Composite metamorphic cast aluminum alloy and preparation method and application thereof

A technology of casting aluminum alloy and compound modification, which is applied in the field of non-ferrous metal casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

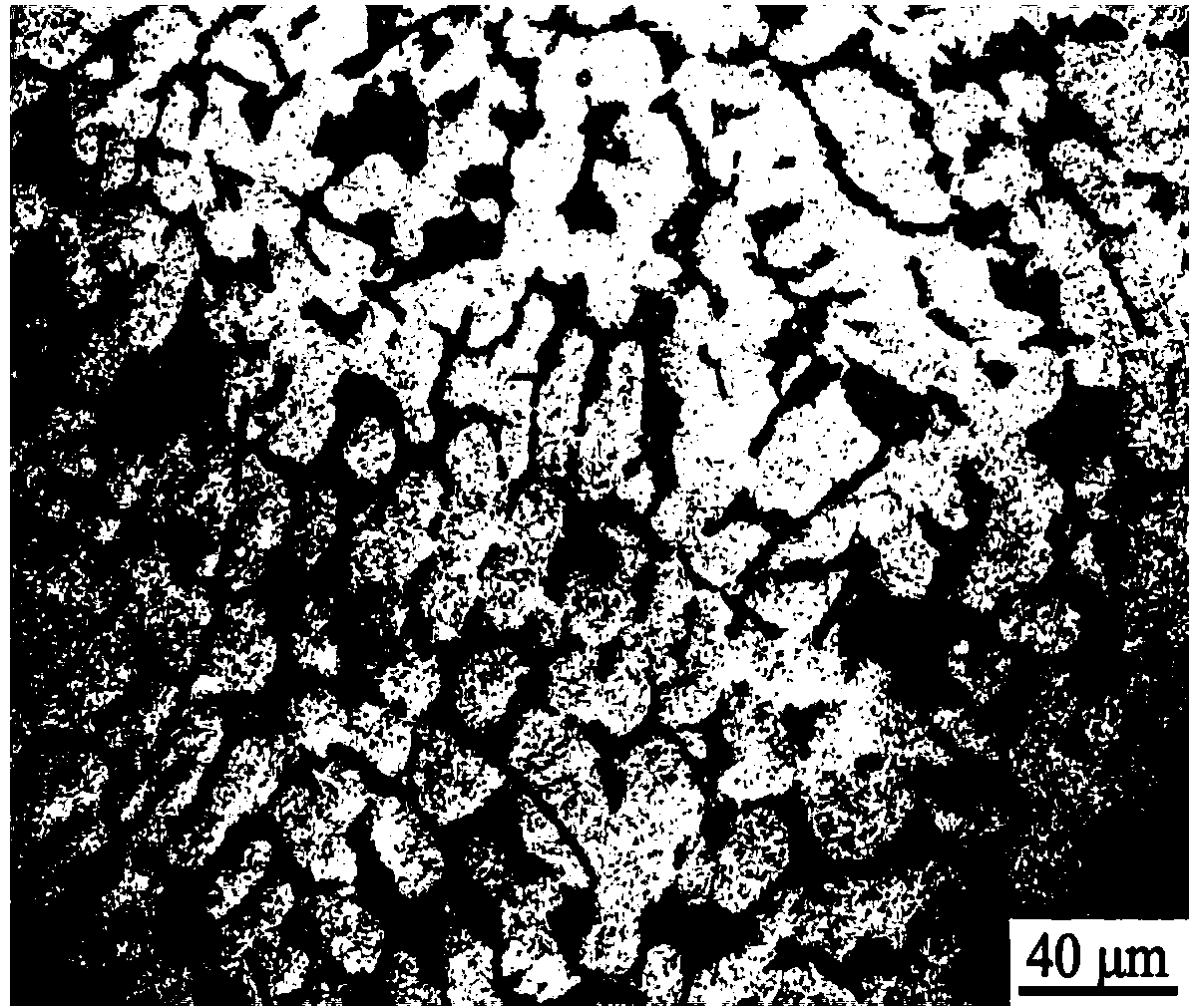

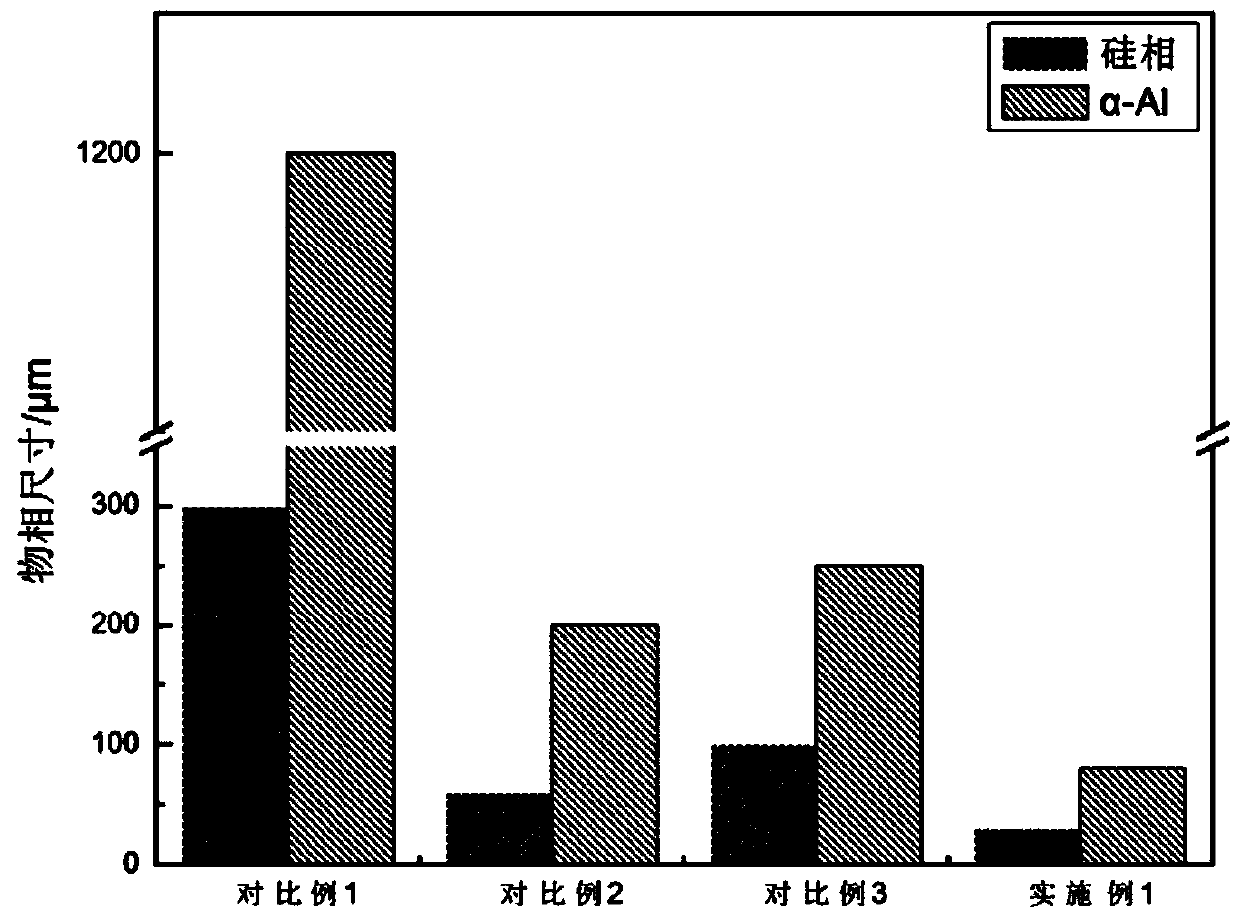

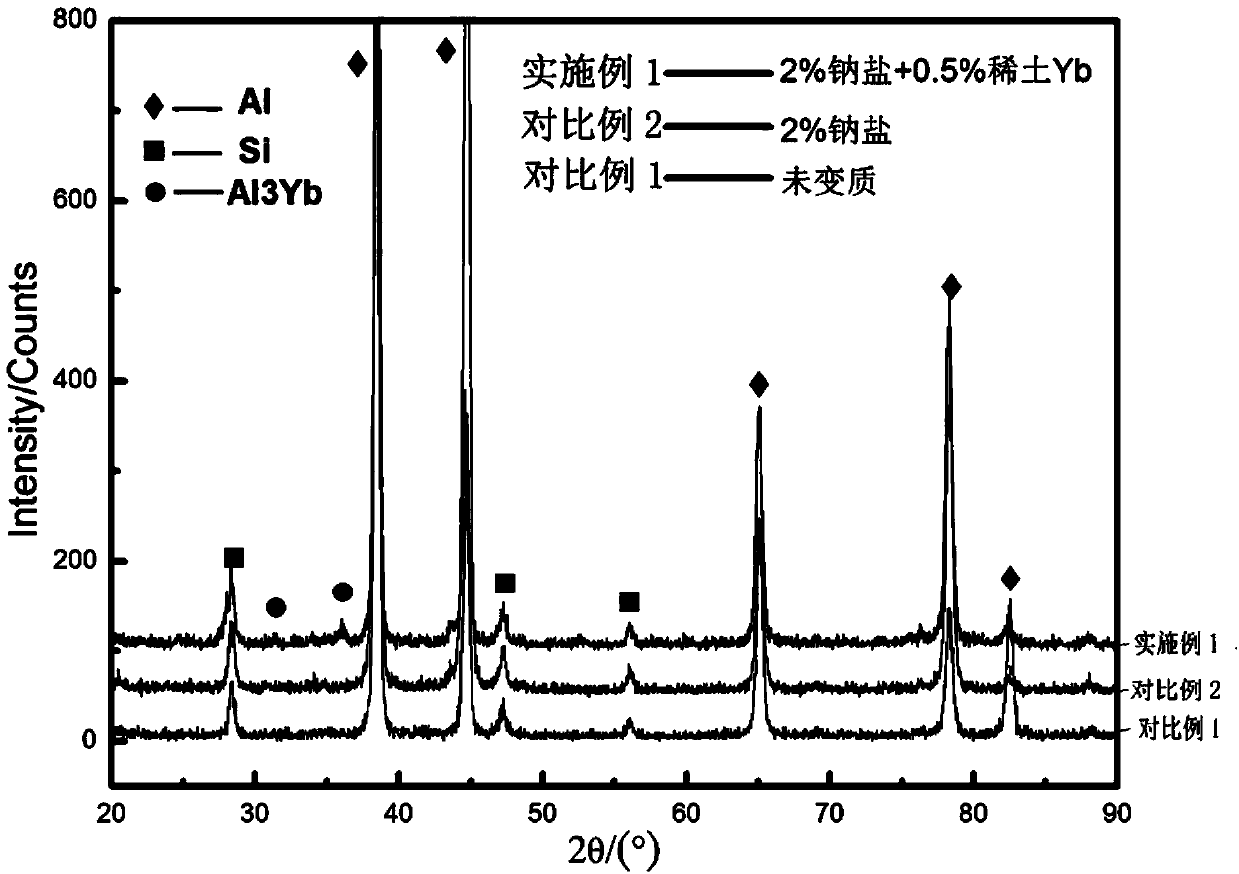

Image

Examples

Embodiment 1

[0048] The composition (weight percentage) of this embodiment is: 9.0% Si, 0.3% Mg, 0.4% Mn, 0.5% Yb, 2.0% sodium salt, limiting impurity elements: Fe<0.2%, Sn<0.1% , Cu<0.1%, Pb<0.05%, the rest is Al.

[0049] The sodium salt is composed of the following weight percentages: 40% NaF; 30% NaCl; 15% KCl; 15% Na 3 AlF 6 .

[0050] Specific steps are as follows:

[0051] The test materials are industrial pure Al ingots (provided by Shanghai Yuhang Aluminum Company, purity ≥99.7%), industrial pure Mg ingots (provided by Shanxi Wenxi Yinguang Magnesium Industry Group Company, purity ≥99.8%), Al-12Si and Al-10Mn master alloy (provided by Tangshan Keyuan Nonferrous Alloy Casting Company, where the value is the mass percentage), Al-20Yb master alloy (provided by Yueyang Yuhua Metallurgical New Materials Company). The total mass ratio is in accordance with the above component ratio. Pit-type resistance furnace and graphite crucible are used for smelting alloy. When the crucible is preheate...

Embodiment 2

[0068] The composition of the present invention (weight percentage) is: 8.5% Si, 0.3% Mg, 0.4% Mn, 0.2% Yb, 1.0% sodium salt, limiting impurity elements: Fe<0.2%, Sn<0.1%, Cu<0.1%, Pb<0.05%, and the rest is Al.

[0069] The sodium salt is composed of the following weight percentages: 40% NaF; 30% NaCl; 15% KCl; 15% Na 3 AlF 6 .

[0070] Specific steps are as follows:

[0071] The alloy composition ratio designed according to Example 2 is intermediate. Pit-type resistance furnace and graphite crucible are used for smelting alloy. When the crucible is preheated to about 400℃, add industrial pure aluminum and Al-12Si master alloy in sequence, and heat up to 730℃; after all melted, add Al-10Mn master alloy and stir to make it fully dissolved, then press into the magnesium with a bell jar Block, stir for 1~2min; when the furnace temperature rises to 740℃, add Al-20Yb master alloy; after all is melted, refining with argon gas for 15min, stand for 10min; increase the temperature to 760℃,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength σb | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com