Method and system for treating phenol-containing acidic water by direct liquefaction with coal

An acid water, direct technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, extraction water/sewage treatment, etc., can solve the problem of low ammonia removal rate, achieve simple process flow, social benefits and economical The effect of significant benefits and low cost of equipment construction or renovation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method and system for treating phenol-containing acidic water from direct liquefaction of coal provided by the present invention will be further described in detail below, but the present invention is not limited thereto.

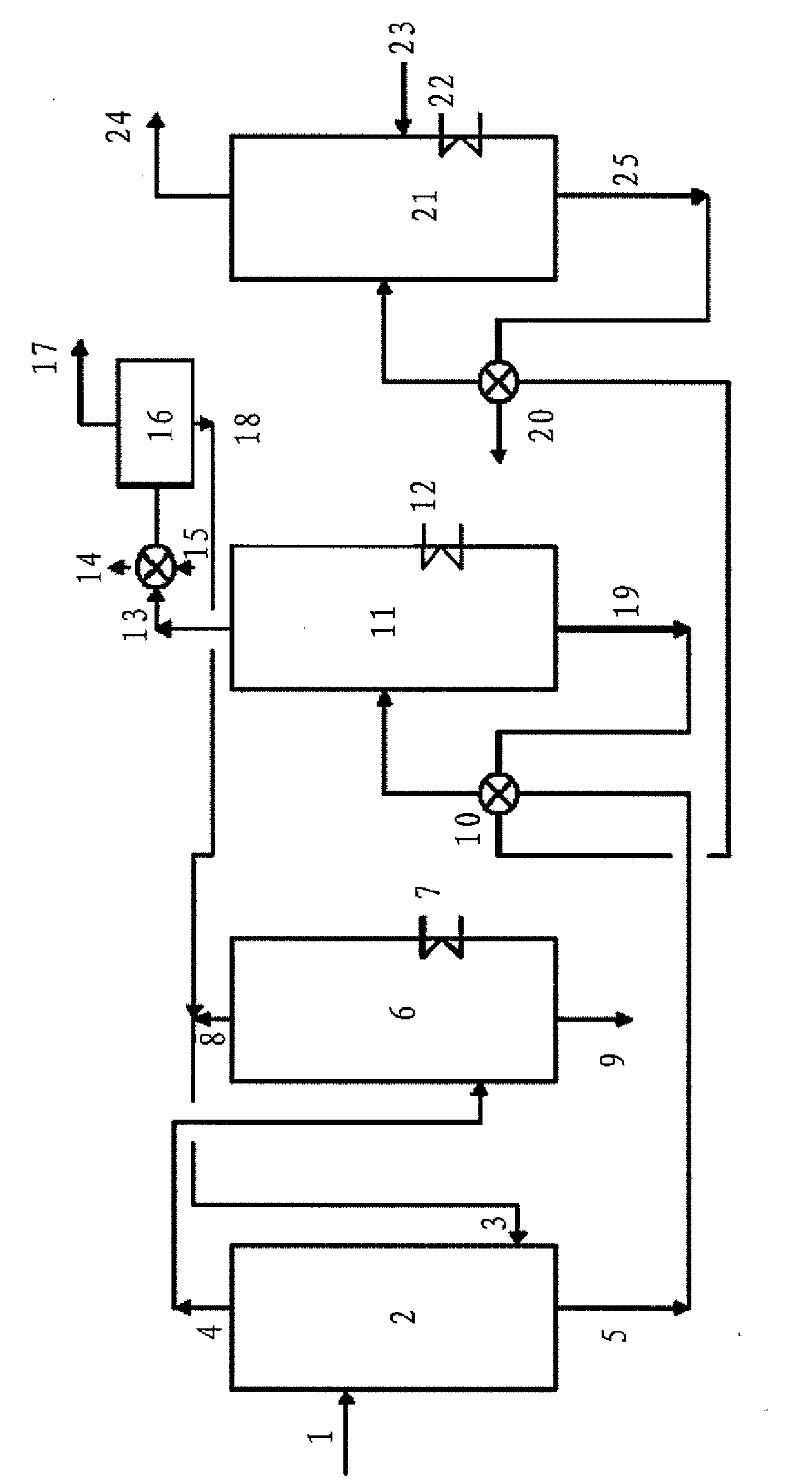

[0029] The treatment method for direct coal liquefaction of phenol-containing acidic water provided by the present invention includes four steps of extraction and removal of phenols with an ether extractant, separation of extracts, recovery of ether solvents and hydrogen sulfide removal by stripping, and deep deamination by stripping. The following are detailed one by one as follows:

[0030] Step 1: Extraction and dephenolization

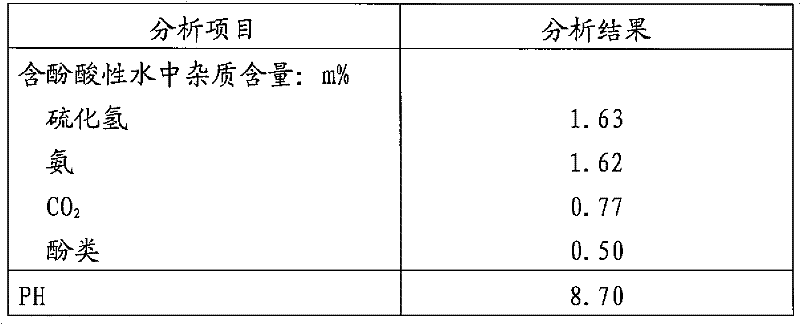

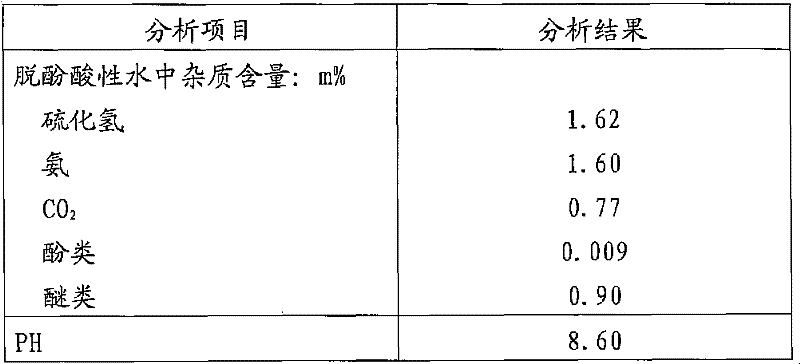

[0031] The purpose of extractive dephenolization is to use ether extractant to extract phenolic organic compounds in the acidic water of coal direct liquefaction. On the one hand, the organic phenols contained in acidic water are recovered as high-value products; on the other hand, after the content of phenolic subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com