Solvent separating unit used for evaporation and recovery of solvent system and application method thereof

A solvent separation and solvent recovery technology, applied in the field of solvent separation, can solve the problems of slow phase separation, poor separation effect, and difficult operation, and achieve the effects of fast phase separation, fewer parts and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

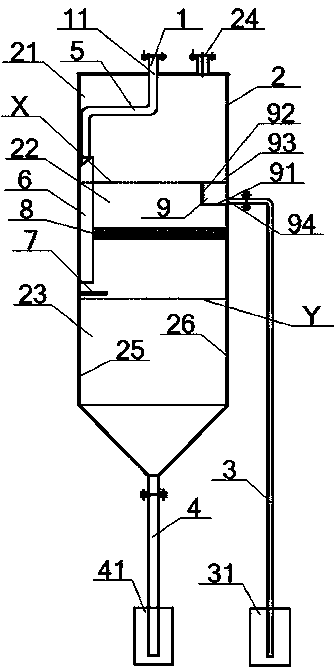

[0054] see figure 1 , a solvent separation device for evaporating and recovering a solvent system, comprising a cylinder body 2, a feed pipe 1, an organic phase discharge pipe 3, an aqueous phase discharge pipe 4, a transition pipe 5, a condensate vertical conduit 6, a condensate Liquid level guide plate 7, metal phase separation net 8 and organic phase overflow tank 9;

[0055] An air cavity 21, an organic phase cavity 22, and a water cavity 23 are sequentially arranged in the cylinder body 2 along the direction from the feed port 11 to the water phase discharge pipe 4, and a liquid cavity is formed at the junction of the air cavity 21 and the organic phase cavity 22. The bit line X, the junction of the organic phase chamber 22 and the water chamber 23 form a two-phase line Y, the top of the air chamber 21 communicates with the feed port 11 and the vent pipe 24, and the side of the organic phase chamber 22 passes through the organic phase The discharge pipe 3 communicates wi...

Embodiment 2

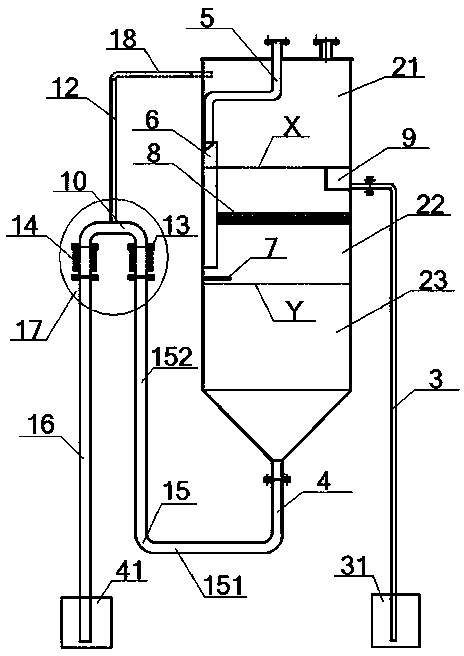

[0061] see figure 2 , the basic content is the same as in Example 1, the difference is that:

[0062] One end of the water phase discharge pipe 4 communicates with the bottom of the cylinder body 2, the other end communicates with the right end of the horizontal section 151 on the L-shaped pipe 15, and the left end of the horizontal section 151 communicates with the bottom end of the vertical section 152 on the L-shaped pipe 15. Connected, the horizontal section 151 and the vertical section 152 are vertically connected, and the top of the vertical section 152 communicates with the water phase receiving tank 41 after passing through the inverted Y-shaped pipe 17. Specifically, the top of the vertical section 152 passes through the No. 1 height-adjustable type The flexible pipe 13 communicates with the liquid inlet end of the inverted U-shaped pipe 10, and the liquid outlet end of the inverted U-shaped pipe 10 communicates with the water phase receiving tank 41 after passing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com