Flash evaporation dealkylation tank for desulfurating pregnant solution

A technology for desulfurization rich liquid and evaporation and dehydrocarbon tank, which is applied in the direction of flash evaporation, liquid separation, gas fuel, etc., which can solve the problems of low conversion rate of sulfur in air distribution, solution foaming and flushing tower, and increase of desulfurization cost, so as to avoid flushing Tower accidents and the effect of reducing desulfurization costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

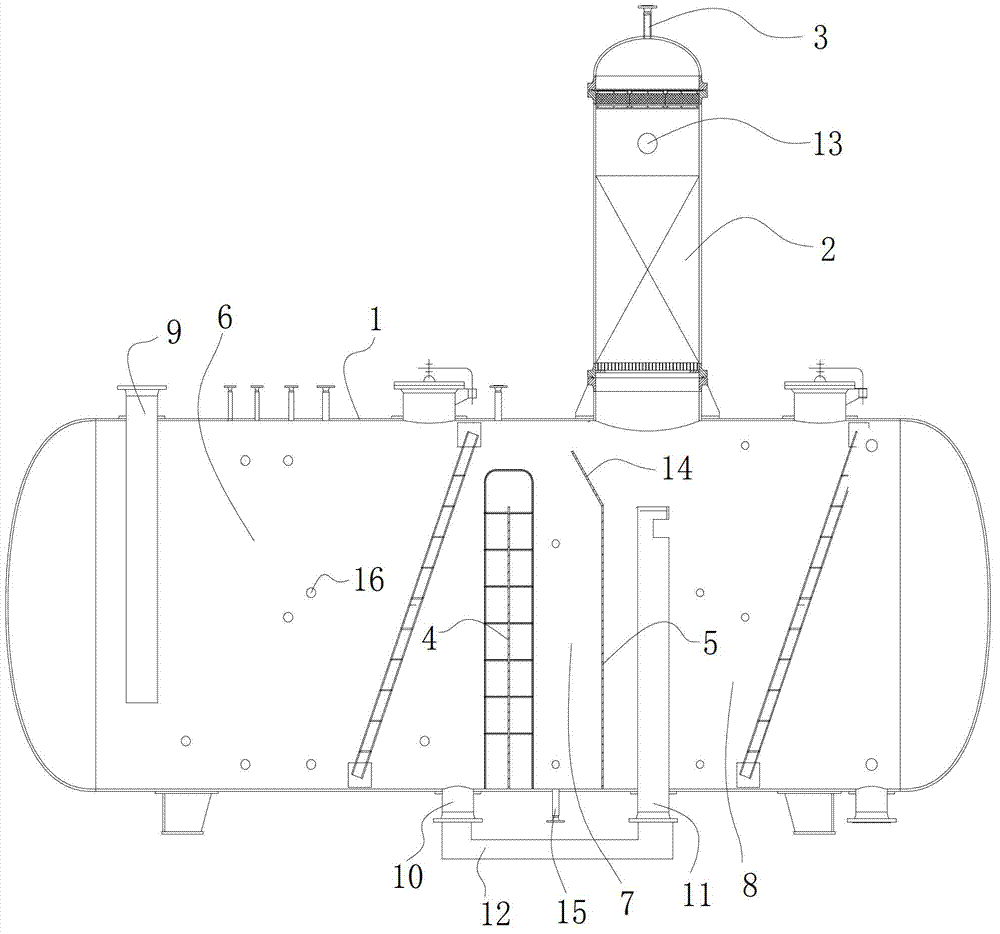

[0018] Such as figure 1 As shown, the flash vaporization and hydrocarbon removal tank for desulfurization rich liquid includes a tank body 1, a gas distribution bag 2 is provided on the top of the tank body 1, and a gas outlet 3 is provided on the gas distribution bag 2, and the tank body 1 A first partition 4 and a second partition 5 are arranged inside. The first partition 4 and the second partition 5 separate the inner cavity of the tank 1 into a rich liquid flash chamber 6, an oil skimming chamber 7, and a hydrocarbon rich liquid A storage cavity 8, the upper part of the rich liquid flash cavity 6 is in communication with the gas distribution bag 2, the upper part of the oil skimming cavity 7 is in communication with the upper part of the de-hydrocarbon rich liquid storage cavity 8, and the rich liquid flash cavity 6 is provided with a rich liquid The inlet 9 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com