Wear-resistant corrosion-resistant multi-element manganese-aluminum bronze brazing alloy and preparation method thereof

A multi-component manganese-aluminum and brazing alloy technology, applied in the field of alloy manufacturing, can solve the problems of no wear resistance and no display of the alloy, and achieve the effects of good corrosion resistance, bright surface and less deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

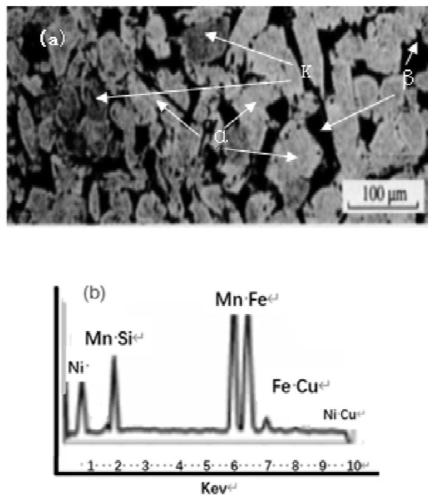

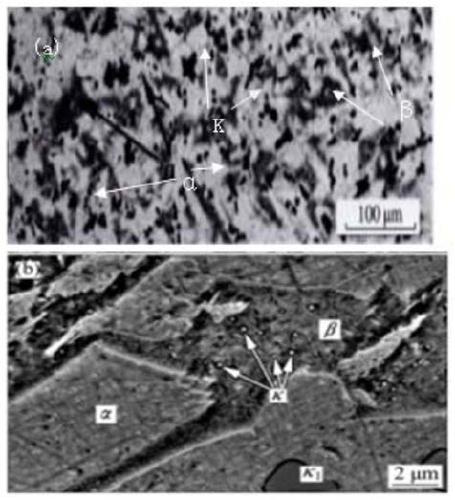

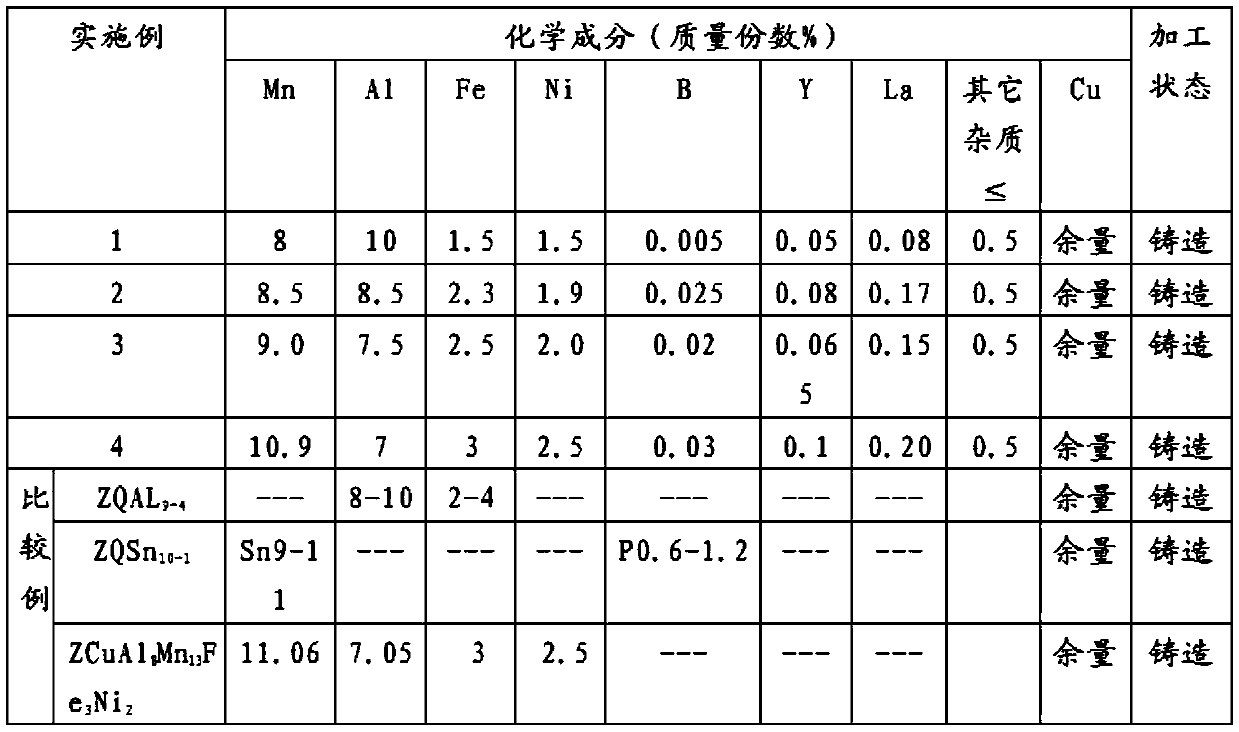

[0033] Embodiment 1-4: A wear-resistant and corrosion-resistant multi-component manganese-aluminum bronze brazing alloy, prepare materials according to the component ratio shown in Table 1; select electrolytic cathode copper, electrolytic aluminum, electrolytic manganese, electrolytic nickel, degreasing and Iron wire or nails with smooth surface, aluminum-5% boron master alloy and pure rare earth yttrium, lanthanum. Use medium frequency induction furnace and graphite crucible for heating and melting.

[0034] A method for preparing a wear-resistant and corrosion-resistant multi-element manganese-aluminum bronze brazing alloy, comprising the following steps:

[0035] ①Charging: Put dry charcoal at the bottom of the crucible, add cathode copper and electrolytic manganese at the same time according to the ratio of Cu:Mn≤2, and the charge should be tight;

[0036] ②Send electricity to heat up, increase the power to melt the furnace charge quickly, after the furnace charge is melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| liquidus temperature | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com