Suspension demulsification device

A demulsification device and demulsification technology, applied in the field of chemical equipment, can solve problems such as inconvenient disassembly, long clarification and separation time, and difficulty in emulsification and separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

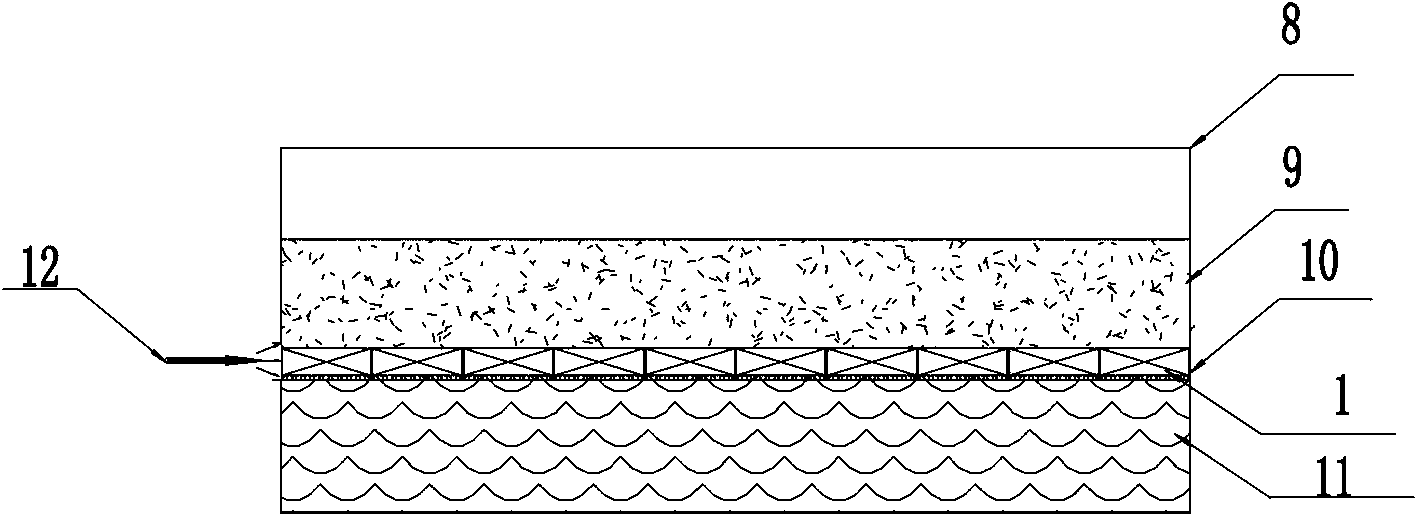

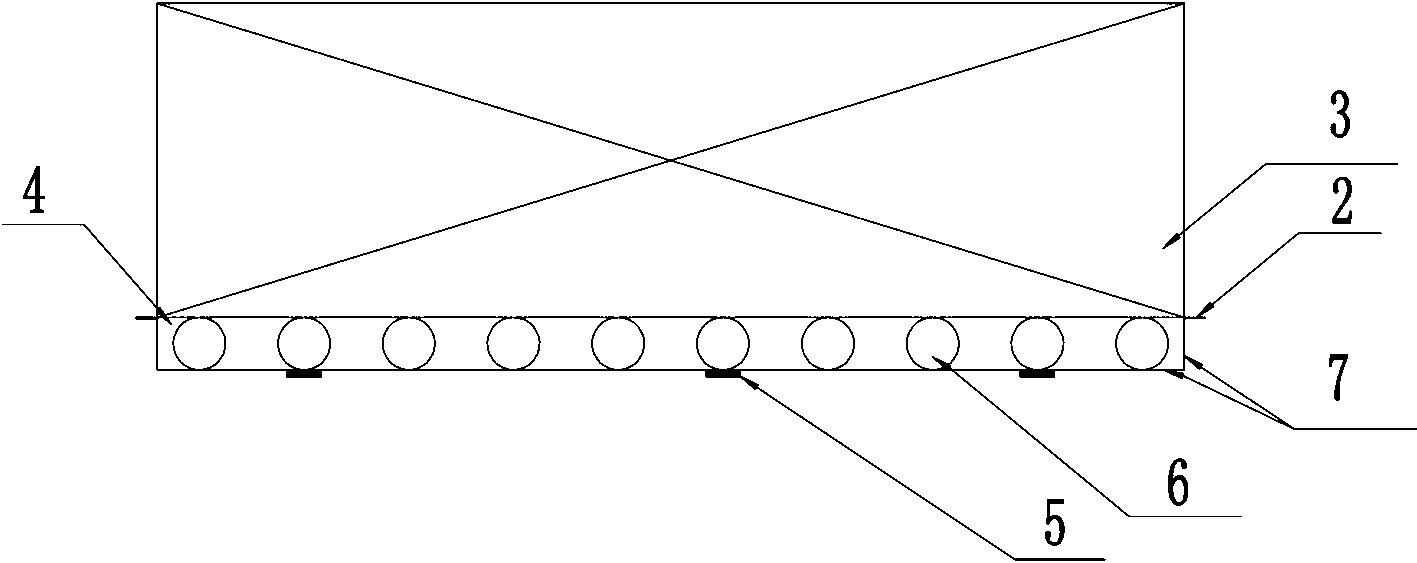

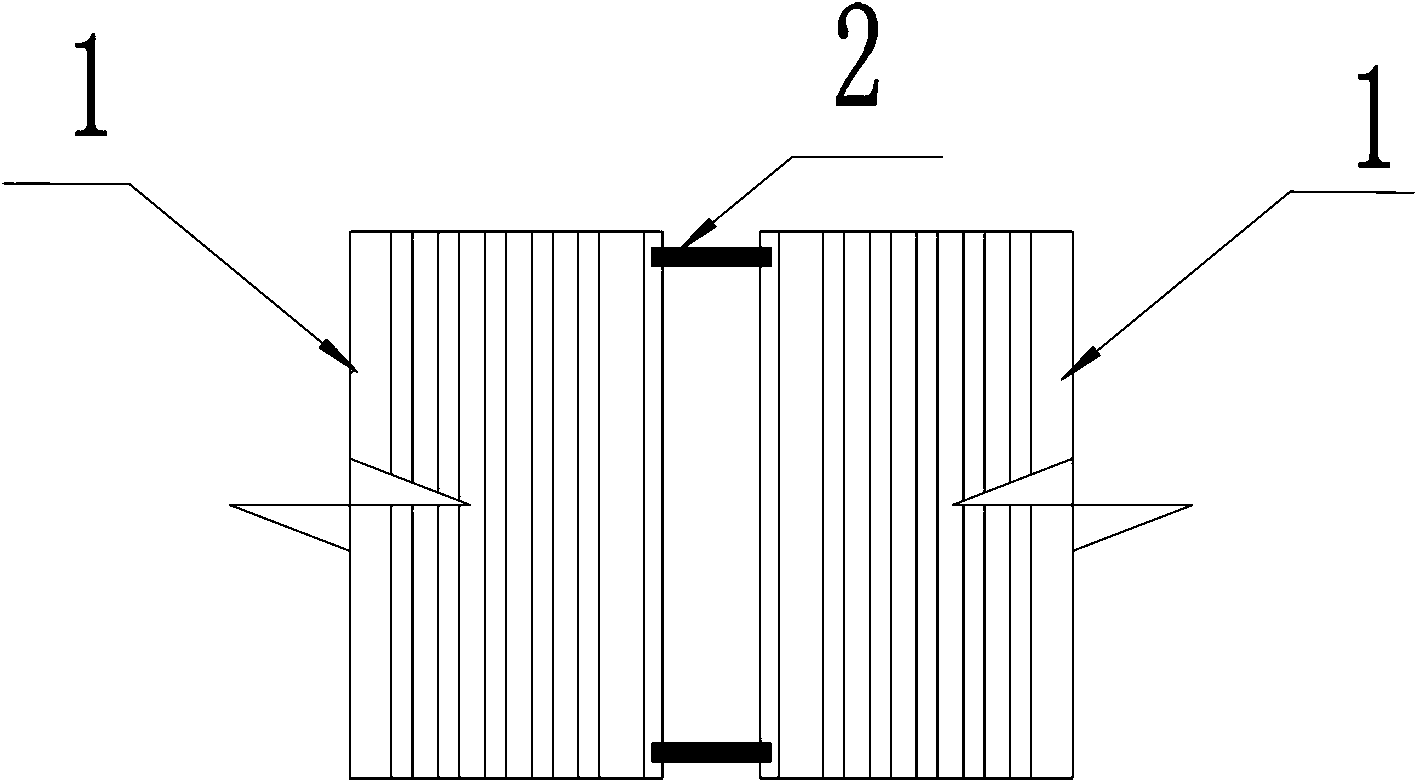

[0029] A suspension demulsification device is used in the extraction tank 8 in the process of extracting and purifying wet-process phosphoric acid with an organic solvent, and it is composed of a plurality of suspension demulsification units 1 sequentially connecting adjacent suspension demulsification units 1 through connectors 2 The buoyancy cylinder 6 of the suspension unit 4 of the suspension demulsification device, the skeleton 7 and the buoyancy adjustment block of the buoyancy adjustment unit 5 adopt 904L sealed round tube or square tube, and the mesh plate of the demulsification unit 3 uses 904L regular wire mesh corrugated packing, The buoyancy adjustment block is connected to the frame 7 through locks or screws, and the suspension is calculated based on the organic solvent in the light phase liquid layer 9, the wet-process phosphoric acid in the heavy phase liquid layer 11 and the density of 904L material, and the working area of the suspension demulsification device...

Embodiment 2

[0031] A suspension demulsification device is used in the extraction tank 8 in the process of extracting and purifying wet-process phosphoric acid with an organic solvent, and it is composed of a plurality of suspension demulsification units 1 sequentially connecting adjacent suspension demulsification units 1 through connectors 2 , the buoyancy cylinder 6 of the suspension unit 4 of the suspension demulsification device, the skeleton 7 and the buoyancy adjustment block of the buoyancy adjustment unit 5 adopt polytetrafluoro tubes or polytetrafluoro plates, and the mesh plate of the demulsification unit 3 uses polytetrafluoro structured orifice plates The corrugated packing and the buoyancy adjustment block are connected to the skeleton 7 through locks or screws, according to the density of the organic solvent in the light phase liquid layer 9, the wet-process phosphoric acid in the heavy phase liquid layer 11 and the polytetrafluoroethylene material, and the working area of t...

Embodiment 3

[0033] A suspension demulsification device is used in the extraction tank 8 in the process of extracting and purifying wet-process phosphoric acid with an organic solvent, and it is composed of a plurality of suspension demulsification units 1 sequentially connecting adjacent suspension demulsification units 1 through connectors 2 , the buoyancy cylinder 6 of the suspension unit 4 of the suspension demulsification device, the skeleton 7 and the buoyancy adjustment block of the buoyancy adjustment unit 5 are composed of polytetrafluoro tubes or polytetrafluoro plates, and the mesh plate of the demulsification unit 3 is made of 904L regular wire mesh corrugation The packing and the buoyancy adjustment block are connected to the skeleton 7 through locks or screws. According to the density of the organic solvent in the light phase liquid layer 9, the wet-process phosphoric acid and polytetrafluoroethylene in the heavy phase liquid layer 11, and 904L materials, the working area of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com