Method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration

A combination of dressing and smelting, lead and zinc oxide technology, applied in the processing of ore, in the field of combined dressing and smelting of high-calcium-magnesium and low-grade lead-zinc oxide ore, it can solve problems such as difficult separation, and achieve improved recovery and good selectivity , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

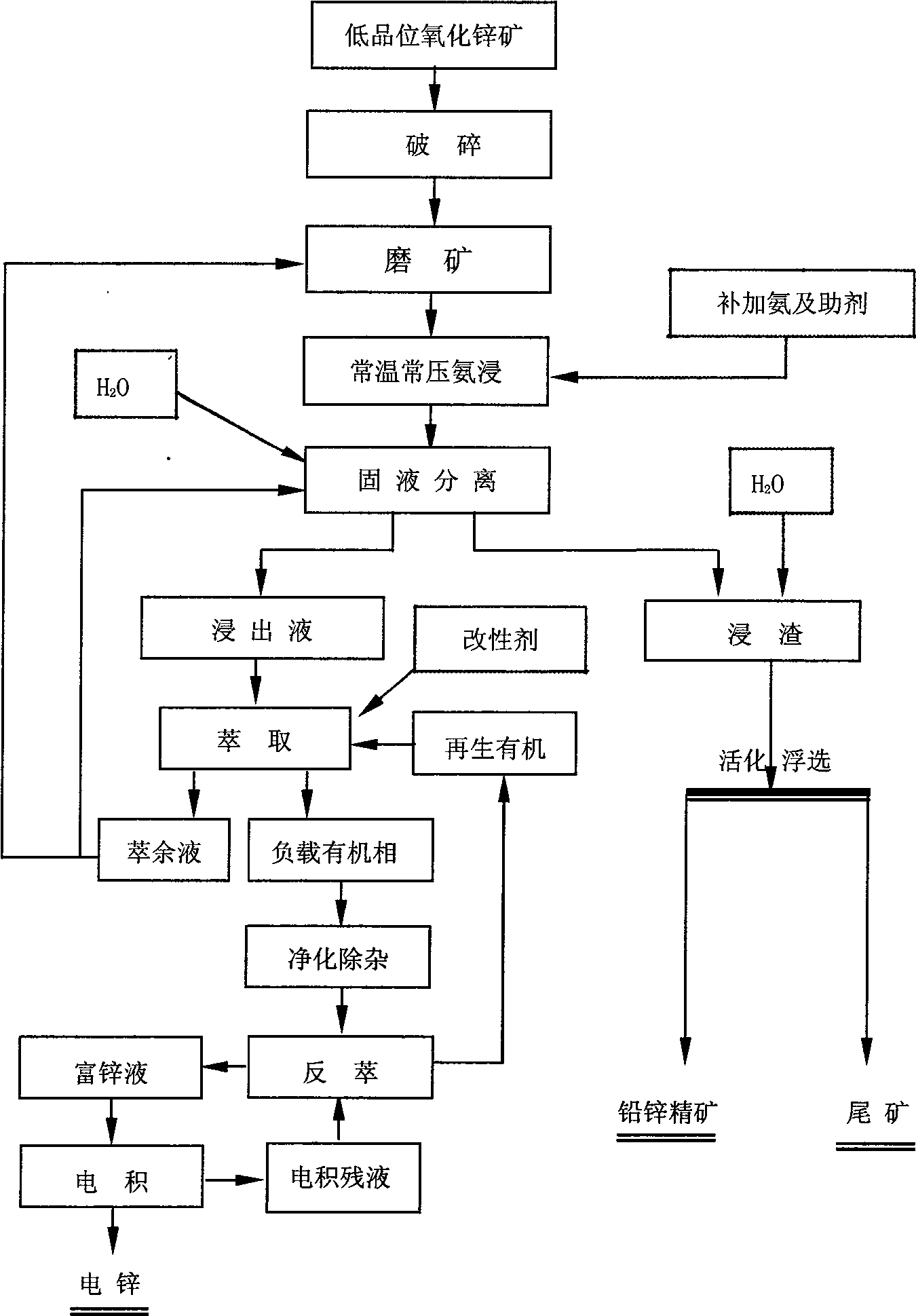

Image

Examples

Embodiment 1

[0028] The raw ore composition of lead-zinc oxide treated: Zn 10.26%, Pb 2.03%, Fe 18.50%, CaO21.35%, MgO 0.55%, SiO 2 13.71%, zinc oxidation rate 84.93%.

[0029] Above-mentioned raw ore is passed through following processing steps:

[0030] (1) Wet ore crushing and grinding of raw ore to a pulp with a fineness of less than 74 μm, accounting for 70%;

[0031] (2) Add ammonia water and ammonium bicarbonate to the above-mentioned grinding pulp until the total ammonia concentration of the pulp is 6mol / L, wherein the molar concentration ratio of ammonia and ammonium salt is 2:1, and the liquid-solid ratio of the pulp is controlled to be 3:1, according to The amount of raw ore is 200g / t, the activator hydrofluoric acid (HF) is added to the pulp, stirred and leached for 2 hours, and after solid-liquid separation, leachate and leaching residue are obtained;

[0032] (3) adding volume ratio in above-mentioned leaching solution is: 15% 2-hydroxyl-5 nonyl-benzaldehyde oxime, 10% iso...

Embodiment 2

[0038] Lead-zinc oxide ore ore composition: Zn 9.12%, Pb 1.94%, Fe 16.25%, CaO 24.57%, MgO 0.65%, SiO 2 21.52%. The zinc oxidation rate is 45.38%.

[0039] The above-mentioned raw ore is subjected to the following process steps:

[0040] (1) Wet crushing and grinding the raw ore to a pulp with a fineness of less than 74 μm accounting for 90%;

[0041] (2) Ammonia water and ammonium carbonate were added to the above-mentioned grinding ore pulp until the total ammonia concentration of the ore pulp was 3 mol / L, wherein the molar concentration ratio of ammonia and ammonium salt was 2: 1, and the liquid-solid ratio of the controlled ore slurry was 3: 1, according to 80g / t amount of raw ore, add activator hydrofluoric acid to the pulp, stir and leaching for 2 hours, after solid-liquid separation, obtain leaching solution and leaching slag;

[0042] (3) adding volume ratio in above-mentioned leach liquor is: 5% 2-hydroxy-5 nonyl-benzaldehyde oxime, 5% C5-9 mixed alcohol, 90% avi...

Embodiment 3

[0048] Lead-zinc oxide ore composition: Zn 15.36%, Pb 2.85%, Fe 13.19%, CaO 26.48%, MgO 0.74%, SiO 2 19.47%. The zinc oxidation rate is 64.33%.

[0049] The above-mentioned raw ore is subjected to the following process steps:

[0050] (1) Wet crushing and grinding the raw ore to a pulp with a fineness of less than 74 μm accounting for 85%;

[0051] (2) Add ammonia water and ammonium sulfate to the above-mentioned grinding pulp until the total ammonia concentration of the pulp is 4.5mol / L, wherein the molar concentration ratio of ammonia and ammonium salt is 2:1, and the control ore slurry liquid-solid ratio is 4:1, press The amount of 150g / t raw ore, add the activator hydrofluoric acid to the pulp, stir and leaching for 1 hour, after the solid-liquid separation, the leaching solution and the leaching slag are obtained;

[0052] (3) adding volume ratio in above-mentioned leach liquor is: 10% 2-hydroxy-5 nonyl-benzaldehyde oxime, 10% C5-9 mixed alcohol, 80% aviation kerosene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com