Sludge thermal hydrolysis and anaerobic digestion integrated treatment process system

A treatment process, anaerobic digestion technology, applied in water/sludge/sewage treatment, sludge treatment, biological sludge treatment, etc., can solve problems such as immature technology and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

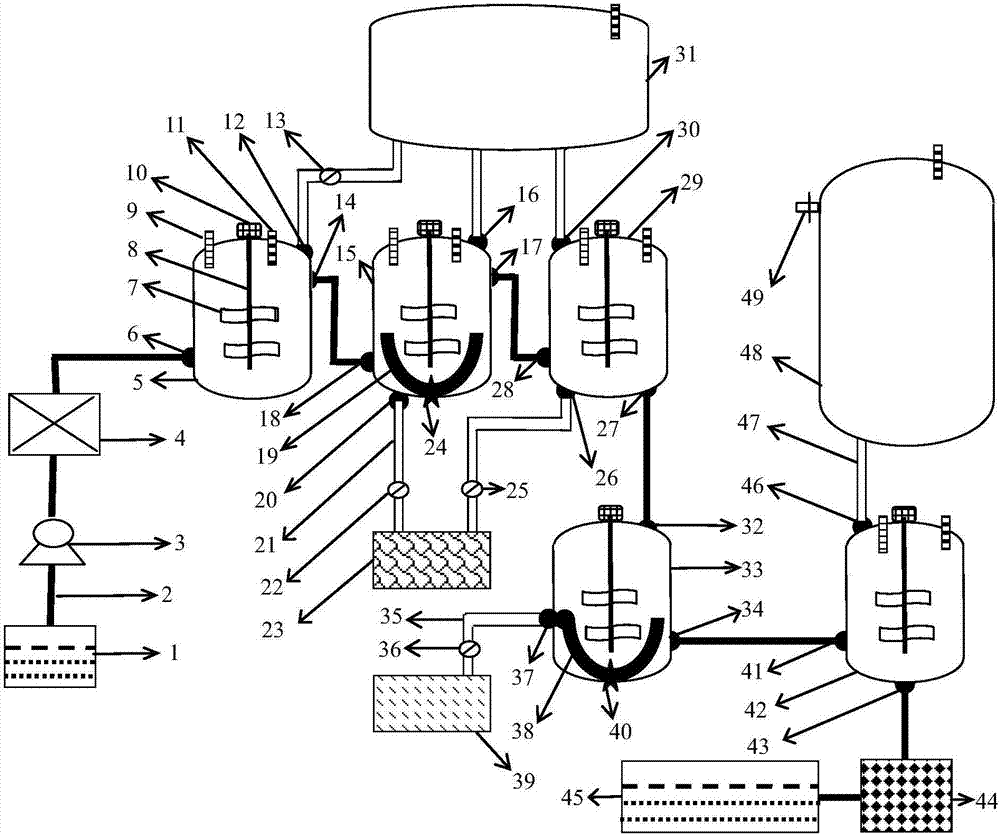

[0090] (1) The preparation process of the sludge thermal hydrolysis and anaerobic digestion integrated treatment process system is as follows:

[0091]The sludge thermal hydrolysis and anaerobic digestion integrated treatment process system consists of sludge inlet tank 1, sludge pipe 2, sludge inlet pump 3, sludge thickener 4, slurry tank 5, slurry tank sludge inlet flange 6, Stirring blade 7, stirring shaft 8, temperature sensor 9, stirring motor 10, pressure sensor 11, slurry tank steam inlet flange 12, slurry tank steam flow valve 13, slurry tank sludge outlet flange 14, thermal hydrolysis Reaction tank 15, thermal hydrolysis reaction tank steam outlet flange 16, thermal hydrolysis reaction tank sludge outlet flange 17, thermal hydrolysis reaction tank sludge inlet flange 18, thermal hydrolysis catalytic tube filled with nickel-based catalyst 19. Thermal hydrolysis reaction tank steam inlet flange 20, steam pipe 21, thermal hydrolysis reaction tank steam flow valve 22, ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com