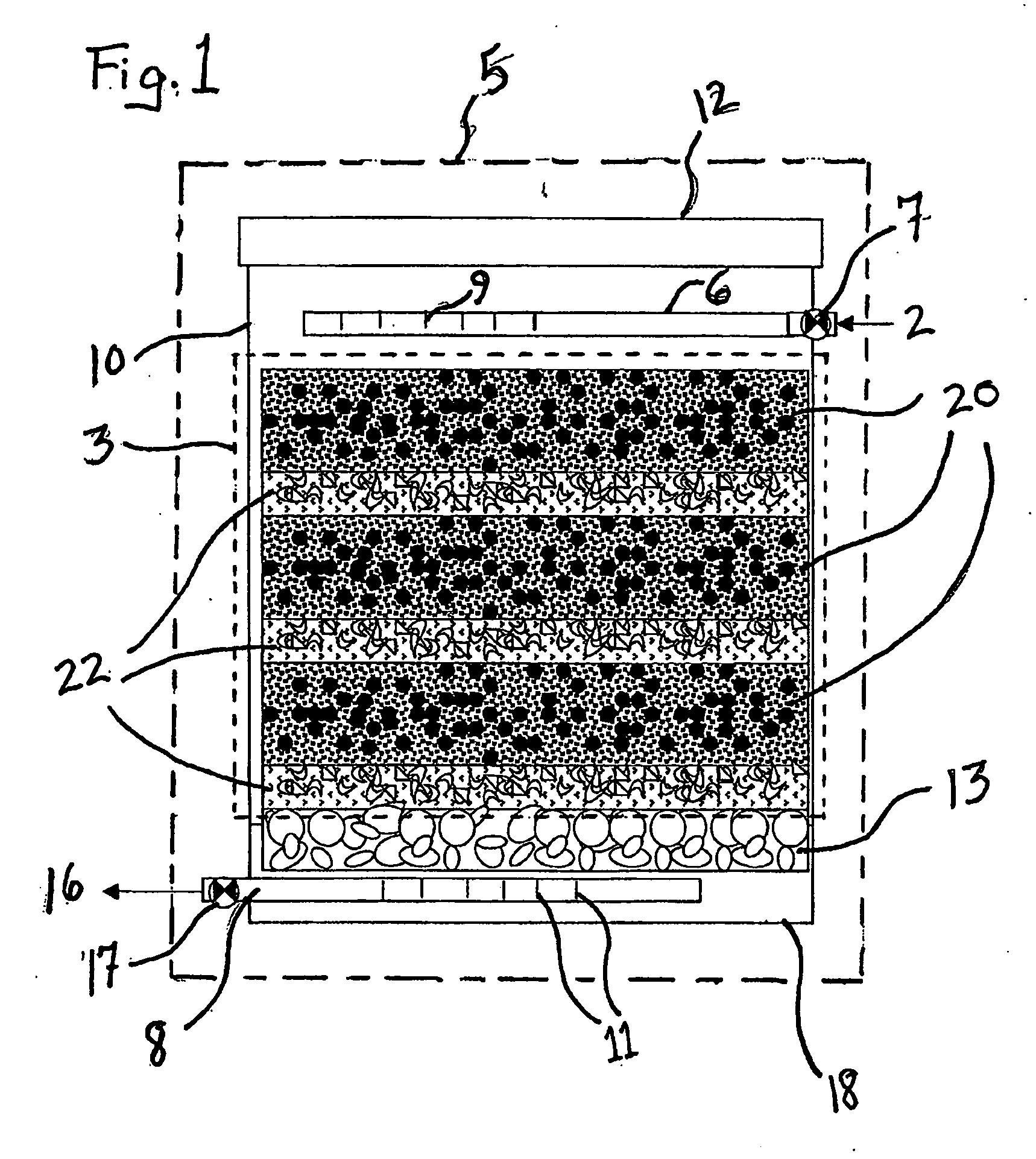

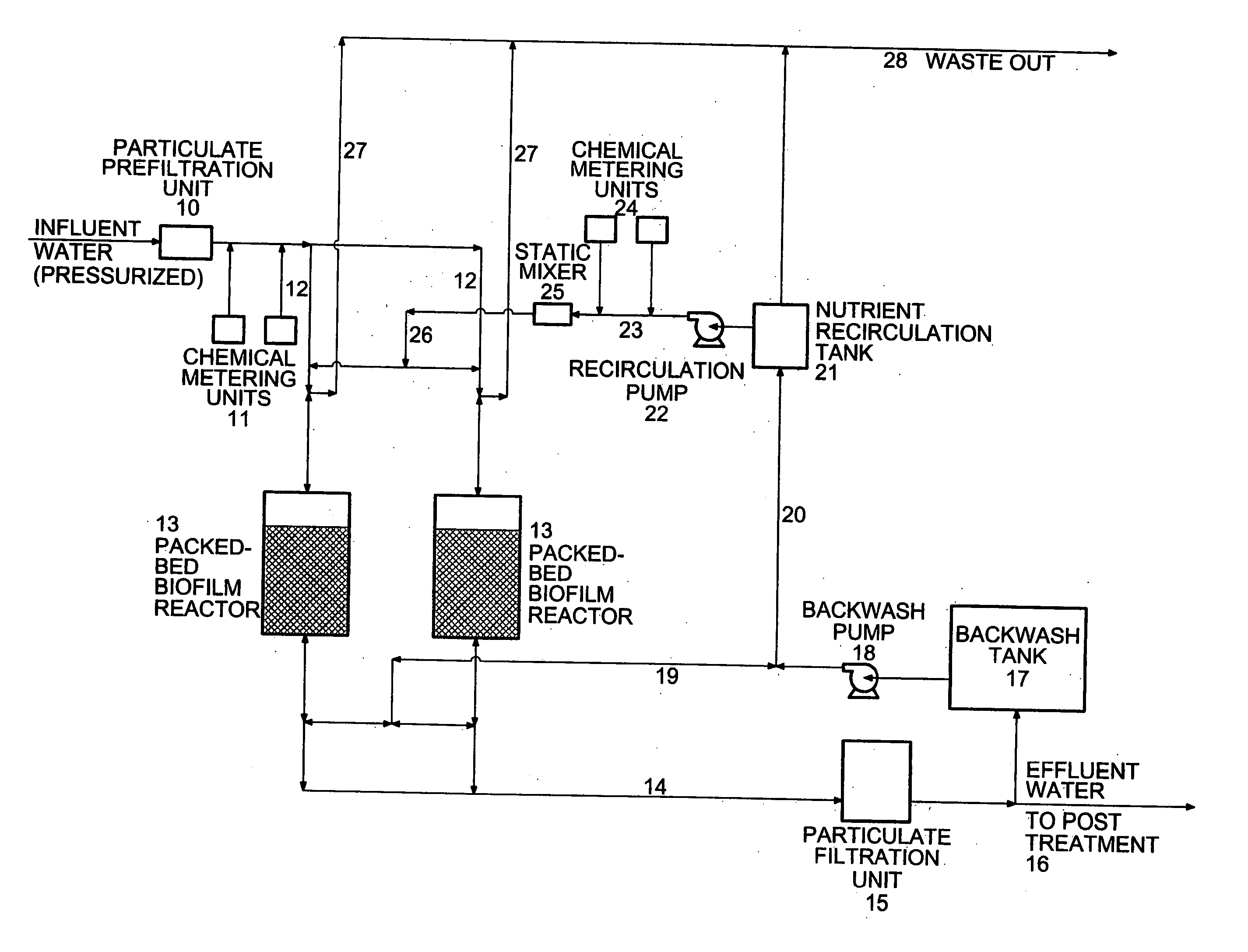

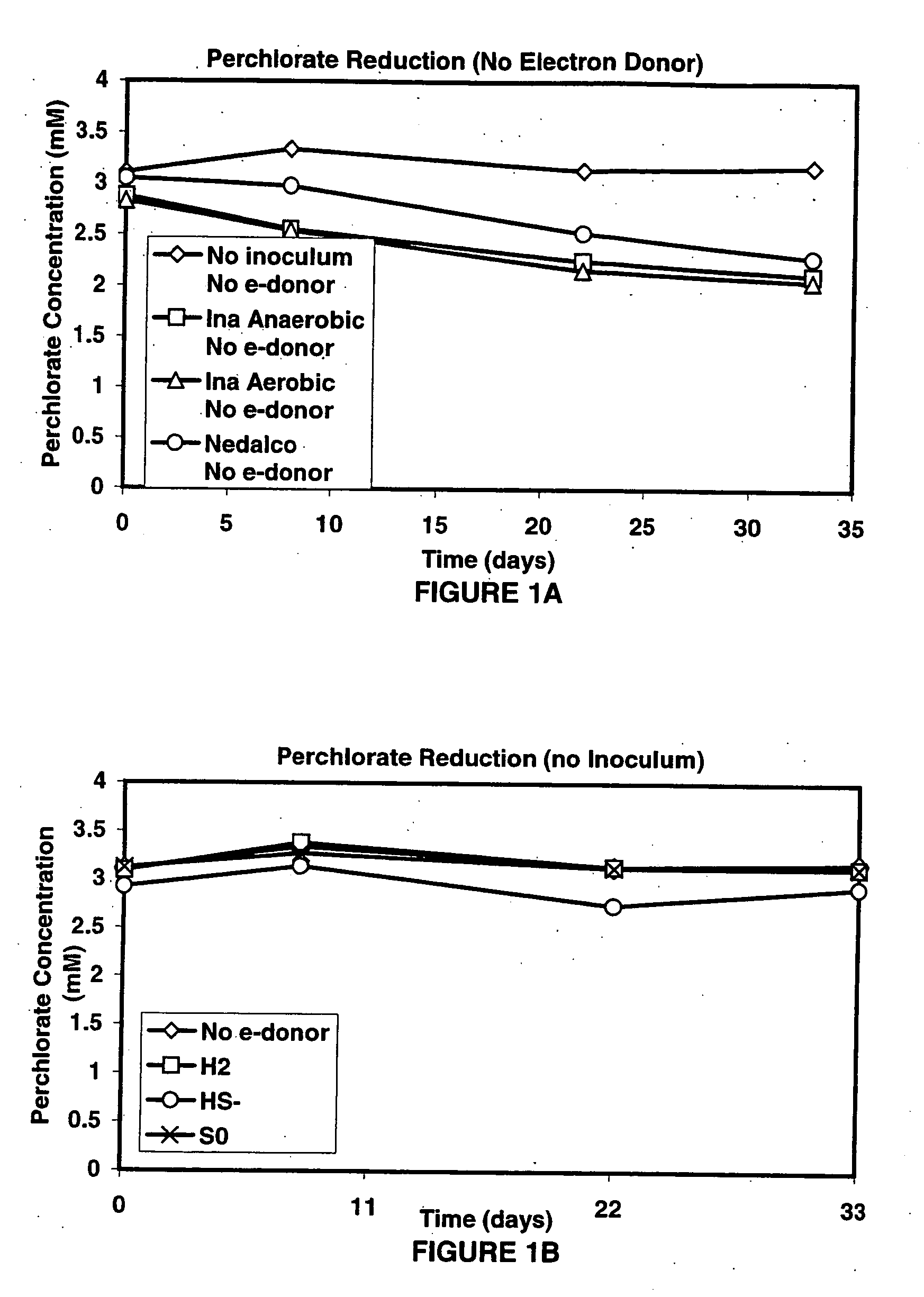

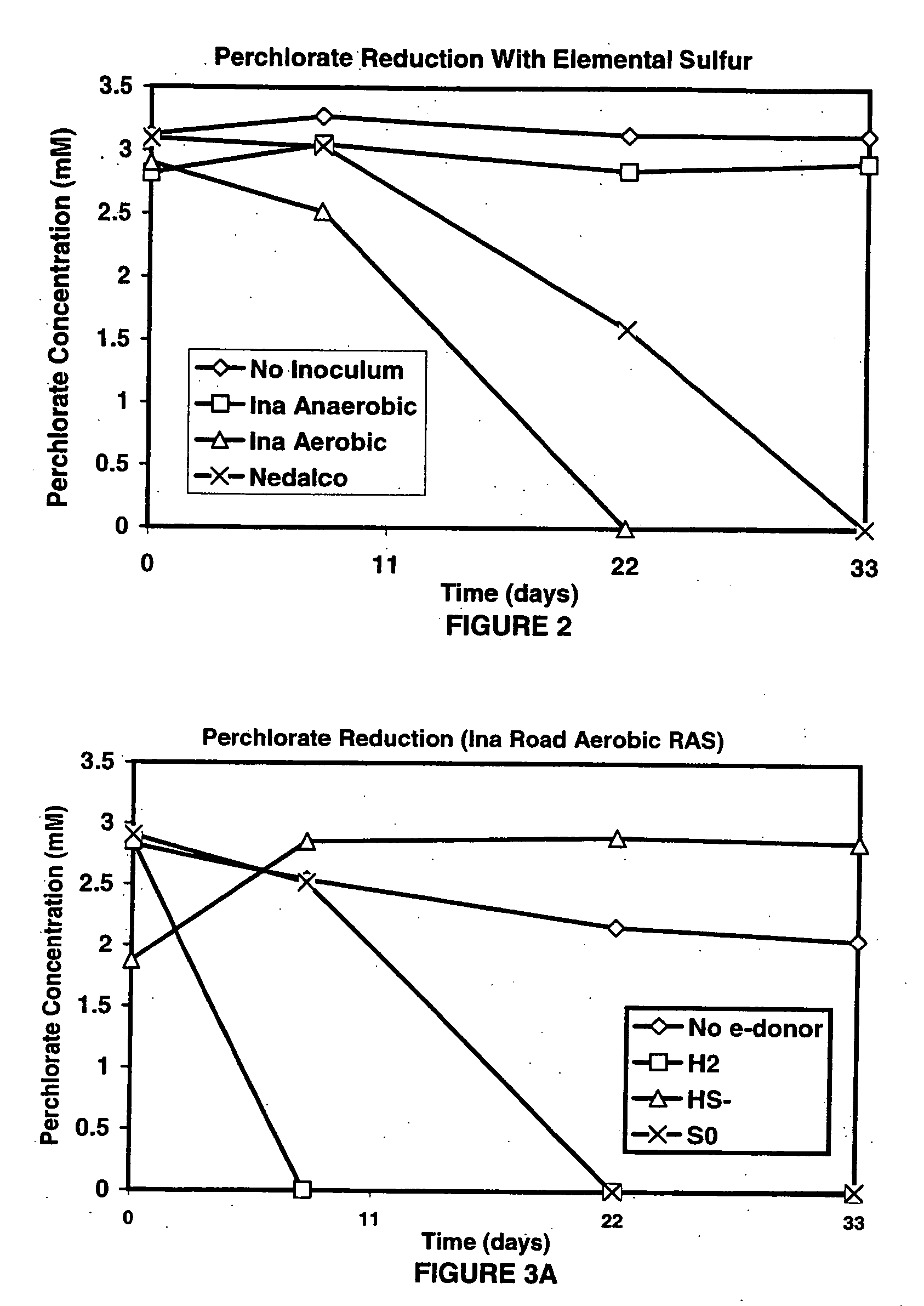

Process for autotrophic perchlorate reduction using elemental sulfur and mollusk shells

InactiveUS20070267346A1Reduce wasted waterReduce loadBioreactor/fermenter combinationsBiological substance pretreatmentsAlkalinityElectron donor

The invention relates to a system and method to reduce perchlorate in wastewater utilizing perchlorate-reducing bacteria, sulfur as an electron donor and mollusk shells as alkalinity agent. Embodiments of the invention include a perchlorate-reduction system comprising a bioreactor unit having perchlorate-reducing media comprising elemental sulfur, oyster shells and a microbial community, and can further include an optional pretreatment unit, wastewater-catchment and / or post-treatment components. Embodiments of the method include multiple steps utilizing the system and additional process steps that achieve enhanced perchlorate reduction.

Owner:UNIV OF MASSACHUSETTS

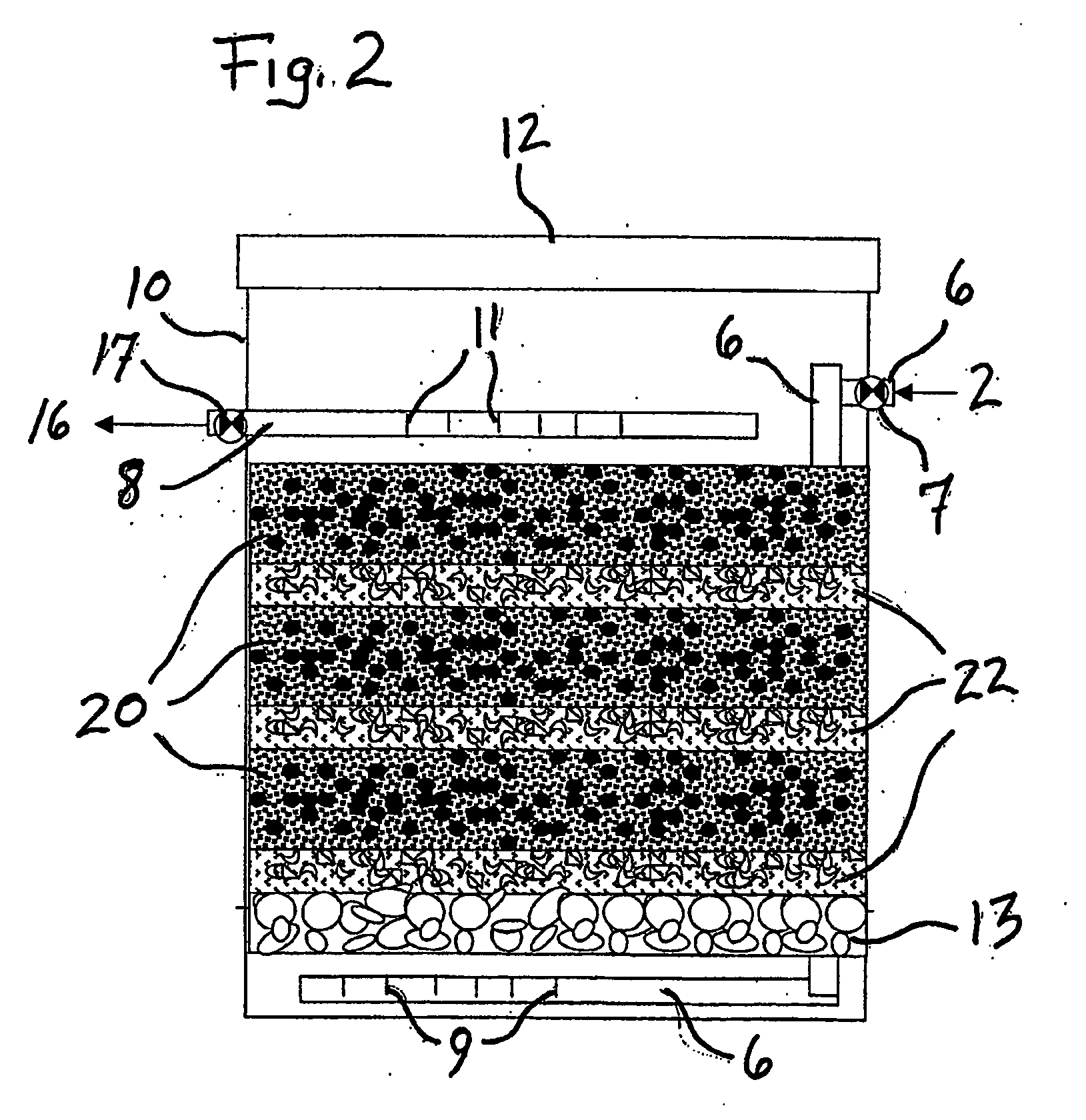

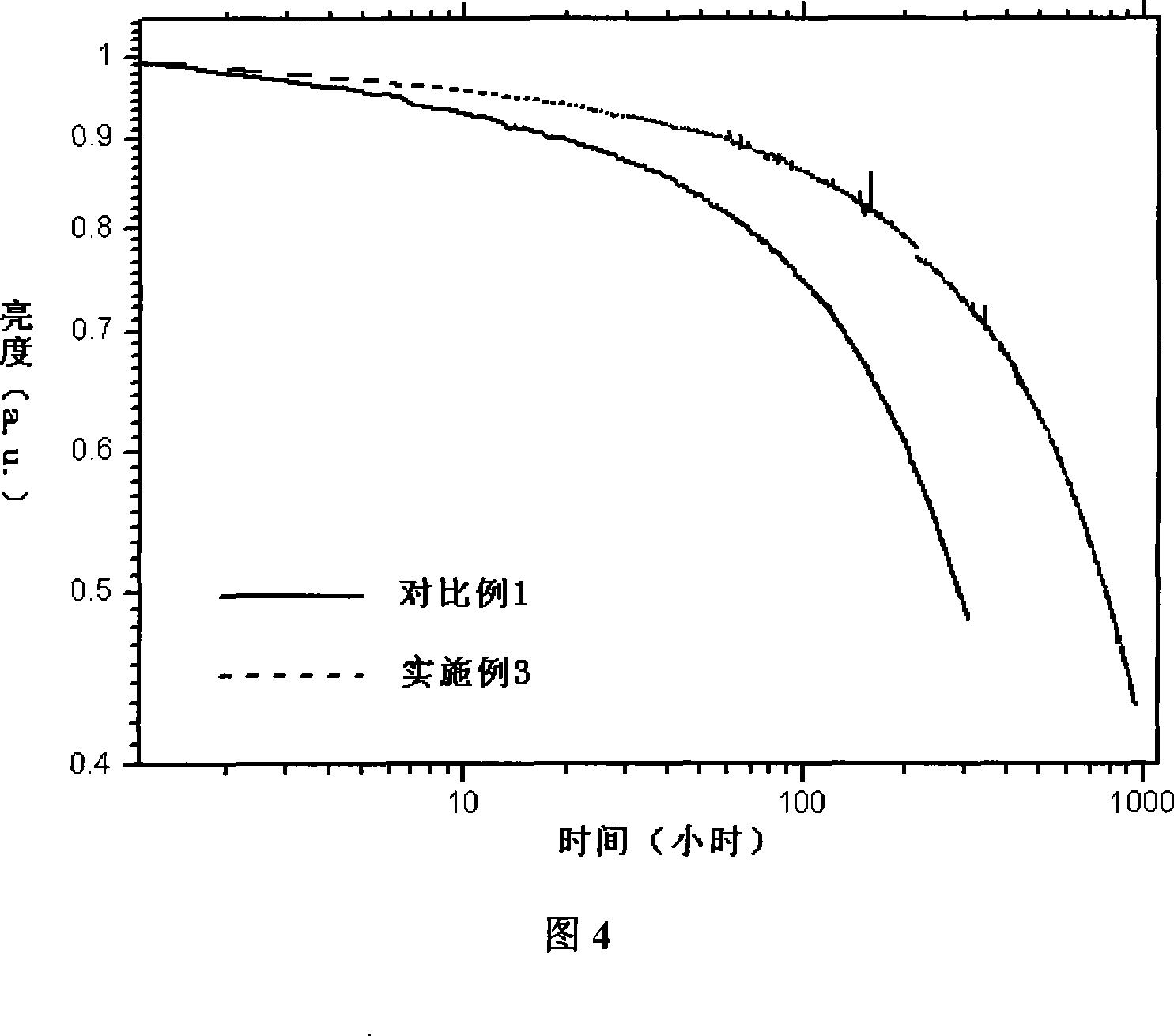

Organic electroluminescence device

ActiveCN101093878ASmall sizeOverall small sizeOther chemical processesSemiconductor/solid-state device detailsAlkaline earth metalOxygen

The organic electroluminescence device (OELD) includes packaging structure. The packaging structure includes a layer of thick film formed from polymeric material. Dryer is doped in the layer of thick film. The dryer includes alkali metals, alkaline earth metal and at least one object selected from following matters: metallic oxide, zeolite, and metal alcoholates with hydrocarbon in long chain, sulfate, halide, and perchlorate. The packaging structure is located at one side or two sides of OELD. The invention simplifies packaging technique, reduces defects in preparing procedures, raising flexibility and performance for obstructing water and oxygen so as to raise service life of device.

Owner:BEIJING VISIONOX TECH

Plasticizers Derived From Renewable Feedstock

Owner:GALATA CHEM LLC

Inorganic contaminant removal from water

ActiveUS20060011550A1Organic anion exchangersIon-exchanger regenerationHigh concentrationPotable water

A method is provided for removing an inorganic ionic species or organometallic ion contaminant, or combination contaminants, including such as arsenic, chromium, bromide, bromate, perchlorate, and / or others from water which contains an unacceptably high concentration of the contaminant(s). The method includes treating the water with an ion exchange resin, preferably a magnetic ion exchange resin such as MIEX® Resin, which is capable of adsorbing the inorganic ionic species contaminant(s), and regenerating and recycling the ion exchange resin back to the process. The method produces potable water from ground water containing such contaminants and eliminates breakthrough and chromatographic peaking problems observed with conventional ion exchange systems.

Owner:IXOM OPERATIONS

Method for forming a silicon oxide layer using spin-on glass

A method is provided for forming silicon oxide layers during the processing of semiconductor devices by applying a SOG layer including polysilazane to a substrate and then substantially converting the SOG layer to a silicon oxide layer using an oxidant solution. The oxidant solution may include one or more oxidants including, for example, ozone, peroxides, permanganates, hypochlorites, chlorites, chlorates, perchlorates, hypobromites, bromites, bromates, hypoiodites, iodites, iodates and strong acids.

Owner:SAMSUNG ELECTRONICS CO LTD

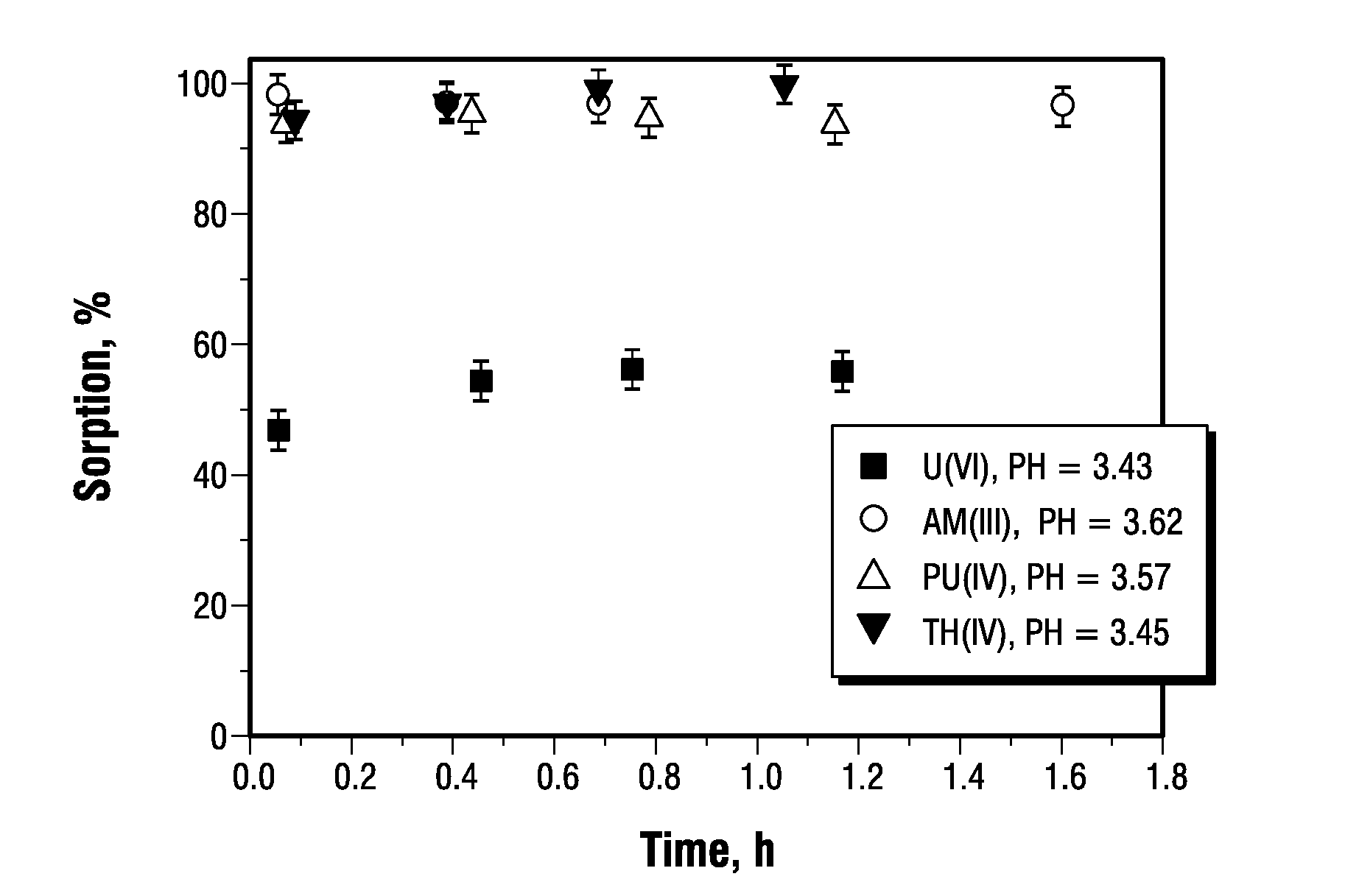

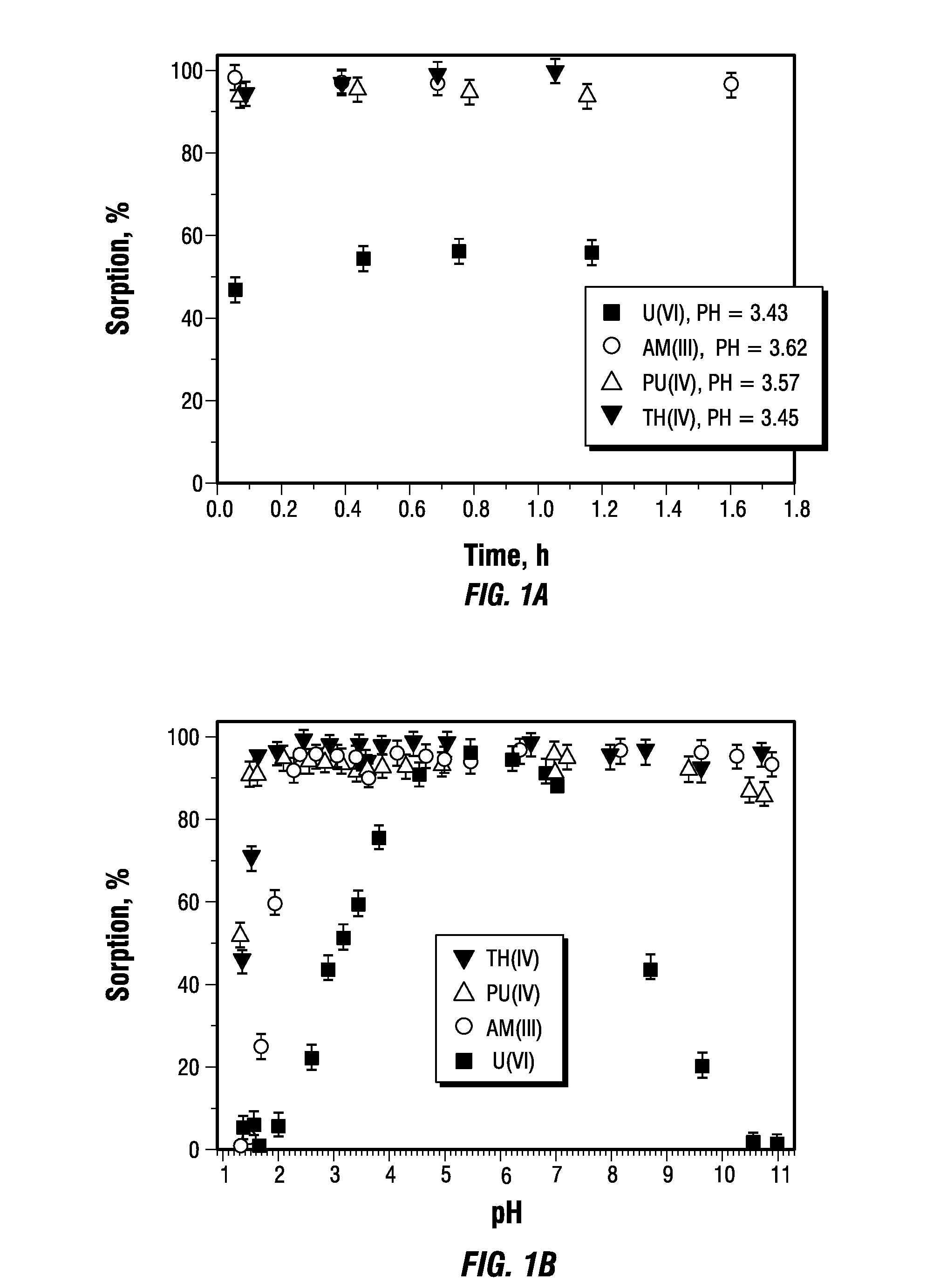

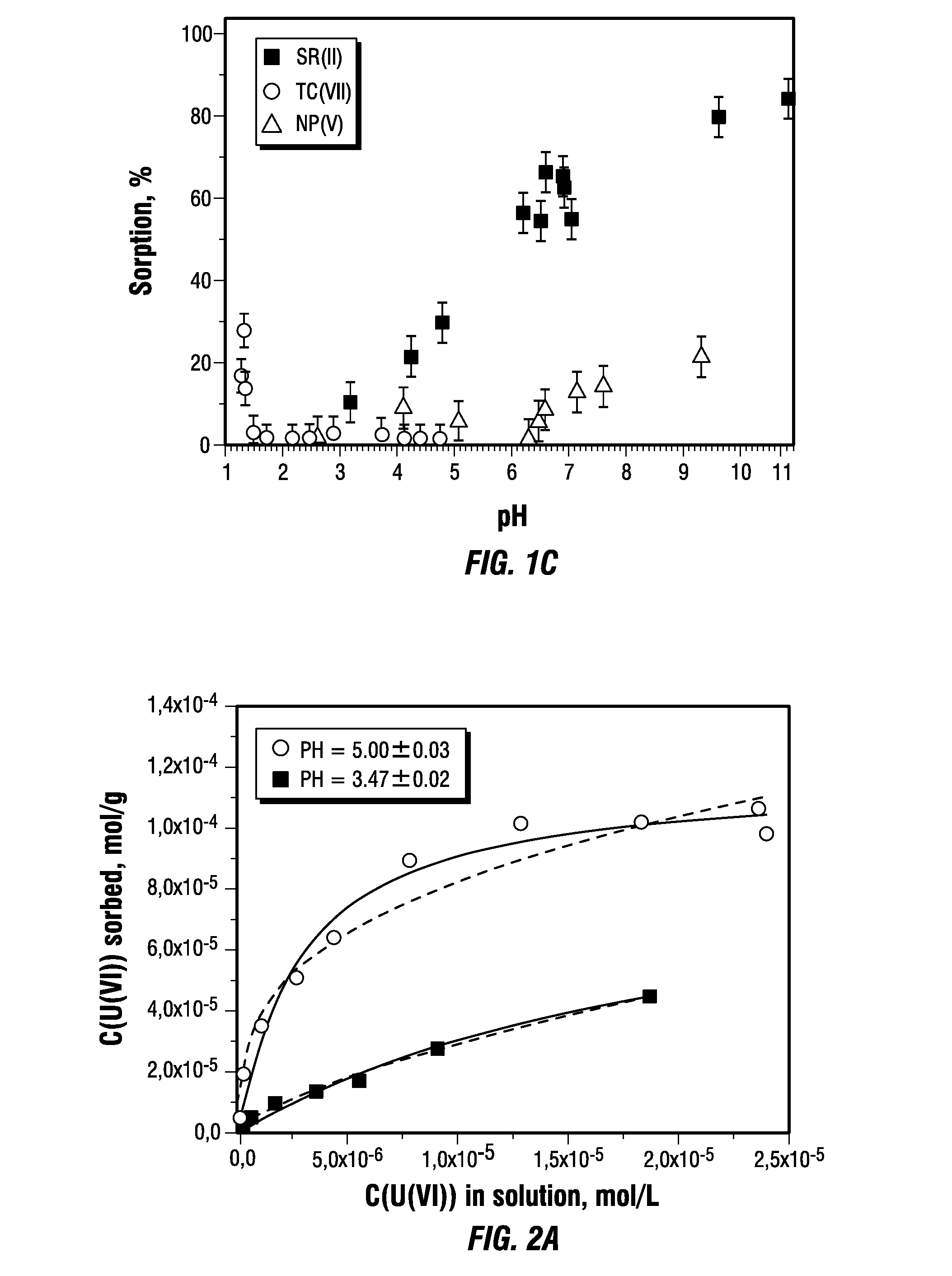

Sorption and separation of various materials by graphene oxides

Various aspects of the present invention pertain to methods of sorption of various materials from an environment, including radioactive elements, chlorates, perchlorates, organohalogens, and combinations thereof. Such methods generally include associating graphene oxides with the environment. This in turn leads to the sorption of the materials to the graphene oxides. In some embodiments, the methods of the present invention also include a step of separating the graphene oxides from the environment after the sorption of the materials to the graphene oxides. More specific aspects of the present invention pertain to methods of sorption of radionuclides (such as actinides) from a solution by associating graphene oxides with the solution and optionally separating the graphene oxides from the solution after the sorption.

Owner:ZONKO LLC

Method and system for treating oxidized contaminant-containing matrix

InactiveUS20060292684A1Reduce maintenanceHigh degreeWater treatment compoundsWater contaminantsSulfurElectron donor

A new and useful way of treating oxidized-contaminant-containing water, soil, rock, other geological or non-geological matrix formation (such as a landfill) is provided. A bioreactor is provided that includes elemental sulfur and a microbial population capable of oxidizing sulfur and reducing pertechnate (TcO4−), arsenate (H2AsO4−), chromate (CrO42−), bromate (BrO3−), chlorite (ClO2−), chlorate (ClO3−), perchlorate (ClO4−), and uranium(VI) oxide, with biological reduction of these oxidized contaminants in the matrix containing the oxidized contaminant performed by the bioreactor, with the elemental sulfur as the electron donor.

Owner:HYDRO GEO CHEM

Metal complexes for use as gas generants

InactiveUS20100084060A1Improve crush strength and other mechanical propertyEfficient combustionInorganic oxygen-halogen salt explosive compositionsNitrated metallo-organic explosive compositionsMetal nitrateHydrogen

Gas-generating compositions and methods for their use are provided. Metal complexes are used as gas-generating compositions. These complexes are comprised of a metal cation template, a neutral ligand containing hydrogen and nitrogen, and sufficient oxidizing anion to balance the charge of the complex. The complexes are formulated such that when the complex combusts, nitrogen gas and water vapor is produced. Specific examples of such complexes include metal nitrite amine, metal nitrate amine, and metal perchlorate amine complexes, as well as hydrazine complexes. A binder and co-oxidizer can be combined with the metal complexes to improve crush strength of the gas-generating compositions and to permit efficient combustion of the binder. Such gas-generating compositions are adaptable for use in gas-generating devices, such as automobile air bags.

Owner:NORTHROP GRUMMAN INNOVATION SYST INC

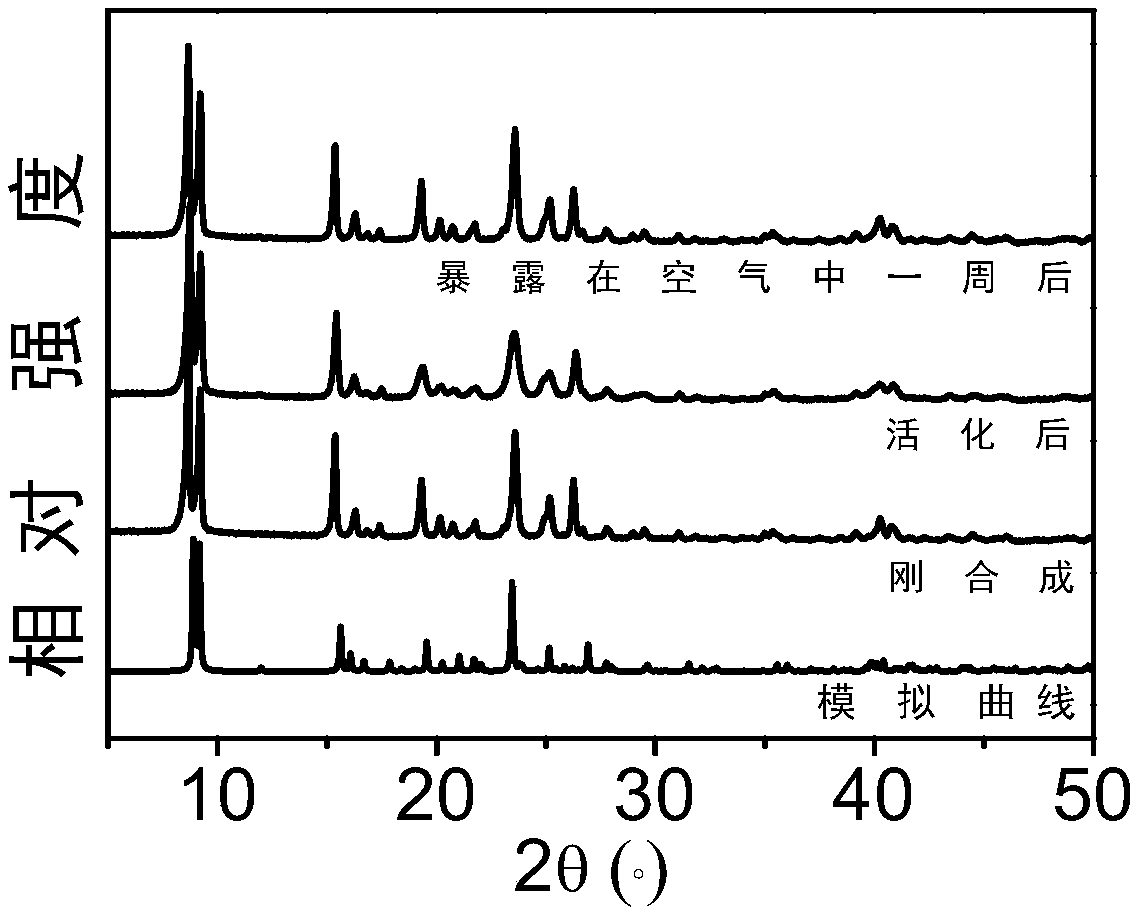

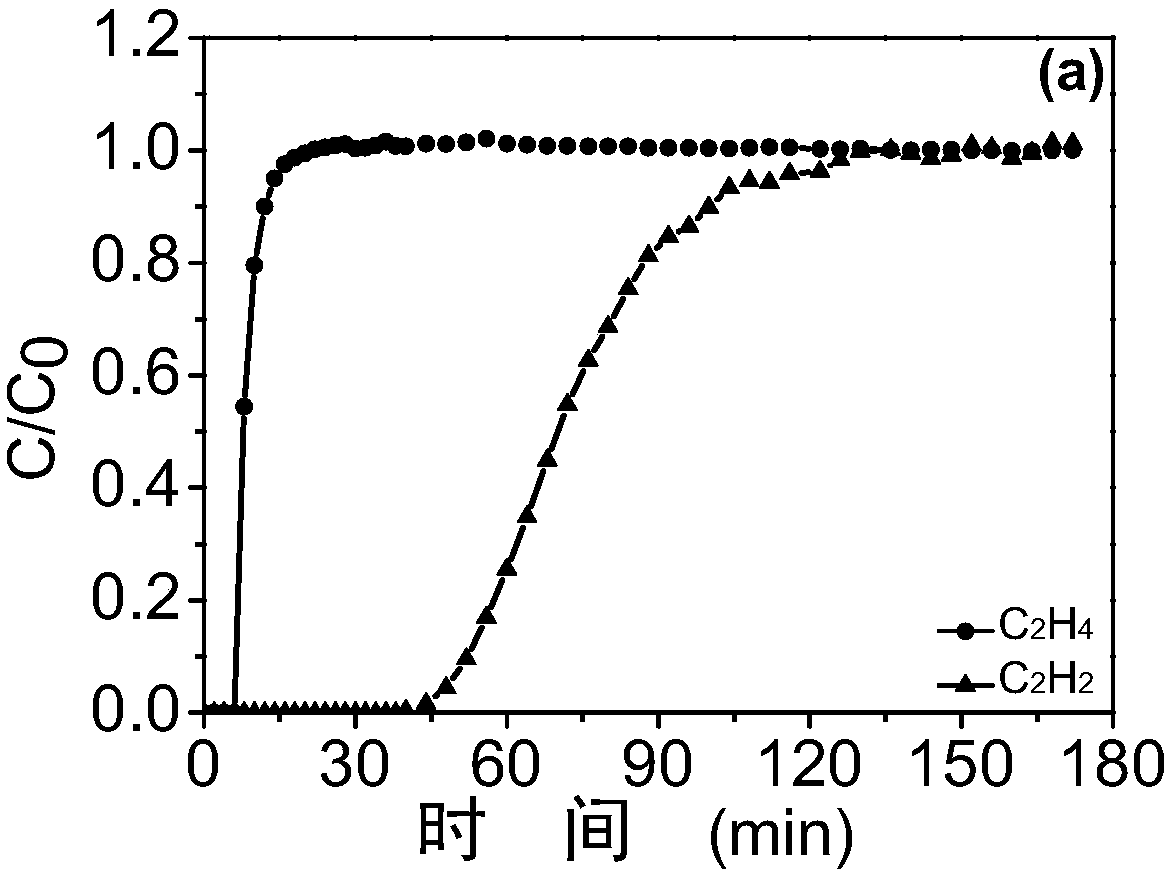

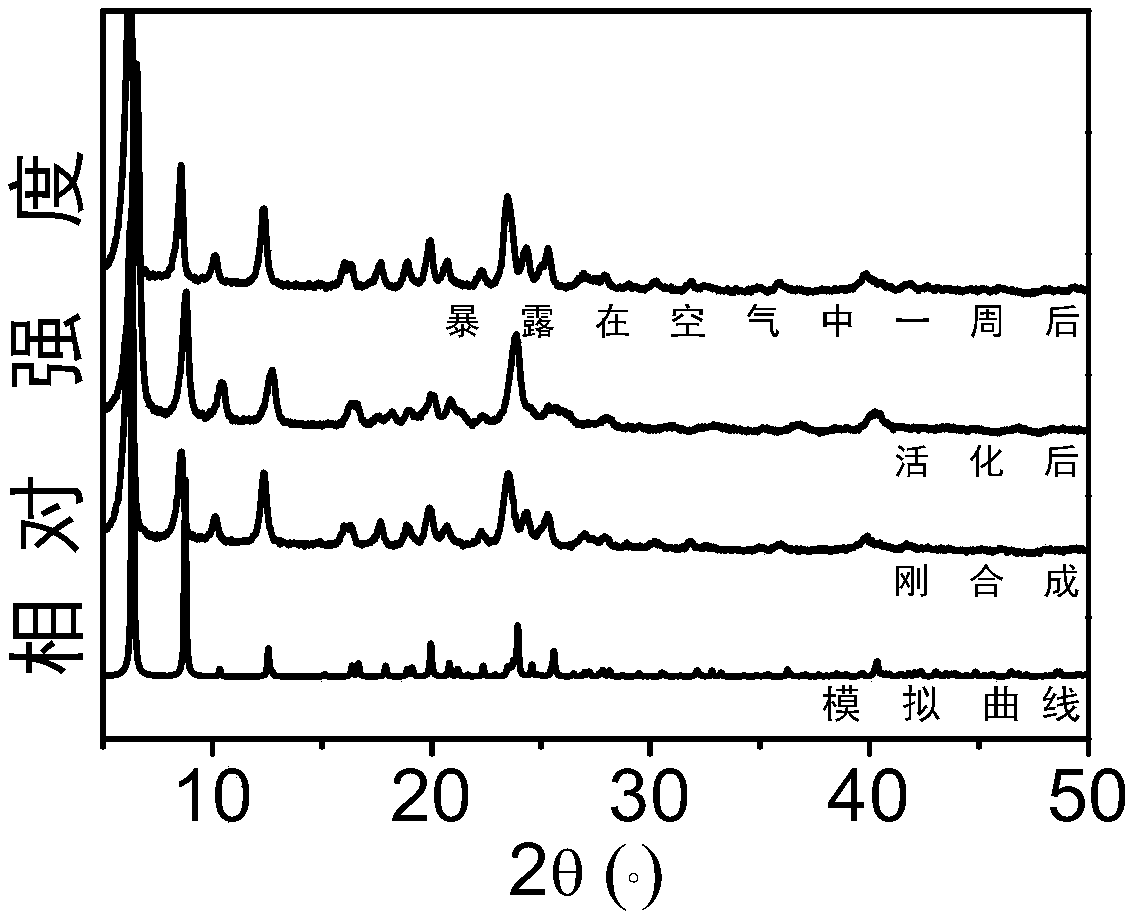

Metal-organic framework material for separating ethylene and acetylene, and method for separating ethylene and acetylene

ActiveCN108671893AImprove stabilityImprove adsorption capacityOther chemical processesDispersed particle separationSorbentPyrazine

The invention provides a metal-organic framework material for separating acetylene and ethylene, and a method for separating ethylene and acetylene. The metal-organic framework material has the advantages of good stability, high adsorption capacity, good adsorption separation selectivity, simple preparation method and low preparation cost. The structural general formula of the metal-organic framework material is Cu2(pzdc)2L.2H2O, pzdc in the formula is pyrazine-2,3-dicarboxylic acid, and the material is a three-dimensional network structure formed by copper ions, the pyrazine-2,3-dicarboxylicacid and an organic ligand A through a coordination bond or an intermolecular action force. The preparation method comprises the following steps: (1) mixing and reacting an inorganic salt, the pyrazine-2,3-dicarboxylic acid, an alkali and the organic ligand in proportion, wherein the inorganic salt is chloride, nitrate, acetate, sulfate or perchlorate of the copper ions; and (2) sequentially washing a product obtained after the reaction is finished with ionized water and anhydrous methanol, and then carrying out vacuum drying to obtain the metal-organic framework material. The metal-organic framework material is used as an adsorbent to adsorb and separate a mixed gas containing ethylene and acetylene.

Owner:ZHEJIANG UNIV

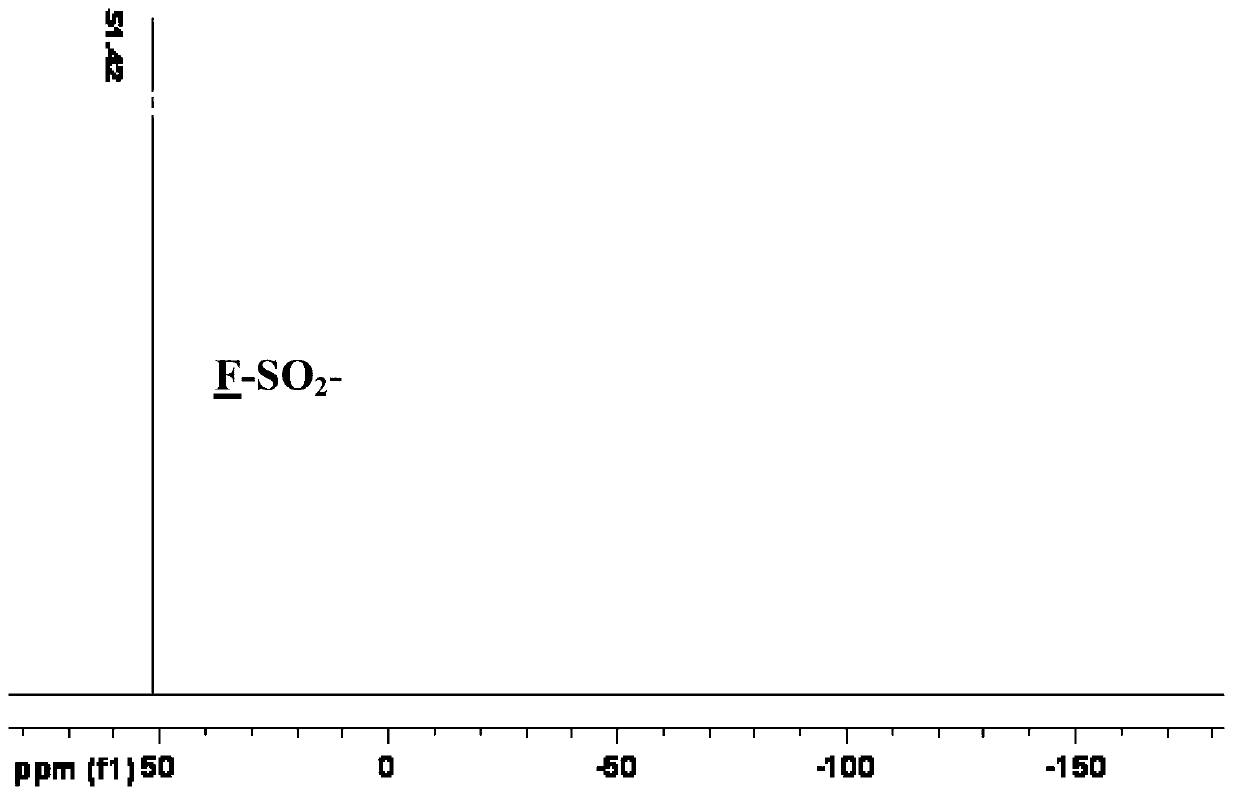

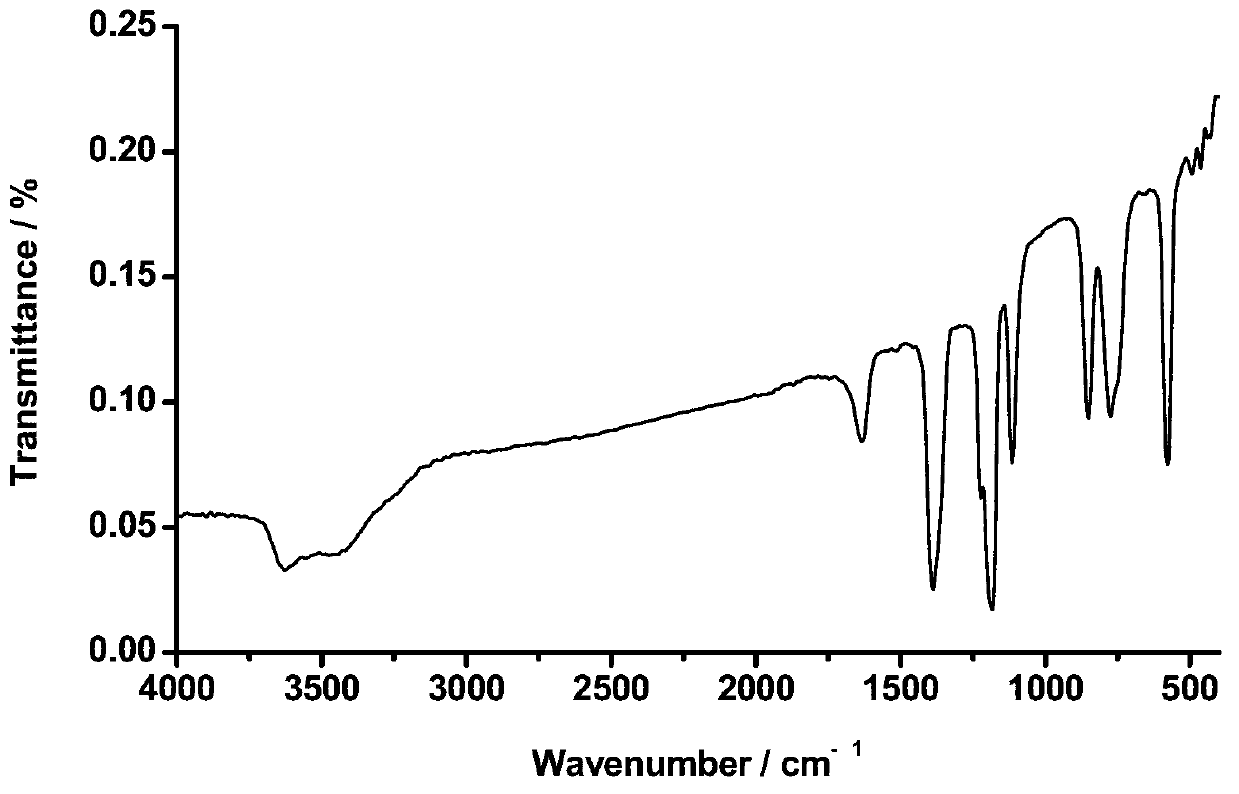

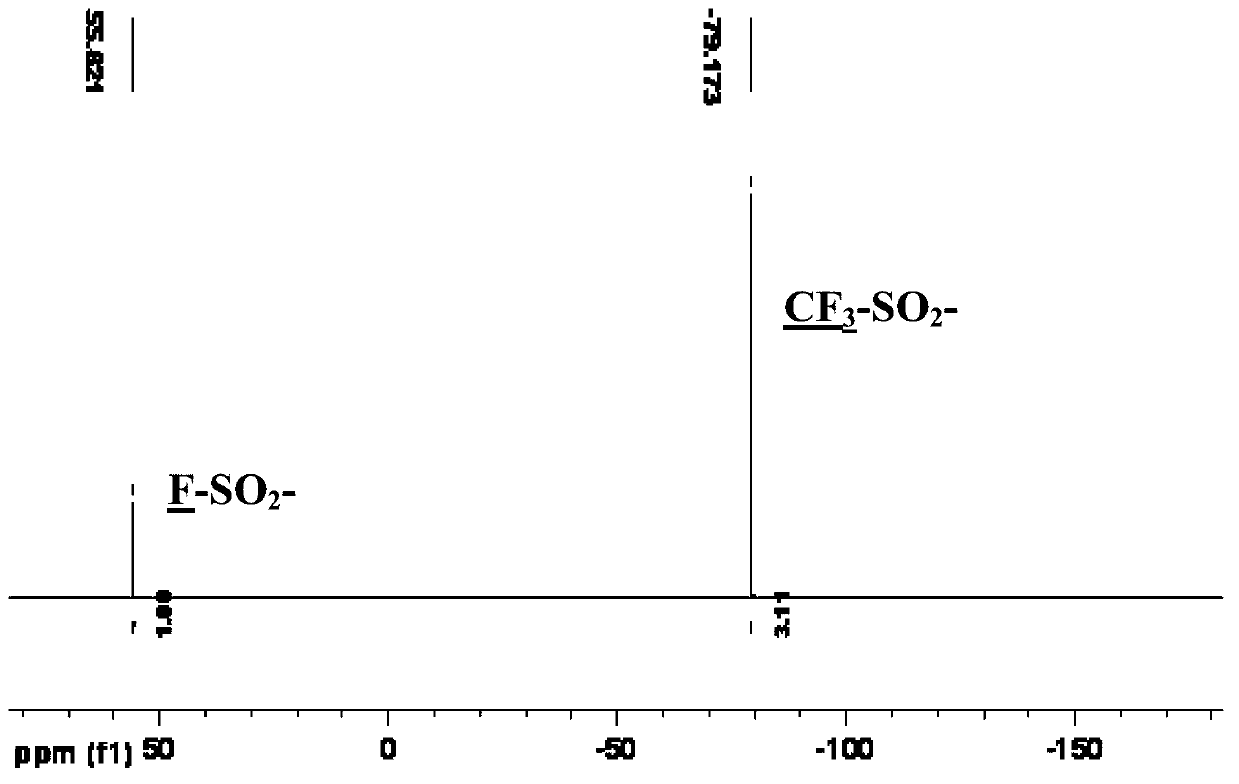

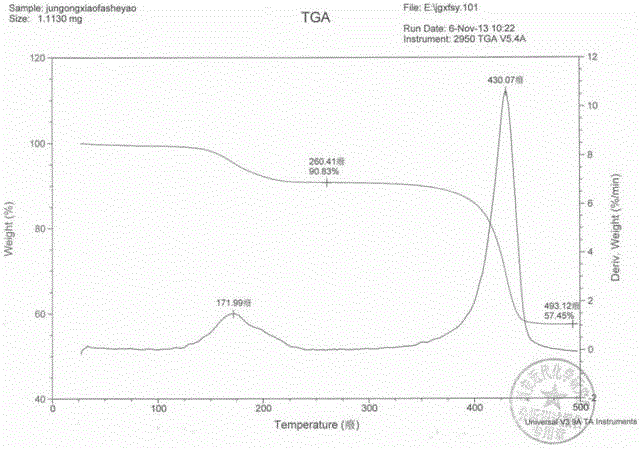

Preparation method of bis(sulfonyl fluoride) imine and (perfluoroalkyl sulfonyl fluorine sulfonyl) imine alkali metal salt

ActiveCN102786452AOvercome operabilityOvercome fatal shortcomings such as difficult product purificationSulfonic acid amide preparationTetrafluoroborateDecomposition

The invention discloses a method for preparing bis(sulfonyl fluoride) imine and (perfluoroalkyl sulfonyl fluorine sulfonyl) imine alkali metal salt. According to the method, sulfamide is utilized to take reaction with thionyl chloride and chlorosulfonic acid for preparing bis(sulfonyl fluoride) imine or (perfluoroalkyl sulfonyl fluorine sulfonyl) imine, then, the bis(sulfonyl fluoride) imine or (perfluoroalkyl sulfonyl fluorine sulfonyl) imine takes reaction with antimony trifluoride and potassium (rubidium or caesium and the like) carbonate, and corresponding high-purity bis(sulfonyl fluoride) imine potassium (rubidium or caesium) salt or (perfluoroalkyl sulfonyl fluorine sulfonyl) imine potassium (rubidium or caesium) salt can be obtained; and the double decomposition exchange reaction of the potassium (rubidium or caesium) salt and lithium (or sodium) perchlorate or lithium (or sodium) tetrafluoroborate and the like in aprotic polar solvents is utilized to obtain corresponding high-purity lithium (or sodium) salt. The method provided by the invention has the characteristics that the operation step is simple, the products can be easily separated and purified, the purity and the yield are high, the environment pollution is avoided, the method is suitable for industrial mass production, and the like.

Owner:武汉市瑞华新能源科技有限公司

Industrial stereospecific synthesis of beta-artemether by using artemisinin as raw material

InactiveCN101857599AReduce usageReduce intermediate processOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSodium bisulfateBeta-Artemether

The invention discloses stereospecific synthesis of beta-artemether by using artemisinin as a raw material through a one-pot method, which comprises the following steps of: in a system of alkaline solution of dichloromethane, taking sodium borohydride as a reducing agent and aluminium tert-butoxide as a catalyst, and reducing to obtain dihydroartemisinin; and separating out a water phase, adding methanol, sodium acid sulfate, aluminum perchlorate nonahydrate, nickelousperchlorate and the like serving as catalysts for methyl etherification, and reacting at room temperature for 2 hours to obtain the beta-artemether, wherein the maximum yield rate of the beta-artemether is 85 percent and the maximum total yield rate of artemether is 93.5 percent. The method has the characteristics of low cost, high yield, short time and simple and safe operation, and is completely suitable for industrial production.

Owner:GUANGZHOU SWELLXIN SCI & TECH

Sulfur-free ring stabilizing agent propellant powder

The invention discloses sulfur-free ring stabilizing agent propellant powder which consists of the following components in parts by weight: 70 parts of an oxidant, 34 parts of a burnable agent, 6 parts of an adhesive, 2 parts of a stabilizing agent, 2 parts of an anti-aging agent, 1 part of a catalyst and 2 parts of an antismoke agent which are uniformly mixed according to a general method, wherein the oxidant is a mixture consisting of potassium perchlorate, amine perchlorate and barium nitrate; the burnable agent is a mixture consisting of potassium hydrogen terephthalate, potassium acid phthalate, nitrocellulose, purified terephthalic acid and hemp stem carbon powder; the stabilizing agent adopts calcium stearate; the anti-aging agent adopts calcium phthalate; the catalyst adopts copper oxide; the antismoke agent adopts aluminum hydroxide; the adhesive is selected from one or a mixture of multiple of phenolic resin, strong adhesive powder, glutinous rice flour and polyvinyl alcohol according to any ratio. The sulfur-free ring stabilizing agent propellant powder is high in power capability and excellent in safety performance indexes and has excellent storage stability, and the environment-friendly performance is greatly improved.

Owner:HUNAN FEIYU NEW MATERIAL CO LTD

Method for preparing active silver electrode

InactiveCN101235515ALarge specific surface areaImprove electrocatalytic activityElectrolytic organic productionElectrodesOxidation statePhenol

The invention provides a method for preparing an active silver electrode, the method comprises the following steps: firstly, carrying out anode oxidation reaction to the silver electrode to form a silver oxidation state layer on the surface of the silver electrode in water solution with anion,, secondly, changing polarity of the silver electrode, and carrying out cathode oxidation reaction to cathode of the silver electrode to obtain the active silver electrode, wherein anion is compounded by one, or two, or more than two following ions, namely, (1) perchlorate ion, (2) hypochlorous acid ion, (3) hydroxide ion, (4) nitrate ion, (5) sulfate ion, (6) carbonate ion, (7) halide ion, (8) organic acid ion and (9) phenol hydroxyl root ion, the active silver electrode which is obtained according to the method of the invention is not only provided with a more specific surface, but also provided with higher electro-catalysis activity, longer electro-catalysis performance and less power loss, and the obtained active silver electrode can be used to electrolyze 3,4,5,6-tetrachloropicolinic acid and to compound 3,6-dichloropicolinic, which not only has lower energy consumption, but also has higher production efficiency.

Owner:ZHEJIANG UNIV OF TECH

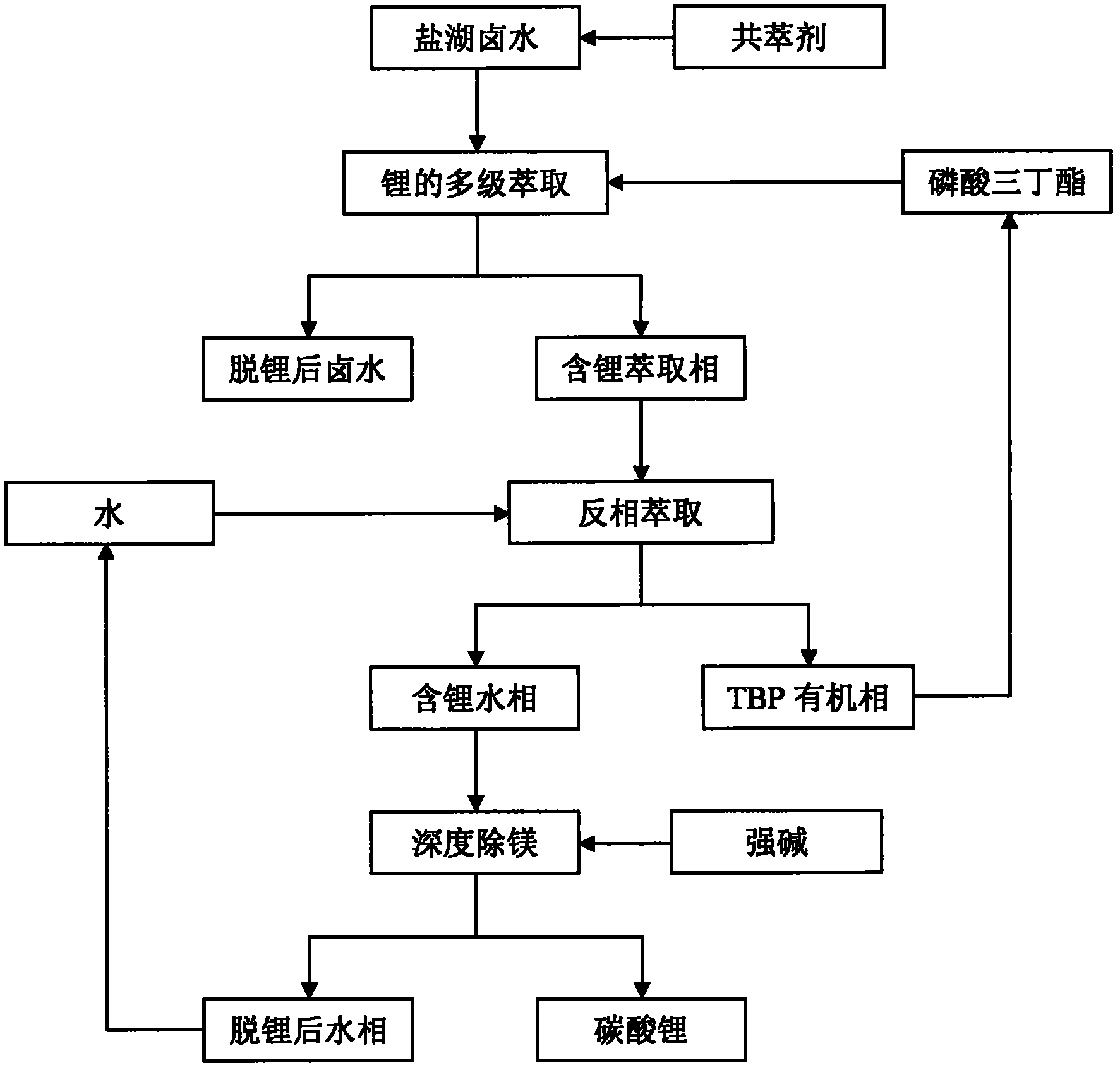

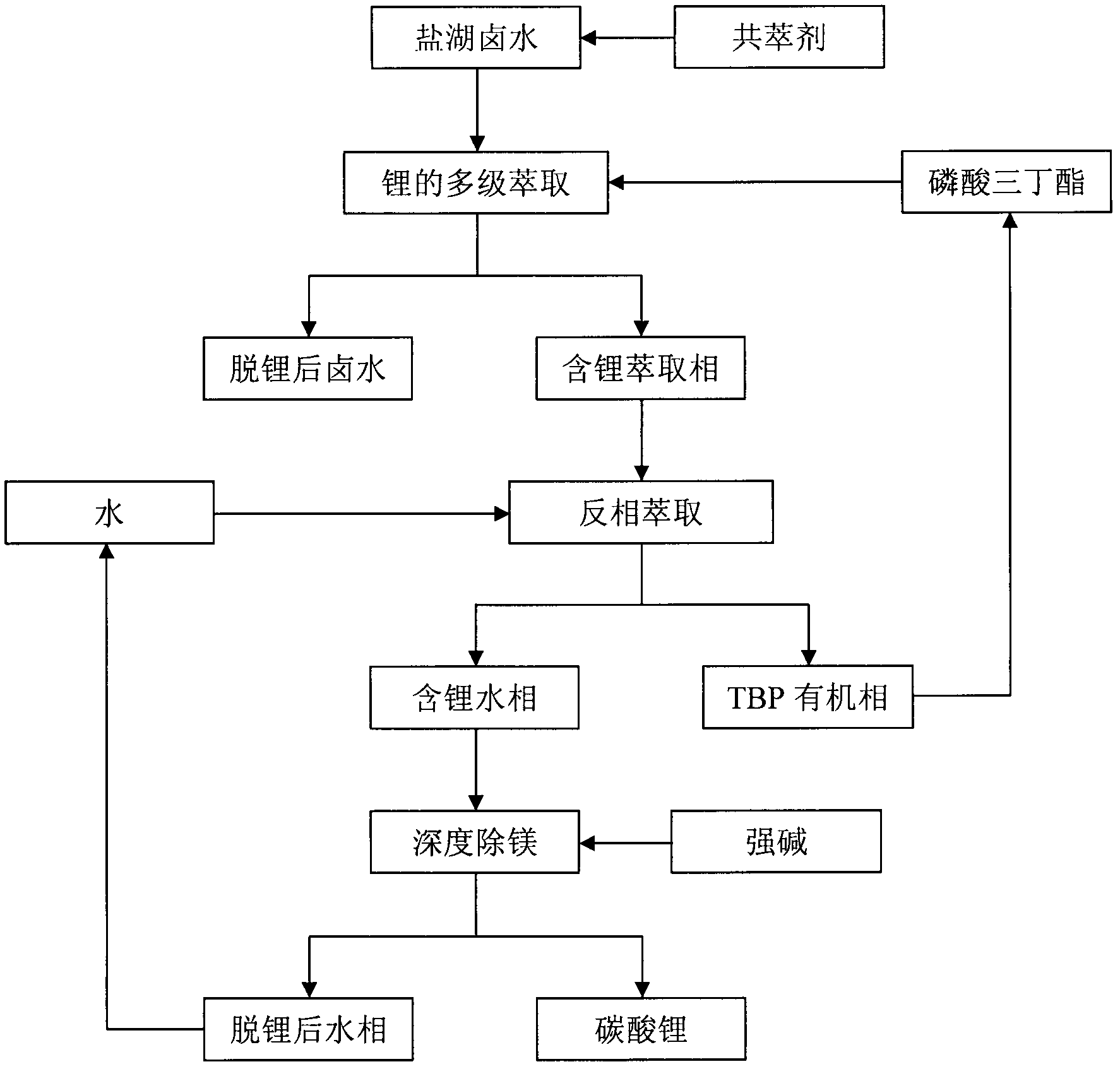

Method for separating magnesium and extracting lithium from salt lake brine with high magnesium-lithium ratio

InactiveCN102633284AStable in natureEasy to separateMagnesium carbonatesLithium carbonates/bicarbonatesHigh magnesiumKerosene

The invention discloses a method for separating magnesium and extracting lithium from salt lake brine with a high magnesium-lithium ratio. With adoption of the method, tributyl phosphate is taken as an extractant, number 200 solvent oil or kerosene is taken as a diluent, perchlorate is taken as a co-extraction agent, and water is taken as a stripping agent to form an extraction system; and lithium carbonate is prepared through extraction, reversed-phase extraction and deep magnesium removal by the salt lake brine. The method has the following beneficial effects: 1. the property of the co-extraction agent is stable, lithium magnesium separation can be carried out in neutral brine and the pH value of an aqueous phase needs not to be controlled; 2. the emulsification phenomenon doesn't exist and a third phase doesn't appear in the extraction process, two phases are easy to separate, the reversed-phase extraction is carried out by water and the device has little corrosion; and 3. the whole technique is simple in process, high in lithium extraction rate, good in separation effect and low in economic cost, is suitable for industrial production of the salt lake brine and is low in environmental damage degree because the co-extraction agent in water can be recycled.

Owner:XIANGTAN UNIV

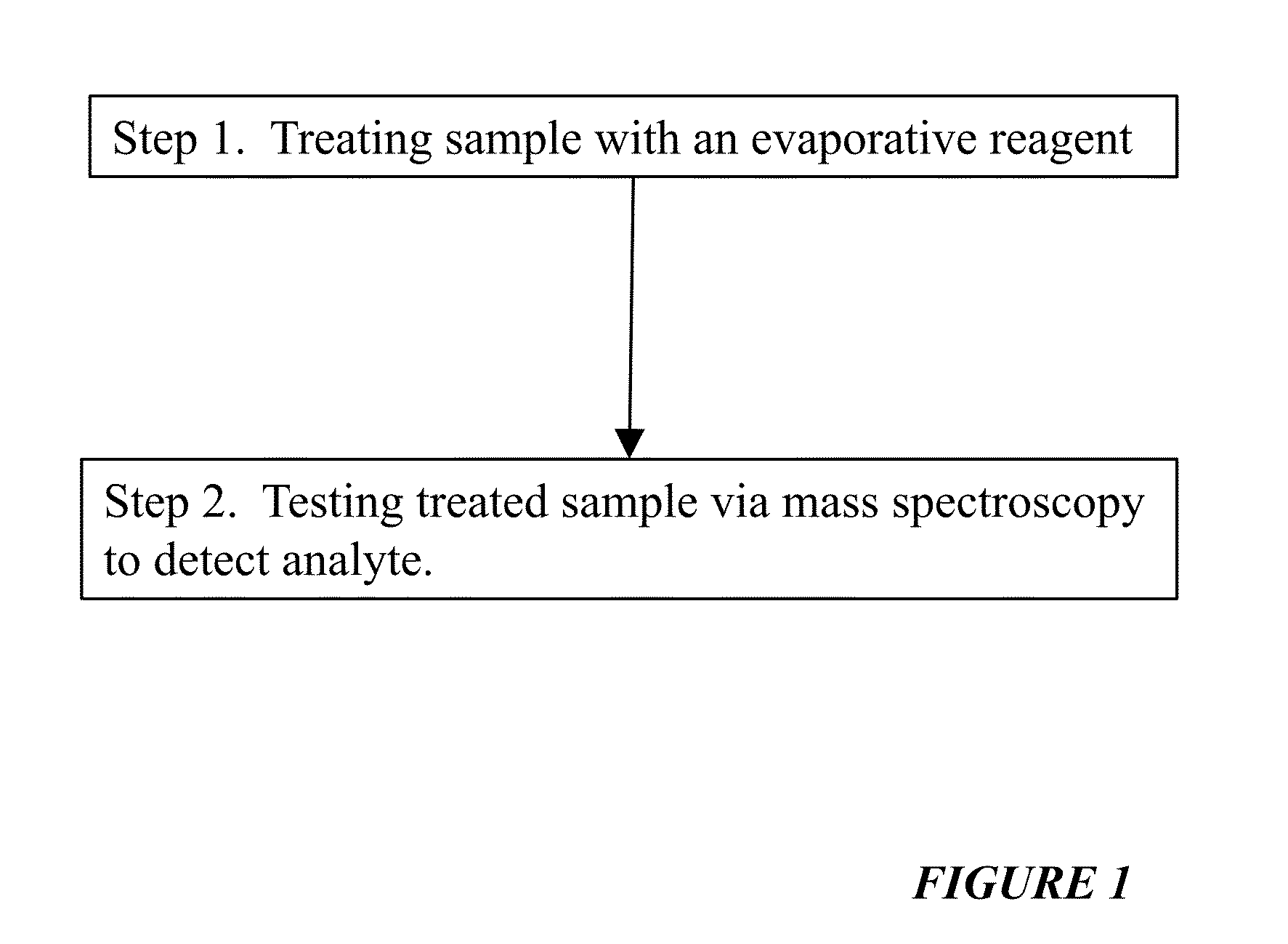

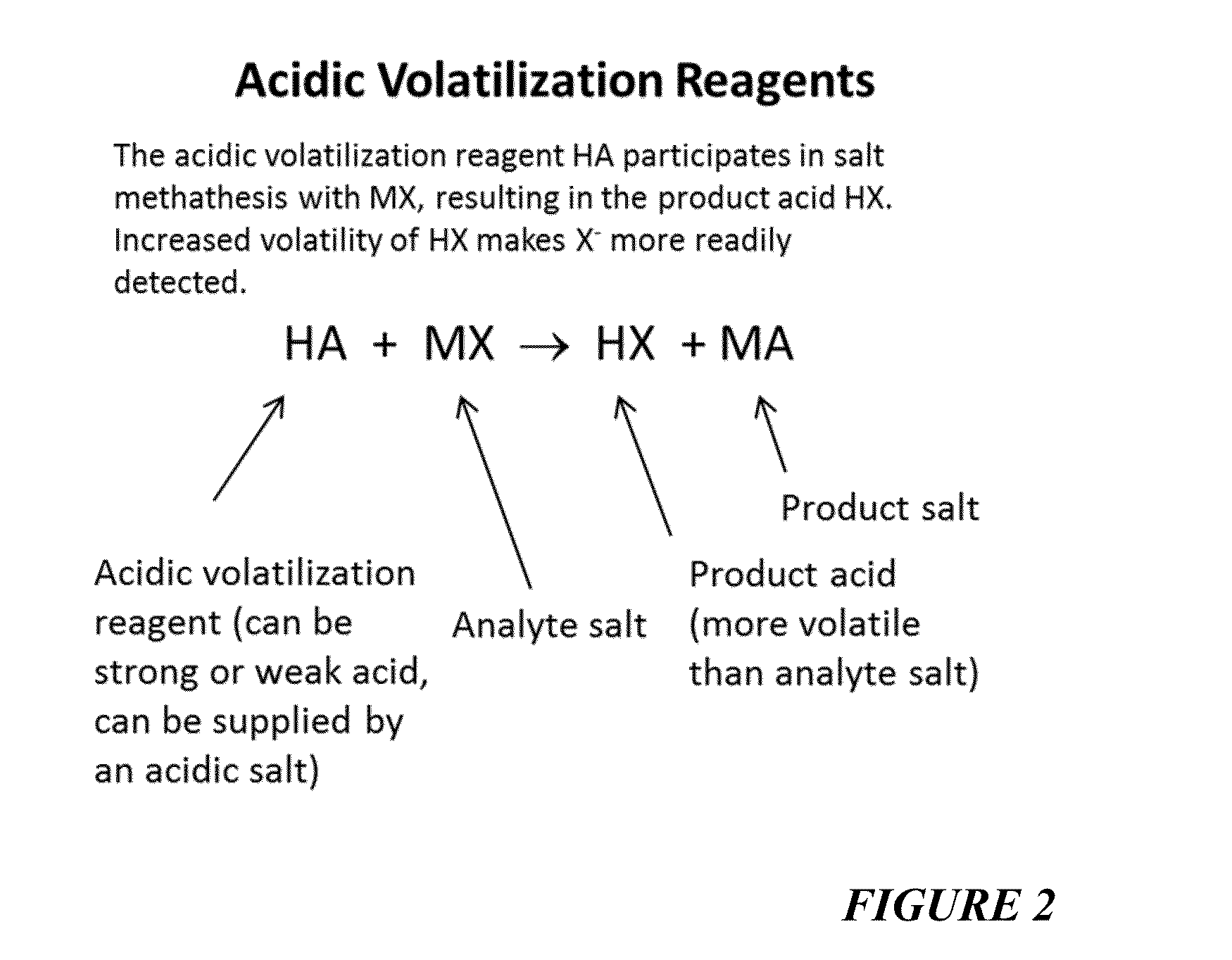

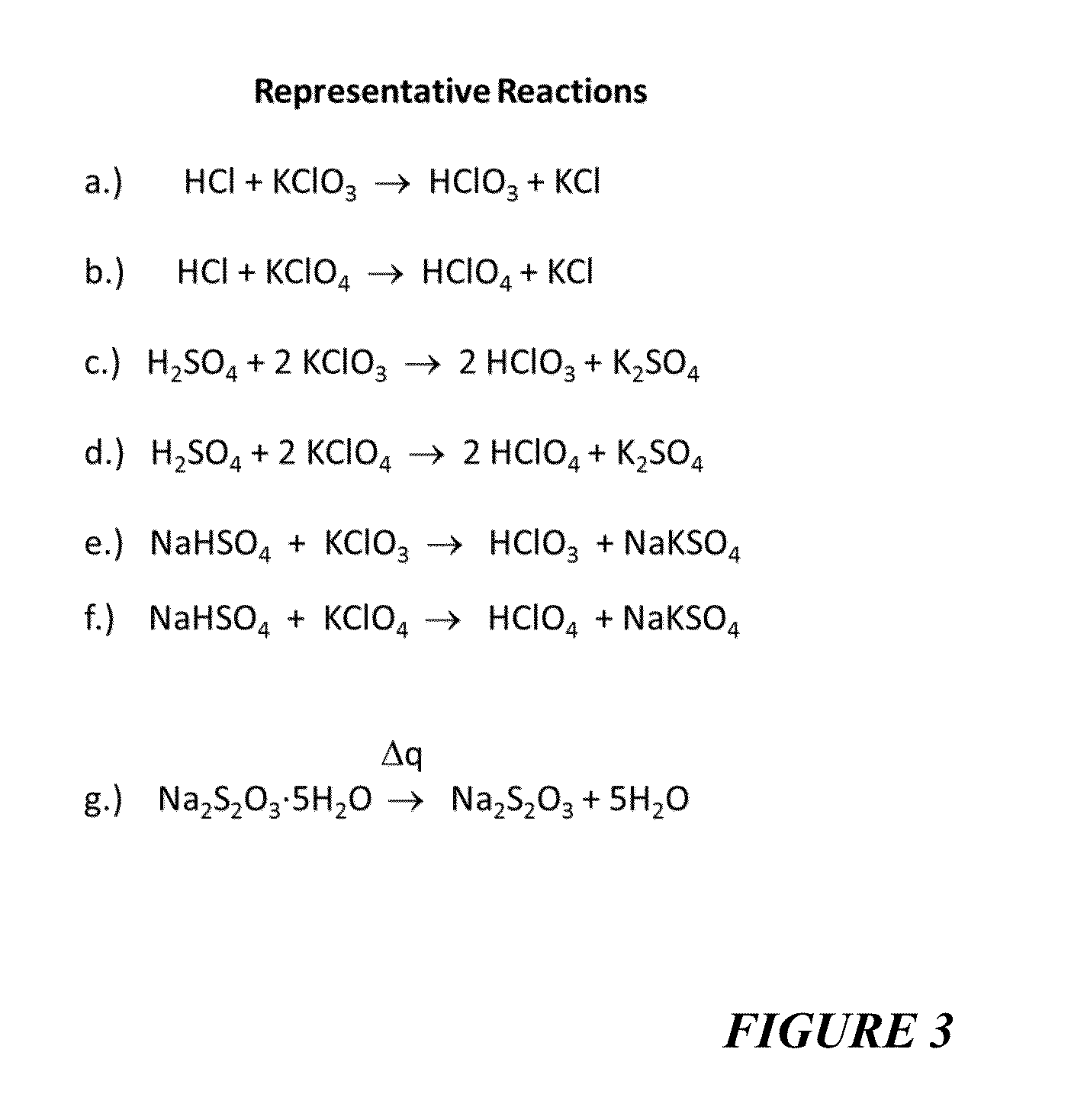

Reagents For Enhanced Detection Of Low Volatility Analytes

ActiveUS20150285780A1Easy to detectEasy to evaporateFuel testingMaterial analysis by electric/magnetic meansOrganic acidInorganic salts

The use of volatilization reagents is disclosed for improved detection of inorganic oxidizers such as, but not limited to, chlorates and perchlorates. Detection methods are disclosed whereby a reagent can transfer a proton to the anion (i.e., chlorate, perchlorate, etc.) of an inorganic salt analyte, forming an acid (i.e., chloric acid, perchloric acid) that is easier to detect by a mechanism whereby the acidified reagent is more easily vaporized, and hence, more easily detected. Concurrently, the anion of the acid forms a new salt with the cation released from the salt that was acidified. The reagents can also include acidic salts or cation-donators, more generally. In some embodiments, hydrated reagents or co-reagents that can release water can be employed. In another aspect of the invention, a class of reagents including polmeric acids, polymeric organic acids and polymeric sulfonic acids are disclosed that can carry out this method. In various embodiments, these reagents can be embedded in a swipe or other substrate, delivered as a liquid infused via nebulizer, or otherwise introduced to a sample to be tested for the presence of a target analyte.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com