Dextran washing and sedimentation system

A technology for washing sediment and dextran, which is applied in the field of dextran washing and sedimentation system, can solve the problems of blocking the delivery pump, poor solubility, yellow color, etc., and achieves the effects of ensuring normal operation, prolonging service life and improving fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

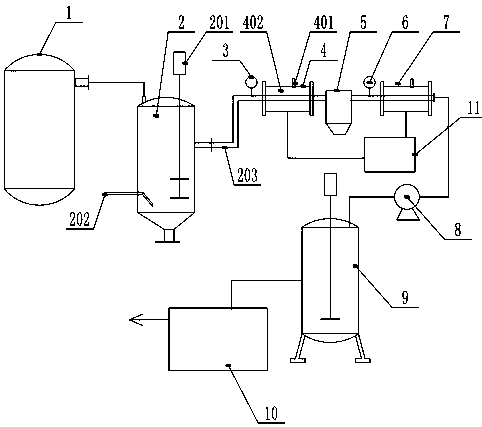

[0014] figure 1 It is the best embodiment of the present invention, below in conjunction with attached figure 1 The present invention will be further described.

[0015] Refer to attached figure 1 A kind of dextran washing and precipitating system, comprising sequentially connected fermenter 1, washing and precipitating tank 2, strainer 5 and hydrolysis tank 9, between washing and precipitating tank 2 and strainer 5, a primary temperature control heat exchange device is added, coarse The output end of the filter 5 is connected to the hydrolysis tank 9 through the Roots pump 8; the washing and sedimentation tank 2 is provided with an electric stirring device, and the lower side is connected to the alcohol input pipe 202.

[0016] The primary temperature control heat exchange device includes a temperature detector one 3 and a primary heat exchanger 4, the temperature detector one 3 is arranged at the inlet end of the primary heat exchanger 4, and the primary heat exchanger 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com