Same-level multi-strand continuous casting device and method for magnesium alloy

A multi-stream continuous casting and magnesium alloy technology, which is applied in the field of magnesium alloy casting devices, can solve the problems of split casting that cannot be exposed in the air, is easy to react with magnesium alloy liquid and burn, and magnesium alloy is easy to oxidize, so as to avoid liquid Undulating surface, saving dosage, uniform and small grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

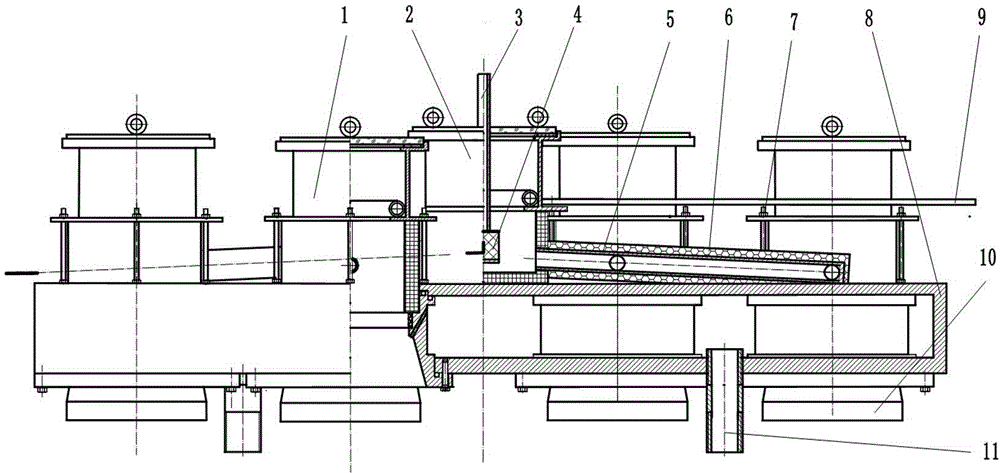

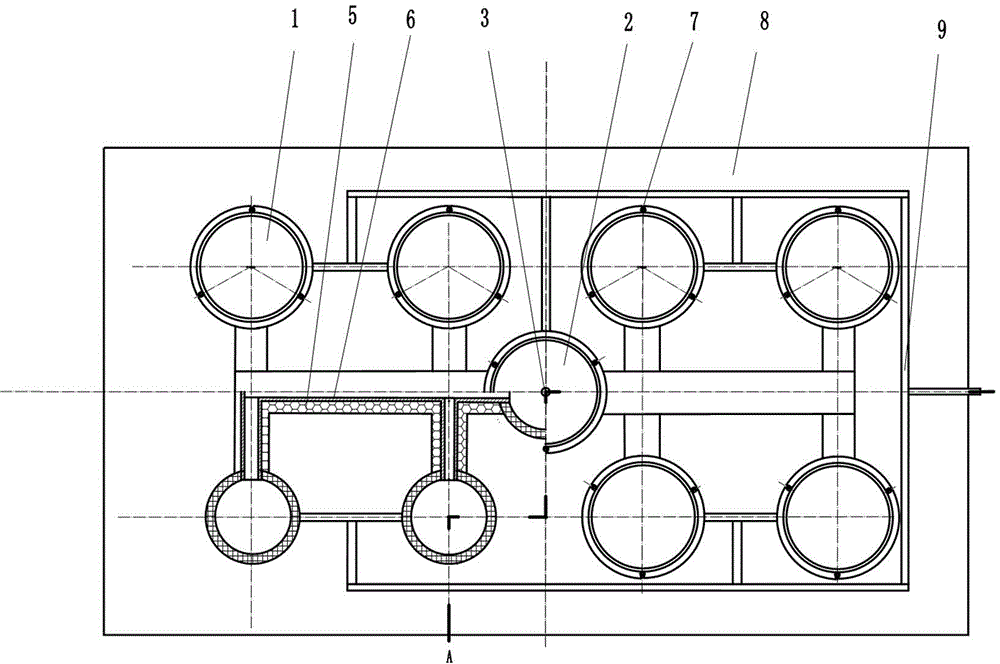

[0040] A magnesium alloy same-level multi-stream continuous casting device, such as figure 1 and figure 2As shown, 1. hot top crystallizer, 2. splitter box, 3. diversion tube, 4. metal filter, 5. splitter tube, 6. heating jacket covering the splitter tube surface, 7. fixing bolts, 8. Water tank, 9, protective gas pipe, 10, dummy block, 11, cooling water inlet pipe.

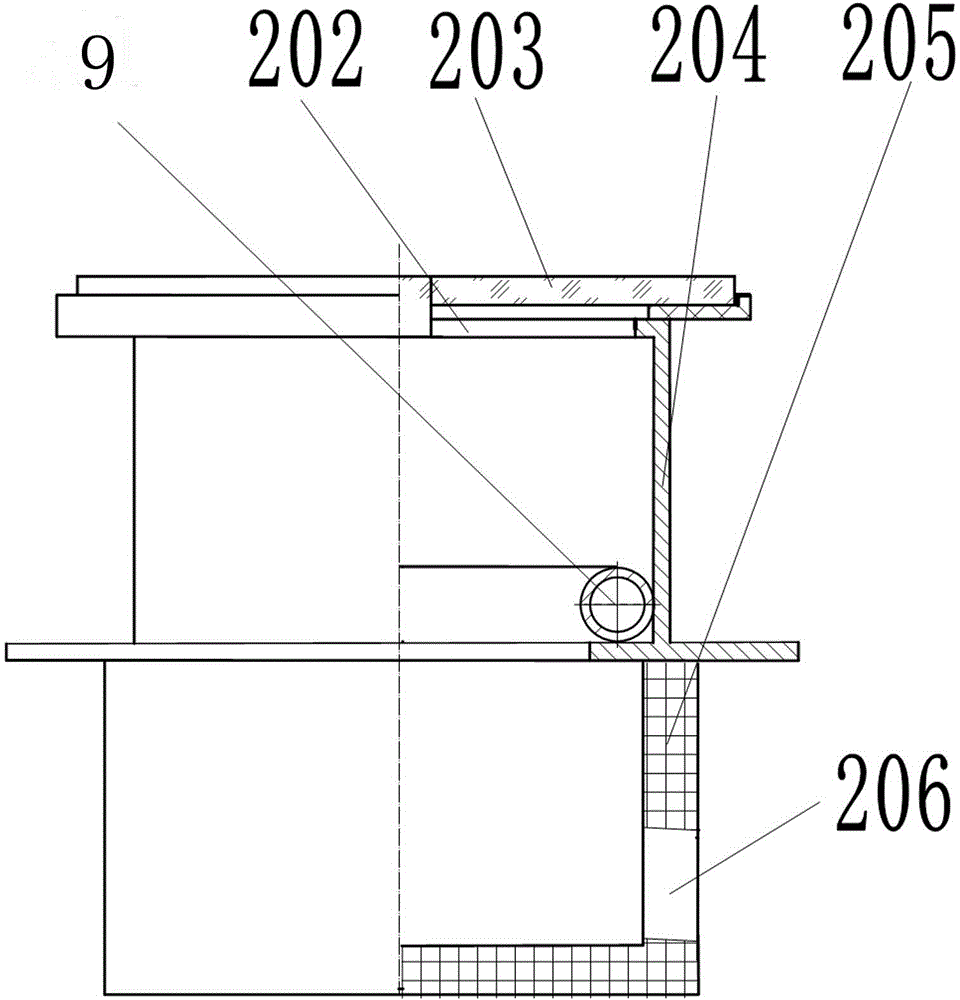

[0041] The device includes a diversion tube 3, a diversion box 2, a plurality of hot top crystallizers 1, a diversion tube 5, a protective gas pipe 9, a water tank 8 and a dummy block 10, and the diversion tube 3 passes through the conduit hole at the top of the diversion box 2 Insert into the shunt box, the shunt box 2 and multiple hot top crystallizers 1 are fixed on the water tank 8 by bolts 7, the connection between the shunt box 2 and the multiple hot top crystallizers 1 is realized through the shunt pipe 5, and the protective gas pipe 9 is connected Shunt box 2 and hot top crystallizer 1, dummy block 10 i...

Embodiment 2

[0057] A magnesium alloy multi-strand continuous casting device at the same level, the device structure is the same as that of embodiment 1, the difference is that the number of hot top crystallizers is 4, and the mesh number of the stainless steel wire mesh of the flow screen is 100 mesh.

[0058] The method for carrying out the same level multi-strand continuous casting of magnesium alloy by using the device includes the following process steps:

[0059] (1) Put the dummy block into the hot top crystallizer for alignment, turn on the heating jacket and heat it to 600~700°C, put cooling water into the water tank, and put high-purity carbon dioxide plus 0.5% six into the protective gas pipe Sulfur fluoride, carbon dioxide pressure is 0.012MPa;

[0060] (2) The smelted and purified magnesium alloy melt with a temperature of 700°C flows into the shunt box through the diversion pipe, and then flows into each hot top crystallizer through the shunt pipe, until the liquid level in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com