Patents

Literature

60results about How to "Fast phase separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

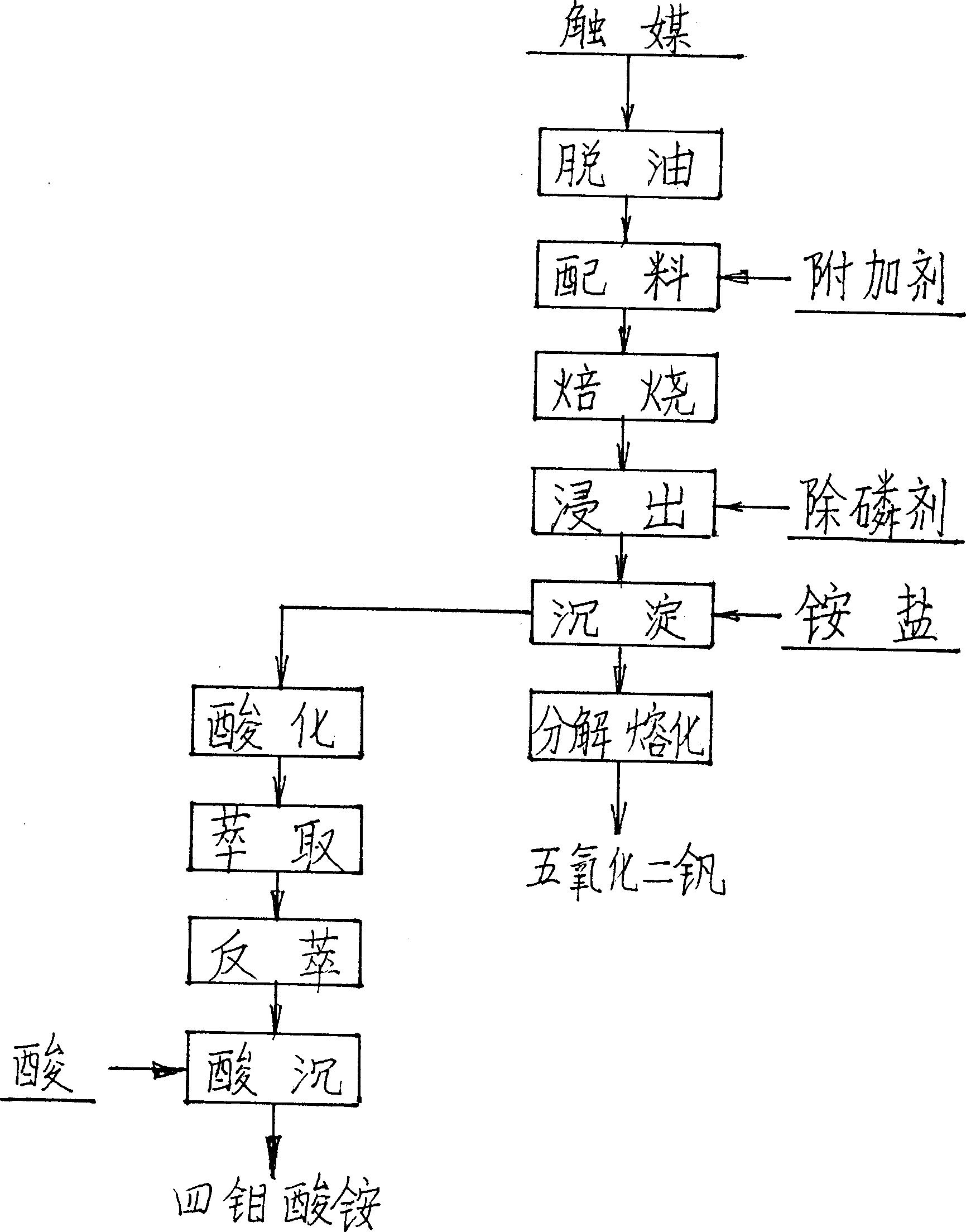

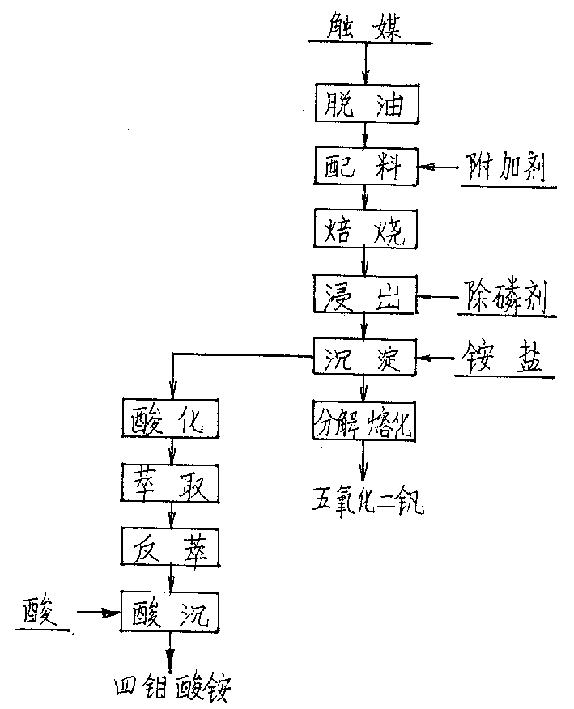

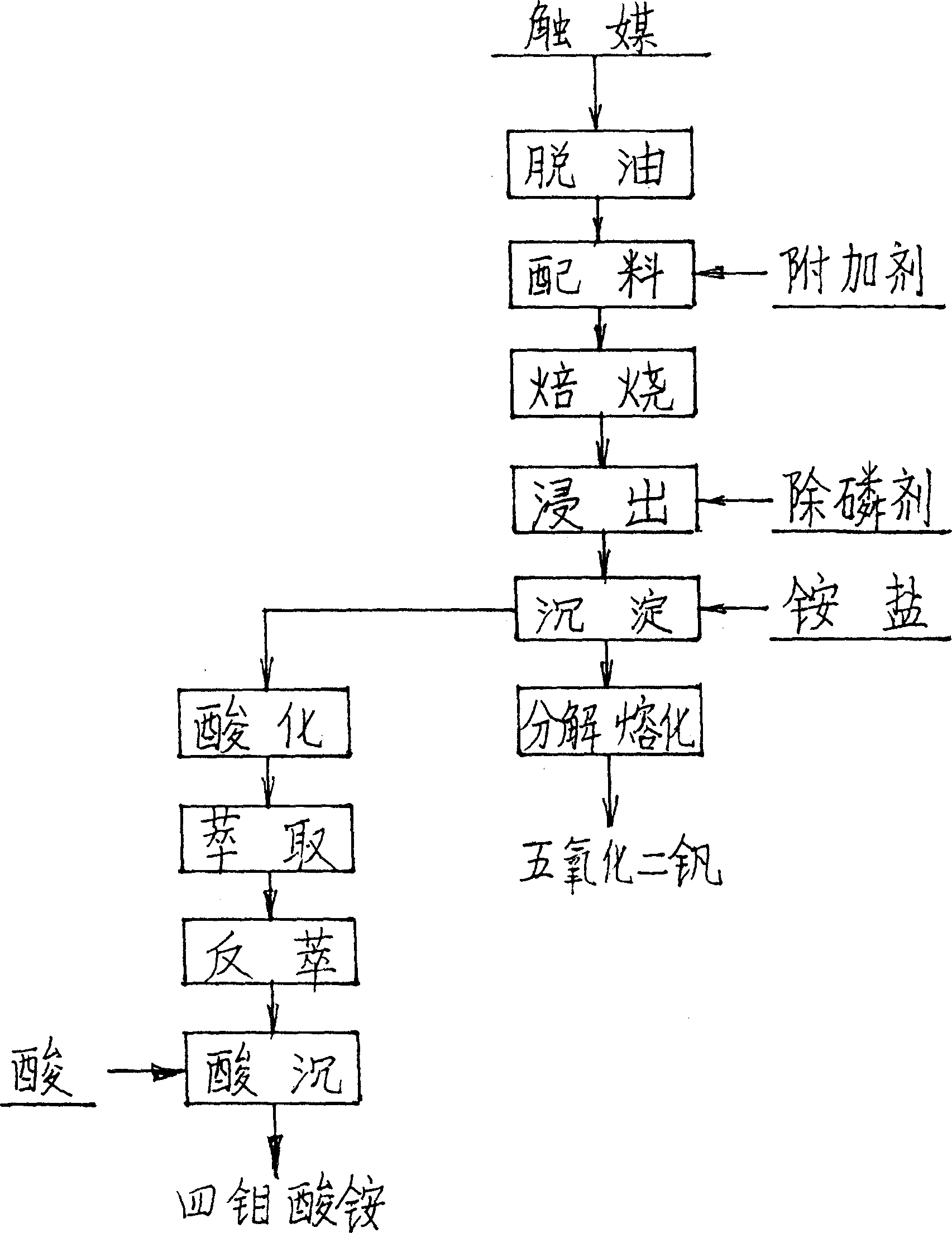

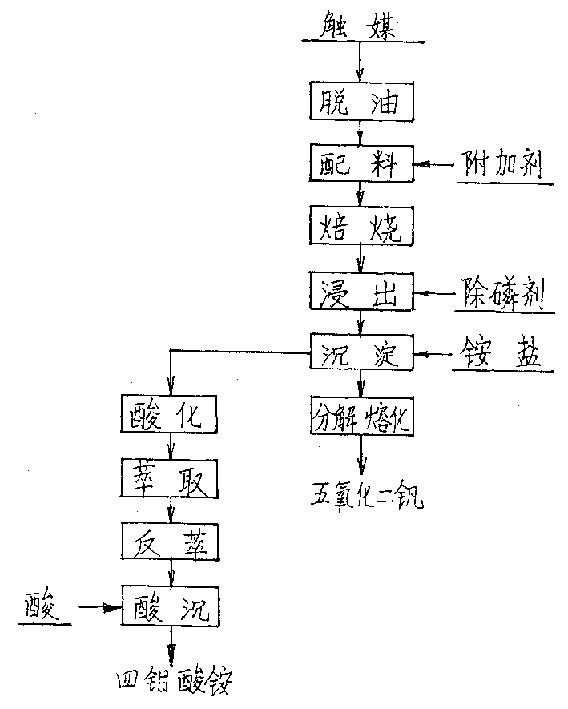

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1453379ALess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

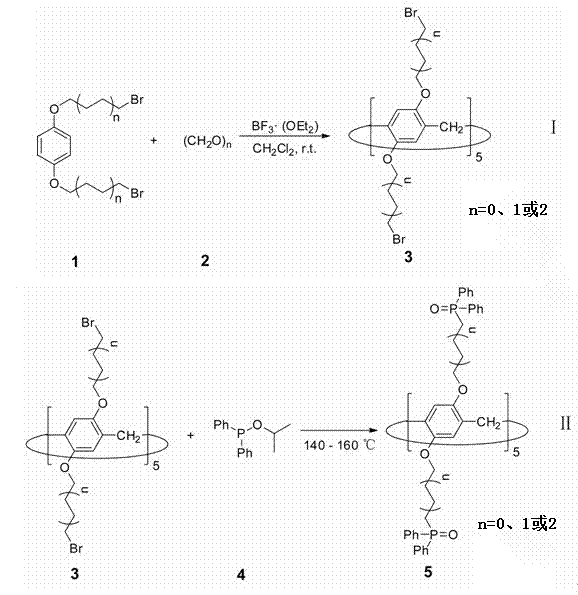

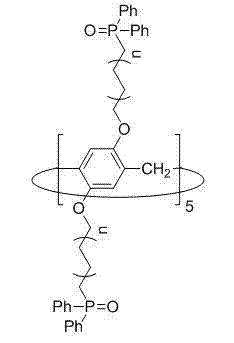

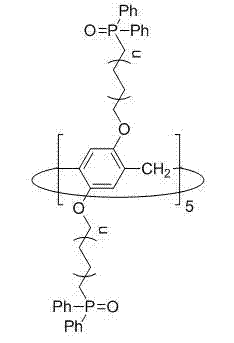

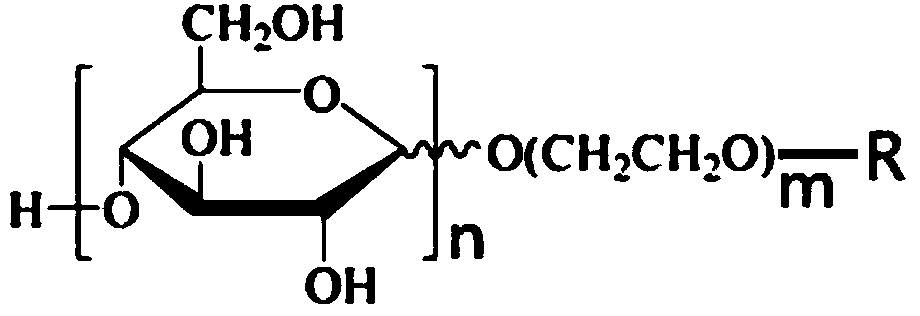

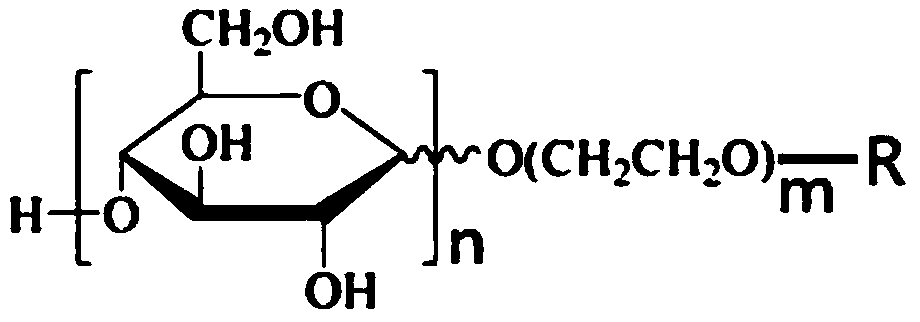

Phosphine oxide-modified pillar (5) arene derivative and application thereof

InactiveCN103087101AEfficient separationGuaranteed efficient selectivityGroup 5/15 element organic compoundsRare-earth elementPhysical chemistry

The invention relates to a phosphine oxide-modified pillar (5) arene derivative and an application thereof, belonging to the technical field of selective separation and extraction agents for thorium (IV) and uranium (VI) from rare earth elements. The phosphine oxide-modified pillar (5) arene derivative is diphenyl phosphine oxide-substituted pillar (5) arene, is used as an extraction agent for selectively separating thorium and uranium from rare earth elements, and can realize the selective separation of uranium to thorium in actinide elements to a certain extent. The extraction agent, namely the phosphine oxide-modified pillar (5) arene in the invention has the advantages of single composition, good chemical stability, simple synthesis and easiness in obtainment, and is suitable for industrial production; furthermore, the using quantity of the extraction agent is low, and the thorium and the uranium can be selectively separated from the rare earth elements under high acidity; and in addition, the extraction agent further has the advantages of high extraction speed, high phase splitting speed and the like. The product disclosed by the invention has great economic benefits and practical application prospects.

Owner:SICHUAN UNIV

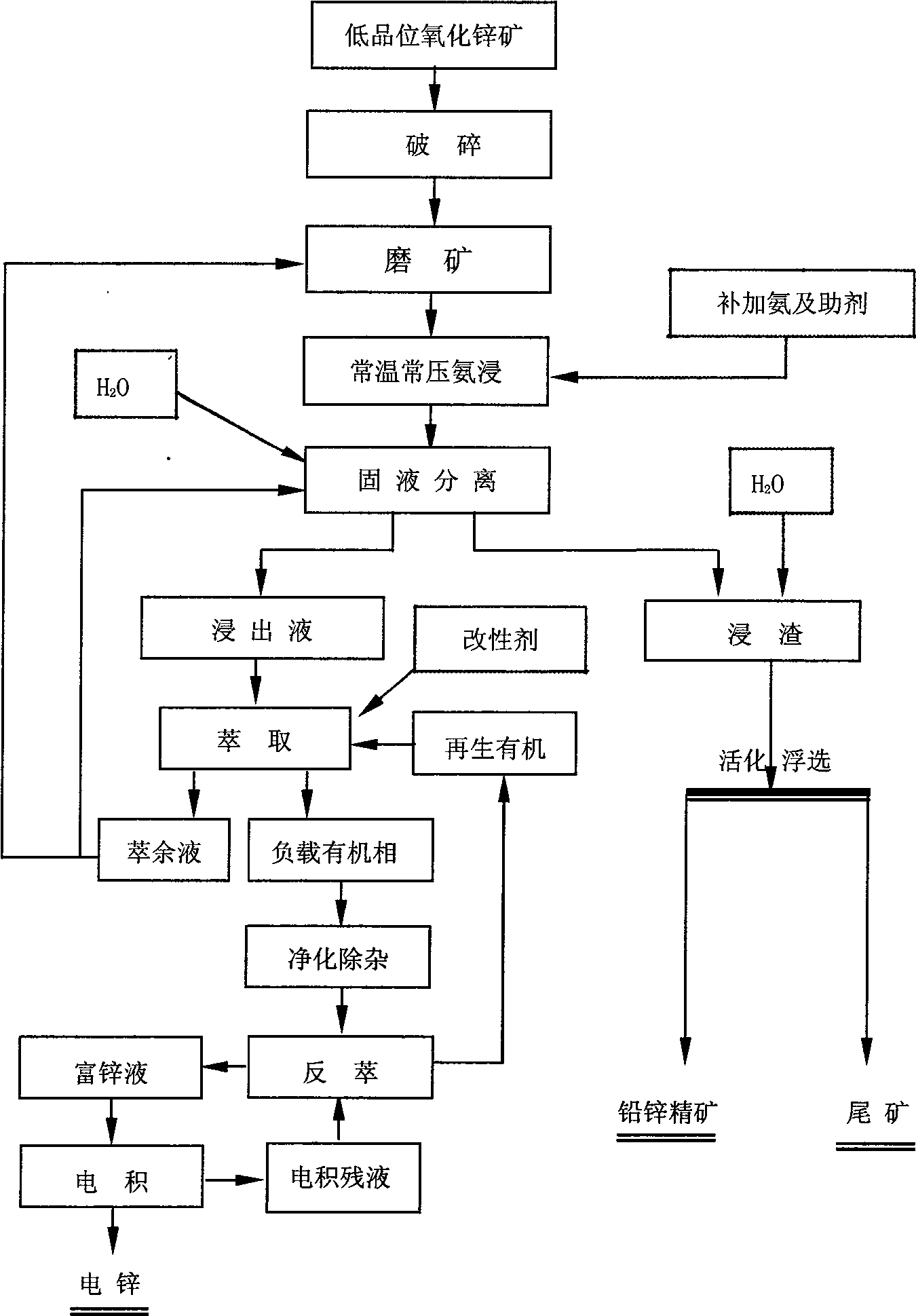

Method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration

InactiveCN101530826AHigh recovery rateReduce the amount of dissolutionWet separationZinc metalResource utilization

The invention provides a method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration, comprising the processing techniques of ammonia leaching under normal temperature and pressure-extraction-electrodeposition-leaching floatation, which not only gives full play to the advantage of wet method melting technique in recovering zinc in the oxidized lead zinc ore but also gives full play to the advantage of floatation technique in recovering vulcanized lead zinc; what is more, the advantages in the two aspects are organically combined and have shared complementary advantages, thus realizing integrated optimization of concentration technique, forming a brand-new combined process for concentration of low-grade zinc oxide ore, improving recovery rate of lead and zinc metal and achieving the effect of improving resource utilization rate and saving energy, lowering energy consumption and reducing pollutants discharge on the whole.

Owner:KUNMING UNIV OF SCI & TECH

Liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent

InactiveCN110052117AAchieve enrichmentReduce total fluid volumeDispersed particle separationAir quality improvementFluid phaseEnvironmental engineering

The invention provides a liquid-liquid phase-change absorbent for capturing carbon dioxide and application of such absorbent. The liquid-liquid phase-change absorbent for capturing the carbon dioxidecomprises, by mass, 20%-60% of synergist, 10%-50% of organic amine, 0%-5% of auxiliary agent and the balance water. The liquid-liquid phase-change absorbent for capturing the carbon dioxide has the advantages that the liquid-liquid phase-change absorbent can be automatically layered into liquid-liquid phases when loading a certain amount of CO2 in the absence of energy consumption, wherein CO2 gathers in a rich phase layer, and a lean phase layer hardly loads CO2, so that CO2 can be effectively concentrated in the rich phase, the total amount of liquid entering a regenerating column is decreased through desorption of the CO2 rich phase, and energy consumption for regeneration and capture cost are reduced.

Owner:HUANENG POWER INT INC +1

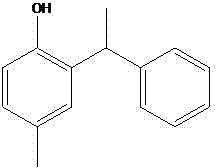

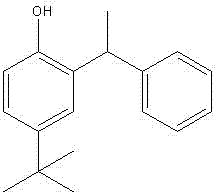

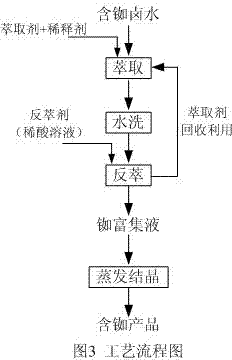

Novel rubidium-potassium separating extracting agent and separating method

InactiveCN103882227AMild extraction conditionsFast phase separationOrganic chemistryOrganic compound preparationPhysical chemistrySolvent

The invention relates to a novel rubidium-potassium separating extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol and a rubidium-potassium separating method. 4-methyl-2-(alpha-methylbenzyl) phenol is taken as the extracting agent, and solvent oil such as D60, and the like, is taken as a diluent for extracting and separating rubidium in alkalescent high-potassium brine, wherein single-stage extraction rate of the rubidium can be over 85%, a rubidium-potassium separating coefficient can be over 30; enriched liquor obtained by reversely extracting an organic phase loaded with rubidium through acid liquor can be evaporated and concentrated to prepare rubidium salt products such as RuCl, RuNO3, and the like. Compared with the normal rubidium extracting agent 4-tertiary butyl-2-(alpha-methylbenzyl) phenol, the novel extracting agent 4-methyl-2-(alpha-methylbenzyl) phenol has the advantages of being high in separating efficiency, simple in synthetic method, low in price, mild in extracting condition, and the like. The extracting agent is applicable to underground brine, salt lake brine and solid ore-decomposed rubidium-containing liquor.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Rare-earth organic extractant and back-extraction process thereof

InactiveCN103602812AAchieve near-zero emissionsReduce pollutionProcess efficiency improvementKeroseneRare earth

The invention discloses a rare-earth organic extractant and a back-extraction process thereof. The organic extractant contains the ingredients in percentage by volume: 20-35% of cyclohexane, 15-45% of liquid ammonia saponification extractant, 15-35% of N235 and 20-40% of sulfonated kerosene, wherein the liquid ammonia saponification extractant is either P507 or P204. The back-extraction process comprises the steps of preparing loading organic phases containing different rare earth concentrations through extraction, back-extracting and precipitating, thereby obtaining rare-earth oxalate with large grain diameter. A non-saponification extraction system is provided by the invention, and near-zero emission of ammonia nitrogen is realized; the back-extraction process disclosed by the invention has the advantages of high phase separation speed, obvious two-phase boundary and high back-extraction ratio; and a crystal is not deposited on a bottom plate of a back-extraction tank and does not scar on the periphery.

Owner:JIANGXI UNIV OF SCI & TECH

Absorption liquid for phase-change capturing of SO2

InactiveCN107158888AIncrease loadIncrease absorption rateDispersed particle separationOrganic solventDesorption

The invention discloses an absorption liquid for phase-change capturing of SO2. The absorption liquid consists of an imidazole derivative and an organic solvent, wherein the mass percentage of the imidazole derivative is 20-30%. By adopting the absorption liquid, an effect of liquid-liquid or liquid-solid phase separation is achieved when SO2 is absorbed, the phase separation speed is rapid, the SO2 absorption load is high, and the content of SO2 of one of two phases can be up to 95% or greater; regeneration is achieved by only feeding an enriched liquid rich in SO2 into a regeneration tower, the treatment capacity of a solution in desorption is reduced, the desorption energy consumption is reduced, and an organic solvent in an upper phase can be recycled to absorb SO2 in a circulation manner. Therefore, the absorption liquid is a phase-change absorbent with excellent properties, has great energy-saving potential and is suitable for being used as a chemical absorbent for capturing SO2 in coal fume and the like.

Owner:KUNMING UNIV OF SCI & TECH

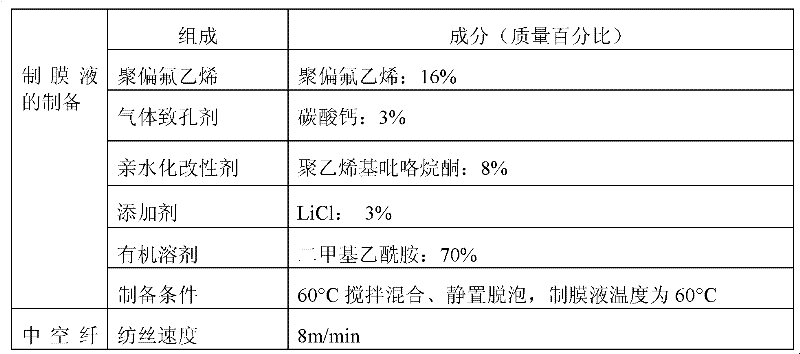

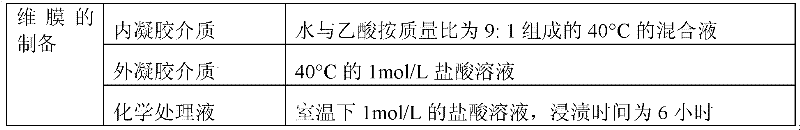

Method for preparing high-flux polyvinylidene fluoride hollow fiber membrane

ActiveCN102512987AImprove throughputFlux does not destroySemi-permeable membranesChemical treatmentChemical reaction

The invention discloses a method for preparing a high-flux polyvinylidene fluoride hollow fiber membrane. The method comprises the following steps of: mixing polyvinylidene fluoride, a gaseous pore-forming agent, a hydrophilic modifier, additives and organic solvents and making a membrane-making solution; allowing an internal gelling medium and the membrane-making solution to pass through spinning nozzles on dry / wet spinning equipment at the same time, injecting into an external gelling medium, and performing phase-splitting treatment to make a primary membrane; and performing special chemical treatment on the primary membrane with a chemical treatment liquid to obtain a high-flux polyvinylidene fluoride hollow fiber membrane. The invention is characterized in that the membrane is reinforced with the pores by chemical reactions between the internal gelling medium, external gelling medium and chemical treatment liquid and the gaseous pore-forming agent; and the polyvinylidene fluoride hollow fiber membrane has a high flux, a high strength, a high entrapment rate and good hydrophilicity.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

Synergistic extraction system for recovering and extracting platinum through extraction method

The invention discloses a synergistic extraction system for recovering and extracting platinum based on a solvent extraction method, belonging to the technical field of resource recovery. The method for recovering and extracting platinum is characterized by comprising the steps of forming the synergistic extraction system by adopting tributyl phosphate (TBP) as an extracting agent, 2-methoxy-phenylthiourea as a synergistic extraction solvent and isoamyl alcohol as a diluting agent; adding a 2-methoxy-phenylthiourea-hydrochloric acid solution into a feed liquid containing platinum, adjusting the acidity namely H<+> concentration to 3-5mol / L, putting the mixture in a thermostatic water bath of 30-45 DEG C for 2-4 minutes, and cooling to obtain an extraction water phase of which the platinum concentration is 0.01-5 microgram / ml; measuring quantified TBP, diluting the quantified TBP into a liquid with the concentration of 0.5-2mol / L by using isoamyl alcohol, and taking the liquid as an organic phase for extraction; and adding the organic phase and a water phase feed liquid into a separating funnel according to a volume ratio of 1:1-1:10, then oscillating for 30s to 2min, then taking the mixture out, standing for liquid separation, and performing reverse extraction on the organic phase after liquid separation. By adopting the synergistic extraction system disclosed by the invention, the cost and pollution are reduced while the extraction efficiency of platinum is improved, so that an efficient, economic and environment-friendly effect is achieved.

Owner:BEIJING UNIV OF TECH

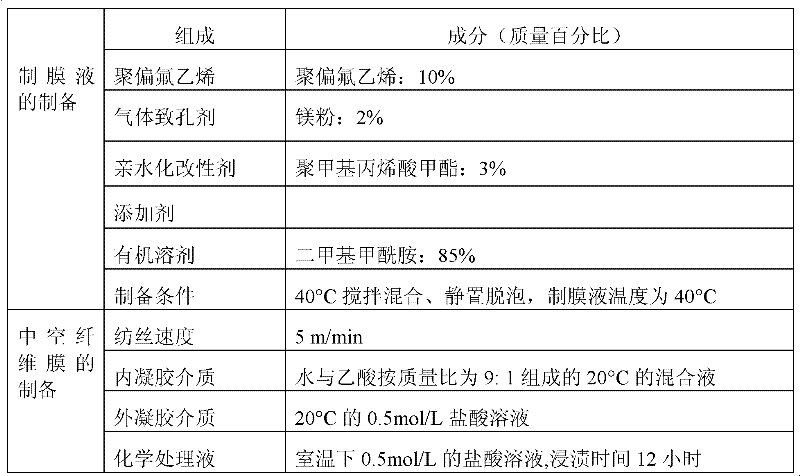

Method for extracting hydroxyacetic acid from water solution mixture containing hydroxyacetic acid

InactiveCN101265174APromote regenerationEasy to prepareCarboxylic compound separation/purificationAcetic acidGlycollic acid

The invention discloses a method of extracting glycolic acid from water solution mixture containing the glycolic acid. The method has the following steps: synergistic extraction agent is delivered into an extraction column from the bottom, the water solution mixture containing the glycolic acid is delivered into the extraction column from the top, extraction phase after extraction flows out of the upper part of the extraction column, and raffinate phase after extraction flows out of the lower part of the extraction column; the extraction phase flowing out of the upper part of the extraction column is delivered into a back-extraction column from the bottom; back-extraction water is delivered into the back-extraction column from the top of the back-extraction column; back-extraction water phase which flows out of the lower part of the back-extraction column is concentrated to obtain the glycolic acid; back-extraction organic phase flows out of the upper part of the back-extraction column. The method has the advantages that the technological process is simpler, the capacity of the organic phase is large, the production capacity of equipment is high, the extractant regeneration is convenient, the energy consumption during the process is small, and the manufacturing cost is low; the volatility of the extractant is small without toxicity, the emulsification is hard, the misphasing speed is high, and the separative efficiency is high; the operation is convenient and stable, and the product quality is high.

Owner:EAST CHINA UNIV OF SCI & TECH

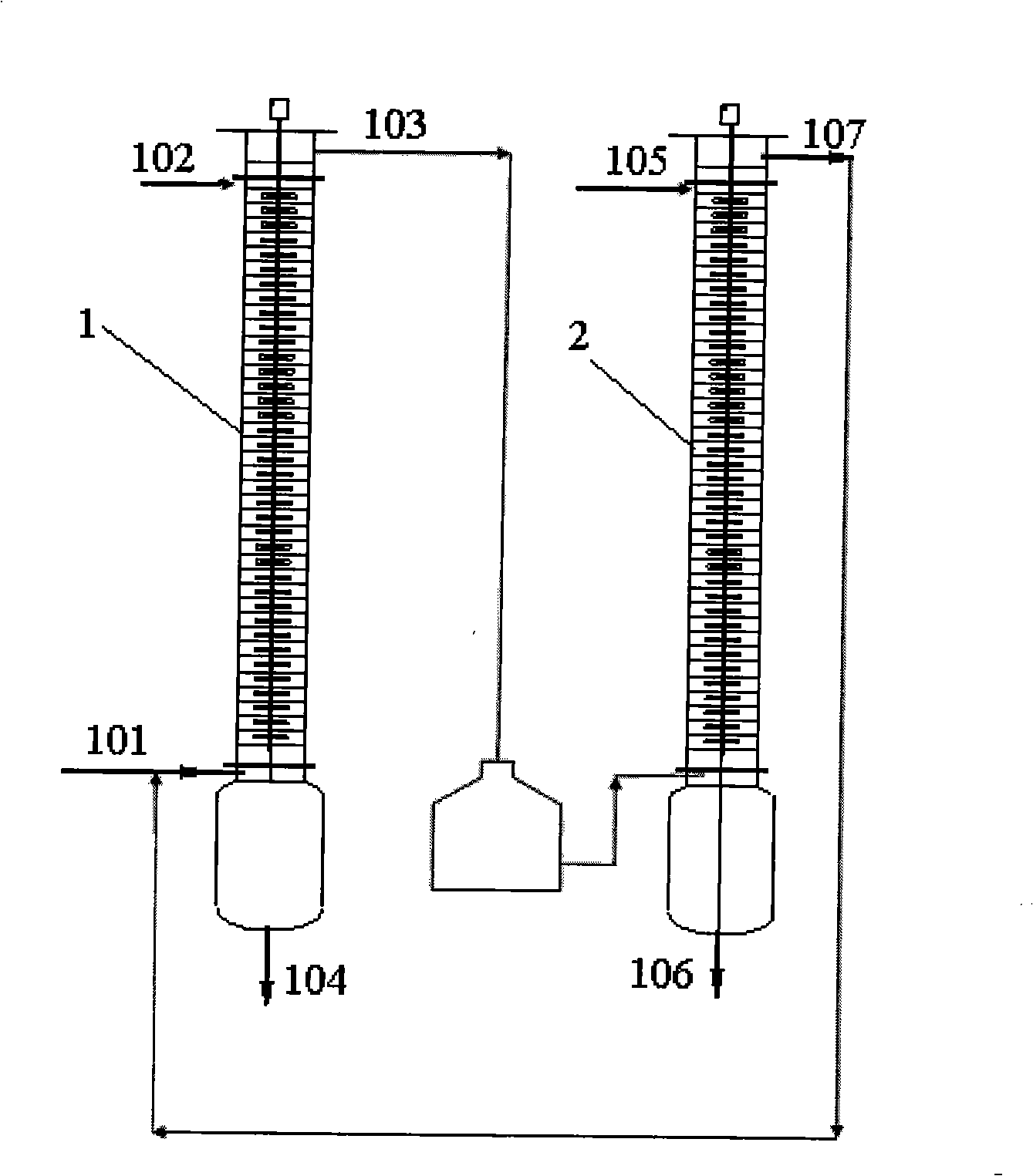

Oil-water separator and separation system

PendingCN110215741AAchieve separationAutomatic separationNon-miscible liquid separationChemical industryVolumetric Mass Density

The invention discloses an oil-water separator for chemical industry and an oil-water separation system. The oil-water separator is of a tank-type hollow structure and is internally provided with a separation channel coated with a hydrophobic membrane, a physical partition plate and a novel liquid level floating plate; and an oil phase discharging hole and a water phase discharging hole are respectively formed in a tank bottom. Due to the arrangement of a hydrophobic membrane layer, the rapid separation of oil and water is realized in the separation channel, and the oil-water separation time is shortened; the density-adjustable oil-water separation liquid level floating plate is designed by adopting a novel air sac floating plate, so that the separation of an oil phase and a water phase isefficiently accelerated; and meanwhile, due to the adoption of a magnetic induction device at a liquid level floating plate end, phase interface positions of the two phases including the oil phase and the water phase can be monitored in real time, the yield of the water phase is directed to be controlled, an effective liquid level monitoring means is provided for a chemical oil-water separation process, and the oil-water separator is suitable for traditional chemical oil-water separation controlled a DCS.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for conducting double aqueous phase extraction, separation and purification on papain through modified polyethylene glycol-sodium tartrate

The invention provides a method for conducting double aqueous phase extraction, separation and purification on papain through modified polyethylene glycol-sodium tartrate. The method comprises the steps that papaya juice is subjected to wall breaking through a repetitive freeze-thawing method; supernatant liquor is collected, and a papain crude extract is obtained; modified polyethylene glycol and sodium tartrate are added into the crude extract, double aqueous phase extraction and layering are conducted in sequence, an upper phase is taken and put into a dialysis membrane of which the interception relative molecular mass is 10,000 to be dialysed for 15 h to 20 h, and a papain aqueous solution is obtained; freeze drying is conducted at -15 DEG C to -10 DEG C for 8 h to 15 h, and papain powder is obtained, wherein the average molecular weight of PEG in modified macrogol ester is 600 or 1,000 or 2,000. According to the method for conducting double aqueous phase extraction, separation and purification on the papain through modified polyethylene glycol-sodium tartrate, the selected double aqueous phase system is high in selectivity to the papain and high in system phase separation speed, phase separation can be conducted rapidly without the help of equipment such as a centrifugal machine, operation is easy and convenient, the equipment is conventional, the method is suitable for industrial production, and the obtained papain product has high purity and yield.

Owner:瑞安市智造科技有限公司

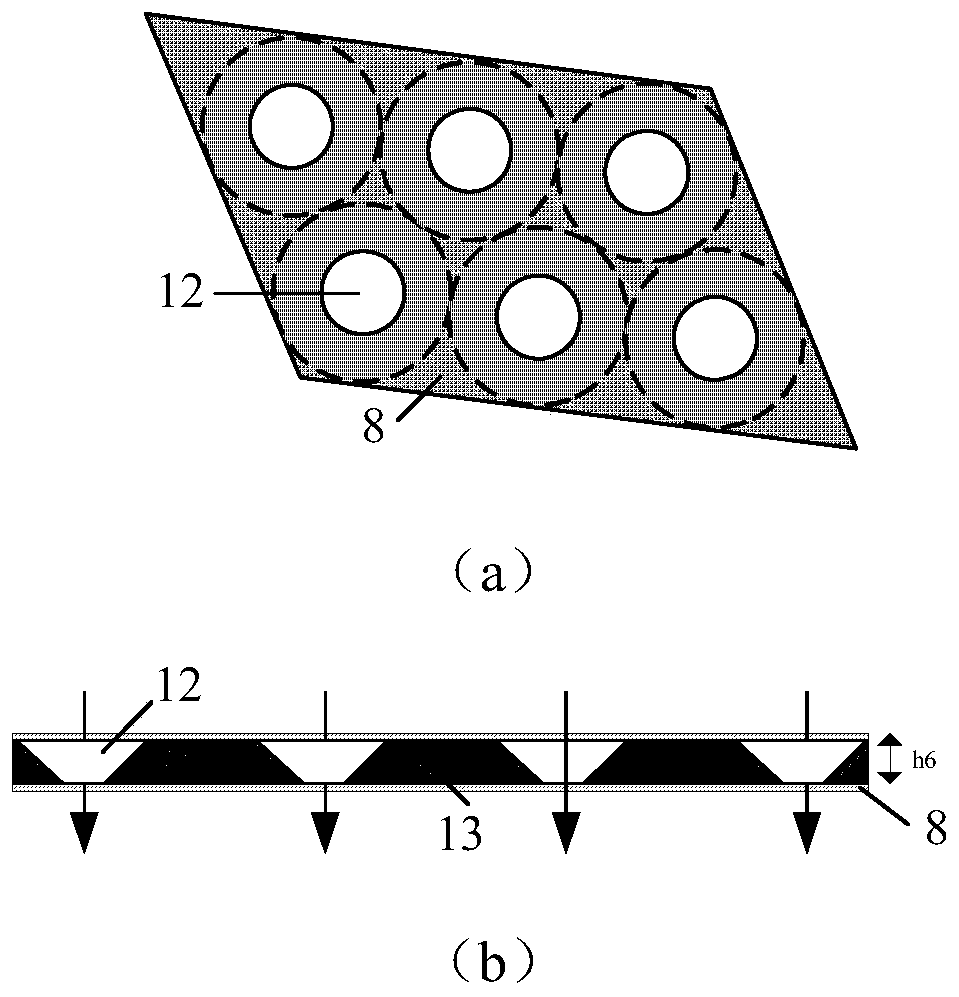

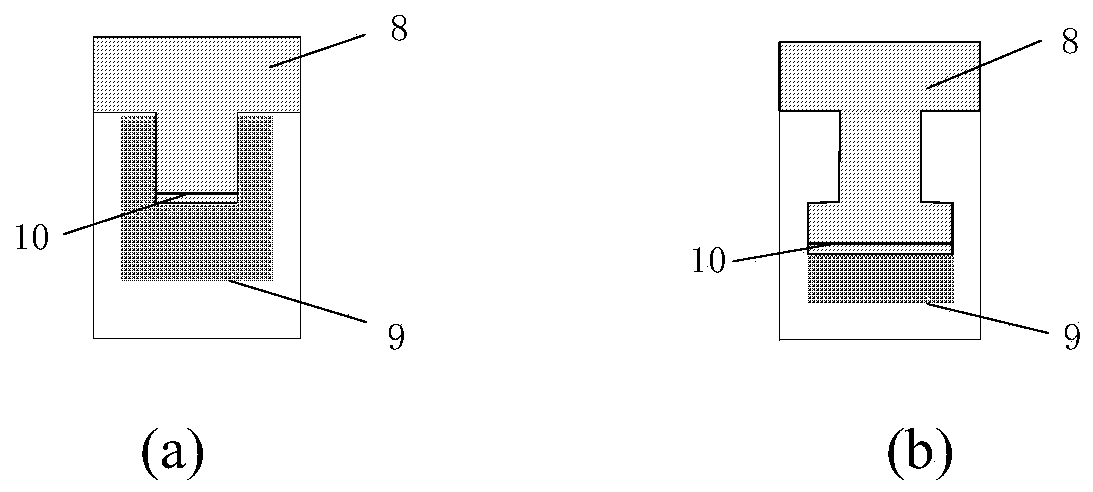

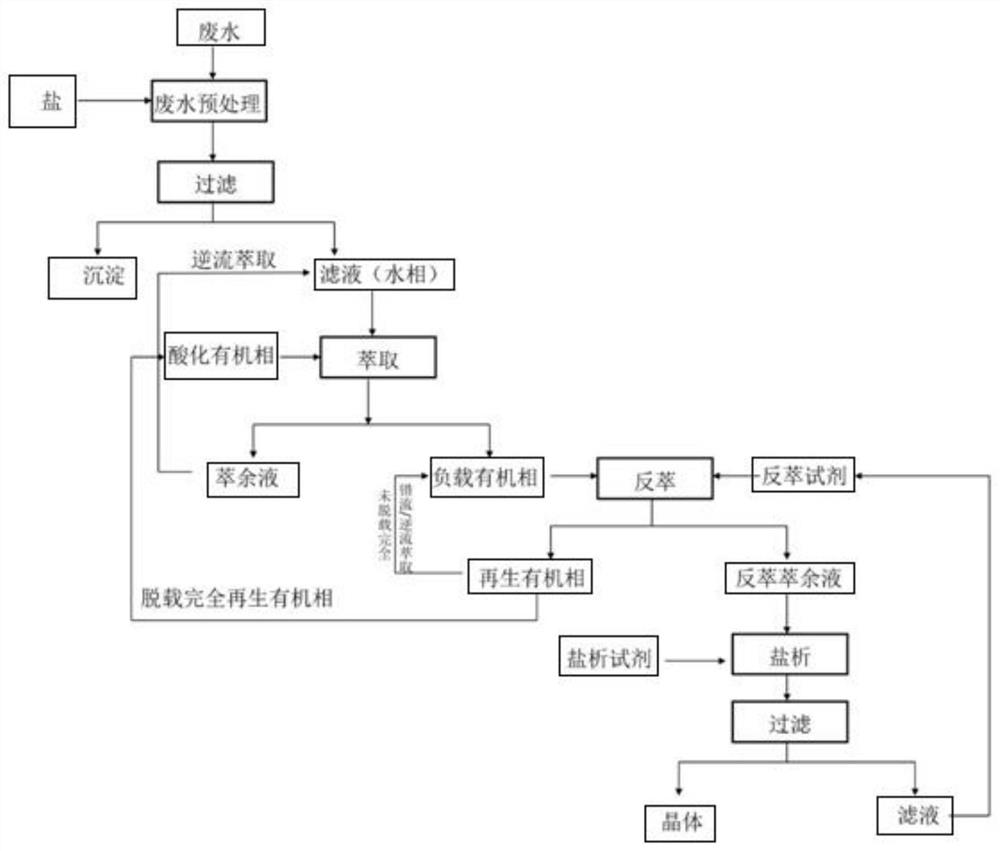

Method for recovering chlorine and preparing chlorine salt based on solvent extraction and salting-out effect integrated technology

PendingCN112299591ALow costEasy to getTreatment involving filtrationMultistage water/sewage treatmentSalting outProcess engineering

The invention belongs to the technical field of wastewater treatment, and particularly relates to a method for recovering chlorine and preparing chlorine salt based on a solvent extraction and salting-out effect integrated technology. By adopting a solvent extraction method and combining the process steps of wastewater pretreatment, acidification, extraction, reverse extraction and salting-out inthe method, the extraction effect on the ultrahigh-concentration chlorine-containing wastewater is remarkable, and a feasible scheme is provided for treatment of the ultrahigh-concentration industrialchlorine-containing wastewater. In the whole process flow, the cost is reduced to the minimum, the extraction agent is recycled, the purity of the product obtained by salting out is high, the filtered solution returns to the reverse extraction process, and secondary pollution is avoided. By adding the phase modifier, the problems of low extraction rate, layering of the extraction agent and the like caused by high viscosity of the extraction agent are solved, and the extraction agent is easy to obtain, high in phase splitting speed, low in investment, low in cost, convenient to use, safe, reliable and convenient for industrialization.

Owner:KUNMING UNIV OF SCI & TECH

Method for separating and purifying phycocyanin by means of combination of two aqueous phase extraction and ultrasonic waves

InactiveCN106008705AHigh selectivityFast phase separationPeptide preparation methodsDepsipeptidesInorganic saltsDialysis membranes

The invention provides a method for separating and purifying phycocyanin by means of combination of two aqueous phase extraction and ultrasonic waves. The method comprises the particular operating steps that spirulina is subjected to wall breaking through a repeated freezing and thawing method, supernatant is collected, and a crude phycocyanin extracting solution is obtained; glucan and inorganic salt two aqueous phase extraction is adopted, the crude phycocyanin extracting solution is put in ultrasonic waves for ultrasonic treatment for 15 min to 30 min, standing is conducted for 10 min to 15 min, the upper phase is taken and subjected to dialysis in a dialysis membrane with the molecular mass cut-off of 5,000 for 12 h to 20 h, freeze drying is conducted, and phycocyanin powder is obtained. The method for purifying the phycocyanin by means of combination of two aqueous phase extraction and the ultrasonic waves has the advantages of being high in selectivity and high in system phase-separation speed, operation is easy and convenient, equipment is conventional, and the method is suitable for industrial production. The phycocyanin purity of the phycocyanin powder prepared through the method reaches up to (A620 / A280) 3.78, and the total yield reaches up to 90.6%.

Owner:瑞安市智造科技有限公司

Method for extracting flavonoid and chlorogenic acid from chrysanthemum by ionic liquid aqueous two-phase

InactiveCN110393736AEasy to operateFast phase separationPlant ingredientsInorganic saltsChlorogenic acid

The invention relates to a method for extracting flavonoid and chlorogenic acid from chrysanthemum by ionic liquid aqueous two-phase. The method for extracting the flavonoid and the chlorogenic acid from the chrysanthemum by the ionic liquid aqueous two-phase comprises the following steps that (1) an ionic liquid solution is added to chrysanthemum powder, after the mixture is mixed uniformly, inorganic salt is added to a system, the mixture is fully mixed to form a uniform suspension; (2) the suspension is ultrasonically extracted, and then the mixture is placed silently to form a two-phase system, the upper layer is an ionic liquid phase rich in the flavonoid and the chlorogenic acid, and the lower layer is an aqueous phase with the dissolved inorganic salt, after the liquid separation, an upper layer solution is obtained, that is, a concentrated solution rich in the flavonoid and the chlorogenic acid; and (3) ionic liquid in the concentrated solution rich in the flavonoid and the chlorogenic acid is separated, and extract rich in the flavonoid and the chlorogenic acid is obtained. The method for extracting the flavonoid and the chlorogenic acid from the chrysanthemum by the ionicliquid aqueous two-phase has the characteristics of simple operation, high phase separation speed, high extraction efficiency, low cost and environmental friendliness.

Owner:上海工微所科技有限公司

Wet process of extracting vanadium and/or molybdenum from waste catalyst

InactiveCN1207409CLess investmentReduce consumptionProcess efficiency improvementMagnesium saltAmmonium metavanadate

The present invention is wet process of extracting vanadium and / or molybdenum form waste petrochemical catalyst alumina carrier containing V, Mo and other elements. The wet process includes high-temperature deoiling the catalyst in natural granularity, mixing with sodium carbonate, high-temperature oxidation and roasting in a kiln or furnace to obtain water soluble sodium vanadate and sodium molybdate; countercurrent water soaking of the chamotte to obtain solution containing V and Mo in certain concentration, adding calcium salt and magnesium salt to eliminate P and other impurities, addingammonium salt solution into the clear solution to obtain ammonium metavanadate, decomposing and melting ammonium metavanadate to obtain V2O5 product; adding acid to the supernatant and organic phase extraction of Mo, ammonia water reverse extraction to obtain ammonium molybdate, and adding acid to precipitate ammonium tetramolybdate or molybdate product.

Owner:CITIC JINZHOU METAL

Extraction method of green prickleyash alkaloids

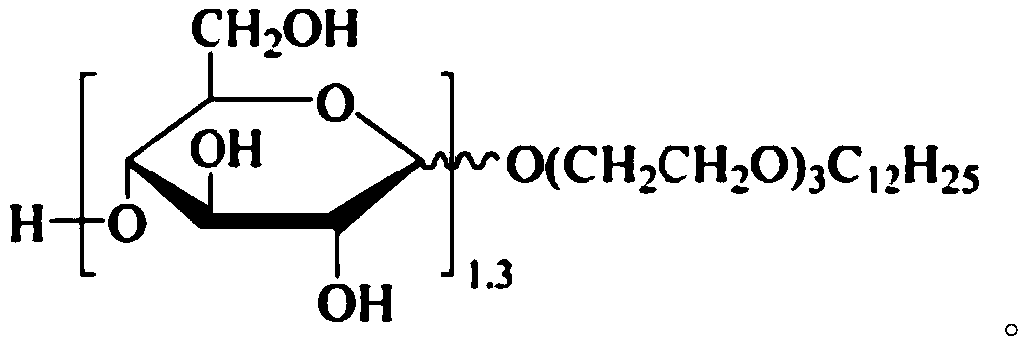

ActiveCN111217864ARaise the ratioEasy to separateAlkaloids chemistryAlkaloidsDipotassium hydrogen phosphateGlycoside

An extraction method of green prickleyash alkaloids, disclosed in the invention, comprises the following steps: carrying out microwave extraction on green prickleyash powder and an aqueous two-phase extraction solvent; filtering the obtained extract solution, standing, and splitting phases; carrying out ultrafiltration and nanofiltration operations on the upper phase; and concentrating and spray-drying to obtain an alkaloid extract, wherein the aqueous two-phase extraction solvent is selected from an alkyl alcohol ether glucoside / dipotassium hydrogen phosphate aqueous two-phase system with thepH value of 5.5-6.5. According to the method, total alkaloids with a high proportion can be obtained, and the phase splitting speed is high, so that the purity and the performances of the alkaloid extract are improved.

Owner:营山椒宝宝花椒有限责任公司

7815 extracting agent as germanium extracting additive and extracting method using said additive

InactiveCN1715429ANon-emulsifyingFast phase separationProcess efficiency improvementAlcoholWater insoluble

The 7815 extracting agent as germanium extracting additive consists of isopentyl alcohol and ethanol in the volume ratio of 3-20. The extracting process with the 7815 extracting agent includes: extracting with the extracting organic phase comprising the 7815 extracting agent and water insoluble diluent and extracting with extracting water phase containing acid medium of germanium to make most of germanium from the extracting water phase to the extracting organic phase; back extracting the organic phase carrying germanium with the counter-extracting water phase containing back extracting agent to make most of germanium from the organic phase to the water phase. Extracting germanium with the germanium extracting additive has the features of no emulsification and fast phase separating speed.

Owner:桂林矿产地质研究院

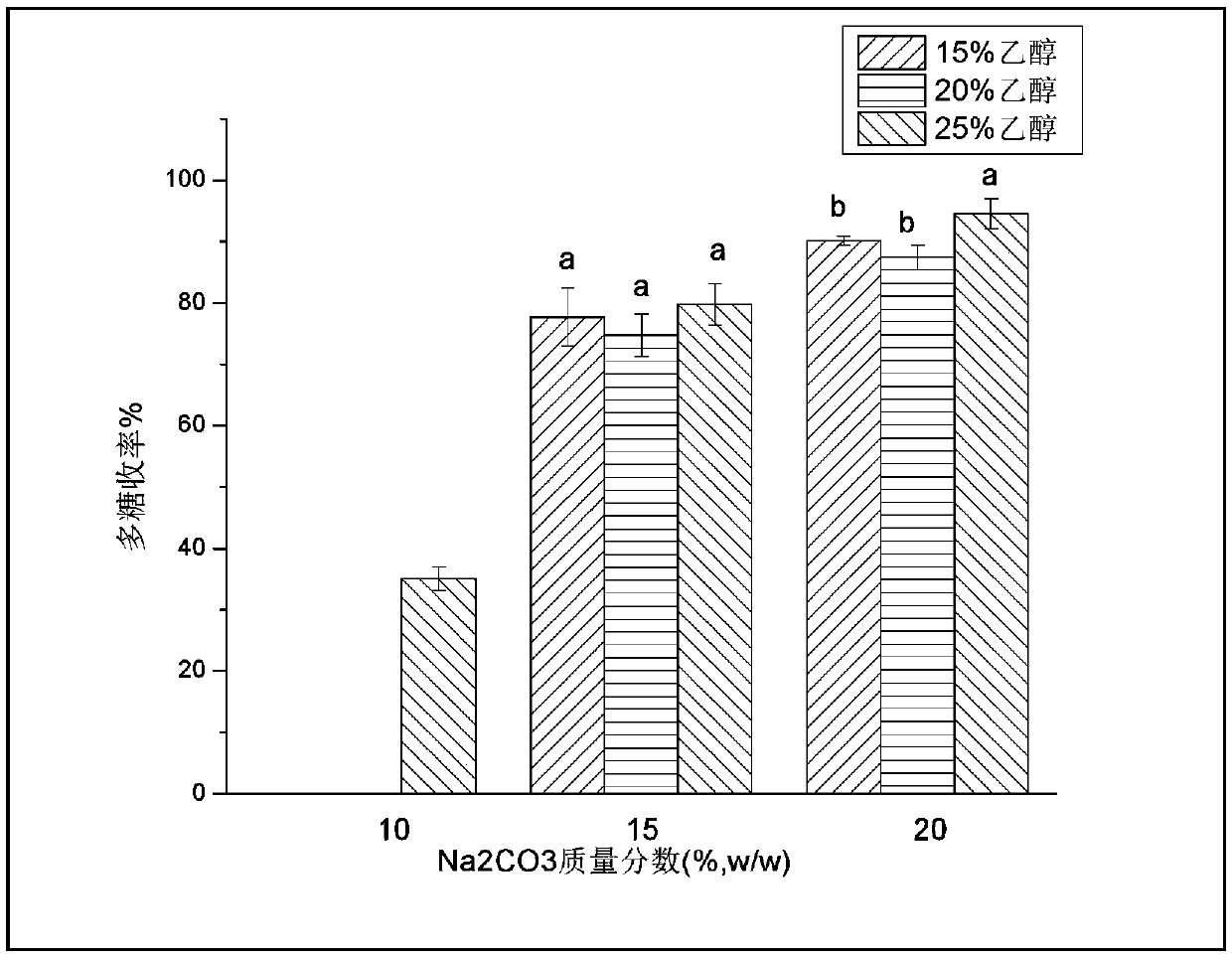

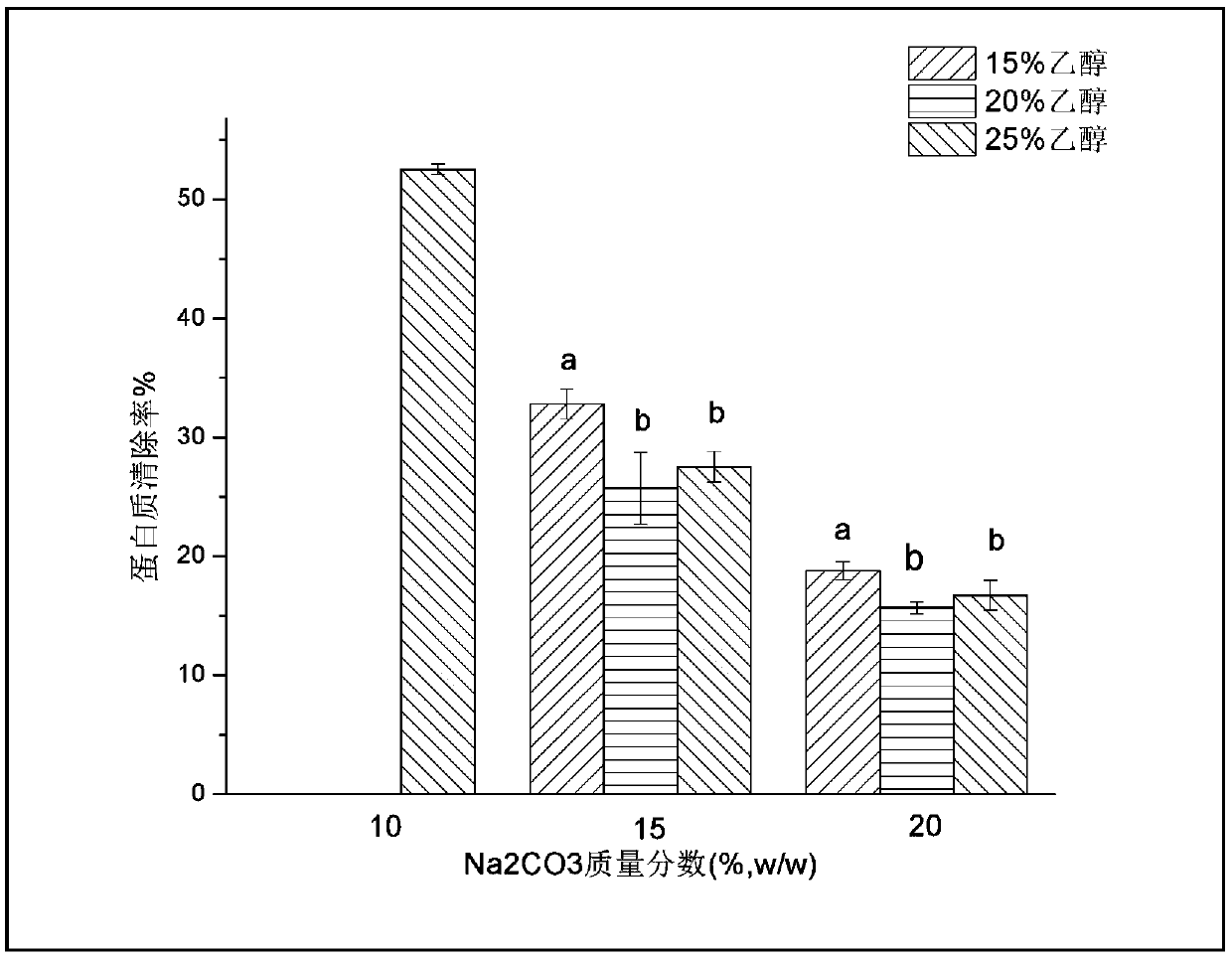

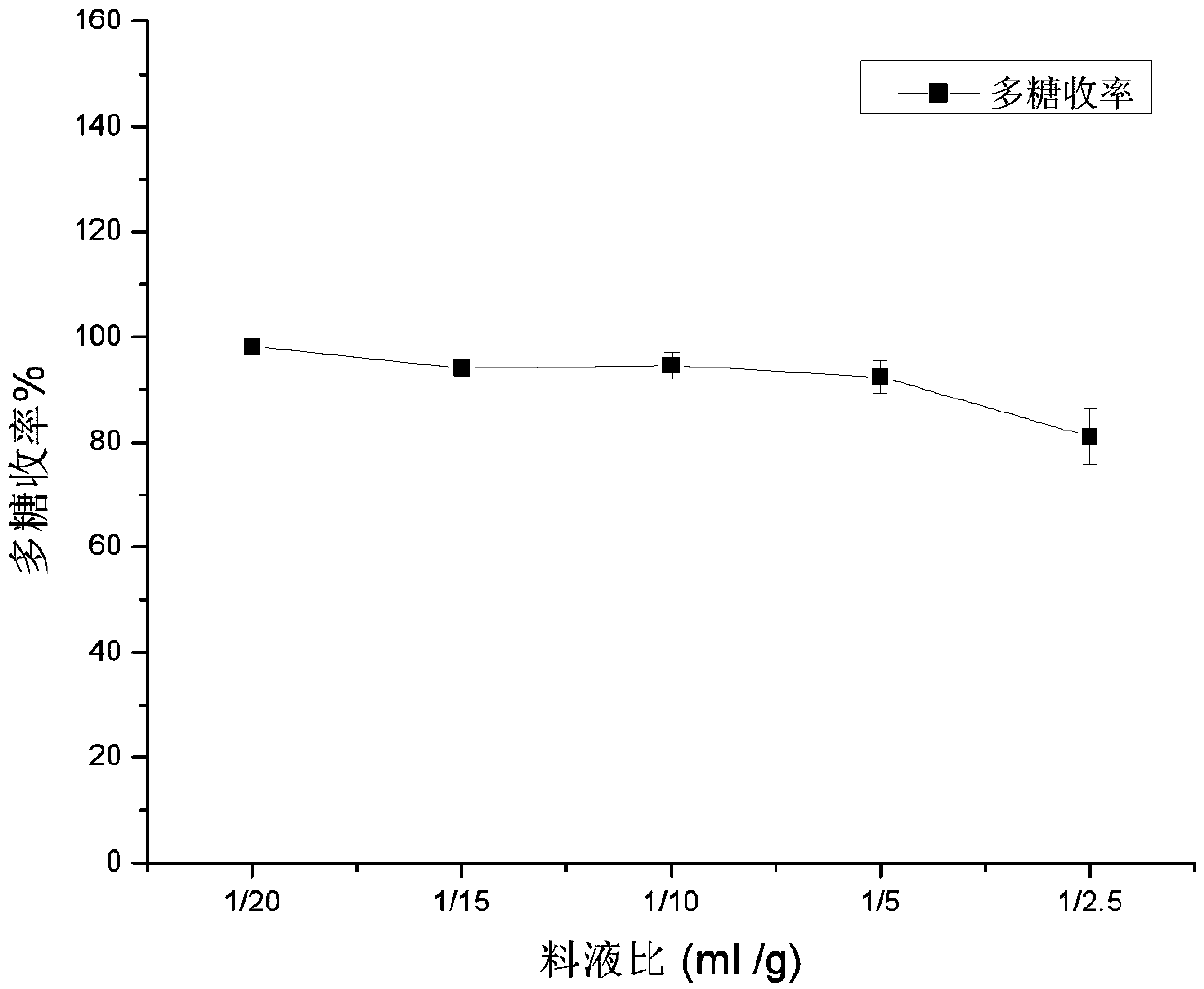

Method for separating and purifying schizophyllan by two aqueous phase extraction

The invention relates to the technical field of schizophyllan extraction, and discloses a method for separating and purifying schizophyllan by two aqueous phase extraction. The method comprises the following steps of preparing schizophyllum fermentation solution and performing extraction by using a sodium carbonate / ethyl alcohol dual water phase extraction system. The schizophyllan extracted by the method has the advantages that the structure is complete; the schizophyllan yield is high; the protein removal rate is high; the operation is simple and convenient; the toxicity is low; the safety is realized and the industrial scale preparation is easy.

Owner:GUANGDONG PHARMA UNIV

Absorption liquid for trapping hydrogen sulfide through phase change

InactiveCN108144415AEasy to separateFast phase separationDispersed particle separationDesorptionResource utilization

The invention discloses absorption liquid for trapping H2S through phase change for the problem that the existing H2S absorption liquid is high in energy consumption in desorption and low in sulfur resource utilization rate and the like. The absorption liquid is prepared from organic amine and organic solvent, and is used for absorbing H2S gas to achieve the liquid-liquid or liquid-solid split-phase effect. The H2S rich phase is sent into a regeneration tower to heat and desorb, the H2S lean phase can cyclically absorb H2S after being recycled without any processing treatment, the treatment quantity of the solution in the desorption is reduced, and the desorption energy consumption is lowered, wherein the distribution ratio of the H2S in the rich phase can achieve 93% or more, and the absorption liquid is appropriate to be used as a chemical absorbent for trapping H2S in the natural gas, the coal gas and refinery gas and the like, and belongs to the technical fields of the energy conservation and emission reduction and gas purification.

Owner:KUNMING UNIV OF SCI & TECH

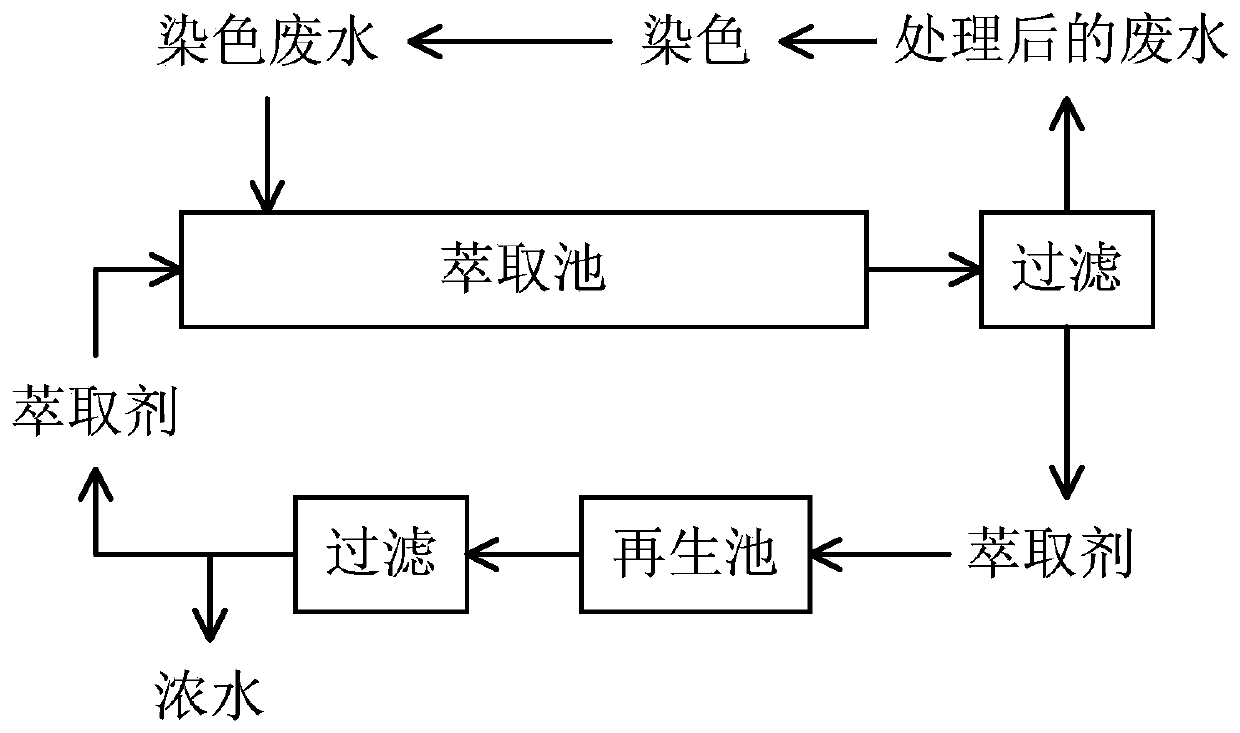

Extracting agent and method for treating reactive dyeing wastewater

ActiveCN104211132AReduce chromaReduce volatilityWater/sewage treatment by extractionAlcoholChemical oxygen demand

The invention provides an extracting agent and a method for treating reactive dyeing wastewater. The extracting agent is composed of the following components in percentage by mass: 20-50% of complexing agent, 8-30% of cosolvent and the balance of diluent, wherein the complexing agent is trialkylamine; the cosolvent is C8-C25 normal alcohol or isomeric alcohol; and the diluent is a substance which is a solid at room temperature and is a liquid at the temperature higher than the room temperature. The method comprises the steps of mixing an extracting agent and reactive dyeing wastewater according to the mass ratio of 1: (20-30); heating until melting the extracting agent, and extracting for 10-20 minutes under stirring; cooling to condense the extracting agent; and filtering after standing for a proper period of time to obtain the treated wastewater and the treated extracting agent. According to the method provided by the invention, the reactive dyeing wastewater is treated by using the solid extracting agent, so that hydrolyzed dyes and polar organic compounds in the dyeing wastewater can be effectively removed; and the primarily-treated wastewater has extremely-low chroma and COD (Chemical Oxygen Demand) so as to be directly used for a dyeing process in the next cycle.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

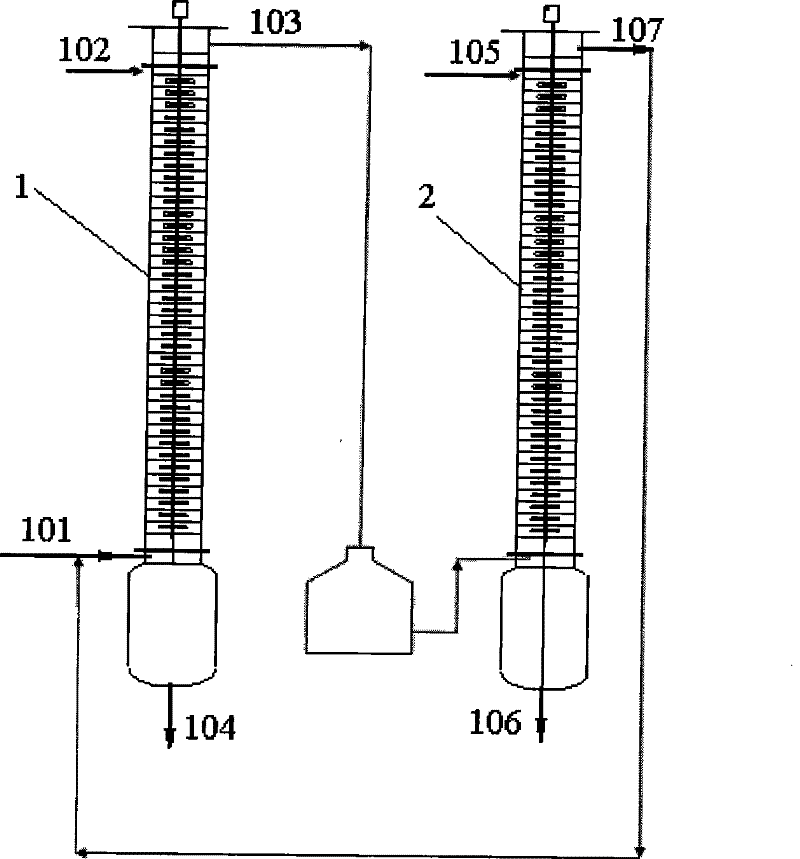

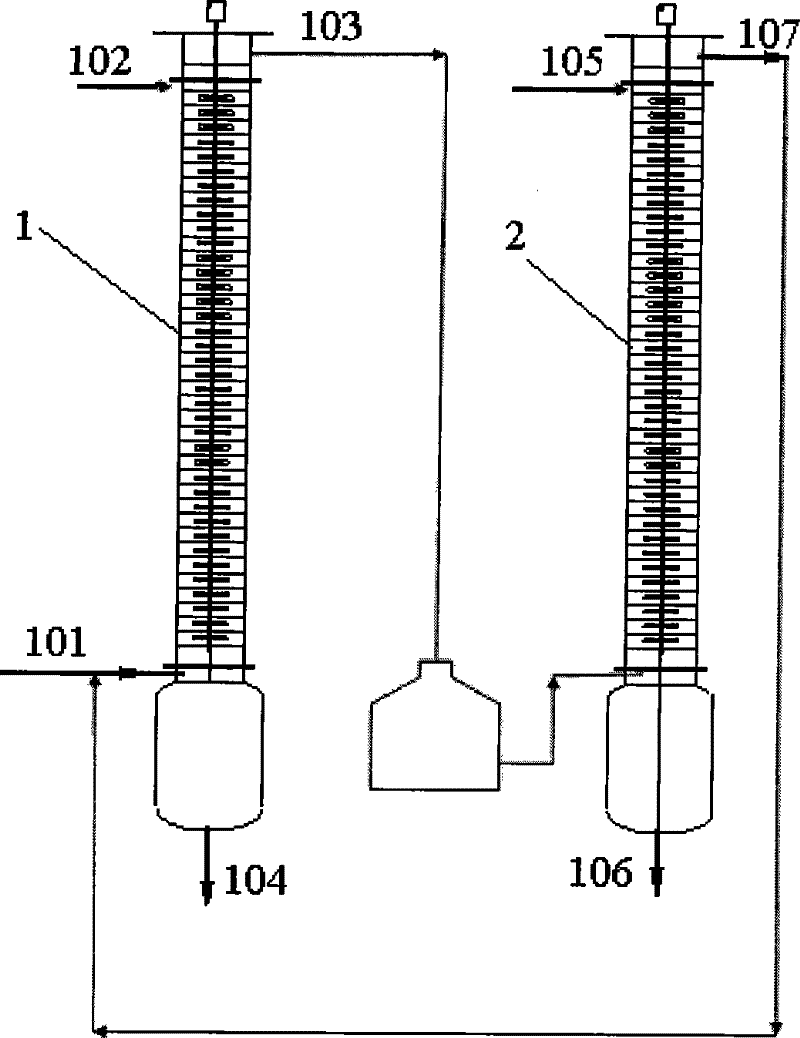

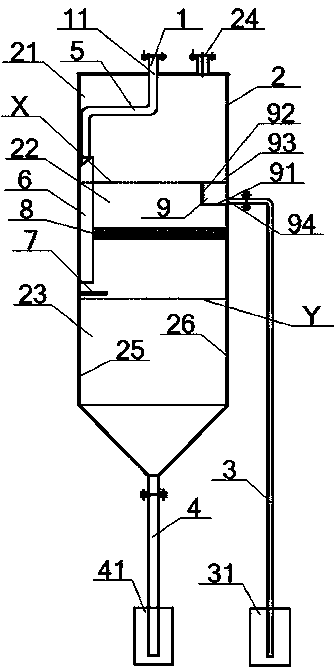

Solvent separating unit used for evaporation and recovery of solvent system and application method thereof

ActiveCN103520956AAvoid emulsificationHigh speedNon-miscible liquid separationPhase splittingEvaporation

The invention provides a solvent separating unit used for evaporation and recovery of a solvent system. A feed pipe arranged at the top of a barrel included by the solvent separating unit is communicated with a vertical condensate conduit through a transition pipe; the lower part of the vertical condensate conduit is provided with a horizontal condensate guide plate which is arranged to be slightly higher than a two-phase line; the central part of the vertical condensate conduit penetrates a metal phase-splitting mesh; an organic phase overflow groove with an upper opening is arranged above the metal phase-splitting mesh; and the top of the organic phase overflow groove is aligned with a liquid level line. In usage, a condensate successively flows through the transition pipe, the vertical condensate conduit and the horizontal condensate guide plate and then into the barrel for phase splitting; a water phase flows into a water phase discharging pipe, and an organic phase successively flows through the metal phase-splitting mesh and the organic phase overflow groove and then into an organic phase discharging pipe; and an inverted Y-shaped pipe can be arranged out of the barrel so as to adjust the two-phase line and prevent siphonage. According to the invention, the solvent separating unit has the advantages of an improved phase splitting effect, an improved phase splitting speed, a simple structure, convenience in operation, a wide application scope and capacity of preventing siphonage.

Owner:吴杰

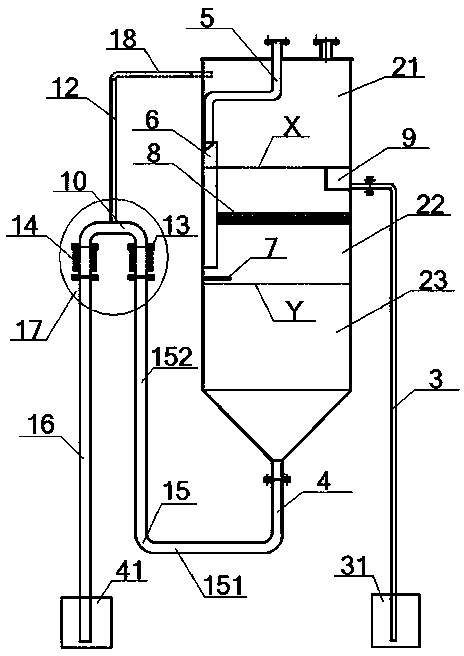

Method for extracting lithium carbonate from salt lake brine with high magnesium/lithium ratio

InactiveCN102275956BReduce lossesNo decrease in recycling efficiencyNanotechnologyLithium carbonates/bicarbonatesInorganic saltsHigh magnesium

The invention discloses a method for extracting lithium carbonate from salt lake brine with high magnesium / lithium ratio, belonging to the technical filed of inorganic salt extraction. The method comprises the following steps of: carrying out extraction, washing and stripping steps to obtain a stripping solution composed of NaCl and LiCl or NH4Cl and LiCl, then introducing CO2 or adding Na2CO3, and controlling the pH value and dynamic conditions to obtain a nanoscale or microscale Li2CO3 product. The method disclosed by the invention has the advantages of simple steps, low equipment requirement and wide sources of raw materials, and is suitable for industrial production.

Owner:TSINGHUA UNIV

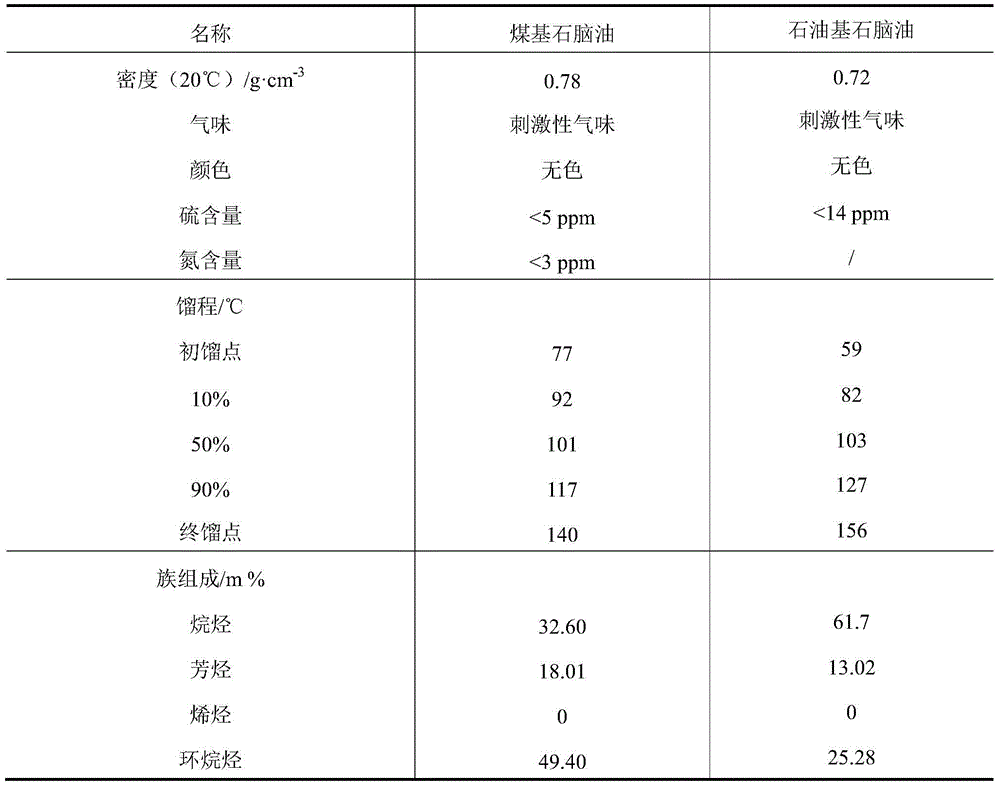

A composite extractant suitable for coal-based naphtha and method for preparing solvent oil

InactiveCN105219422BReduce dosageDearomatization effect is goodHydrocarbon oils refiningSulfolaneNaphtha

The invention provides a composite extractant suitable for coal-based naphtha and a method for preparing solvent oil. The composite extractant is composed of 70 parts of sulfolane, 20 to 30 parts of propylene carbonate, and 8 to 15 parts of triethylene glycol ether. and 2 to 3 parts of water, prepared according to conventional processes, so that it can produce a synergistic effect, ensure good solubility while ensuring high selectivity, reduced non-aromatic hydrocarbon content, fast phase separation speed, and high extraction efficiency; when coal is used Base naphtha is used as raw material, and the composite extractant is used to prepare solvent oil by countercurrent extraction and fractionation in an extraction tower. The novel composite extractant of the present invention is used to extract aromatic hydrocarbons from coal-based naphtha under appropriate process conditions. It is mentioned that compared with petroleum-based naphtha, the solvent oil obtained has higher purity, less aromatic hydrocarbon content, and low toxicity, and the raw material is coal-based naphtha instead of traditional petroleum-based naphtha, which alleviates the pressure on international petroleum resources and broadens the scope of acquisition from non-petroleum resources. Channels for mineral spirits.

Owner:NORTHWEST UNIV

Method for efficiently separating and purifying puerarin

The invention provides a method for efficiently separating and purifying puerarin. The method comprises the steps that puerarin powder is subjected to reflux extraction in a 50-70% alcohol-water solution for 12-24 h to obtain crude extract, modified glucan-inorganic salt two aqueous phase extraction layering is carried out, the upper phase is dialyzed in a dialysis membrane with the molecular mass cut-off of 10000 for 15-20 h to obtain a puerarin water solution, the puerarin water solution is frozen and dried at the temperature of -15--10 DEG C for 8-15 h to obtain puerarin powder, and the modified glucan is caproic acid partially-esterified glucan. The 50-70% alcohol-water solution is adopted as the extraction solution, so that high yield and high purity are obtained, and meanwhile solid and liquid phases can be rapidly separated; the modified glucan / inorganic salt two aqueous phase system is high in selectivity for puerarin, the system phase separation speed is high, and rapid phase separation can be achieved without equipment such as a centrifugal machine; according to the puerarin powder prepared through the method, the puerarin purity reaches up to 97.5%, and the total recovery reaches up to 87.5%.

Owner:陕西乾翔健康科技有限公司

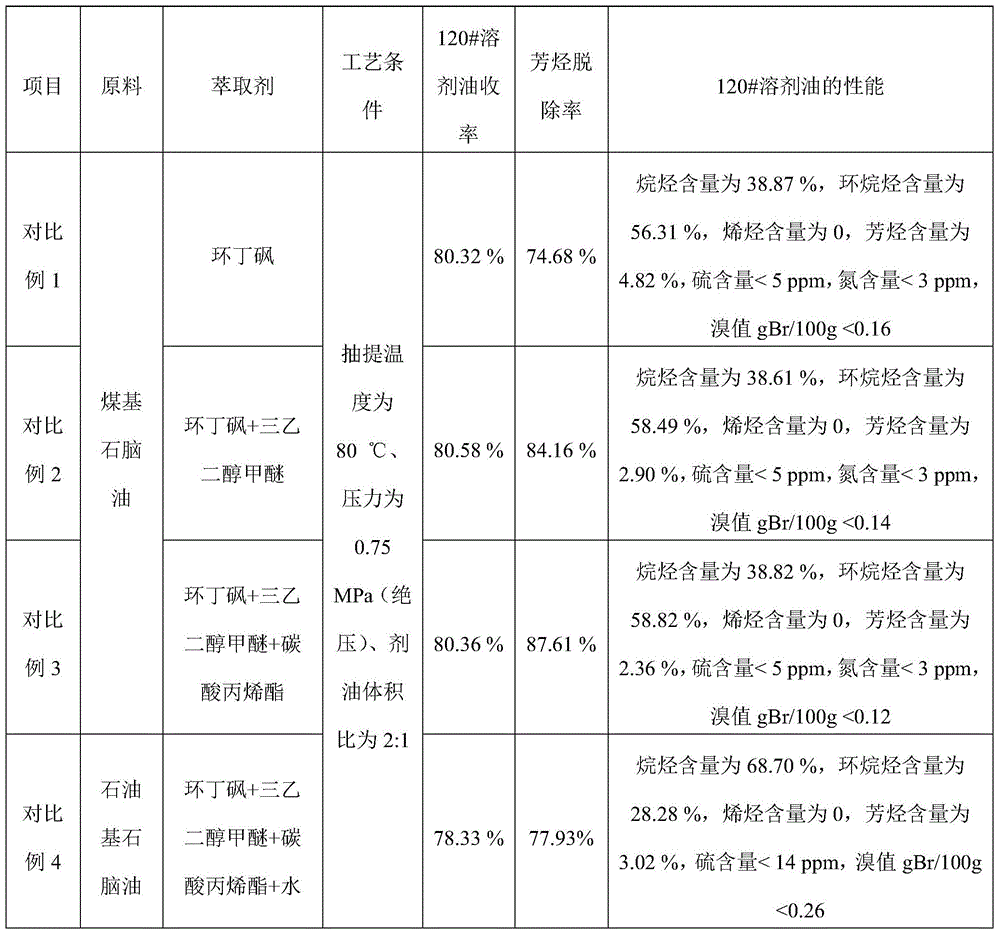

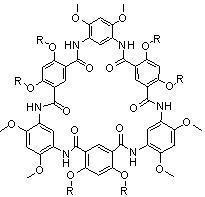

Application of cyclophane amide compound containing three central hydrogen bonds as extracting agent in separation of rare-earth elements

InactiveCN102002590AGood chemical stabilityReduce dosageProcess efficiency improvementCombinatorial chemistryCyclophane

The invention relates to application of a cyclophane amide compound containing three central hydrogen bonds as an extracting agent in separation of rare-earth elements, wherein, the cyclophane amide compound containing the three central hydrogen bonds is applied to the separation of the rare-earth elements. The cyclophane amide extracting agent containing the three central hydrogen bonds has single composition, good chemical stability and less consumption; the extracting agent can carry out extraction in neutral solution; the dissolubility of the extracting agent in different solvents can be adjusted through an R group; and the extracting agent further has the advantages of fast extraction speed, fast phase separation speed and the like while extracting the rare-earth elements. Therefore, the cyclophane amide containing the three central hydrogen bonds is taken as a novel extracting agent for extracting and separating the rare-earth elements has practical application prospect.

Owner:SICHUAN UNIV

Method for separating and purifying puerarin by combination of double-aqueous phase extraction-ultrasonic wave

The invention provides a method for separating and purifying puerarin by combination of double-aqueous phase extraction-ultrasonic wave. The method comprises the specific operation steps: extracting kudzu vine root powder with 50%-70% alcohol water solution under refluxing for 12-24 hours to obtain crude liquid; carrying out polyethylene glycol-inorganic salt double-aqueous phase extraction and putting the liquid into ultrasonic wave to be subjected ultrasonic treatment for 20-40 minutes; then standing for 10-20 minutes; taking an upper phase and dialyzing in a dialysis membrane with the molecular mass cut-off of 5000 for 20-26 hours; and freeze-drying to obtain puerarin powder. The method takes the 50%-70% alcohol water solution as an extracting solution, so that high yield and high purity can be obtained and solid and liquid phases can be rapidly separated; a double-aqueous phase extraction-ultrasonic wave combined method is used for purifying the crude liquid and the selectivity on the puerarin is high; a phase separation speed of the system is rapid and rapid phase separation can be realized without the help of equipment including a centrifuge and the like; and the purity of the puerarin in the prepared puerarin powder is up to 97.5% and the total yield is up to 86.6%.

Owner:苏州善淮堂生物科技有限公司

Suspension demulsification device

ActiveCN103285622AFast phase separationHigh extraction rateNon-miscible liquid separationEmulsionWhole body

The invention discloses a suspension demulsification device. The suspension demulsification device consists of a suspension demulsification unit body or a plurality of suspension demulsification unit bodies which are sequentially connected, wherein each suspension demulsification unit body comprises a demulsification unit, a suspension unit and a connection piece; each demulsification unit is movably or fixedly connected to a part above or below the corresponding suspension unit; each connection piece is arranged on the corresponding suspension unit and can be connected with two adjacent suspension demulsification unit bodies. The suspension demulsification device is applicable to elimination of an emulsion phenomenon in a two-phase or multi-phase mixture. By combining the demulsification units, the suspension units and a buoyancy regulating unit, a module single body or a module whole body in certain standardization is formed, and is suspended in the liquid in an extraction groove, so that the emulsion degree of a mixed solution in the extraction groove can be reduced, and the resistance of material flowing in the extraction groove can be reduced.

Owner:HUBEI SANNING CHEM

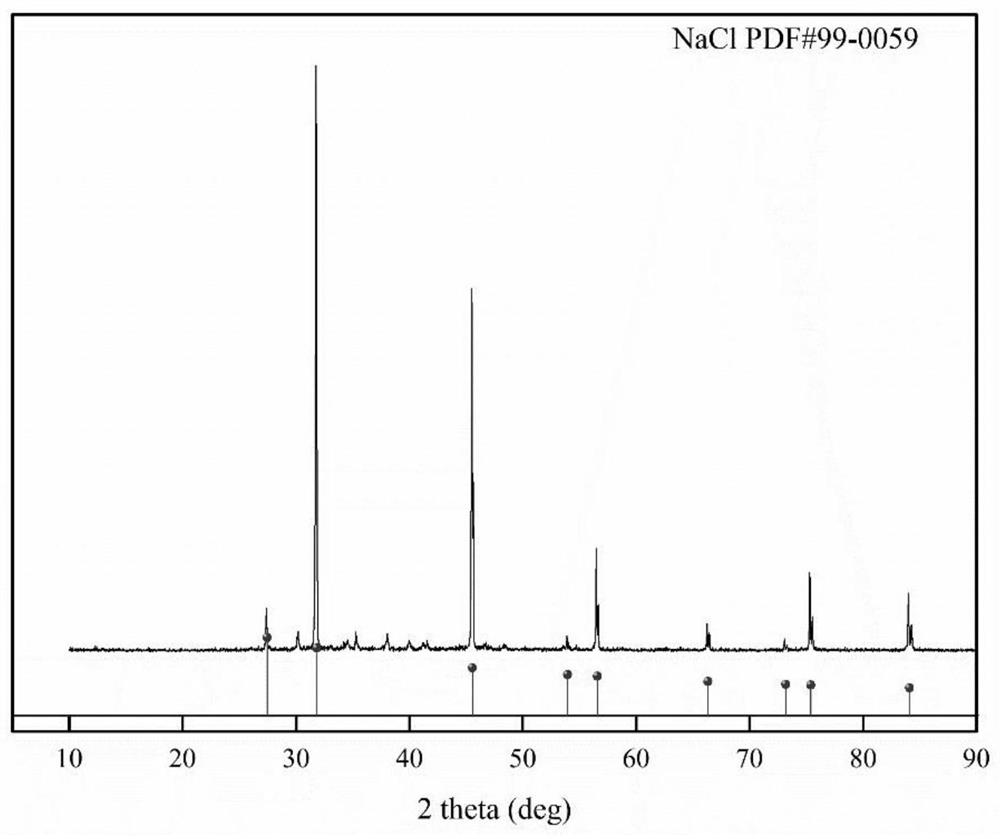

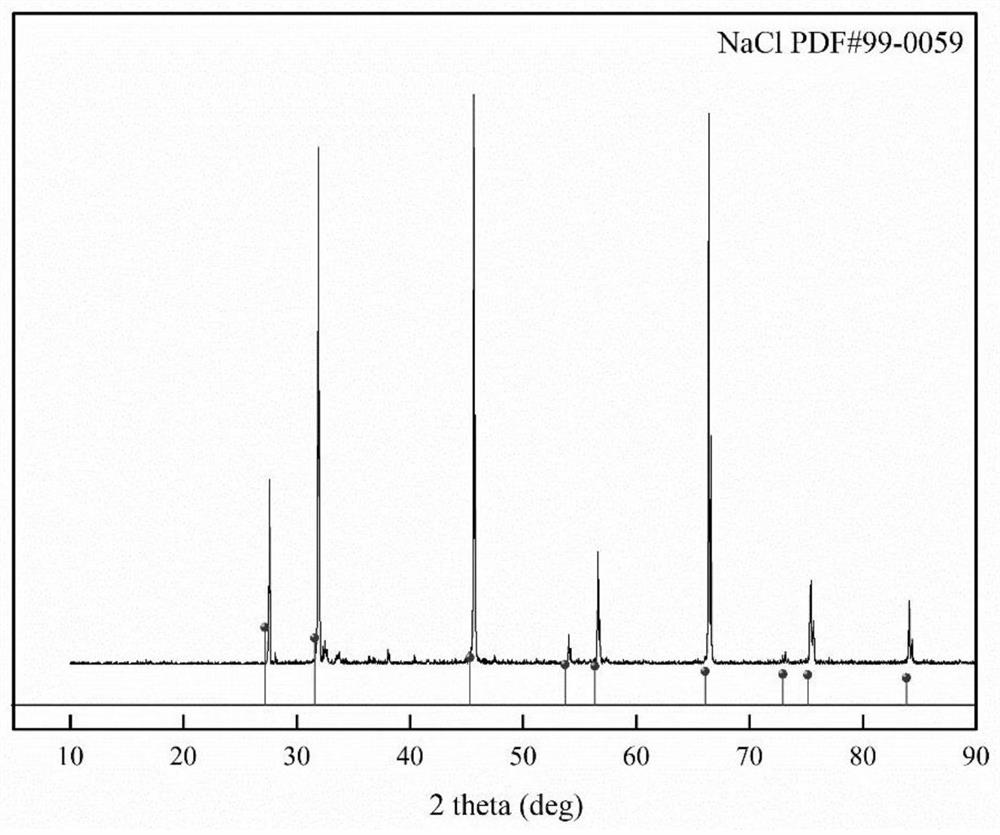

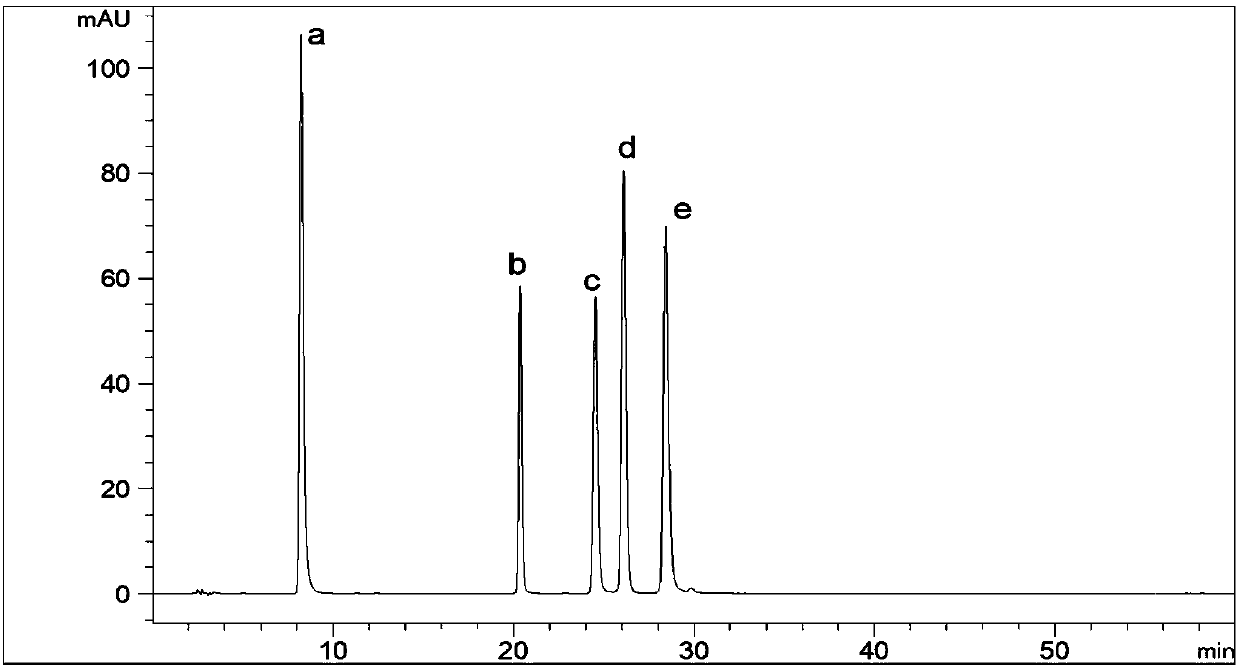

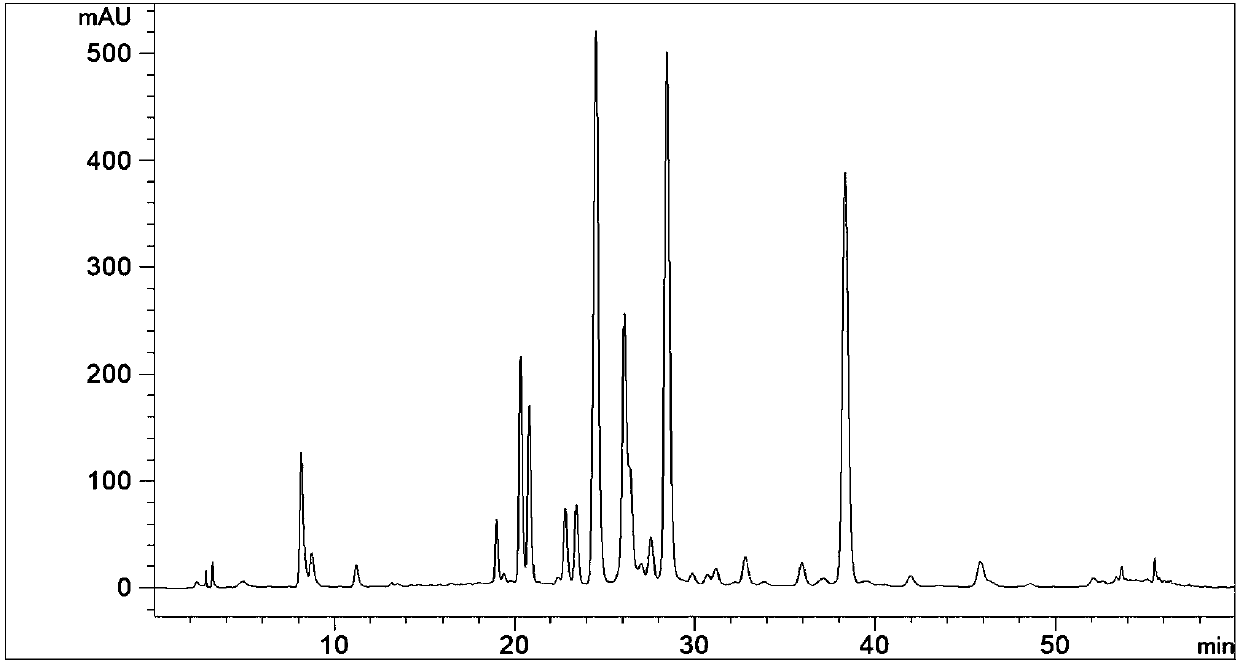

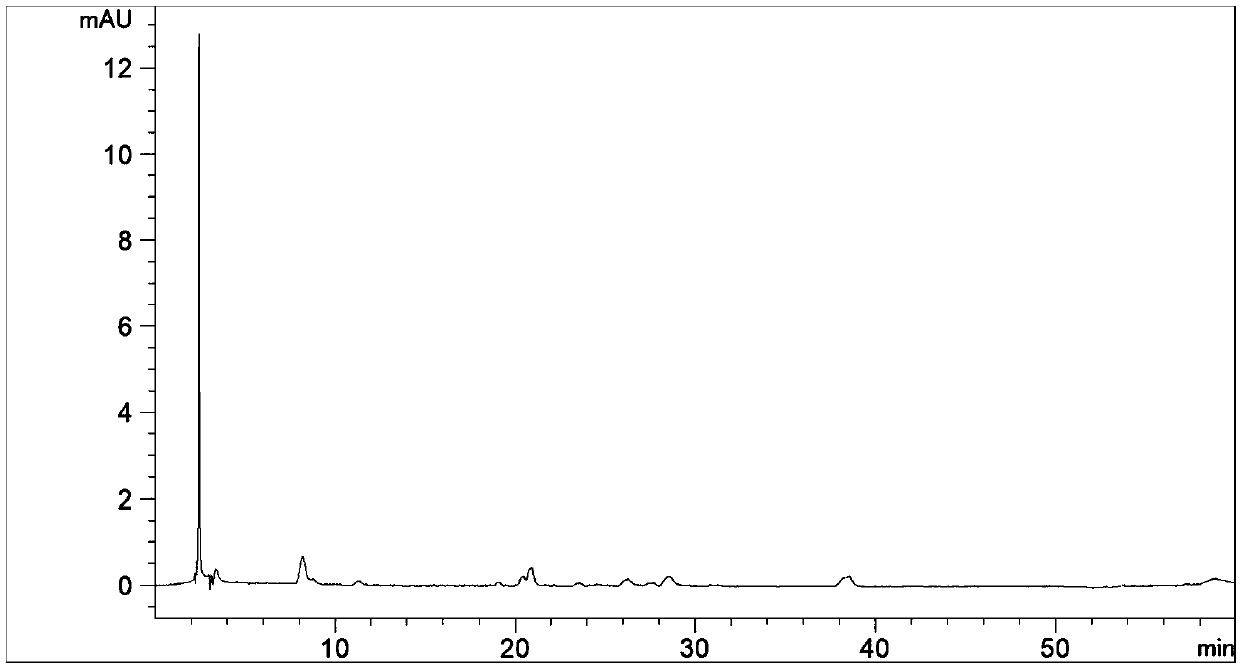

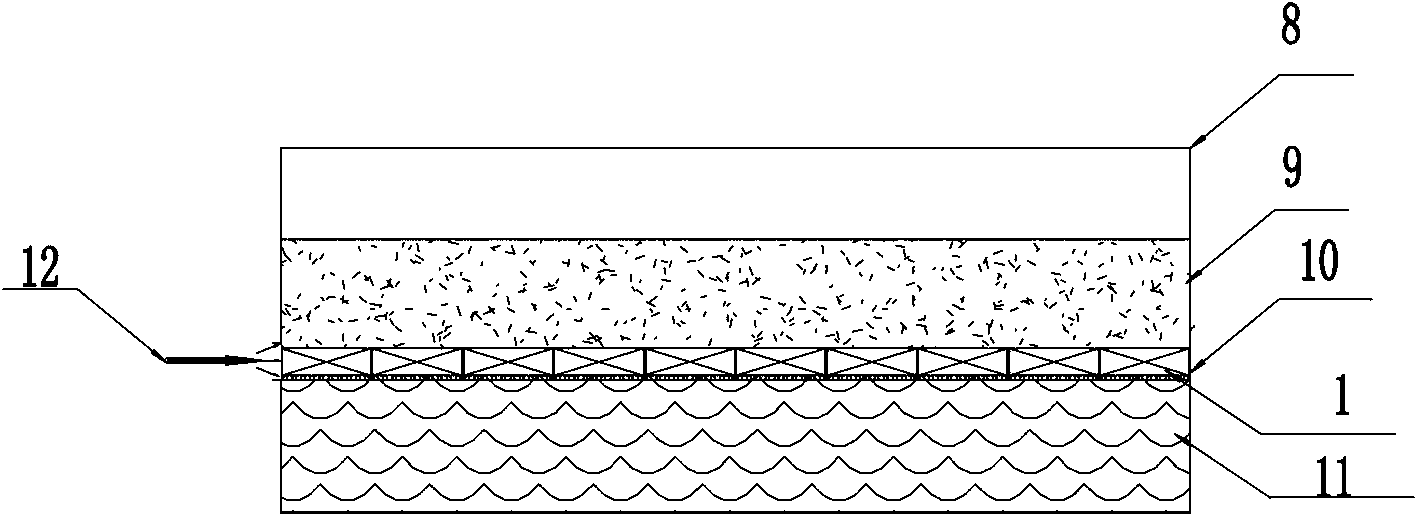

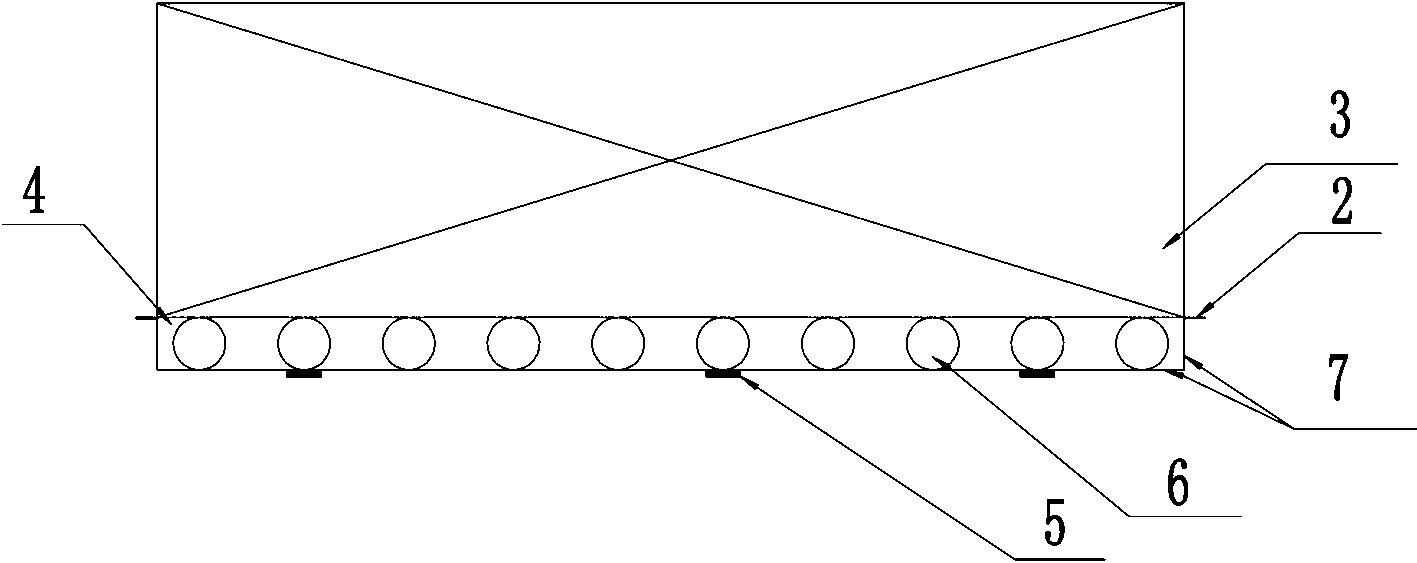

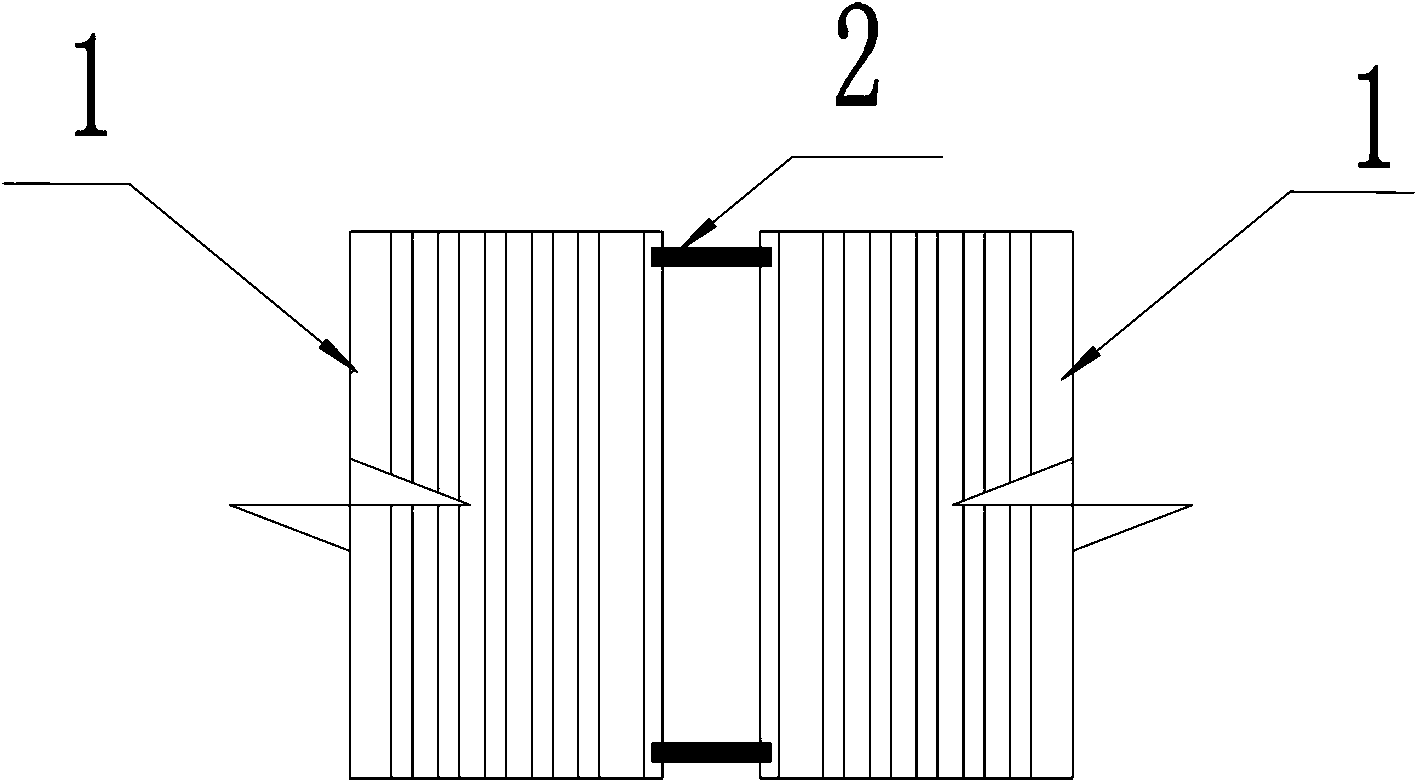

A kind of phosphine oxide modified pillar [5] arene derivative and its application

InactiveCN103087101BEfficient separationGuaranteed efficient selectivityGroup 5/15 element organic compoundsRare-earth elementPhysical chemistry

The invention relates to a phosphine oxide-modified pillar (5) arene derivative and an application thereof, belonging to the technical field of selective separation and extraction agents for thorium (IV) and uranium (VI) from rare earth elements. The phosphine oxide-modified pillar (5) arene derivative is diphenyl phosphine oxide-substituted pillar (5) arene, is used as an extraction agent for selectively separating thorium and uranium from rare earth elements, and can realize the selective separation of uranium to thorium in actinide elements to a certain extent. The extraction agent, namely the phosphine oxide-modified pillar (5) arene in the invention has the advantages of single composition, good chemical stability, simple synthesis and easiness in obtainment, and is suitable for industrial production; furthermore, the using quantity of the extraction agent is low, and the thorium and the uranium can be selectively separated from the rare earth elements under high acidity; and in addition, the extraction agent further has the advantages of high extraction speed, high phase splitting speed and the like. The product disclosed by the invention has great economic benefits and practical application prospects.

Owner:SICHUAN UNIV

Method for extracting hydroxyacetic acid from water solution mixture containing hydroxyacetic acid

InactiveCN101265174BPromote regenerationEasy to prepareCarboxylic compound separation/purificationAcetic acidGlycollic acid

Owner:EAST CHINA UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![A kind of phosphine oxide modified pillar [5] arene derivative and its application A kind of phosphine oxide modified pillar [5] arene derivative and its application](https://images-eureka.patsnap.com/patent_img/889ee391-3fff-4cae-917f-632d3c7144c1/130129140243.PNG)

![A kind of phosphine oxide modified pillar [5] arene derivative and its application A kind of phosphine oxide modified pillar [5] arene derivative and its application](https://images-eureka.patsnap.com/patent_img/889ee391-3fff-4cae-917f-632d3c7144c1/126390DEST_PATH_IMAGE001.PNG)

![A kind of phosphine oxide modified pillar [5] arene derivative and its application A kind of phosphine oxide modified pillar [5] arene derivative and its application](https://images-eureka.patsnap.com/patent_img/889ee391-3fff-4cae-917f-632d3c7144c1/160762DEST_PATH_IMAGE001.PNG)