Extraction method of green prickleyash alkaloids

An extraction method, the technology of green pepper, applied in the direction of alkaloids, alkaloids, chemical instruments and methods, etc., can solve the problems of low extraction rate, slow phase separation speed of two-phase system, and separation effect of total alkaloids and substances to be separated Instability and other problems, to achieve the effect of fast phase separation, improved purity and performance, and stable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

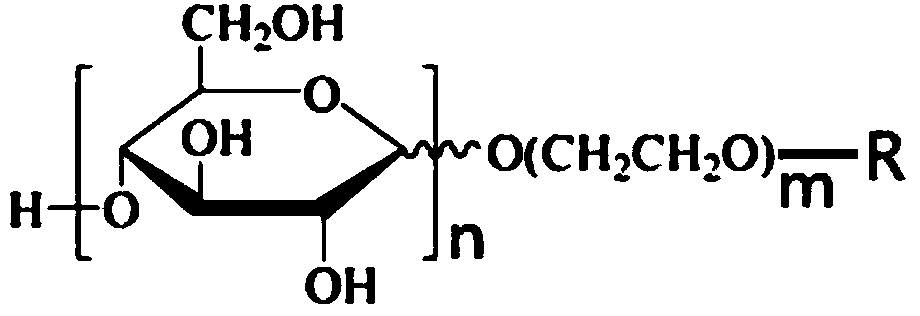

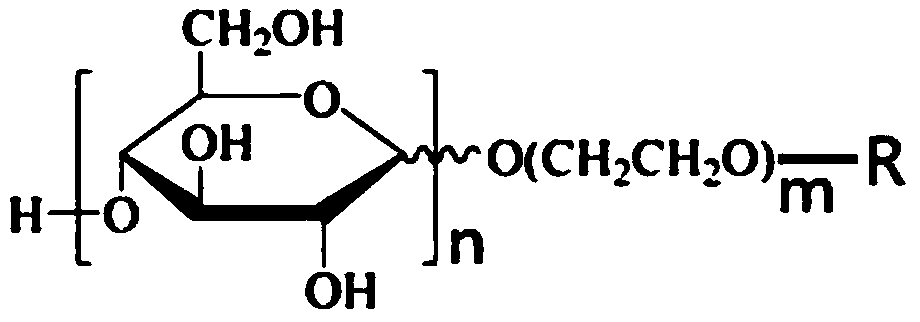

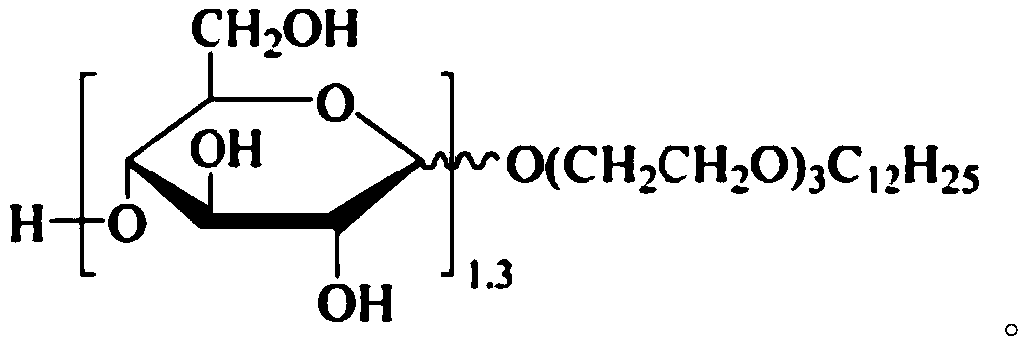

[0052] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 100 mesh to obtain green peppercorn powder. Prepare a two-phase aqueous extraction solvent, adjust pH=6.0 with 18wt% of alkyl alcohol ether glycoside AEG30, 22wt% of dipotassium hydrogen phosphate, 1.5wt% of potassium chloride and the rest of deionized water; then at 40°C Mix well, and let stand at constant temperature. According to the solid-liquid ratio of 1:12g / mL, weigh 100 mesh green pepper powder, place it in a closed microwave extraction device, add a two-phase extraction solvent, and extract at 60°C to obtain an extract. The microwave extraction conditions are: microwave power 260W; extraction time 20min. The extract was filtered with a 0.22 μm filter membrane, added to a separatory funnel and allowed to stand for phase separation to obtain an upper phase and a lower phase. Use the polysulfone ultrafiltration membrane with a molecular weight ...

Embodiment 2

[0054] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 80 mesh to obtain green peppercorn powder. Prepare a two-phase aqueous extraction solvent, adjust pH=6.5 with 20wt% of alkyl alcohol ether glycoside AEG30, 20wt% of dipotassium hydrogen phosphate, 1wt% of potassium chloride and the rest of deionized water; then at 45°C Mix well and let stand at constant temperature. According to the solid-liquid ratio of 1:10g / mL, weigh 80 mesh green pepper powder, place it in a closed microwave extraction device, add a two-phase extraction solvent, and extract at 65°C to obtain an extract. The microwave extraction conditions are: microwave power 240W; extraction time 18min. The extract was filtered with a 0.22 μm filter membrane, added to a separatory funnel and allowed to stand for phase separation to obtain an upper phase and a lower phase. Purify the upper phase at an operating pressure of 0.4 MPa and room temper...

Embodiment 3

[0056] Dried green peppercorns (place of origin: Laiwu, Shandong) to moisture content ≤ 10%, and crushed to a particle size of 120 mesh to obtain green peppercorn powder. Prepare a two-phase aqueous extraction solvent, adjust pH=5.5 with 16wt% of alkyl alcohol ether glycoside AEG30, 24wt% of dipotassium hydrogen phosphate, 2wt% of potassium chloride and the rest of deionized water; then at 35°C Mix well and let stand at constant temperature. According to the solid-liquid ratio of 1:14g / mL, weigh 120 mesh green pepper powder, place it in a closed microwave extraction device, add a two-phase extraction solvent, and extract at 55°C to obtain an extract. The microwave extraction conditions are: microwave power 280W; extraction time 22min. The extract was filtered with a 0.22 μm filter membrane, added to a separatory funnel and allowed to stand for phase separation to obtain an upper phase and a lower phase. Purify the upper phase at an operating pressure of 0.2 MPa and room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com