Method for preparing methyl acetate, and reaction rectification tower possessing spatial column plates of mass transfer

A technology of three-dimensional mass transfer trays and reactive distillation towers, applied in fractionation, organic chemistry, etc., can solve the problems of large liquid layer height drop, uneven liquid layer drop, entrainment of mist, etc., and improve liquid holding capacity. , the effect of improving the generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

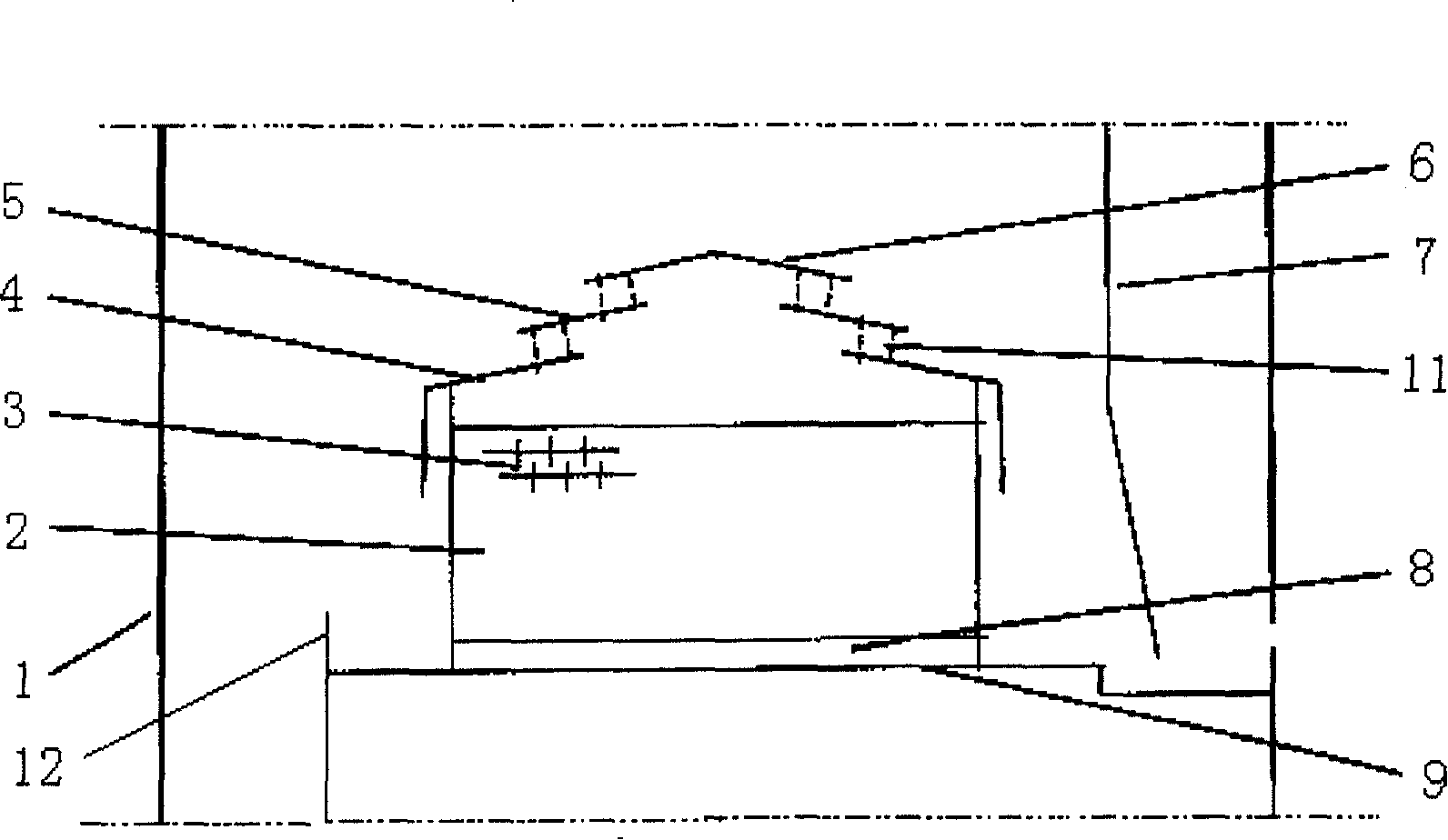

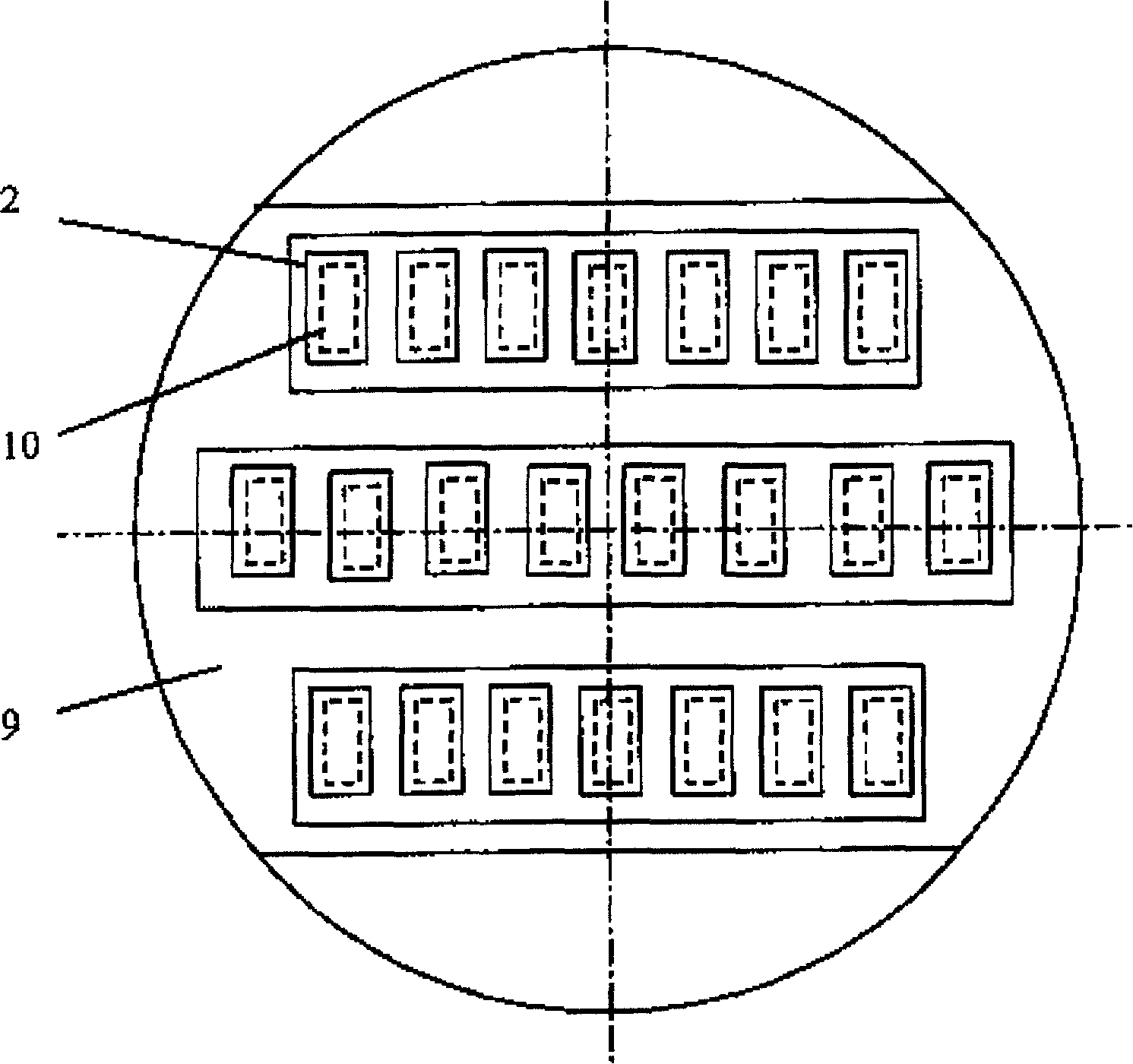

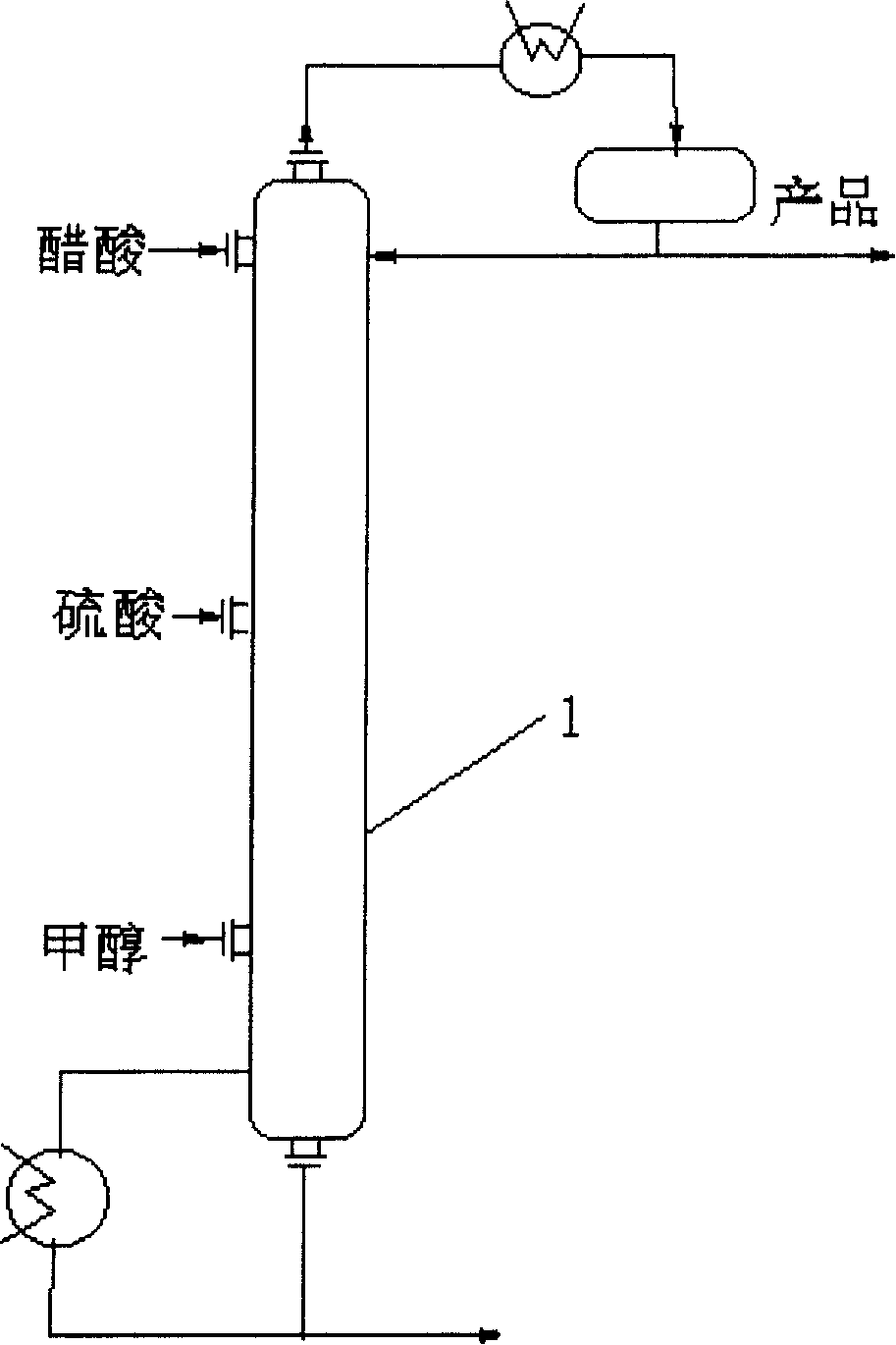

[0031] use as figure 1 , figure 2 and image 3 In the shown reactive distillation tower, methanol and acetic acid are fed into the reactive distillation tower from the lower and upper parts respectively, and sulfuric acid is fed into the reactive distillation tower from the middle.

[0032] The outlet weir is a toothed structure, and the height of the outlet weir is 200mm;

[0033] The tray spacing is 450mm;

[0034] The number of trays in the reaction section is 21;

[0035] 14 trays in the rectification section;

[0036] There are 18 trays in the extraction section;

[0037] Raw material molar ratio: methanol: acetic acid=1.2;

[0038] The amount of sulfuric acid added was 0.6% of the total feed weight of methanol and acetic acid. Using different reflux ratios, the results are shown in the table below

[0039] Reflux ratio

Embodiment 5

[0041] Using the same method and device as in Examples 1 to 4, the number of trays in the reaction section is 29, the molar ratio of raw material feed: methanol / acetic acid=1.0, the reflux ratio is controlled at 1.1, and the content of methyl acetate obtained at the top of the tower is 99.5 %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com