Continuous casting and continuous rolling production process for 5356 aluminum alloy welding rods

A production process, continuous casting and rolling technology, applied in the direction of metal rolling, etc., can solve the problems of affecting the quality of welds, time-consuming and labor-intensive, increasing energy consumption, etc., to achieve the effect of reducing joints and avoiding performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

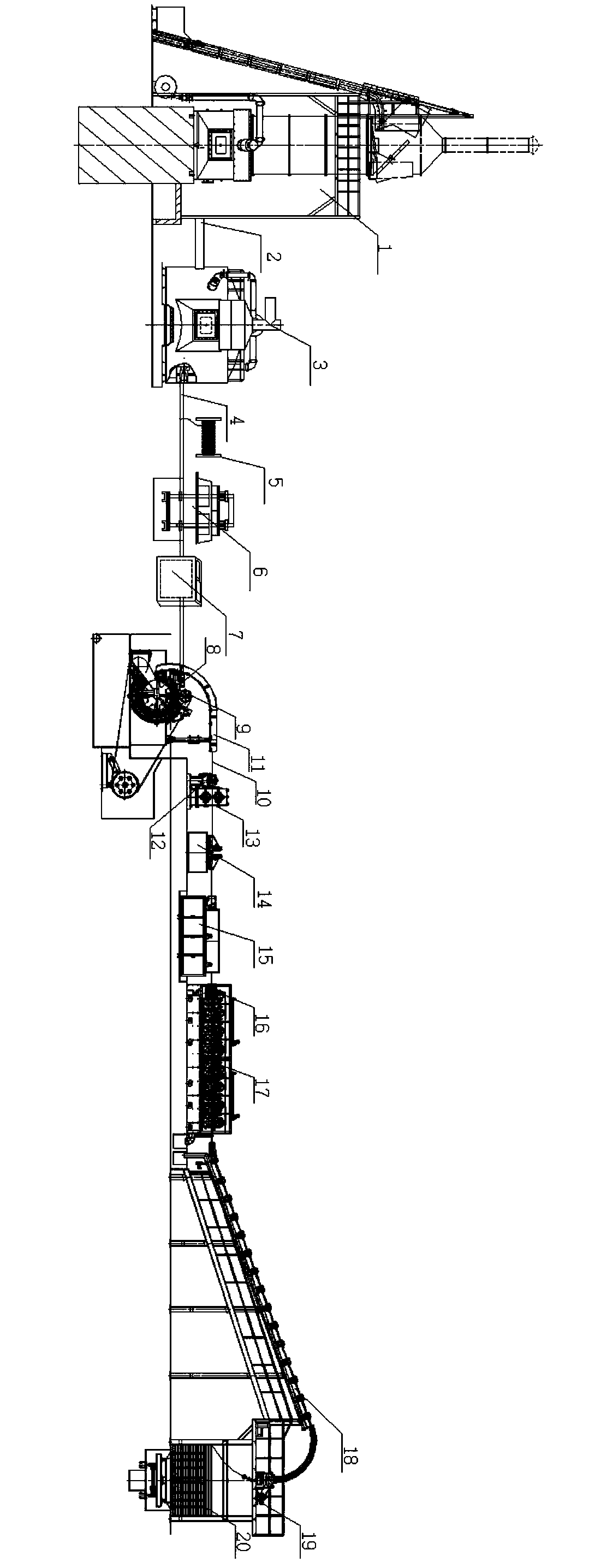

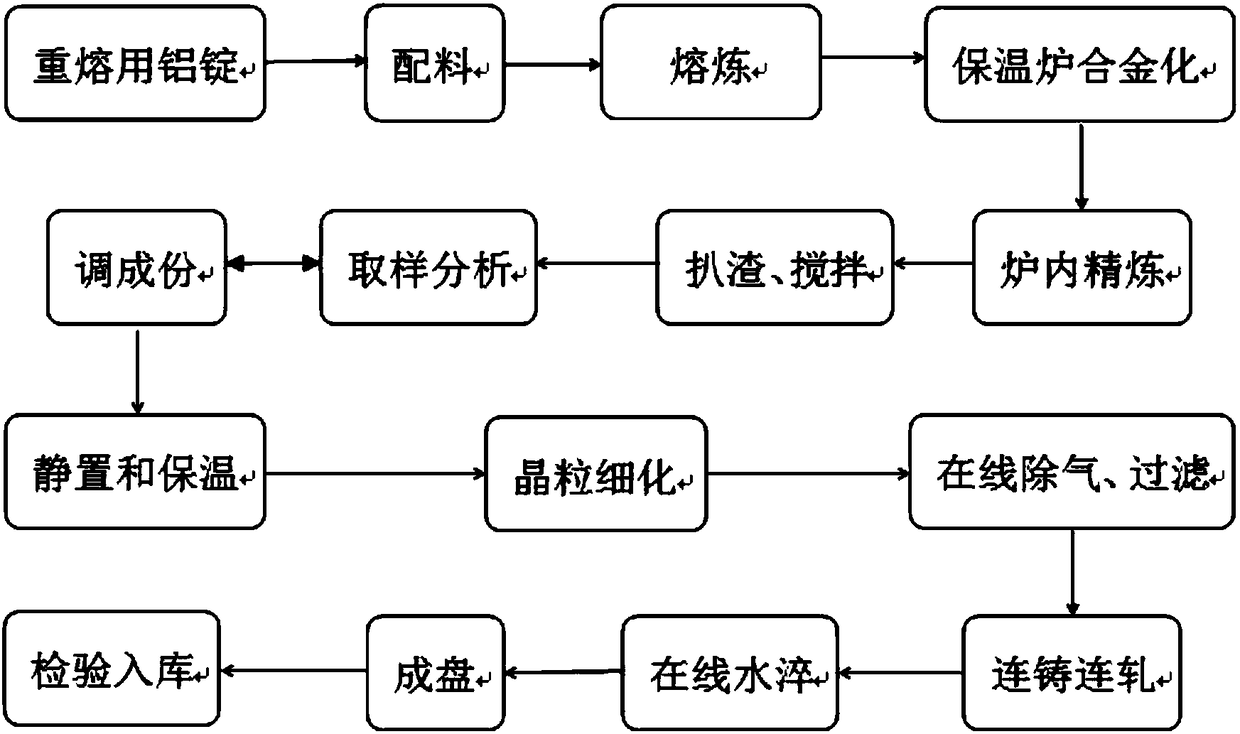

Method used

Image

Examples

Embodiment 1

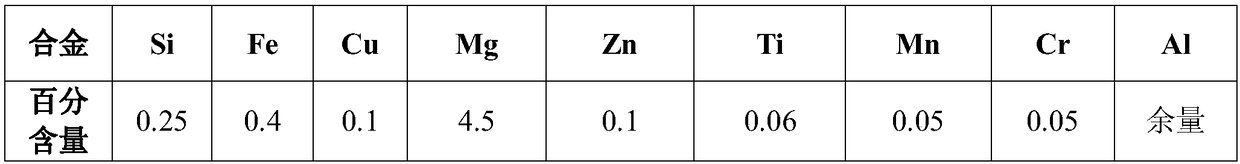

[0051] Product Chemical Composition

[0052]

[0053] (1) Melting: a. Melting and alloying of aluminum ingots. Add 8 tons of aluminum ingots with a percentage of Al99.90% into the aluminum melting furnace. The melting temperature is 750 ° C. After the aluminum material is completely melted, the aluminum melt is removed from the melting The aluminum furnace is transferred to the holding furnace, and the intermediate alloy is added sequentially to the holding furnace while stirring according to the designed amount of the intermediate alloy. Cr and Mn are added in the form of master alloy Al-20%Cr, Al-20%Mn.

[0054] b. Purify the alloyed melt in the holding furnace for degassing, impurity removal, slag removal, covering, heat preservation and standing. The specific refining methods are: powder spraying refining and bottom blowing high-purity N 2 or Ar 2 refining. After the aluminum melt is refined and slag removed, it is evenly covered with a covering agent, and then the ...

Embodiment 2

[0065] Product Chemical Composition

[0066]

[0067] The melting process is the same as in Example 1.

[0068] Continuous casting and rolling: the casting temperature is 720°C, the casting cooling water temperature is 30°C, the casting speed is 8m / min, and the cross-sectional area of the cavity formed by the copper wheel and the steel strip is 2200mm 2 , the diameter of the copper wheel is Φ1600mm.

[0069] Then adopt the process of entering rolling temperature of 510°C, finishing rolling temperature of 390°C, entering rolling speed of 11.5m / min, finishing rolling speed of 5.95m / s, emulsion temperature of 60°C, emulsion concentration of 20%, and emulsion flow rate of 20L / min The 5356 aluminum alloy welding rod that has been continuously rolled to Φ9.5mm after 13 passes is cooled to 100°C at a cooling rate higher than 100°C / min through the oil-free lead rod water quenching system, and the post-traction and continuous winding rod system Under the action, the double frame...

Embodiment 3

[0072] Product Chemical Composition

[0073]

[0074] The melting process is the same as in Example 1.

[0075] Continuous casting and rolling: the casting temperature is 720°C, the casting cooling water temperature is 30°C, and the casting speed is 8m / min. The cross-sectional area of the cavity formed by the copper wheel and steel strip is 2200mm 2 , the diameter of the copper wheel is Φ1800mm.

[0076] Then adopt the process of entering rolling temperature at 510°C, finishing rolling temperature at 390°C, entering rolling speed at 11.5m / min, finishing rolling speed at 5.3m / s, emulsion temperature at 60°C, emulsion concentration at 20%, and emulsion flow rate at 20L / min The 5356 aluminum alloy welding rod that has been continuously rolled to Φ9.5mm after 14 passes is cooled to 100°C at a cooling rate higher than 100°C / min through the oil-free lead rod water quenching system, and then pulled by the rear traction and continuous winding machine Under the action, the doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole density | aaaaa | aaaaa |

| Cross-sectional area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com