Refractory high-entropy alloy and forming method thereof

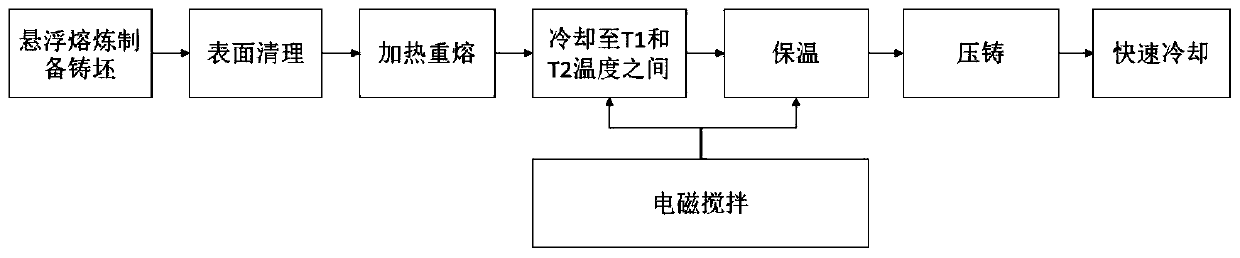

A high-entropy alloy and forming method technology, applied in the field of refractory high-entropy alloy and its forming, can solve the problems of refractory alloy element segregation, unreachable quality, poor anisotropy, etc., and achieve fine and uniform grain size, The effect of high density and refined grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: AlCoCrFeNi refractory high-entropy alloy and its forming method.

[0031] Weigh 54g of Al, 118g of Co, 104g of Cr, 112g of Fe and 118g of Ni according to the equal atomic percentage, and use differential thermal and thermogravimetric analysis (TD+TGA) and differential scanning calorimetry (DSC) to measure The solidus temperature T1 and liquidus temperature T2 of the AlCoCrFeNi refractory high-entropy alloy during the heating and melting process, the measured solidus temperature T1 is 800°C, and the liquidus temperature T2 is 1678°C.

[0032] In a vacuum of 10 -3 Under the vacuum environment of Pa, use the electromagnetic induction suspension melting process, under the electromagnetic stirring, melt the above-mentioned raw materials of the AlCoCrFeNi refractory high-entropy alloy, and fully mix the components in the liquid metal, and keep it at 1730℃±5℃ for 20min , cast into a mold, and cool to room temperature at 500° C. / min to obtain a cast billet.

[0...

Embodiment 2

[0036] Example 2: TiZrNbMoV refractory high-entropy alloy and its forming method

[0037] According to equal atomic percentage, weigh 96g of Ti, 182g of Zr, 186g of Nb, 192g of Mo and 102g of Ni, and use differential thermal and thermogravimetric analysis (TD+TGA) and differential scanning calorimetry (DSC) to measure The solidus temperature T1 and liquidus temperature T2 of the TiZrNbMoV refractory high-entropy alloy during the heating and melting process, the measured solidus temperature T1 is 1730°C, and the liquidus temperature T2 is 2295°C.

[0038] In a vacuum of 10 -3 Under the vacuum environment of Pa, using the electromagnetic induction suspension melting process, under the electromagnetic stirring, the above-mentioned raw materials of the TiZrNbMoV refractory high-entropy alloy are melted, and the components in the liquid metal are fully mixed, and kept at 2490 ° C ± 5 ° C for 40 minutes , cast into a mold, and cool to room temperature at 200° C. / min to obtain a cas...

Embodiment 3

[0042] Example 3: TiZrNbMoV refractory high-entropy alloy and its forming method

[0043] According to the equal atomic atomic percentage, weigh 96g of Ti, 182g of Zr, 186g of Nb, 192g of Mo and 102g of Ni, first form Ti-Zr-Mo and Nb-V master alloys respectively, and use differential thermal and thermogravimetric analysis (TD+TGA) and differential scanning calorimetry (DSC) to measure the solidus temperature T1 and liquidus temperature T2 of the TiZrNbMoV refractory high-entropy alloy during the heating and melting process. The measured solidus temperature T1 is 1750 ° C, The liquidus temperature T2 was 2420°C.

[0044] In a vacuum of 10 -4 Under the vacuum environment of Pa, using the electromagnetic induction suspension melting process, under the electromagnetic stirring, the above-mentioned intermediate alloy raw materials of the TiZrNbMoV refractory high-entropy alloy are melted, and the components in the liquid metal are fully mixed, at 2525 ° C ± 5 ° C Keep warm for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com