Industrial hemp peeling machine

A hemp peeling machine, industrial technology, applied in mechanical processing, fiber mechanical separation, textiles and paper making, etc., can solve the problems of low efficiency of hemp peeling, achieve strong skin and bone separation ability, high peeling rate, fresh stem peeling high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

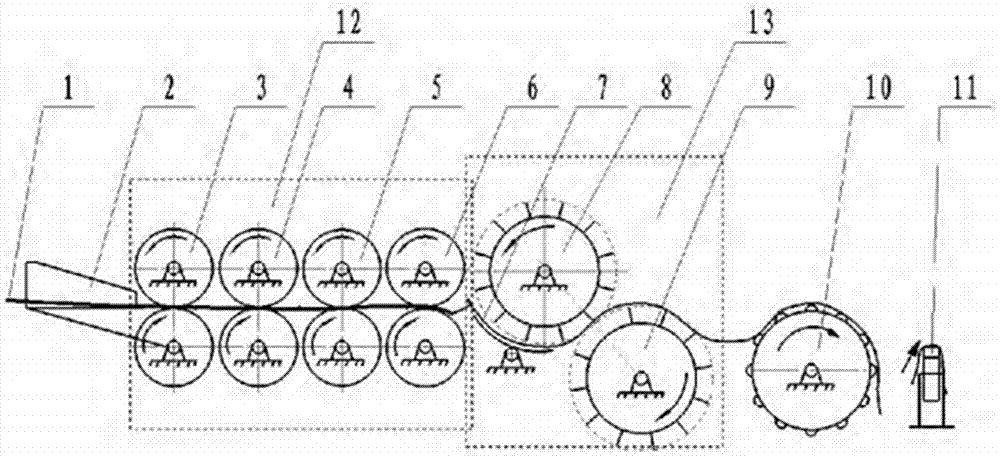

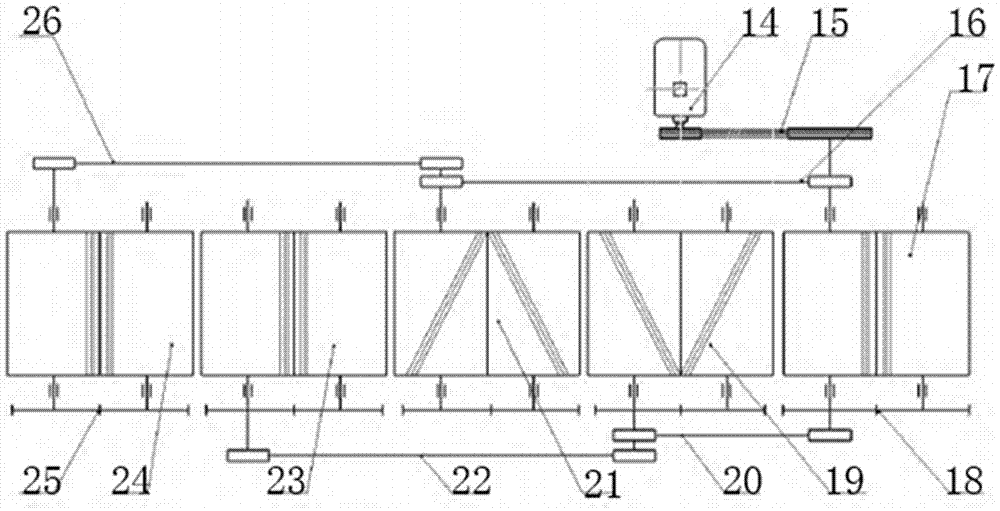

[0014] exist figure 1 Including stalks, feeding hopper, 1st pair of crushed stem rollers, 2nd pair of crushed stem rollers, 3rd pair of crushed stem rollers, 4th pair of crushed stem rollers, peeling concave plate, upper peeling roller, lower peeling roller, The hemp receiving drum, the hemp collecting device, the stalk rubbing part, the fiber combing part, and the separation of the hemp skin and bone are mainly completed by the two major devices of the prototype, the stalk rubbing part (12) and the fiber combing part (13). The fresh industrial hemp stems are preliminarily separated after passing through the stem rubbing device (12), and then combed through the combing device (13) to clean the broken bones attached to the bast, and the clean hemp husk is passed through the hemp receiving roller (10) and the hemp collecting roller (10). The device (11) collects; the rubbing device (12) consists of four pairs of crushing stem rollers with the same structure and different rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com