Oil-water separator and separation system

A technology of oil-water separator and separation channel, applied in liquid separation, separation method, immiscible liquid separation, etc., to achieve the effect of convenient automatic control, high-efficiency oil-water separation effect, and acceleration of oil-water separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

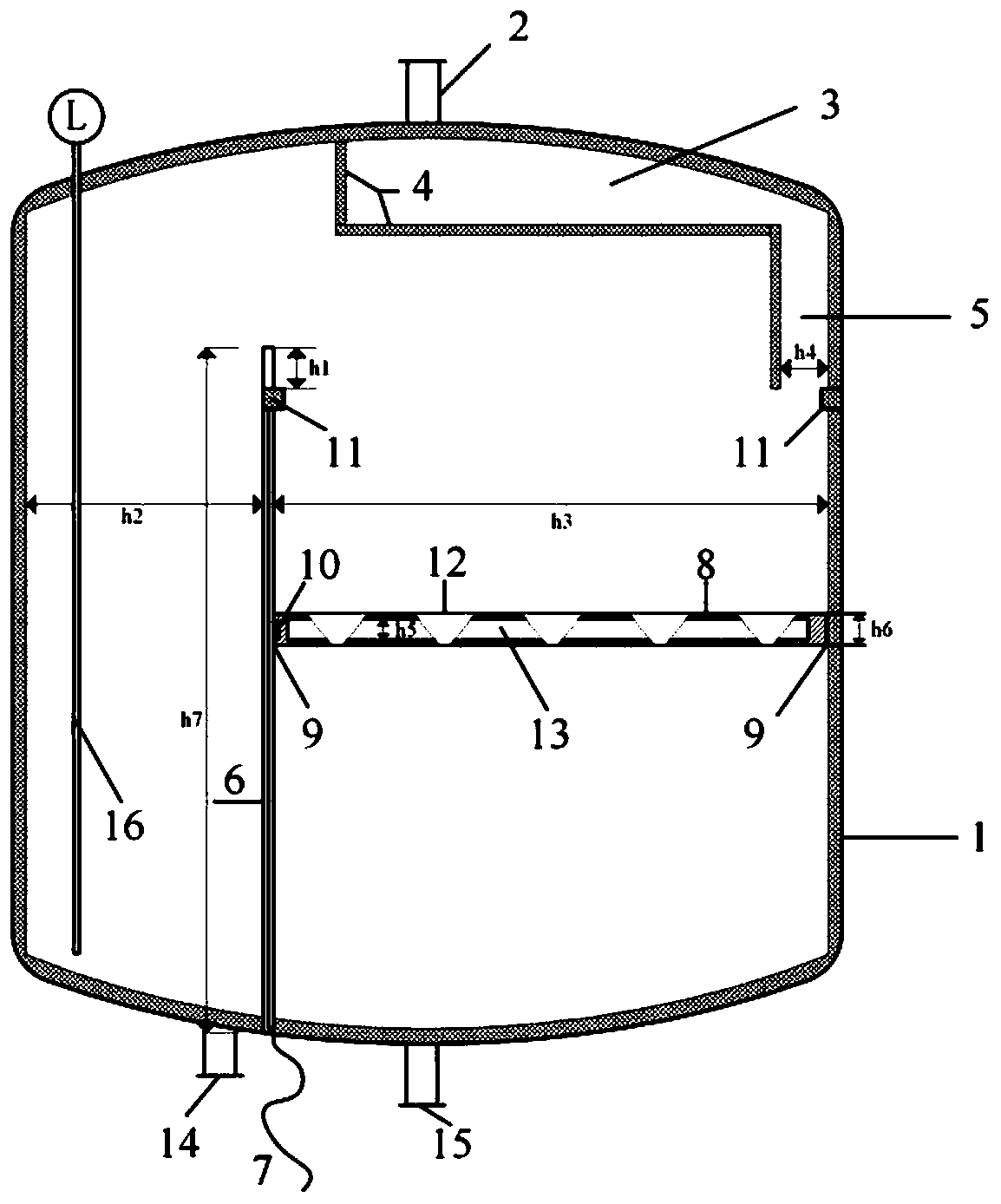

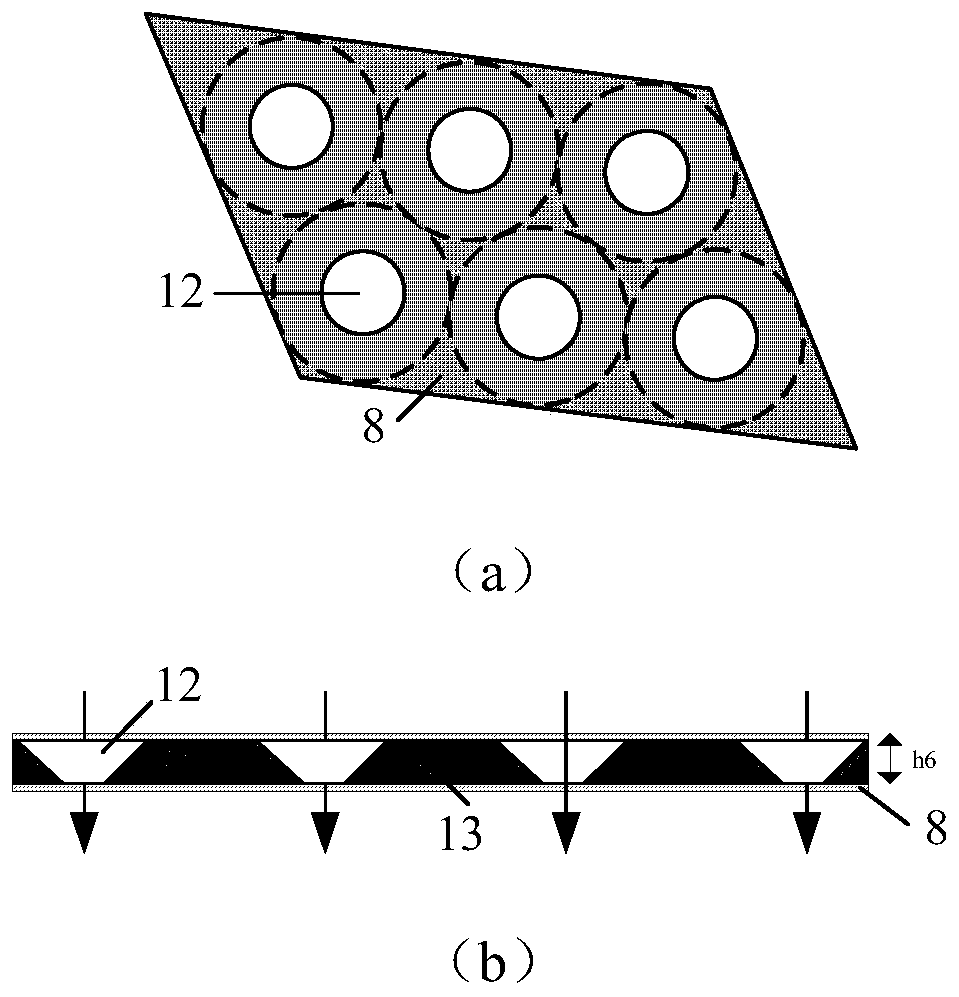

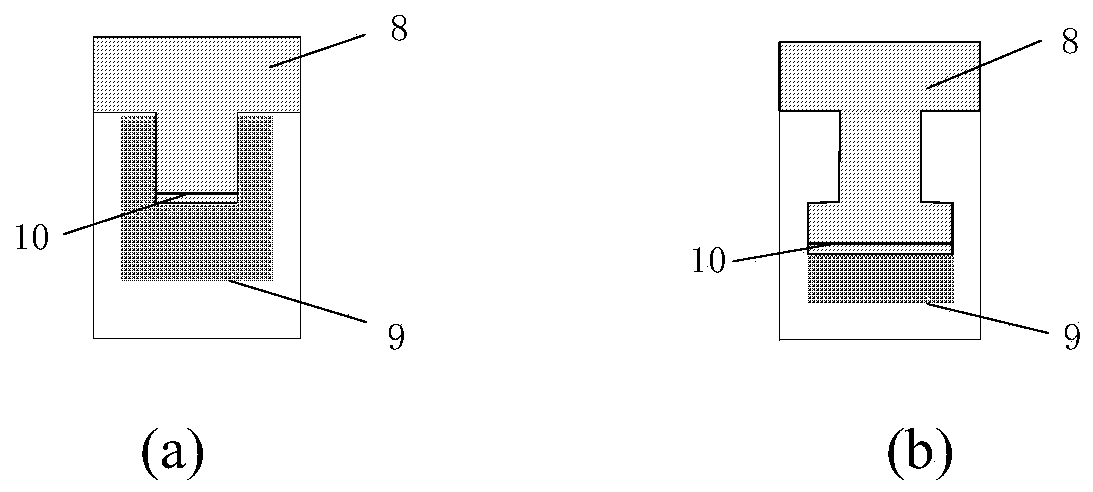

[0037] This embodiment provides an oil-water separator, such as figure 1 and 2 As shown, it includes 1 oil-water separator tank, 2 feed inlet, 3 separation channel, 4 hydrophobic membrane, 5 downcomer, 6 physical partition, 7 magnetic induction signal device, 8 liquid level floating plate, 9 groove guide rail , 10 magnetic induction end, 11 limit block, 12 liquid level floating plate groove, 13 air bag, 14 oil outlet, 15 water outlet. In particular, a layer of hydrophobic membrane 4 is coated on the inner wall of the separation channel, which can improve the efficiency of oil-water separation; at the same time, a physical partition 6 is connected to the bottom of the oil-water separator tank, and a magnetic induction liquid level signal device is arranged in the physical partition 6 7. The liquid level in the water phase area can be connected to the physical partition 6 through the magnetic induction terminal 10 at the end of the liquid level floating plate 8, so that real-ti...

Embodiment 2

[0039] This embodiment provides an oil-water separation system, such as image 3 As shown, it includes 16 oil phase liquid level monitoring instruments, 17 feed control valves, 18 water outlet control valves, 19 oil outlet control valves, and 20 water level monitoring instruments.

[0040] The mixed solution containing MMA and water enters the oil-water separator 16 through the feed regulating valve 17 on the feed pipeline, realizes the separation of MMA and water in the oil-water separator 16, controls the water phase recovery rate by the water outlet regulating valve 18, and passes The oil discharge control valve 19 regulates the recovery rate of MMA.

[0041] During the process of separating MMA and water, MMA and water are separated in the oil-water separator 16 . When the liquid level of the water phase in the oil-water separator 16 is high, the water level monitoring instrument 20 is used to increase the opening of the water control valve 18 to increase the recovery rat...

Embodiment 3

[0043] The present embodiment provides a kind of utilizing the oil-water separator of embodiment 1 to separate MMA and water mixture, and the characteristic parameter of oil-water separation tank mainly is: 1) feed inlet diameter is 25mm, and the diameter of separation channel is described feed inlet diameter 2) The diameter of the oil-water separation tank is 800mm, and the diameter of the liquid level floating plate h3 is 480mm; 3) The height of the oil-water separation tank is 1800mm, and the height of the physical partition h7 is 1080mm. The liquid level floating plate 8 is a hollow structure filled with air. According to the density difference between MMA (density 0.94g / ml) and water (density 1.0g / ml), the density of the liquid level floating plate is adjusted to 0.97g / ml. Make it at the separation interface of the water phase area and the mixed phase area, and can accurately indicate the liquid level of the water phase area.

[0044] Liquid level floating plate grooves 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com