A fiber liquid film contactor amine washing desulphurization device and an amine washing desulphurization method

A fiber liquid membrane and contactor technology, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as low mass transfer efficiency, no mention of sulfur effect, and increased run loss of amine solution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

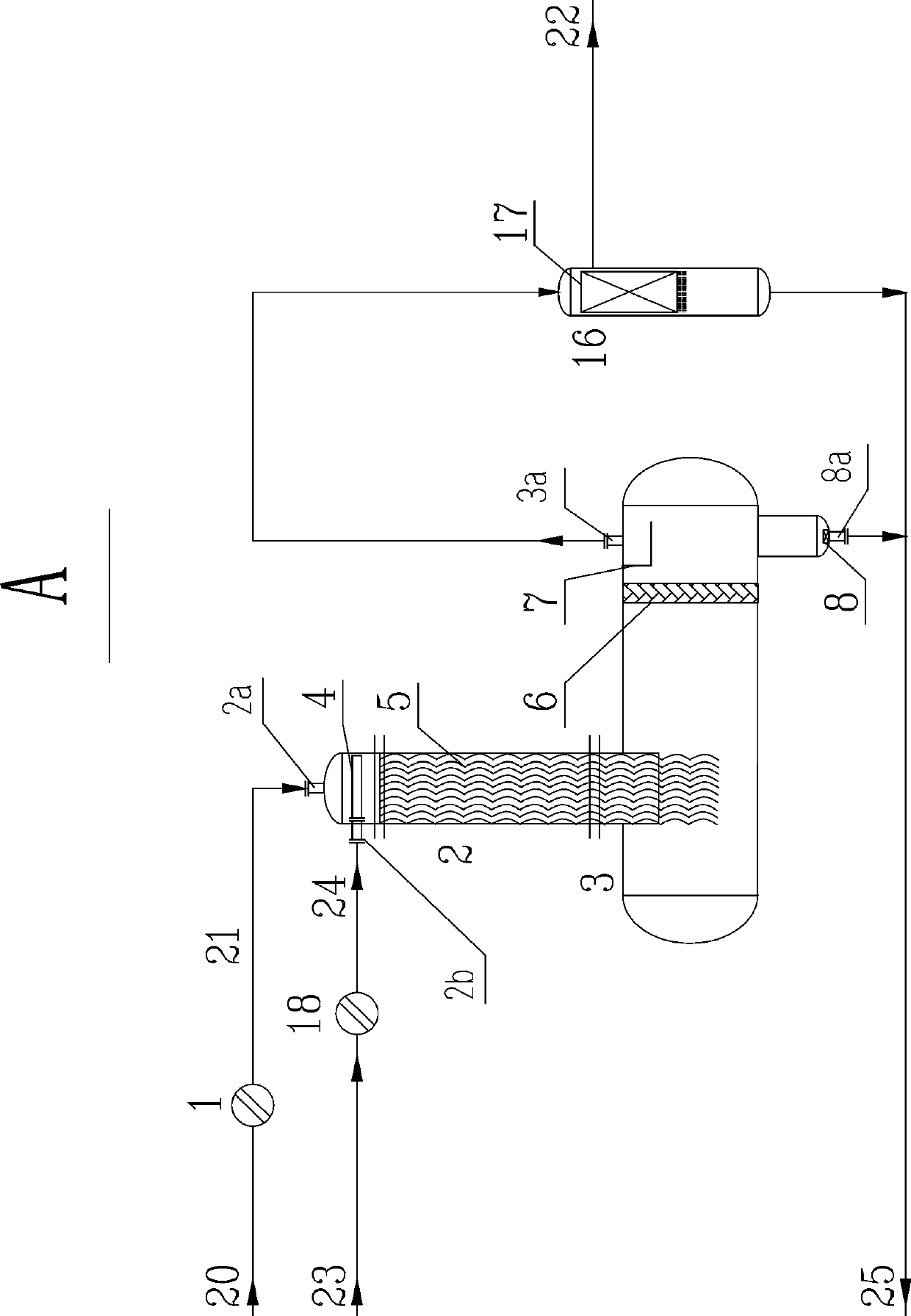

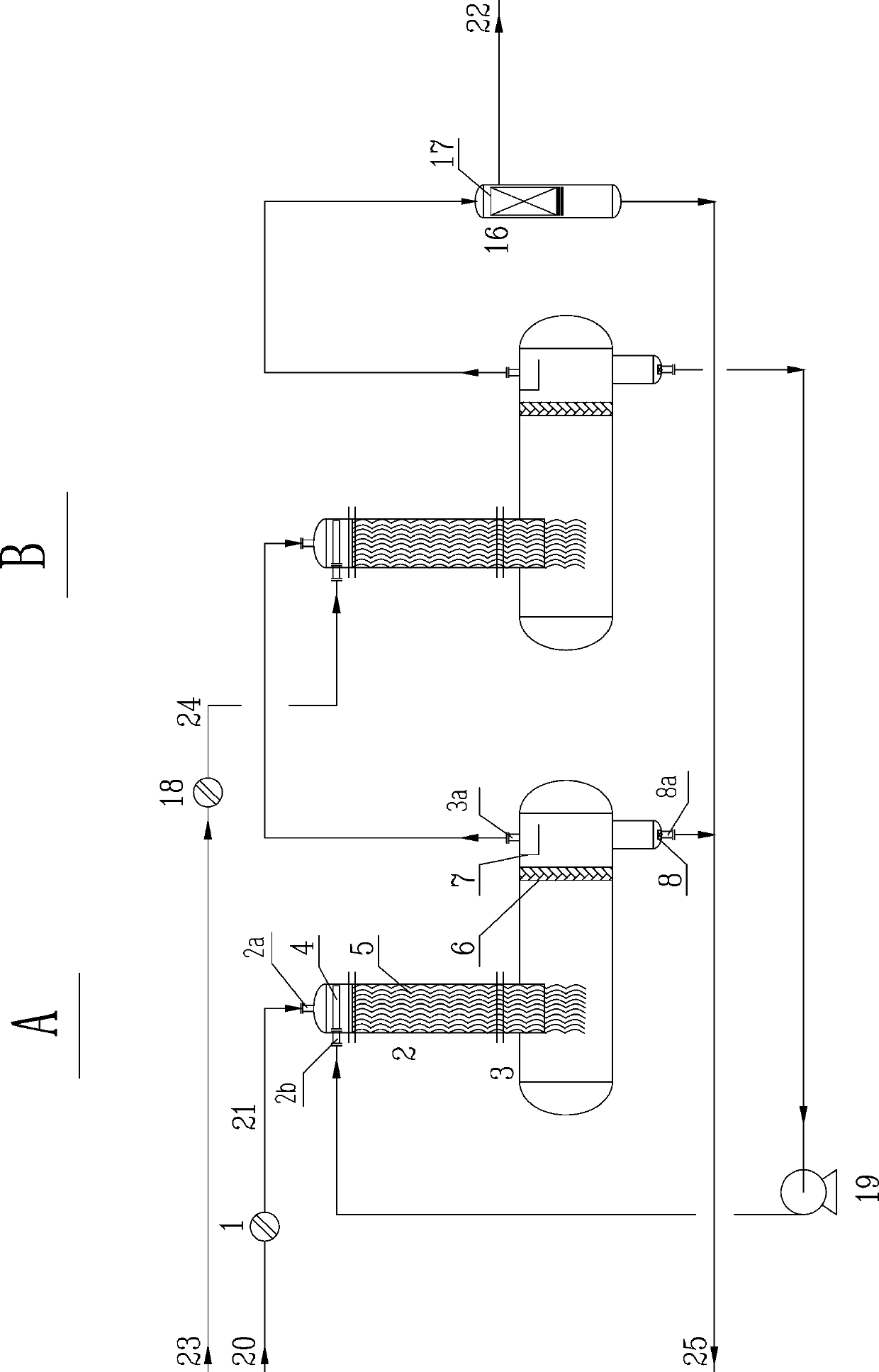

[0020] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see Figure 1~2 As shown in the figure, it is marked as follows: fiber liquid membrane mass transfer contactor assembly A, fiber liquid membrane mass transfer contactor assembly II B, light hydrocarbon filter 1, fiber liquid membrane contactor 2, light hydrocarbon inlet 2a, amine liquid Inlet 2b, settling separation tank 3, light hydrocarbon outlet 3a, liquid distributor 4, stainless steel fiber wire 5, coalescing plate 6, L-shaped baffle 7, liquid separation bag 8, amine liquid outlet 8a, coalescer 16, inner Core 17, amine liquid filter 18, amine liquid circulation pump 19, light hydrocarbon feed pipe 20, light hydrocarbon connecting pipe 21, light hydrocarbon discharge pipe 22, amine liquid feed pipe 23, amine liquid connecting pipe 24, amine liquid Outlet pipe 25.

[0021]According to the different hydrogen sulfide content in light hydroc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com