Rapid drying and collecting device for micro nano powder

A nano-powder and rapid drying technology, which is applied in drying chambers/containers, dry solid materials, and dry cargo handling, etc., can solve the problems of uncontrollable drying time, low collection rate, and small dosage, and achieve accurate and reliable drying time. Controlling, reducing the probability of re-collection, and the effect of high powder collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

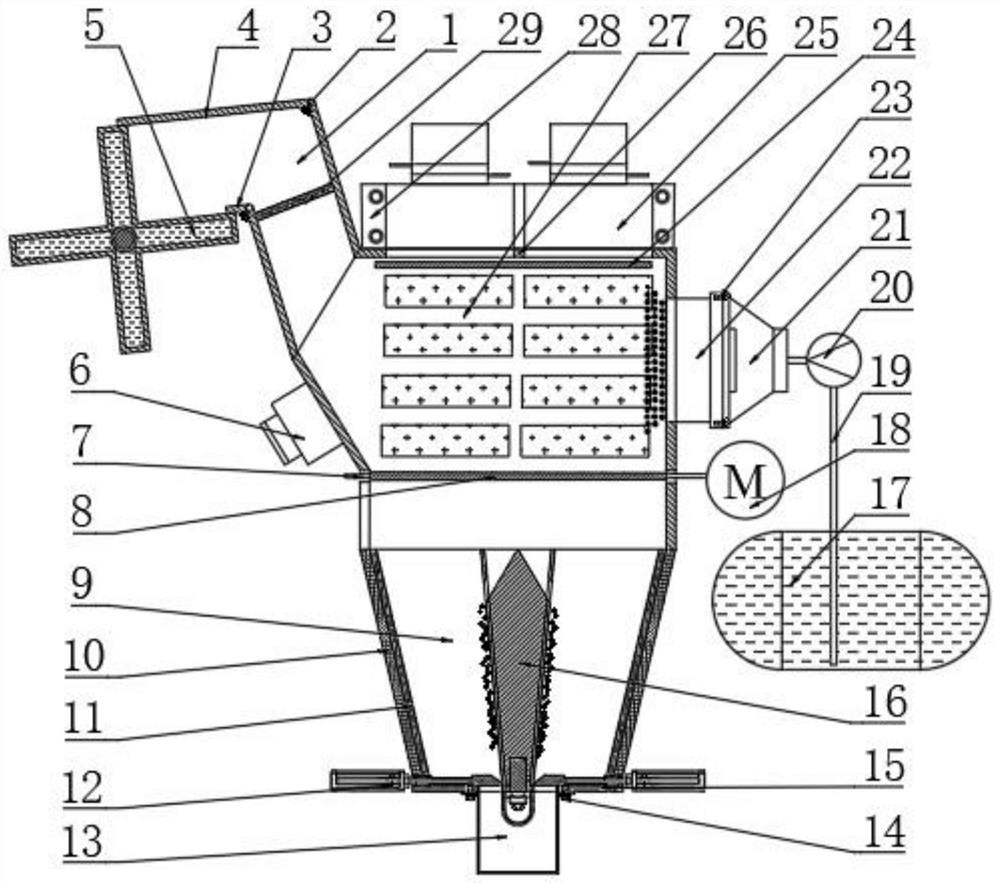

[0045] refer to figure 1 A device for rapid drying and collection of miniaturized nanopowder, comprising a micro droplet spraying device, a rapid drying device, a dehumidification device and a powder collecting device.

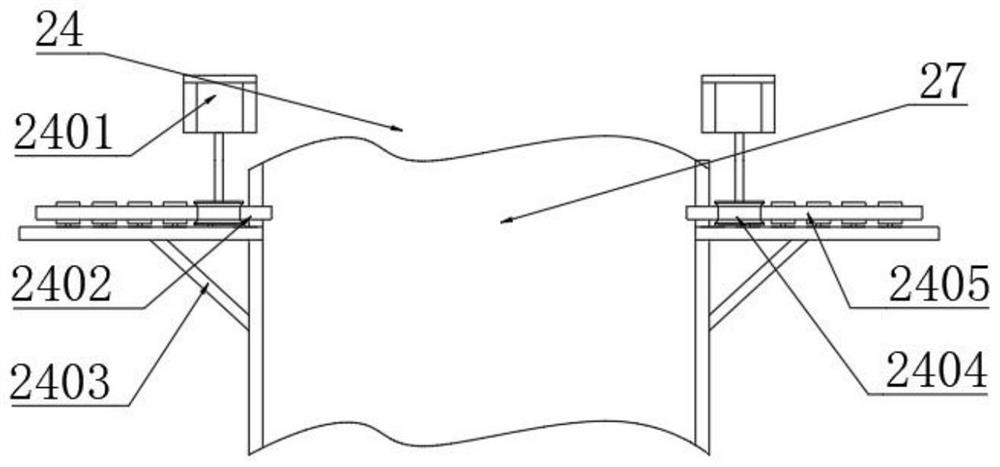

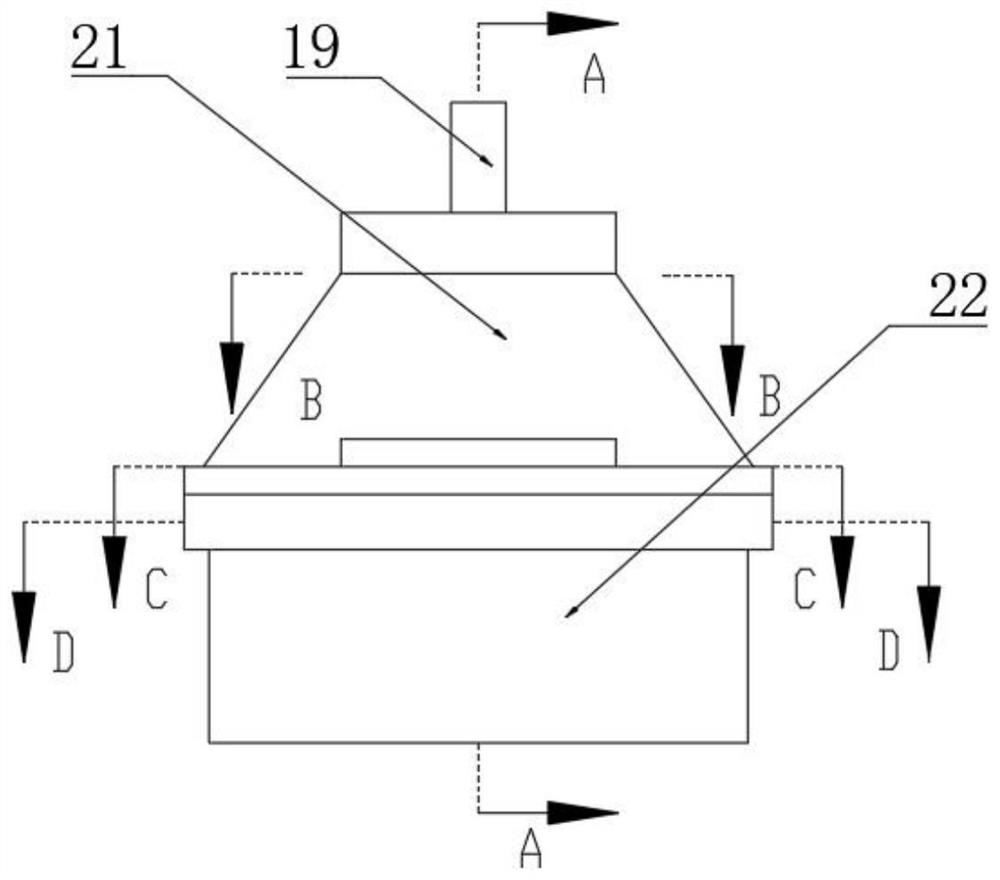

[0046] Specifically, the fast drying device includes a drying chamber housing 26, a magnetron 6 and an ultrasonic vibrator 25, and the ultrasonic vibrating element 25 is fixed on the top of the drying chamber housing 26 through an ultrasonic vibrator clamp 28, and the drying chamber housing 26 It is made of metal material, and the magnetron 6 is fixedly installed on the lower left of the drying chamber casing 26 , and the inside of the drying chamber casing 26 is a drying chamber 27 . The magnetron 6 can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com