High-efficiency and low-breakage corn ear peeling device

A corn ear and high-efficiency technology, applied in grain processing, application, grain pod removal, etc., can solve the problems that rubber rollers do not have the ability to tear, the peeling rate of fresh corn husks is low, and the broken rate of corn kernels is high. The effect is high efficiency and low breakage, improving the grasping and tearing ability, and the peeling effect is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

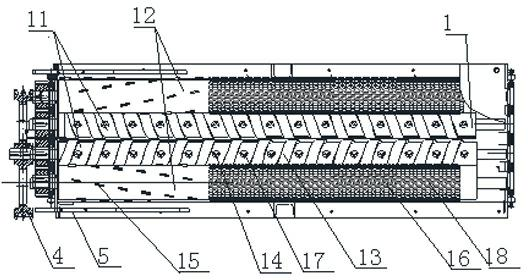

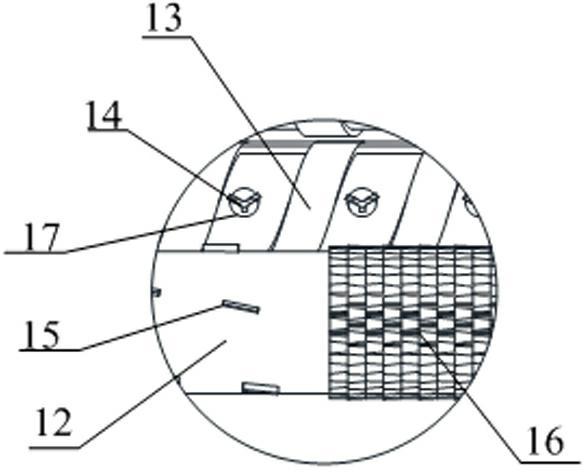

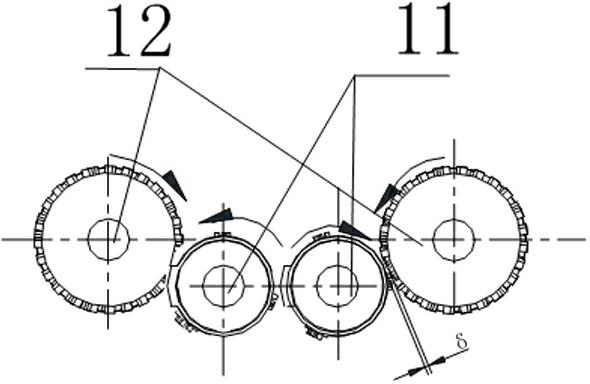

[0023] Embodiment 1: as Figure 1-7 Shown, a kind of high-efficiency low broken corn ear peeling device comprises feed hopper, discharge hopper, transmission system (motor, belt pulley, gear) 4, frame, support 5 etc., by transmission system 4, peeling roller device 1 The rotating speed is 320~500 rpm. On the said stand 5, a peeling roller device 1 is provided, and said peeling roller device 1 comprises two pairs of a first pair of peeling rollers 11 and a second pair of peeling rollers 12 which are engaged respectively and are parallel to each other. The pair of peeling rollers 11 is a fixed peeling roller, and the second pair of peeling rollers 12 is a floating peeling roller. The surface of the first pair of peeling rollers is provided with metal strip-shaped spiral protrusions 13 and herringbone bract leaf teeth 14; The first pair of peeling rollers 11 surfaces are provided with a cork 17 in the concave part of the metal strip-shaped spiral protrusion 13, and the cork 17 i...

Embodiment 2

[0028] Embodiment 2: Same as Embodiment 1, the difference is that the peeling roller speed is 380-550 rpm, the upper end of the herringbone bract leaf teeth is slightly higher than the band-shaped spiral raised surface by 1-2.5mm, the fixed peeling roller and the floating The meshing peeling gap δ between the peeling rollers is 1.0-3.0mm, and the peeling mechanism is suitable for peeling corn ears for feed.

Embodiment 3

[0029] Embodiment 3: Same as Example 1, the difference is that the peeling roller speed is 400-620 rpm, the upper end of the herringbone bract leaf teeth is slightly higher than the band-shaped spiral raised surface by 0.5-2.0mm, the fixed peeling roller and the floating The meshing peeling gap δ between the peeling rollers is 1.0-2.5mm, and the peeling mechanism is suitable for peeling the ears of corn seeds.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com