Processing technology for flavored kenaf seed oil with high stability

A technology with high stability and high processing technology, which is applied in the direction of edible oil/fat, fat oil/fat production, fat oil/fat refining, etc. It can solve the problem of insufficient stability of kenaf seed oil, difficulty in processing kenaf seed, and low production cost, etc. problems, to achieve the effect of reducing bad flavor, unique and pleasant flavor, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

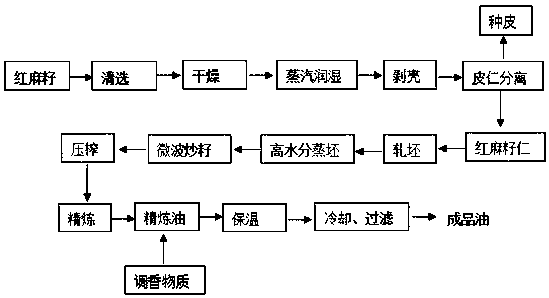

Image

Examples

Embodiment 1

[0024] A processing technology of high-stability flavor type kenaf oil comprises the following steps:

[0025] (1) Kenaf seeds require mature and plump kernels. After cleaning (screening, winnowing, magnetic separation), the proportion of damaged kernels is 2%, and the impurity content is 0.5%.

[0026] (2) After the kenaf seeds are dried in a drying oven until the moisture content of the whole seeds is 5%, the moisture content of the seed coat is quickly adjusted to 15% by direct steam. Use a disc sheller to peel the shells, and separate the shells and kernels through screening and winnowing.

[0027] (3) The separated kenaf seeds are softened and rolled in a rolling mill with a thickness of 0.2 mm.

[0028] (4) Under the action of direct steam, the moisture content of the blank is adjusted to 22%, and the temperature is raised to 100°C; the seeds are fried with a microwave seed frying machine for 7 minutes, so that the moisture content of the blank is reduced to 6%, and the...

Embodiment 2

[0033] (1) Kenaf seeds require mature and plump kernels. After cleaning (screening, winnowing, magnetic separation), the proportion of damaged kernels is 1%, and the impurity content is 1%.

[0034] (2) After the kenaf seeds are dried in a drying oven until the moisture content of the whole seeds is 8%, the moisture content of the seed coat is quickly adjusted to 12% by direct steam. The disc shelling machine is used for shelling, and the shell and kernel are separated by screening and winnowing.

[0035] (3) The separated kenaf seeds are softened and rolled in a rolling mill with a thickness of 0.4 mm.

[0036] (4) Under the action of direct steam, the moisture content of the blank is adjusted to 18%, and the temperature is raised to 95°C; the seeds are fried with a seed frying machine for 5 minutes to reduce the moisture content of the blank to 8%, and the discharge temperature is controlled at 110°C.

[0037] (5) In the frying pan of the press machine, further adjust the w...

Embodiment 3

[0041] (1) Pretreatment of raw materials: kenaf seeds require mature and plump kernels. After cleaning (screening, winnowing, magnetic separation), the proportion of damaged kernels is 1.5%, and the impurity content is 0.2%.

[0042] (2) After the kenaf seeds are dried in a drying oven until the moisture content of the whole seeds is 7%, the moisture content of the seed coat is quickly adjusted to 14% by direct steam. The disc shelling machine is used for shelling, and the shell and kernel are separated by screening and winnowing.

[0043] (3) The separated kenaf seeds are softened and rolled in a rolling mill with a thickness of 0.3 mm.

[0044] (4) Under the action of direct steam, adjust the moisture content of the blank to 20%, and raise the temperature to 98°C; fry the seeds with a seed frying machine for 10 minutes to reduce the moisture content of the blank to 5%, and control the discharge temperature at 112°C.

[0045] (5) In the frying pan of the press machine, furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com