Multi-layer multi-pass composite wire arc additive manufacturing method and system for metal structure

A multi-layer, multi-channel, additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of complex metal parts with many structural features, low forming accuracy of the side walls of the parts, and inconsistent height of the arc closing position, so as to shorten the development cycle and reduce the Effect of interlayer defects and improvement of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

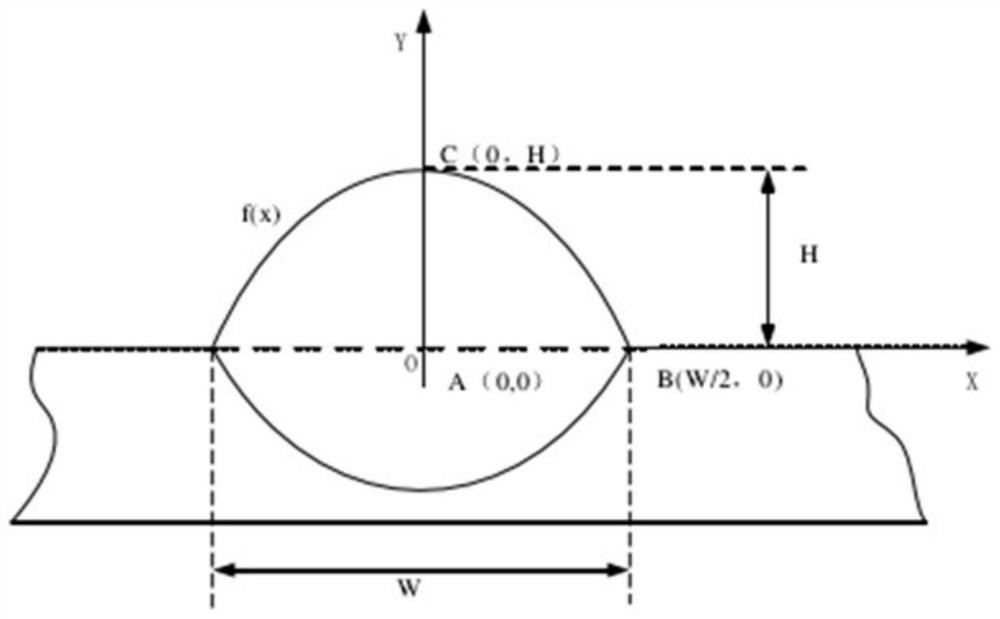

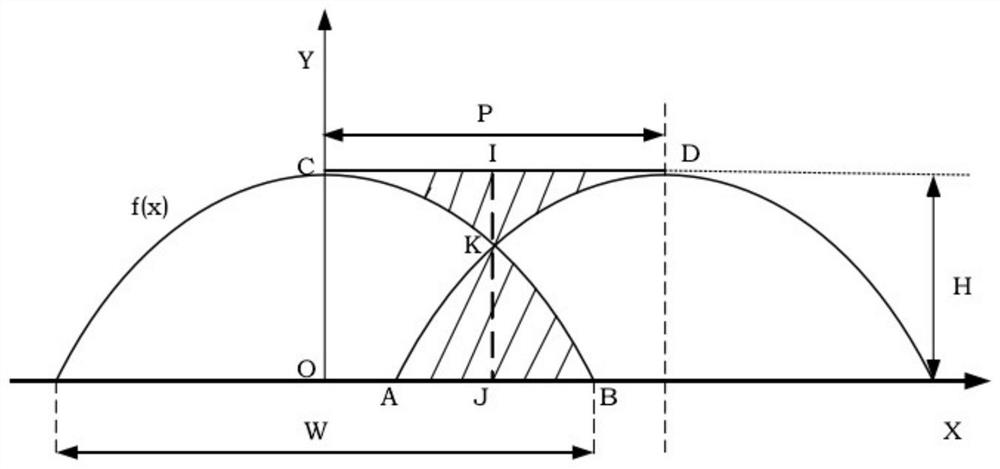

Method used

Image

Examples

Embodiment 1

[0198] Example 1: Multi-layer multi-channel arc additive manufacturing of connecting frame

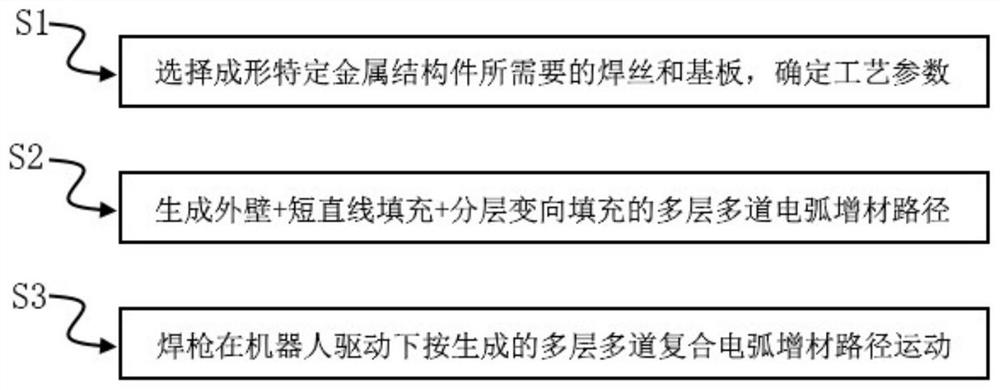

[0199] Such as Figure 5 As shown, the connecting frame is used to generate the outer wall + short straight line filling + layered and direction-changing filling of the multi-layer and multi-channel arc additive path according to the method of the present invention, and the required process parameters are obtained through calculation. It is manufactured by adopting a multi-layer multi-channel electric arc additive method for metal structural parts described in the present invention. Specifically:

[0200] Print the selected 6061 aluminum alloy sheet with a substrate thickness of 20mm. The welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. Substrate level.

[0201] The STL model is processed by the STL slicing algorithm based on the geometric characteristics of the triangular surface, and then the outer wall + short filling + layered direction-changing pr...

Embodiment 2

[0203] Example 2: Multi-layer multi-channel arc additive manufacturing of square box

[0204] Such as Image 6 As shown, the square box is generated according to the method of the present invention to form a multi-layer and multi-channel arc additive path of outer wall + short straight line filling + layered and direction-changing filling, and the required process parameters are obtained through calculation. It is manufactured by adopting a multi-layer multi-channel electric arc additive method for metal structural parts described in the present invention. Specifically:

[0205] Print the Q235 carbon steel aluminum sheet with a substrate thickness of 16mm. The welding wire used is 308 stainless steel wire with a diameter of 1.2mm. Substrate level.

[0206] The STL model is processed by the STL slicing algorithm based on the geometric characteristics of the triangular surface, and then the outer wall + short filling + layered direction-changing printing path is calculated, s...

Embodiment 3

[0208] Example 3: Multi-layer and multi-channel electric arc additive manufacturing of reinforcing rib cylinder

[0209] Such as Figure 7 As shown, the reinforcing rib ring is used to generate the outer wall + short straight line filling + layered and direction-changing filling of the multi-layer and multi-channel arc additive path according to the method of the present invention, and the required process parameters are obtained through calculation. It is manufactured by adopting a multi-layer multi-channel electric arc additive method for metal structural parts described in the present invention. Specifically:

[0210] The thickness of the substrate selected for printing is 16mm6061 aluminum alloy plate, and the welding wire used is 4043 aluminum alloy welding wire with a diameter of 1.2mm. .

[0211] The STL model is processed by the STL slicing algorithm based on the geometric characteristics of the triangular surface, and then the outer wall + short filling + layered d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com