Mg alloy anode material and preparation method thereof

A technology of anode material and magnesium alloy, applied in the field of magnesium alloy anode material and its preparation, can solve the problems of low discharge activity, high use efficiency, low discharge voltage, etc., achieve excellent electrochemical performance, shorten processing cost, and shorten processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

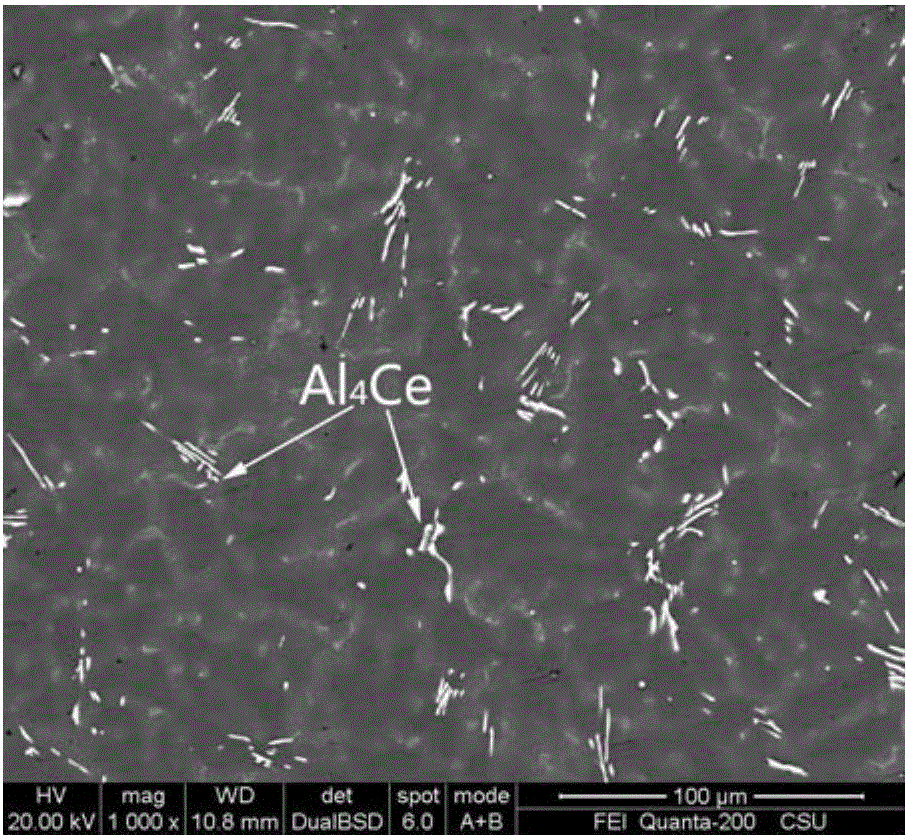

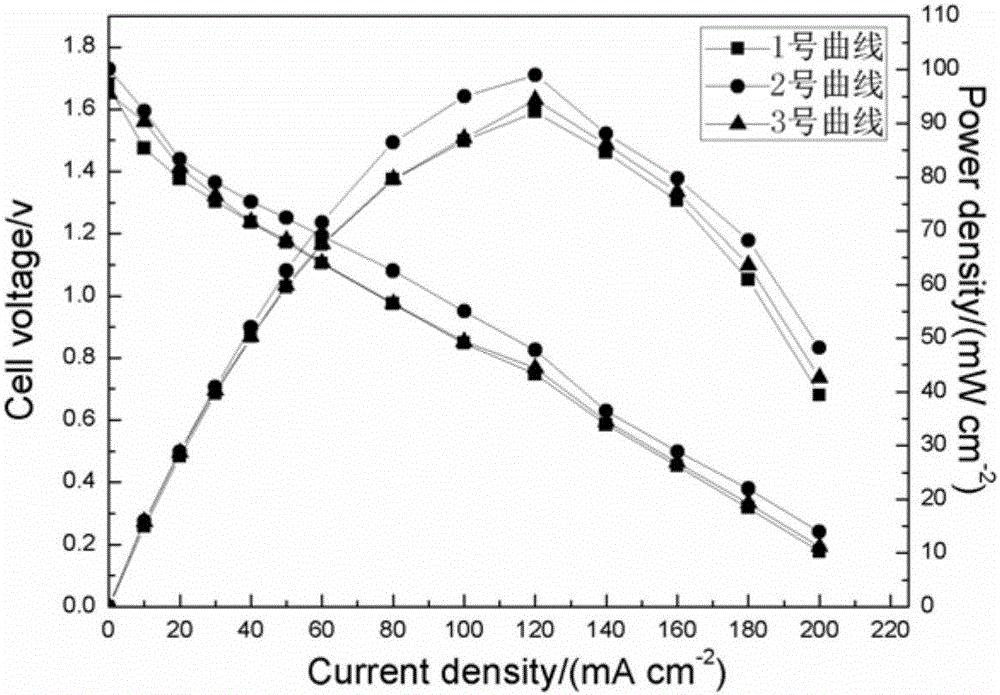

Embodiment 1

[0052] Pure magnesium (Mg≧99.9%), alloying elements aluminum (Al≧99.9%), tin (Sn≧99.9%), according to the composition ratio: Al: 5%, Sn: 0.8%, Ce: 0.2%, the balance For magnesium, it is prepared into an alloy. First melt magnesium in a graphite crucible at a melting temperature of 750°C. After the magnesium alloy is completely melted, add alloy components aluminum and tin. After the alloy elements are melted, stir with a graphite rod for 10 minutes (min), and then add magnesium The cerium master alloy is stirred again with a graphite rod for 10 minutes (min), and at the same time, the temperature is controlled at 700 ° C, and it is still for 10 minutes (min), and poured into a steel mold with a preheating temperature of 250 ° C to obtain a cylindrical or It is a block casting billet.

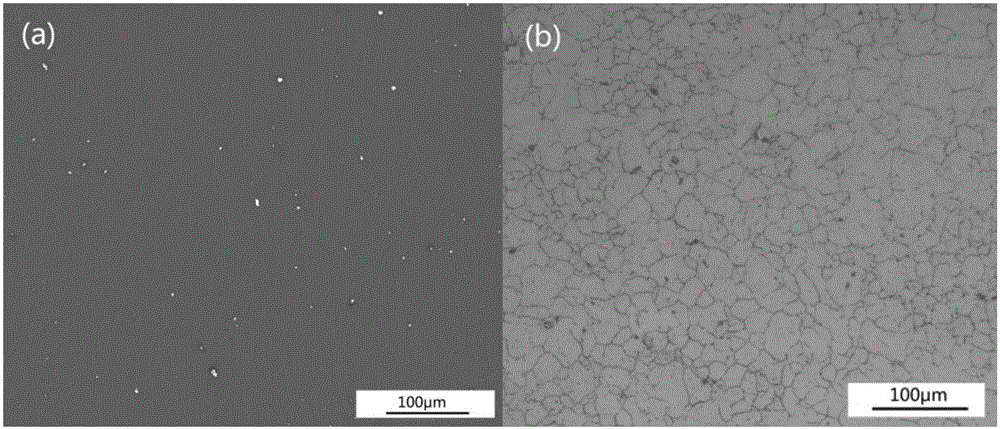

[0053] The magnesium alloy anode material billet was subjected to homogenization annealing at 400° C. for 24 hours, so that the alloy components could be uniformly diffused at high temperature....

Embodiment 2

[0055] Pure magnesium (Mg≧99.9%), alloying elements aluminum (Al≧99.9%), tin (Sn≧99.9%), according to the composition ratio: Al: 5.8%, Sn: 0.9%, Ce: 0.3%, the balance For magnesium, it is prepared into an alloy. First melt magnesium in a graphite crucible at a melting temperature of 750°C. After the magnesium alloy is completely melted, add alloy components aluminum and tin. After the alloy elements are melted, stir with a graphite rod for 10 minutes (min), and then add Magnesium-cerium master alloy, stir again with graphite rod for 10 minutes (min), at the same time control the temperature at 700 ° C, stand still for 10 minutes (min), pour into a steel mold with a preheating temperature of 250 ° C, and obtain a cylindrical shape Or block cast ingots.

[0056] The magnesium alloy anode material billet was subjected to homogenization annealing at 450° C. for 24 hours, so that the alloy components could be uniformly diffused at high temperature. Preheat the evenly diffused mag...

Embodiment 3

[0058] Pure magnesium (Mg≧99.9%), alloying elements aluminum (Al≧99.9%), tin (Sn≧99.9%), according to the composition ratio: Al: 6.5%, Sn: 1.0%, Ce: 0.1%, the balance For magnesium, it is prepared into an alloy. First melt magnesium in a graphite crucible at a melting temperature of 750°C. After the magnesium alloy is completely melted, add alloy components aluminum and tin. After the alloy elements are melted, stir with a graphite rod for 10 minutes (min), and then add magnesium The cerium master alloy is stirred again with a graphite rod for 10 minutes (min), and at the same time, the temperature is controlled at 700 ° C, and it is still for 10 minutes (min), and poured into a steel mold with a preheating temperature of 250 ° C to obtain a cylindrical or It is a block casting billet.

[0059] The magnesium alloy anode material billet was subjected to homogenization annealing at 350°C for 24 hours, so that the alloy components could be diffused uniformly at high temperature....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com