Alloy liquid extrusion casting forming device and process method thereof

A squeeze casting and molding device technology, which is applied in the field of alloy liquid squeeze casting molding devices, can solve problems such as low dimensional accuracy, cracking of forgings, waste of working hours, etc., and achieve high dimensional accuracy, easy exhaust, and short time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

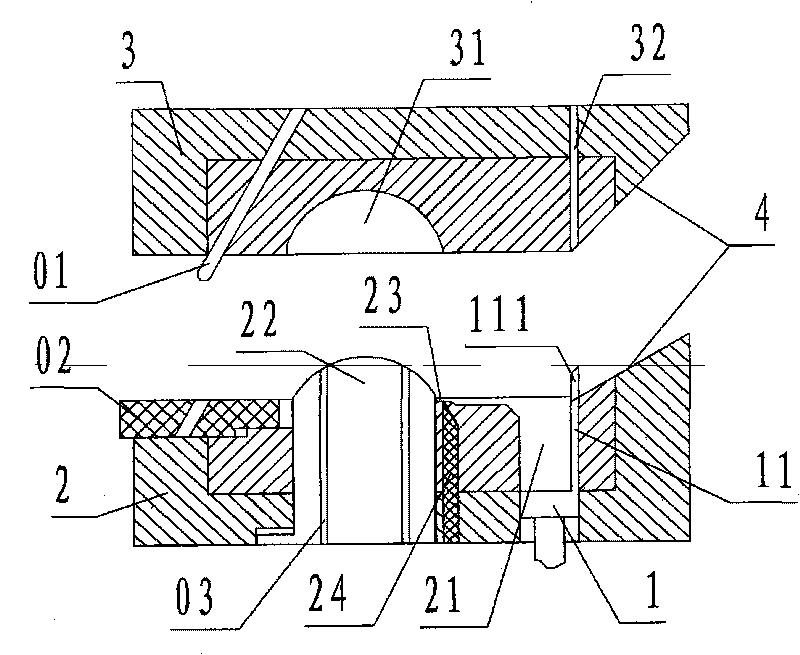

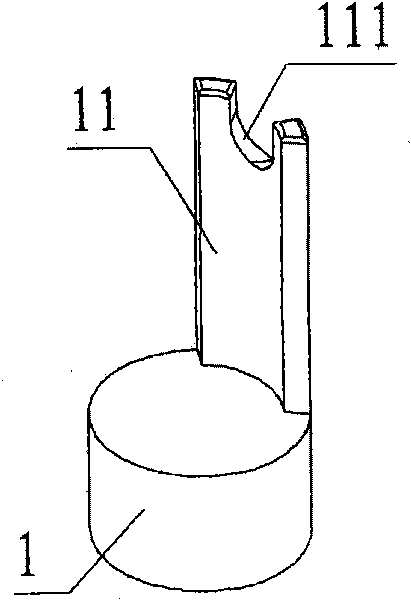

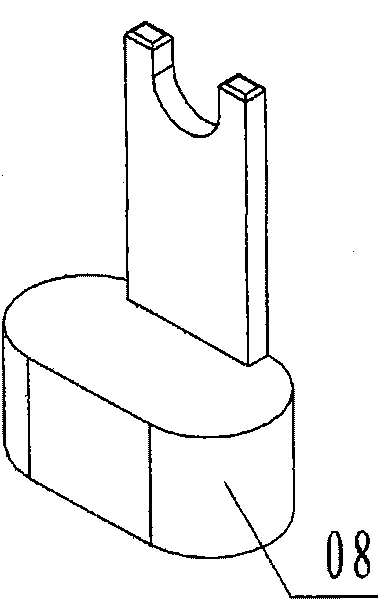

[0035] refer to Figure 1 to Figure 9, an alloy liquid squeeze casting molding device and its process method of the present invention, comprising an alloy liquid squeeze casting molding device and an alloy liquid squeeze casting process method, wherein: the alloy liquid squeeze casting molding device includes a hammer Head 1, static mold 2, movable mold 3, sprue 4, wherein, the hammer head 1 is a cylindrical step piston cylinder made of steel, and the upper end surface of the hammer head is provided with a circle extending upward along the right side. A sealing knife 11 formed by a ring-shaped cylinder, the center of the top of the sealing knife 11 is provided with a section of vertically downward groove-shaped pass groove 111 along the diameter line; the static mold 2 is the lower mold part of the vertical die-casting mould. A core 22 is provided, and the parting surface on the right side of the core 22 is provided with an ingate 23 runner formed by a groove, and a cutting kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com