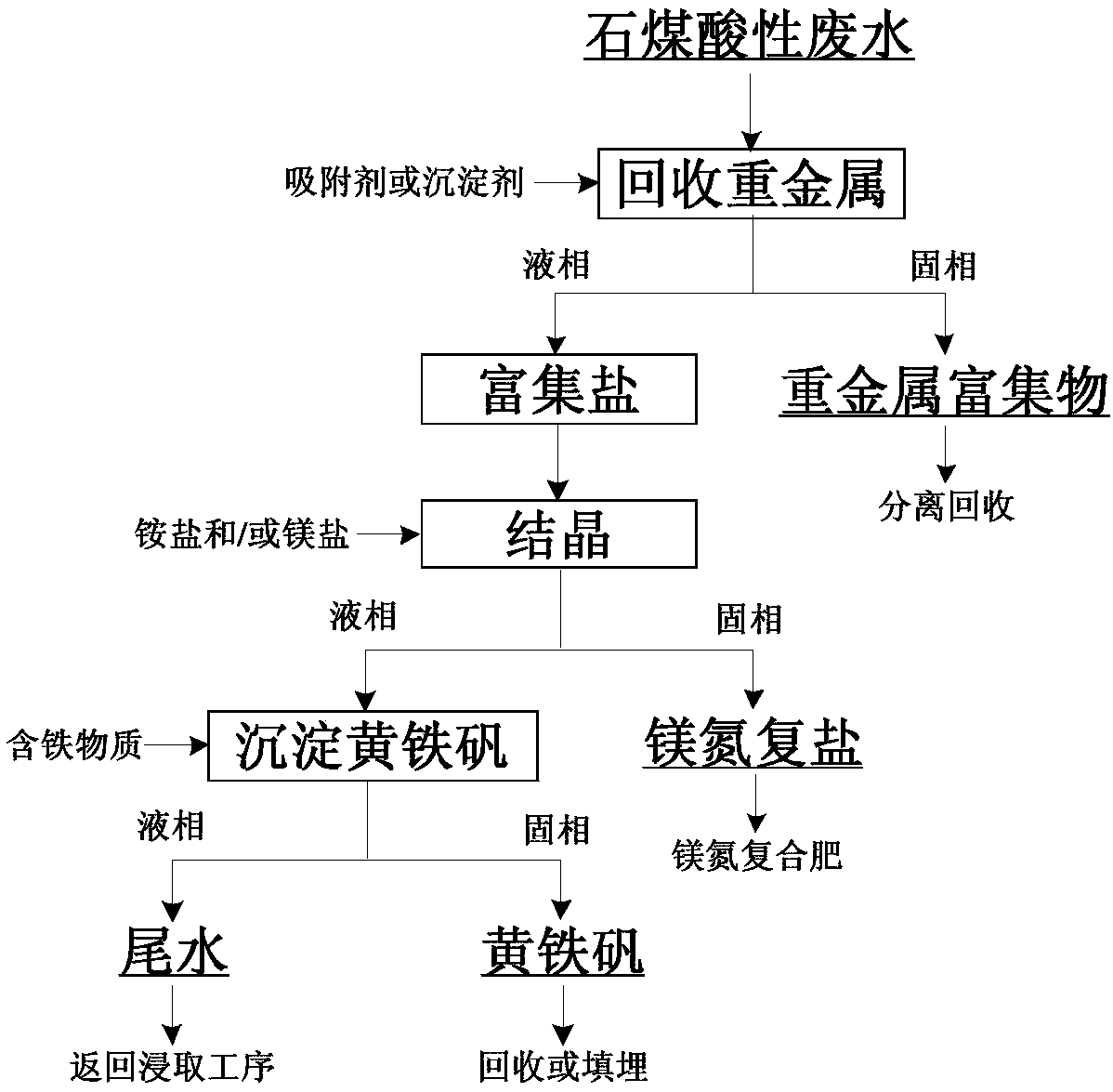

Stone coal acidic waste water resource utilization method

A technology for acid wastewater and recycling, applied in chemical instruments and methods, applications, water/sewage treatment, etc., can solve the problems of low equipment investment, low cost, and consideration of the overall composition of wastewater, and achieve zero discharge, low cost, The effect of efficient separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0092] This embodiment provides a method for resource utilization of stone coal acid waste water, the main components and concentrations of the stone coal acid waste water are respectively: Na + 5.16g / L, K + 0.56g / L, NH 4 +1.75g / L, Mg 2+ 1.82g / L, SO 4 2- 8.92g / L. In addition, the stone coal acid wastewater also includes: vanadium 0.055g / L, chromium 0.0032g / L, nickel 0.0044g / L, copper 0.021g / L, cobalt 0.0039g / L, cadmium 0.0013g / L L, arsenic 0.0002g / L, zinc 0.083g / L, iron 0.086g / L, aluminum 0.023g / L, described method comprises the following steps:

[0093] (1) Selective recovery of heavy metals from stone coal acid wastewater through nitrogen-containing chelating resin adsorbent to obtain heavy metal enrichment and solution, the concentration of vanadium, chromium, nickel, copper, cobalt, cadmium, zinc, iron and aluminum in the solution are less than 0.1ppm, and the heavy metal enrichment is separated and recovered according to the existing process;

[0094] (2) Return th...

Embodiment 2

[0098] This embodiment provides a method for resource utilization of stone coal acid wastewater. The components and concentrations in the stone coal acid wastewater refer to Example 1. The method includes the following steps:

[0099] (1) Selectively recover heavy metals from stone coal acid wastewater through sulfide precipitant to obtain heavy metal enrichment and solution. The concentrations of vanadium, chromium, nickel, copper, cobalt, cadmium, zinc, iron and aluminum in the solution are all less than 0.1 ppm, the heavy metal enrichment is separated and recovered according to the existing process;

[0100] (2) The solution obtained in step (1) is returned to the stone coal leaching process, and a high-concentration saline solution is obtained through multiple cycles of leaching enrichment, and each ion concentration in the high-concentration saline solution is Na + 15.24g / L, K + 1.36g / L, Mg 2+ 12.33g / L, NH 4 + 4.97g / L, add ammonium bisulfate and magnesium bisulfate to...

Embodiment 3

[0104] This embodiment provides a method for resource utilization of stone coal acid wastewater. The components and concentrations in the stone coal acid wastewater refer to Example 1. The method includes the following steps:

[0105] (1) Selective recovery of heavy metals from stone coal acid wastewater through oxygen-containing and sulfur-containing chelating resin adsorbents to obtain heavy metal enrichment and solutions, in which vanadium, chromium, nickel, copper, cobalt, cadmium, zinc, iron and The concentration of aluminum is less than 0.1ppm, and the heavy metal enrichment is separated and recovered according to the existing technology;

[0106] (2) The solution obtained in step (1) is returned to the stone coal leaching process, and a high-concentration saline solution is obtained through multiple cycles of leaching enrichment, and each ion concentration in the high-concentration saline solution is Na + 126.46g / L, K + 23.83g / L, Mg 2+ 42.89g / L, NH 4 + 70g / L, adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com