Green glycine max husking machine

A technology of green soybean peeling machine and frame, which is applied in the direction of solid separation, chemical instruments and methods, food science, etc., and can solve problems such as hindering the development of green soybean industry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

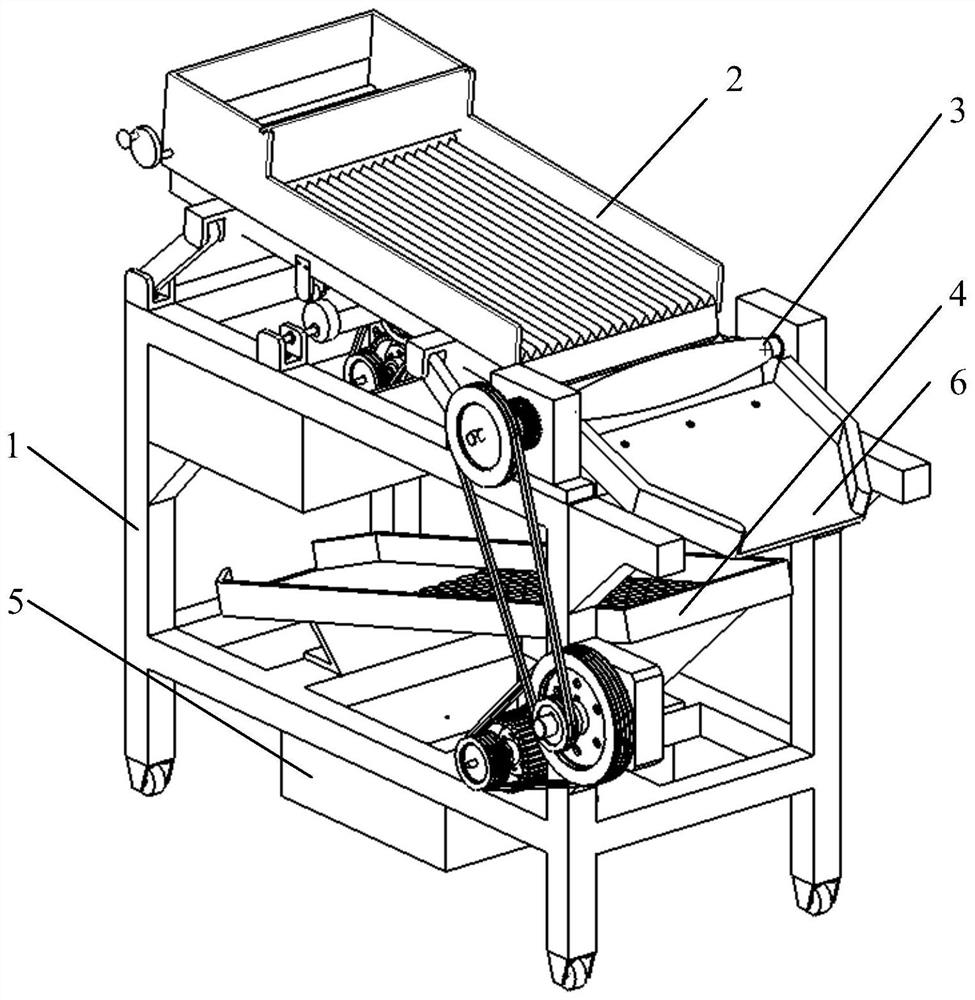

[0026] Such as figure 1 As shown, this small green soybean peeling machine is mainly composed of frame 1, vibrating feeding device 2, roll shelling device 3, screening device 4, grain collecting box 5 and guide plate 6, the most critical part of which is vibrating feeding device, roll shelling device and screening device.

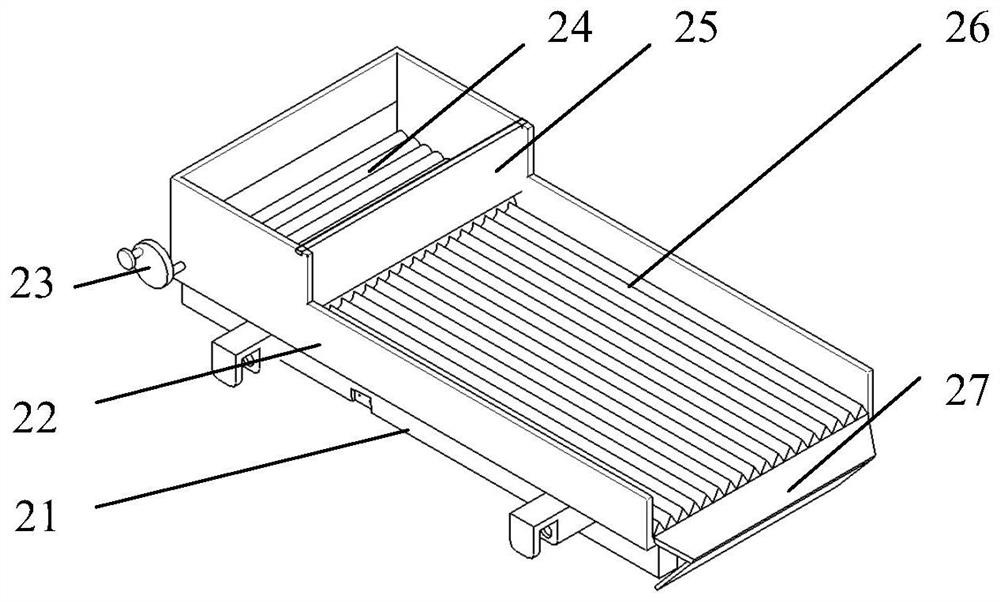

[0027] Vibrating feeding device 2 is made up of support frame 21, body 22, rocking wheel 23, feeding roller 24, discharge control plate 25, triangular material guide 26 and material guide plate 27, as figure 2 shown. The support frame 21 and the body 22 are connected by welding, and the triangular material guide plate 26 and the material guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com