Corn peeling device

A technology of corn and peeling rollers, which is applied in threshing equipment, agricultural machinery and implements, applications, etc., and can solve the problems of increased grain loss rate and reduced bract leaf peeling rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

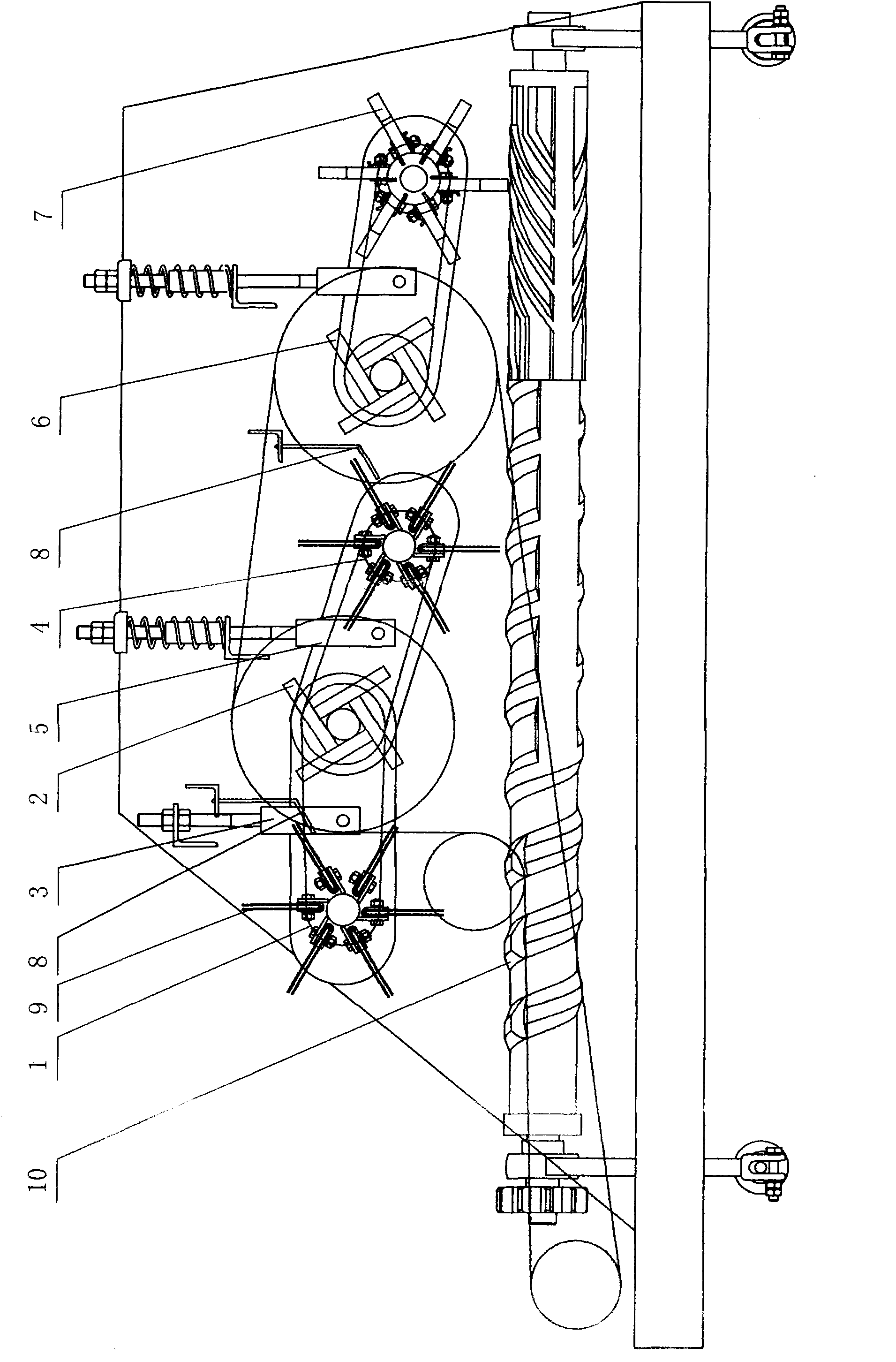

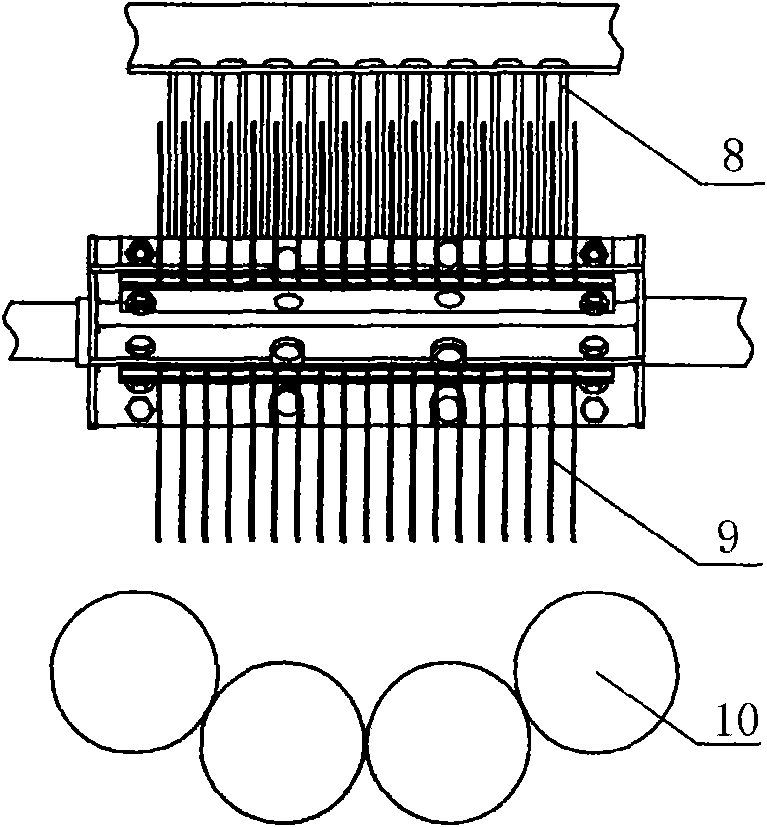

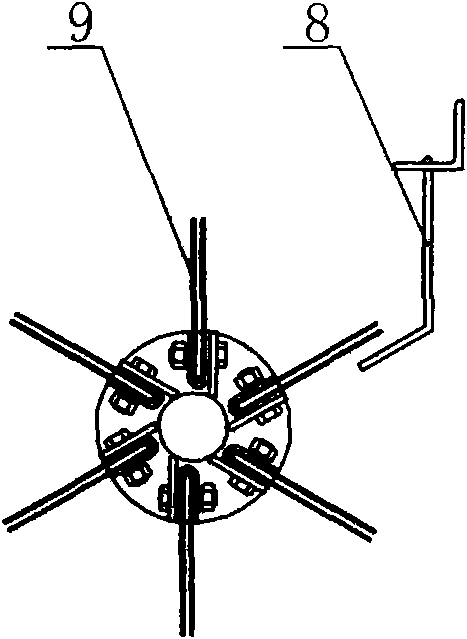

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 Commonly shown, the corn peeling device comprises a frame; a peeling roller group consisting of peeling rollers 10, said peeling roller group comprising a pair of rigid rollers and a pair of rubber rollers, said rigid rollers and rubber rollers are arranged in parallel, at intervals and Arranged in a groove shape, the roller surface of the rigid roller is provided with spiral ribs, which can increase the ability to grasp the bracts and help to peel off the bracts. The peeling roller group is rotatably installed on the frame and Driven by the power device; the pressure feeder driven by the power device, the pressure feeder is rotatably installed on the frame, and the pressure feeder is at least two and arranged in sequence along the conveying direction of the fruit ears at the top of the peeling roller group Above, including the first pressure feeder 2 near the ear inlet end, the floating pressure feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com