Method for low temperature preparation of diboride-carbide solid solution multiphase ceramic by reaction hot press sintering method

A diboride, hot pressing sintering technology, applied in the field of multiphase ceramic materials, can solve the problem of high sintering temperature, and achieve the effect of reducing sintering temperature, improving strength and toughness, and uniform and fine grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] (1) Mix the zirconium diboride powder and titanium carbide powder according to the molar mass ratio of 1:1, and use a high-energy ball mill for ball milling. The ball milling conditions are: ball material ratio 40:1, ball milling time 20h, speed 425r / min , to obtain a composite powder with uniform composition and fine particles;

[0022] (2) Put the composite powder in the mold, under vacuum or inert atmosphere, raise the temperature of the material at 30°C / min to 1750°C, pressurize at 30MPa at the temperature, keep it for 1h, and then lower it to room temperature at 30°C / min ;Demoulding, get (Ti,Zr)B 2 -(Zr,Ti)C solid solution composite ceramics (i).

[0023] For (Ti,Zr)B 2 -(Zr,Ti)C solid solution composite ceramic (i) was characterized for its mechanical properties. The results show that the hardness of the material at room temperature is 27.3±1.0GPa, the three-point bending strength is 597±32MPa, and the fracture toughness is 5.01MPa m 1 / 2 . The density of the m...

specific Embodiment approach 2

[0025] (1) Mix the zirconium diboride powder and titanium carbide powder according to the molar mass ratio of 1:1, and use a high-energy ball mill for ball milling. The ball milling conditions are: ball material ratio 40:1, ball milling time 20h, speed 425r / min , to obtain a composite powder with uniform composition and fine particles;

[0026] (2) Put the composite powder in the mold, under vacuum or inert atmosphere, heat the material at 30°C / min to 1800°C, pressurize at 30MPa at the temperature, keep it for 1h, and then lower it to room temperature at 30°C / min ;Demoulding, get (Ti,Zr)B 2 -(Zr,Ti)C solid solution composite ceramics (ii).

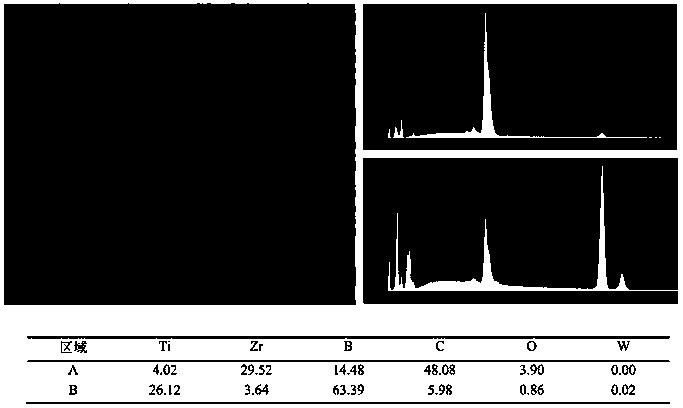

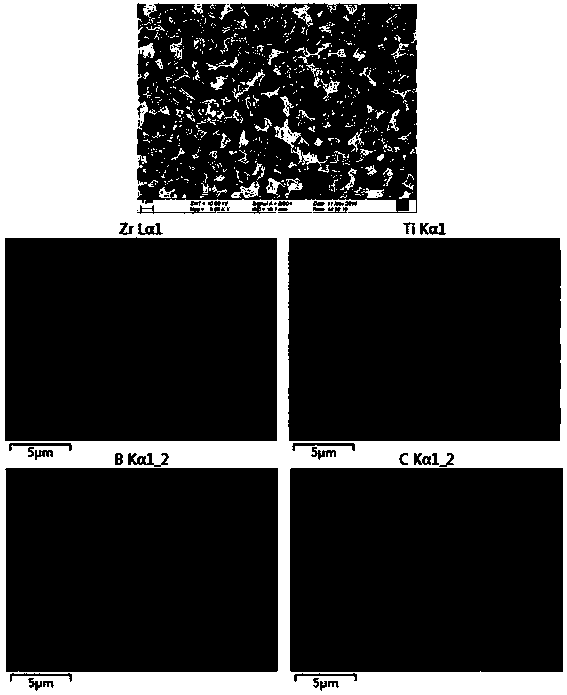

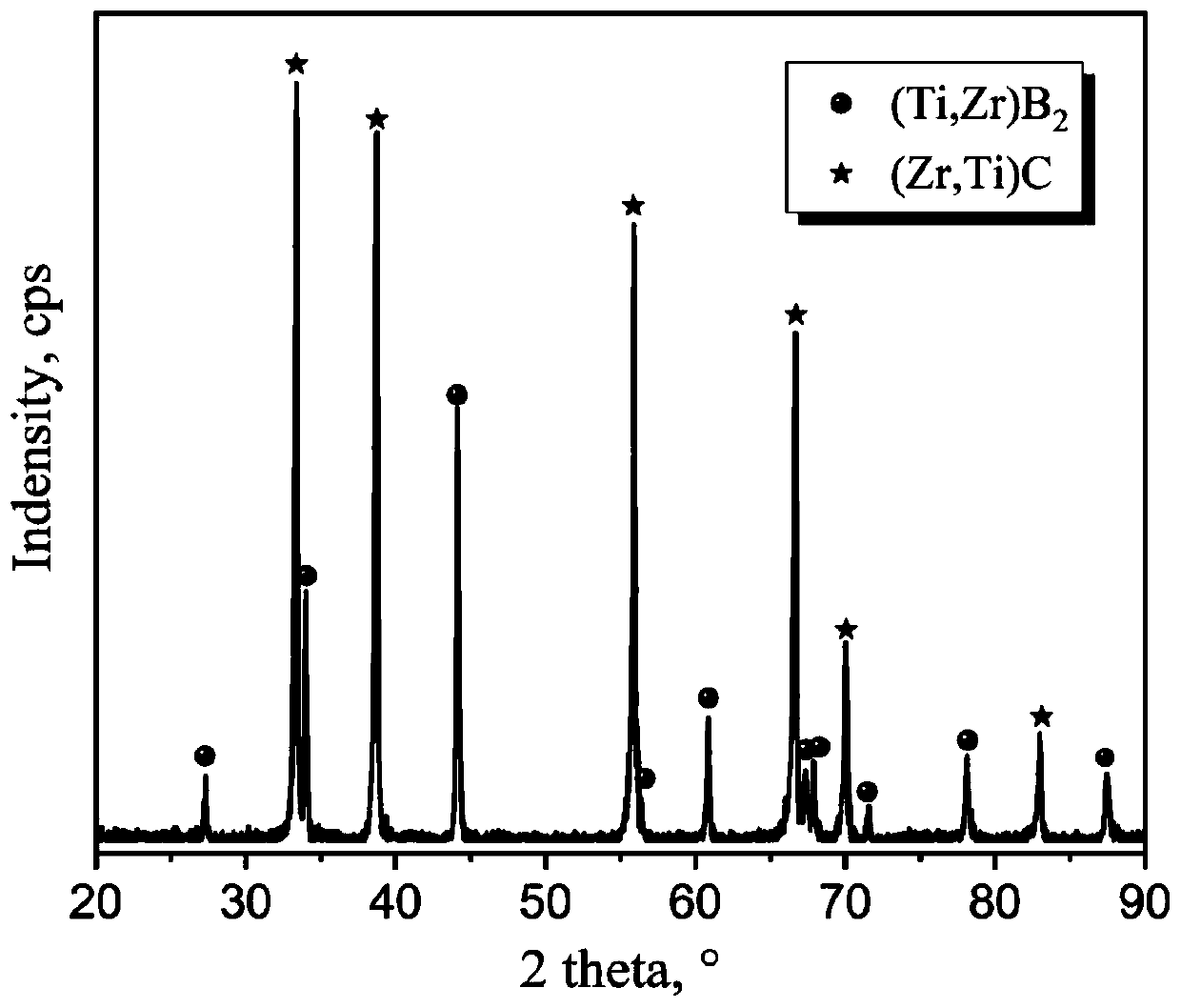

[0027] For (Ti,Zr)B 2 -(Zr,Ti)C solid solution composite ceramics (ii) XRD test, the test results are as follows figure 1 shown. Depend on figure 1 It can be seen that diboride and metal carbide undergo a solid-phase exchange reaction, and at the same time, the products can be solid-dissolved with each other to obtain a boride and car...

specific Embodiment approach 3

[0033] (1) Mix the zirconium diboride powder and titanium carbide powder according to the molar mass ratio of 1:1, and use a high-energy ball mill for ball milling. The ball milling conditions are: ball material ratio 40:1, ball milling time 20h, speed 425r / min , to obtain a composite powder with uniform composition and fine particles;

[0034] (2) Put the composite powder in the mold, under vacuum or inert atmosphere, heat the material at 30°C / min to 1900°C, pressurize at 30MPa at the temperature, keep it for 1h, and then lower it to room temperature at 30°C / min ;Demoulding, get (Ti,Zr)B 2 -(Zr,Ti)C solid solution composite ceramics (iii).

[0035] For (Ti,Zr)B 2-(Zr,Ti)C solid solution composite ceramic (iii) was characterized for its mechanical properties. The results show that the hardness of the material at room temperature is 27.3±1.5GPa, the three-point bending strength is 709±33MPa, and the fracture toughness is 5.61MPa m 1 / 2 . The density of the material is 5.65g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com